| Author |

Topic Search Topic Search  Topic Options Topic Options

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 1941 B project... Topic: 1941 B project...

Posted: 25 Aug 2024 at 4:25pm |

Further to my original post here-: https://www.allischalmers.com/forum/new-member-first-time-allis-b-owner_topic202799.html I thought I'd best start a new thread in the Farm equipment forum to follow on seeing as that has developed from an introduction into progress/ideas to get her up & working again (And maybe even tidy her up a hair one day!)

Not a huge amount to this update, although I've got the bottom end back together now & given the carb a once over. Apart from some cobwebs & bits of seed it was remarkably clean inside and from the look of the brass parts I'd say it's never seen ethanol in it's life which would add weight to my theory that it was stripped and the engine rebuild fudged a lot of years ago.

In other news, the fellow I bought her from may have located the head bolts and rocker assembly which would be a huge bonus so I don't have to fiddlefart around modifying the Ford parts I have dug out. On the magneto front, I'm not so hopeful of getting the original unit (and if I did, of it being serviceable) so with regards to that I may modify a distributor and go with battery ignition. The block has been tapped to accept a generator bracket so at least I can keep it charged easily. Even though I have no plan to fit an electric starter currently (pun intended) it'd be nice to have a reliable fat spark & some lights for winter time.

Anyhoos, will post any other findings or queries that arise as I get to them. Oh boy, there will be some when I get to the water pump and brakes believe me on that!

Cheers, Dan

Edited by ekjdm14 - 25 Aug 2024 at 4:26pm

|

|

|

Sponsored Links

|

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 25 Aug 2024 at 4:32pm Posted: 25 Aug 2024 at 4:32pm |

|

for the distributor, there are two types of drives... One goes all the way into the timing gear area and is for the "normal" distributor .... The second time is a distributor that has a short shaft and two lugs on the end that LOOKS like the end of the mag.. and plugs into the MAG timing gear / governor shaft.

|

|

Like them all, but love the "B"s.

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Aug 2024 at 4:50pm Posted: 25 Aug 2024 at 4:50pm |

Thanks, I wasn't aware there was a unit that would be essentially a bolt-in. As previously mentioned my neck is a beautiful shade of magenta & I have a 4 cylinder Ford car unit on hand which I may modify to fit (remove vacuum advance, modify advance stops as needed, shorten the shaft/make a coupler that will engage the governor shaft & a bracket to clamp it in place.

I will however look into the "correct" unit as an option, you wouldn't happen to know a part number for that would you?

Cheers, Dan

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2024 at 9:59am Posted: 28 Aug 2024 at 9:59am |

Quite a big day for the B today. Wasn't feeling great with some sort of stomach bug so elected to sweat it out by lifting the rear end up level, "installing" the right rear wheel (don't have a spline nut for that side, tube is shot & splines are pretty sacked out but it's a good enough placeholder) and then fitting up the bottom end/clutch assembly to the torque tube.

Will have to try and grab a photo but she's starting to look more tractor shaped and less like I dumped a pile of iron scrap on the front of the house!

Rain stops play once again now, but managed to get the block covered & overall I'm quite pleased with the progress. Plus my idea of sweating out this bug seems to have worked, I'm feeling much better too! Manual labour, the cure to all ills...  |

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 28 Aug 2024 at 1:03pm Posted: 28 Aug 2024 at 1:03pm |

I dont know of a specific part number for the distributor with lug drive.. You see them on e-bay every now and then... the "NORMAL" drive is more common. It can be switched over with a new cover/ shaft / timing gear...

I have considered a retrofit of an auto distributor before.. 4 cylinder (VW, FORD) or any other should work.... nice little project.. You want one that you can START about TDC, then have 30 degrees centrifugal advance by 1000 RPM..

Splines on hub shaft are a problme when the nut gets loose... If not completely destroyed, you can put a thick layer of devcon ( liquid metal) and put the hub and and snug it up good.. Let it set for 24 hours, then torque to 500 ft pounds..

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Aug 2024 at 1:13pm Posted: 28 Aug 2024 at 1:13pm |

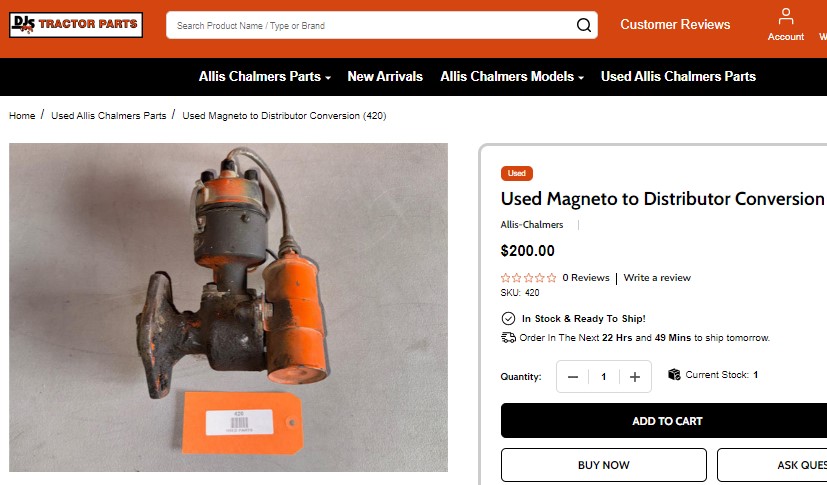

looks something like this...

|

|

Like them all, but love the "B"s.

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Aug 2024 at 6:59am Posted: 30 Aug 2024 at 6:59am |

Brilliant thank you, lots of good info there. On the spline situation, the chemical metal idea sounds like a good one especially since my tractor has the spline to 5 stud adaptors so that could be made a semi-permanent union. I think there's enough left to work with anyhow, most of the damage appears to be in the adaptor not the shaft & it doesn't appear to push too far on.

Newest problem (or not) is that on cleaning up the steering gearbox it was painted green, and on further inspection is actually a Fordson unit from a standard Major (especially weird, my first guess would've been JD or Oliver from the colour!)

Fortunately the seller is a good guy & along with locating the head bolts plus possibly the rocker assy. & may be able to find the steering gear with help of his father on whose behalf he sold the tractor.

For the moment I'll oil up the top end well, cover that & get to looking at the rest of the puzzle with the bracketry for the seat/tank,tins etc. and maybe look at the distributor.

Really appreciate the help and suggestions, we'll have the old girl feeling better soon :)

|

|

Steve in NJ

Orange Level Access

Joined: 12 Sep 2009

Location: Andover, NJ

Points: 11833

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Aug 2024 at 9:39am Posted: 30 Aug 2024 at 9:39am |

If you're interested in flipping your B over from Mag to Distributor, I offer two complete kits. One points and one electronic ignition. Units are all rebuilt top to bottom, new Coil of choice, ign. switch, wiring, spark plugs and wires, and installation instructions. Visit our website and check it out if interested... Steve@B&B bb-customcircuits.com

|

|

39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Aug 2024 at 11:51am Posted: 30 Aug 2024 at 11:51am |

Thanks Steve in NJ will check out your website but I think cost is going to factor your kits out sadly, especially so as we're in the UK (more's the pity!)

Also even if I was able to spend real money on the tractor, it'd be ruled out for the moment as I've just royally F'*£ed up while loading an old sofa onto our car & dropped a ratchet strap on the windscreen. Right smack in front of the driver, after all where else would it break? So I'm now working out how & IF I can even keep the tractor and afford the new glass...

If every cloud has a silver lining, I should be making superb quality solder joints for years out of this one!

Thanks anyway, appreciate the thought & will check out the website to distract myself...

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5422

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 31 Aug 2024 at 5:38am Posted: 31 Aug 2024 at 5:38am |

|

Dan

There use to be an Owner Registry as part of the 'Unofficial Allis' Website.

In that Registry were over 20 Allis B and EB Owners listed in the UK.

PM me your email address and I will send you a copy of those Owners.

Gary

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Sep 2024 at 8:48am Posted: 06 Sep 2024 at 8:48am |

Thank you Gary. will shoot a pm across later on or tomorrow.

Not much to report on the B for the moment, new glass for the one car is going to be around £400 or so (not claiming insurance, that's a joke for another time anyway!) hence have decided to focus on getting one of my others on the road since the work it needed for MoT (inspection) was only going to cost about £30 and a good few hours of sweat and blood.

I'm well and truly spent now, having been rolling around on the driveway for the better part of the last week welding and throwing tools! But she's about ready now & should have a year's ticket on Monday so I should at least be able to keep the old B for the moment & maybe do a bit of R&R on that in the next week whilst the welding stuff is out front.

Need to weld a nut onto the oil drain plug that's rounder than the tyres & one of the final drive pans is rusted through, not to mention what little is left of the tinwork.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 1998

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Sep 2024 at 9:32am Posted: 07 Sep 2024 at 9:32am |

|

Did you ever end up finding the last digit/letter in the engine serial number?

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Sep 2024 at 8:18am Posted: 20 Sep 2024 at 8:18am |

Oops, seems I lost this thread as I thought I'd replied already but nothing there! Yes I ascertained the letter (not number, thanks for the pointer wjohn!) is in fact a K.

Makes sense seeing as I've found kerosene/TVO specific parts in the pile of bits.

Anyway, I've got a few photos of the tractor as it sits but will have to get them from phone to computer in order to post them.

Also, now got a few little bits from a long dead MF65 diesel abandoned in the hills (Sadly the whole thing is returning to the earth, most bolt heads unrecognizable, 4.203 locked solid with moss growing from the exhaust and even injector lines rotted out) and it's neighbour, half of what appears to have been a 35 diesel with no cylinder head or front end.

Not huge things, just a few fine thread bolts, block drain cock & a water pump from the 65 which was somehow still free.

Why the water pump? Well the one I have is just the casing with no bearing, seal, shaft, hub or impeller. The only moving part I had was the adjustable pulley. I was originally thinking to use the shaft & impeller from the Perkins but as that would require machining the larger impeller I've had a look and I *think* I can actually make this water pump work on the B engine.

Two of the bolt holes line up with the ones in the block, I should be able to "clock" it in such a way that the bottom hose lines up pretty good & I can make a backplate for it and block off two outlet stubs to direct flow through the block like standard.

I will of course get photos of this spectacular rig-up if I get it to fit. Just over here doing what our forefathers would'a done to get by I suppose haha

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 1998

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Sep 2024 at 3:42pm Posted: 21 Sep 2024 at 3:42pm |

Great! That all lines up then. The lower compression kerosene tractor engines were pushed for a while here but they seemed to decline pretty rapidly, maybe after WWII. As you get later into B production the K engines are much less common and they are mostly higher compression gas engines.

The kerosene engines have less power if they still have the original pistons but many have been rebuilt and changed out since then. Some other makes of tractors (IH, for example) also had different cylinder heads for distillate/kerosene. I think in most AC tractors it was mostly the pistons and manifolds which were different, and easy enough to swap out at time of engine rebuild.

If you have all the parts to put it back to original that would be neat and worth doing in my opinion.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 7:42am Posted: 23 Nov 2024 at 7:42am |

Sadly don't have much in the way of original parts & what I do have is rusty and mismatched (petrol tank has the studs torn out, plastic petcock from a briggs or something, kero tank has a bung and brazed in newer fitting etc, it's got later rear wheels with spline adaptors too)

The pistons are reasonably flat-topped with a small (maybe 10-15cc) shallow bowl, combustion chambers in the head are pretty huge in comparison so not sure on CR as yet. If I'd known this whilst the pistons were out I'd have pulled numbers off them but as things are it'll remain a mystery.

Anyway the bolts & washers for the head have finally arrived, just in time for the weather to warm up and go all biblical on the rain for a few days... Sooo, may bring the head indoors to prep that for install & God willing get a chance sometime over the week to clean the block surface, bolt holes etc to finally get the head installed. At least have the engine sealed up properly for over winter.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 7:53am Posted: 23 Nov 2024 at 7:53am |

|

Standard B pistons are FLAT on top.. I have personally never seen one that was DISHED.( i know they exist, but not common around ME)... I would assume those are the Low Compressison Pistons... 15cc is 1 cubic inch.. That is a pretty good DISH for a small piston ... Standard pistons come up about FLUSH with the deck ..

Edited by steve(ill) - 23 Nov 2024 at 8:23am

|

|

Like them all, but love the "B"s.

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 7:58am Posted: 23 Nov 2024 at 7:58am |

It's possible I've overestimated the size of the dish, I've not laid eyes on the top end for over a month really save for throwing a bit of oil down it & covering it back up. There's a definite dish to them though I will say that.

Really wish the site's photo hosting was more flexible, I do have some pics but resizing them all to upload is a PITA even for a youngin like me!

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 4765

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 8:00am Posted: 23 Nov 2024 at 8:00am |

|

I've torn down many "K" serial number engines that had dished and mostly cast iron pistons. You can't say anything for certain, unless you've seen it all. I've done probably 100s of BE/CE engines and I'll bet there are still some things I haven't seen yet.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 1998

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 9:04am Posted: 23 Nov 2024 at 9:04am |

PaulB wrote: PaulB wrote:

I've torn down many "K" serial number engines that had dished and mostly cast iron pistons. You can't say anything for certain, unless you've seen it all. I've done probably 100s of BE/CE engines and I'll bet there are still some things I haven't seen yet. |

I didn't even know Allis made a B with a Zenith carb specifically set up for burning alcohol until a few months ago, as one example - not that I have torn apart anywhere near the number of tractors you and some other guys have, but there are lots of neat little things I will probably never see in person on these tractors.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 796

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Nov 2024 at 11:56am Posted: 23 Nov 2024 at 11:56am |

ekjdm14 wrote: ekjdm14 wrote:

...

The pistons are reasonably flat-topped with a small (maybe 10-15cc) shallow bowl, combustion chambers in the head are pretty huge in comparison so not sure on CR as yet....

... Sooo, may bring the head indoors to prep that for install... |

While the head is indoors it is a simple matter to pour a suitable liquid (something benign such as vegetable oil will suffice) into the combustion chamber to get a rough guess of its volume. Do the same with the pistons/cylinders and do the math to ascertain the compression ratio. It will be rather low.

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Nov 2024 at 9:49am Posted: 24 Nov 2024 at 9:49am |

Yeah that would'a been a cool idea, unfortunately (or fortunately!) the head is now installed!

Caught a break in the rain & was adjusting the fan belt on the car, that allowed a neat little segue into cleaning up the block & threads, weather held long enough to do the job. Nicely!

I think I did overestimate the bowl size in the pistons, probably only hold a few cc but dished nonetheless, so most likely lower comp Kero special items.

Another potential issue I ran into though, I think the spark plugs were some old 2-piece types & the bottom part has been left in the head. Here's hoping they come out OK! Never mind though, it's the best bit of progress so far on the project & I can move onto building a rocker assembly to suit now. Love getting into the chewy redneck bits like this...

Also placed an order for some bolts to hold the front wheels on so she'll be able to roll even, once the right rear brake is unlocked...

Edited by ekjdm14 - 24 Nov 2024 at 1:51pm

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Nov 2024 at 4:24am Posted: 26 Nov 2024 at 4:24am |

Modification of the Ford crossflow rocker assembly has begun, turns out an old 1/2" drive extension was the same diameter so an extra 1 1/2" has been welded to the shaft & ground to a reasonable approximation. Will have to move the pedestals along a bit to suit the Allis' bolt spacing, which will entail grinding bolt reliefs to match & filling/drilling oil holes to work with the Allis' oiling system.

Only issue foreseen is the very last rocker on one end won't get fed oil so will wear more but should get at least some splash over from it's neighbours. Then it's onto building up the rocker arms to reach the valve stem as they currently just miss & would push on the keeper & cutting/extending the back ends to line up with the pushrods (should be fun times, they're cast! Also need to look at some pics to ascertain the Allis rockers are in fact a 1.0 ratio since the Crossflow items are beginning as 1.35 ratio. Worse case this old motor gets a bit extra valve lift for all the powahhh!).

The spark plug bases left in the head might actually be anti-fouling inserts, will see if they turn out or not but may be OK left in place if they fight.

One other thing of note perhaps, I've been trying out my son's new inverter welder (A cheapie from Ebay, "Conentool" brand 200A multi-process unit) and I'm super impressed with the flux core side of things. Much easier and quicker to set up & get started than my old transformer unit & the high-frequency arc burns much smoother. Literally just tell it the wire size, material thickness and pull the trigger, beautiful looking solid weld from the get go. That's one for the Christmas list!

Cheers all, will be back on sometime hopefully with news of compression when it spins!

EDITED to add-: Fairly productive afternoon measuring, grinding and welding onto cast(!) and we have the rocker shaft in such shape as it fits the B's head & contacts the valve stems as needed. Not pretty by any stretch, just tacked on some extensions & blobbed around/ground back but good enough for who it's for. The pushrod side needs to "grow" by 1" to line up with the pushrods & end up as 1-1 rocker ratio (no extra horses for me haha). Anti-foulers came out just dandy so that's one less worry, the bit's back between my teeth now & I wanna hear her at least make some kind of noise before 2025.

May do a short walkaround video/tour of the hackery once it's running, just because it's easier than doing photos for me.

Edited by ekjdm14 - 26 Nov 2024 at 9:42am

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 9 hours 16 minutes ago at 11:16am Posted: 9 hours 16 minutes ago at 11:16am |

Bit more progress this evening. Just a small thing but have a starting handle now courtesy of an old jack handle, 3/4" ring spanner & a chunk of M10 bolt. Yet to weld it all up but it's fitted together & will work nicely.

Dark & rain = game over for tonight but hoping to get some playtime tomorrow and at least finish the rocker assembly if not get started with mounting the distributor. Only need to get the rockers/pushrods, ignition & oil line to the head sorted and be nearly ready to try and fire up the abomination!

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 81440

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 8 hours 10 minutes ago at 12:22pm Posted: 8 hours 10 minutes ago at 12:22pm |

I have done a LOT OF MODIFICATIONS in my life time.. but i can truthfully say i have never cut up a FORD rocker arm and stretched out followers to install in an ALLIS tractor !!

|

|

Like them all, but love the "B"s.

|

|

ekjdm14

Bronze Level

Joined: 20 Aug 2024

Location: Manchester UK

Points: 152

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 4 hours 23 minutes ago at 4:09pm Posted: 4 hours 23 minutes ago at 4:09pm |

Definitely not my crowning glory, or remotely close to done right, but should work enough to make the machine a runner at least! Spent a bit of time this evening going through the Ford dizzy to ready that for the tractor also. Stripped it down & cleaned/lubed everything, removed the vacuum advance & nipped down the pivot to lock that part off, and on inspection the mechanical advance is already set to give 30* which is a nice bonus so just removed the heavier of the springs to make it come in sooner. Will have to check the curve when it's running but ought to be close enough for now & a lot better than it was with both springs.

Points look decent after a clean & those and the condenser even have the FoMoCo script on them so they're oldies but goodies. Rather trust a 50 year old capacitor than a modern Chinese one!

Hoping for a break in the weather tomorrow & more progress. The little B's Christmas present may be to come to life once more, at this rate.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

PaulB wrote:

PaulB wrote: