| Author |

Topic Search Topic Search  Topic Options Topic Options

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 8070 Dual PTO Install Topic: 8070 Dual PTO Install

Posted: 02 Mar 2023 at 8:22am |

I'm finally getting around to doing the 540/1000 install in my 8070 I restored a year or so ago. I was planning to do this during the restoration process, but time didn't allow for it. The tractor having only 1000 RPM was really limiting it's usefulness in our operation. There have been many times where it would have been handy to have the 540 PTO because all the other tractors were busy. It'll mostly get used on NH 450 Crop Cutter round baler, but also hay tedder, rake and small square baler in some instances I'm sure.

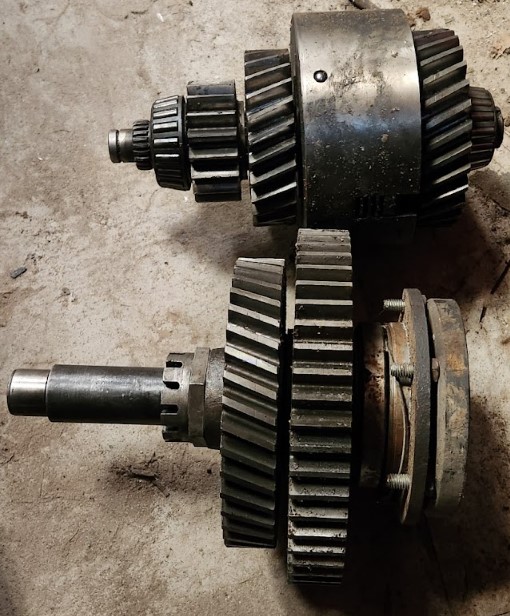

I sourced both the upper and lower shafts from an 8050 from Abilene Machine for around $1000 dollars shipped. This included a new reversable shaft.

All new bearings and seals were sourced from my local Agco dealer that was around $450. I disassembled the lower shaft last evening, cleaned everything up and installed the new bearings inside the 540 hollow shaft as well as new seals in the bearing retainer. The plan is to use the clutch assembly and things that are currently in the 8070. hope to get it installed this weekend. More pictures of that process to follow.

Much thanks to forum user LB0442 for their post on doing this to their 7080. If anyone has any advice or pitfalls to watch out for, please do let me know!

|

|

|

Sponsored Links

|

|

|

8070nc

Orange Level Access

Joined: 21 Mar 2019

Location: North Carolina

Points: 534

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2023 at 8:42am Posted: 02 Mar 2023 at 8:42am |

|

Ive got one im getting ready to do. Ill be paying close attention

|

|

1984 80780

1957 D14

DES 300 with 25000 engine

616 tractor

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8354

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 02 Mar 2023 at 11:32am Posted: 02 Mar 2023 at 11:32am |

|

All I can add is that plate beneath pto holds a gallon or so fluid if you need to remove it. Seems like 5 gallon when it lands on you....

|

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2023 at 1:49pm Posted: 02 Mar 2023 at 1:49pm |

Thanks for that! Not that I don't enjoy a good oil or antifreeze bath from time to time, but too much of a good thing can go bad.

|

|

bigal121892

Orange Level

Joined: 05 Jan 2010

Location: Nebraska

Points: 805

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2023 at 3:37pm Posted: 02 Mar 2023 at 3:37pm |

|

I would recommend dropping the plate under the PTO the night before, and let it drip overnight.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8410

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Mar 2023 at 6:32pm Posted: 02 Mar 2023 at 6:32pm |

|

Would this process be similar for a 7080? What is the title of that thread? I need to do this to mine.

Edited by CrestonM - 02 Mar 2023 at 6:46pm

|

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Mar 2023 at 8:32am Posted: 03 Mar 2023 at 8:32am |

The process should be identical for the 7080. The name of the 7080 thread is "7080 dual PTO install" and you can find it in the knowledge base.

|

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Mar 2023 at 7:59pm Posted: 05 Mar 2023 at 7:59pm |

Project complete! All told it took my dad and I 3/4 of a day, not counting the time it took to drain the oil the evening before and the couple hours I spent before hand getting the donor parts ready for install. I would say, overall I have a 10 hour day in it. I didn't take many pictures, but I'll post what I did take. It would certainly be possible to do it all in one day, but draining the oil the night before as Big Al recommended is a big plus. Another thing I did was remove the rear bearing retainer from the tractor and pull the shaft out of the front bearing cup. There was some oil backed up behind it that would have been dripping on my head all day if I hadn't done that the night before as well. Overall, from the donor tractor I used the 4 gears and the output shaft components. I used the clutch assembly and shaft from the 8070. For the most part, just follow the factory service manual and things will go well. The biggest challenge was getting the 8070's 1000 RPM shaft out of the tractor. Getting the front bearing off proved to be a real fight. The manual shows using a split bearing puller, but all ours are too big to get up in the housing. I ended up getting the shaft down out of the housing enough to drive the bearing off with a hammer and punch. Not easy, but doable. Here are the donor parts I used cleaned up and ready to roll.

Removing the drawbar is a must and if I had to do it over again, I would probably remove the drawbar yoke as well. It's not necessary to remove, but it would have just been one less thing in the way.

There is a good one or two gallons of oil laying on top of the bottom access plate. I managed to get it all into a bucket by removing all the bolts accept the left outside three. I only backed them out about 1/4 inch and then put a bucket under the tractor. Then I just pushed the cover down and all the oil ran out the right hand side into the bucket. Once it was done dripping, I removed the remaining bolts and then the cover. It was stuck on there pretty good with gasket maker, so it didn't just want to fall off.

One step that I disagree with the manual on is when installing the hollow 540 RPM shaft and gear, they tell you to install the hollow shaft until the retaining bolts can be started. Try as I might, there was just no way to get the gear into the housing from the bottom without hitting the clutch output gears above. We ended up taking the hollow shaft back out, I held the gear in place from the bottom while my dad put the shaft in place. After that, reassembly was easy. One thing you'll need is a 2 3/8" wrench to tighten the big nut that sets the preload on the output shaft assembly. It's not something most people have. I tried to use a massive 24" crescent wrench, but it didn't fit very well. I ended up taking an old junker 2" wrench I had and machining it out to 2 3/8".

The manual says to measure the rolling torque on the 1000 RPM shaft to set preload. To do this, I put the reversable shaft on and then used a 1 5/16 inch socket. I laid a shop rag over the shaft and then jammed the socket on the rag. It worked really well.

Overall, the rolling torque came out to be about 50 inch pounds on the 1000 shaft. Afterwards, I measured our 8010 and it was identical. It would have been assembled at the factory, so I'm pleased that it came out the same.

I ran it on a small grain auger today for several hours to see if it stayed quiet and happy and so far so good!!

All said and done, it wasn't a terribly difficult project. My dad and I are both pretty mechanically inclined, so that helps. Two people are a must. I'm not saying it can't be done with one person, but it would be a real challenge at points.

Now, if the hay would just grow so I can put it thru it's paces!

|

|

AC7060IL

Orange Level

Joined: 19 Aug 2012

Location: central IL

Points: 3433

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Mar 2023 at 8:00am Posted: 06 Mar 2023 at 8:00am |

|

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8410

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Mar 2023 at 8:15am Posted: 06 Mar 2023 at 8:15am |

|

Thank you for posting the process and your findings!

|

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 07 Mar 2023 at 9:07am Posted: 07 Mar 2023 at 9:07am |

|

Glad to do it. Hopefully someone finds it useful.

|

|

Meanolallis

Bronze Level

Joined: 04 Sep 2013

Points: 132

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2023 at 9:01am Posted: 11 Mar 2023 at 9:01am |

|

Does installing the 2 speed give you weaker components or more gears involved in the 1000 rpm drive? In other words, is the single speed better if you wanted to use high hp out of it for long durations (is there a downside to the 2 speed?) ?

Thanks!

|

|

PAFarmer

Bronze Level

Joined: 06 Oct 2020

Location: Pennsylvania

Points: 114

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2023 at 10:08am Posted: 11 Mar 2023 at 10:08am |

The 1000 RPM gears in the 2 speed setup are a bit narrower than the factory 1000 single speed. I didn't measure, but I would guess somewhere in the .25 inch ballpark. So, in theory, will the factory setup transfer more power than the dual speed? Yes, I would assume so. With that said, I don't think the reduction in size is enough to really cause concern for any applications I use my 8070 for. The dual speed PTO gears are still very beefy compared to some PTO drivelines I've seen in similar sized modern tractors.

The PTOs in these tractors seem to be built like tanks.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8483

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2023 at 1:14pm Posted: 11 Mar 2023 at 1:14pm |

Was there a reason for not putting in factory 540/1000. Would guess maybe cost savings. Tractors D-21,210,220,7080,8070 right

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20982

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Mar 2023 at 2:28pm Posted: 11 Mar 2023 at 2:28pm |

|

The SAE engineers had a lot to do with how tractors were configured. There's a reason tractors over 165 PTO HP have that huge 1 3/4" PTO shaft...because SAE said so. I think the 540 PTO speed max HP got adjusted over the years and A-C kind of protected themselves by making their dual speed 540 shaft twist off if overloaded.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8354

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Mar 2023 at 10:09pm Posted: 12 Mar 2023 at 10:09pm |

|

Anecdotal story. Cousin has 7020 that has twisted 2 540/1000 setups running a 15ft batwing. He put the big 1000 in and hasn't had trouble since. Apparently there is a necked shaft to clear a gear and that's where it breaks.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)