| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 444 baler needles Topic: 444 baler needles

Posted: 27 Jul 2024 at 9:14am |

|

Just bought a 444 baler and it misses knots on left side. Changing the bill hooks because they are in need of changing. But I was looking at the needles and the left one measures 25” from needle point to 3 bolt mounting flange and the other one measures 24”. Anyone out there have any experience with this? Impossible to adjust so that they are even. Guy I bought it from said it had problems tying but he wasn’t the original owner and had not worked on it. Can’t find any numbers on the needles either. Thanks in advance

|

|

|

Sponsored Links

|

|

|

Ky.Allis

Orange Level

Joined: 31 Jan 2010

Location: Kentucky

Points: 1034

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 1:11pm Posted: 27 Jul 2024 at 1:11pm |

|

I used to own a 444 baler and never needed needles, so I can't help with a source. My guess is they are almost impossible to find nowadays. I can't imagine that they are not both the same length, but who knows, I guess it's possible.

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 4:33pm Posted: 27 Jul 2024 at 4:33pm |

|

I thought it was my eyes playing tricks on me,they looked uneven mounted on the baler so I tried adjusting so they were even(level)with the one that ties perfect and it was impossible to do so I measured the length and the one that doesn’t tie is exactly an inch longer even though the needles look identical. Thanks for the reply Ky,Allis any information is better than no information.

Edited by Model 70 - 27 Jul 2024 at 4:37pm

|

|

RP Farms

Bronze Level

Joined: 29 Jul 2023

Location: Southern Illino

Points: 49

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 4:48pm Posted: 27 Jul 2024 at 4:48pm |

|

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 4:59pm Posted: 27 Jul 2024 at 4:59pm |

I would not waste time on it until you get a pair of matching needles. Well more correctly a mate to the one on the side tying.

Mostly delt with wire twisters on balers, but the last years have adjusted several twine knotters. The first step is delivering the twine to the knotter with the needle. So if the twine is not there to be picked up it is waste of time adjusting other parts.

In the past the unfindable part has been found by asking here. So I wish you luck in finding a needle, that is correct.

In my option the guy that put the wrong needle in and then sold to an inexperienced person should be dumped head first into the baler. But then again maybe they were that dumb themselves and really thought it would work.

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2024 at 5:42pm Posted: 27 Jul 2024 at 5:42pm |

|

Thanks again to everyone for replying. I do have a manual coming but I knew that I’d find a vast amount of knowledge on here. I’m going to check out those used needles. Thank you

|

|

orangereborn

Orange Level

Joined: 12 Sep 2009

Location: NW WI

Points: 1499

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jul 2024 at 1:23am Posted: 28 Jul 2024 at 1:23am |

|

I have baler needles.. thanks. Dale

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jul 2024 at 8:32am Posted: 28 Jul 2024 at 8:32am |

|

Just ordered the ones off eBay. Hopefully they work.

|

|

DanielW

Silver Level

Joined: 19 Sep 2022

Location: Ontario

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 5:08am Posted: 29 Jul 2024 at 5:08am |

One of the needles probably got bent into a little wider of a radius when it hit something. Not uncommon for this to happen. At least Allis used steel rather than aluminum needles, so you should be able to carefully heat and bend the long one back into shape by tightening the radius and making it match the other. Lots of balers out there have had this happen.

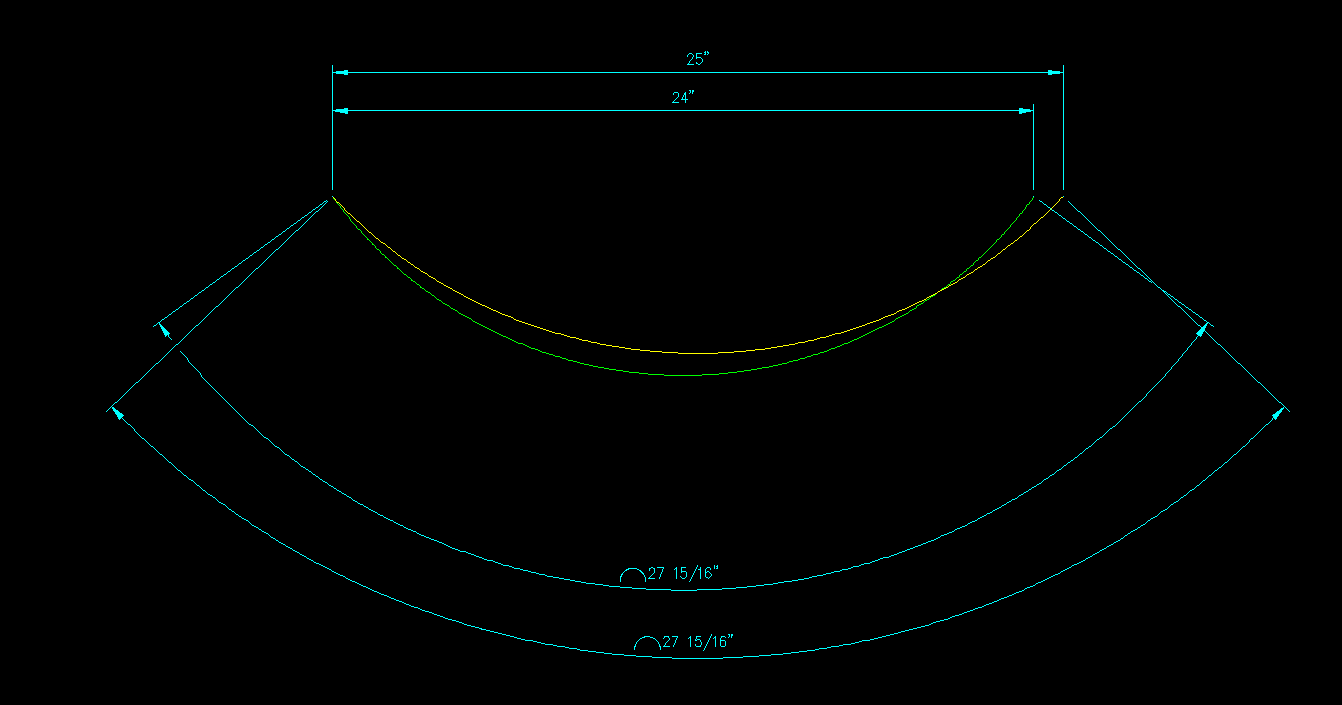

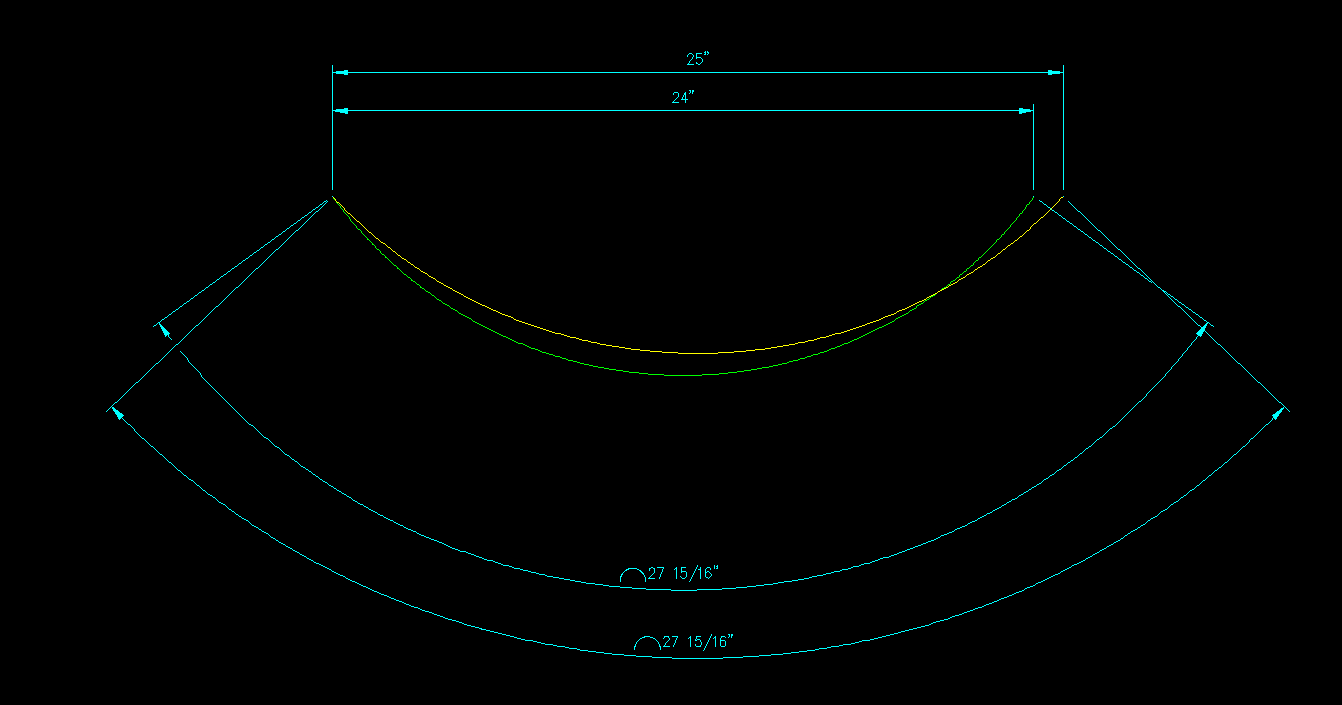

In the picture below you can see, for instance, how both curves have the same overall length (27 15/16"), but because the green one's bent into a slightly tighter radius, it only measure 24" point-to-point, versus the yellow one which is 25".

Edited by DanielW - 29 Jul 2024 at 8:51am

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 8:09am Posted: 29 Jul 2024 at 8:09am |

|

Never thought of that,I will check that out and see if I can heat and reshape that one. Thanks for the advice

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22174

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 8:17am Posted: 29 Jul 2024 at 8:17am |

|

Kind of a risky thing to do, but I'd remove them both and lay one on top of the other to SEE what the difference really is instead of guessing.

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 9:43am Posted: 29 Jul 2024 at 9:43am |

|

Great idea, I will do that.

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 12:01pm Posted: 29 Jul 2024 at 12:01pm |

Never thought of bending a needle. But I have only really delt with NH ones, they are made to break. I have welded the NH ones that were broken in to 3 pieces. Hopefully AC has a plunger stopper to save the needles the same as NH uses. The spring breaking and not pulling the stopper into place has caused my troubles. But on occasion have broken only , and had to assume a stick or rock had been in the hay and the needle hit it to break.

A non prefect needle will work so long as it delivers the twine to the right place for the other knotter parts to pick it up as was intended.

|

|

DanielW

Silver Level

Joined: 19 Sep 2022

Location: Ontario

Points: 252

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 12:12pm Posted: 29 Jul 2024 at 12:12pm |

Ray54 wrote: Ray54 wrote:

Never thought of bending a needle. But I have only really delt with NH ones, they are made to break.

|

Many other manufacturers (like many NH models) used cast needles, others use aluminum. These typically break rather than bend. I'm assuming the 444 is similar to the 442, however, which uses formed/stamped steel needles, which I like better as they're stronger and more ductile (less brittle and likely to crack), and can also be welded easier if they break.

I'd try tripping the knotter manually rolling the baler over watching the needles deliver twine to the cam discs. As Ray54 mentioned, as long as they deliver the twine in-line with the grooves in the discs (and as long as the groves in the discs are aligned), you should be ok.

Edited by DanielW - 29 Jul 2024 at 12:29pm

|

|

Model 70

Bronze Level

Joined: 09 Jan 2021

Location: Minnesota

Points: 151

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jul 2024 at 12:54pm Posted: 29 Jul 2024 at 12:54pm |

|

That’s exactly what I did and how I found out the left needle was different because it would come up around 4” above the twine disc and only once in a great while it would grab the twine. Where as the right side needle was barely above the disc and would grab it every time. No matter how you tried to adjust the left needle you could never get it close enough. That’s when I started measuring and found an inch difference. Now that I’ve read all the comments on the forum I bet the left side is bent and you can’t see it. Manuals are great but the knowledge on this site definitely prevails.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Ray54 wrote:

Ray54 wrote: