Hi all,

I'm working through the electrical system of my 1956 WD45 and I have some questions as well as things to share.

IDENTIFYING GENERATOR

First question - how do I identify the generator that I have? It's still 6v pos ground and switch controlled field, but there doesn't appear to be a number plate on the genny, including under the cutout relay. I ask because I'd like to upgrade to a regulator at some point.

SECOND QUESTION

How on earth do I take apart the taillight? I need to get the socket out and replace wire. It LOOKS like the stud would just drive out from the bottom to the inside, but I'd rather not break it if I can avoid it.

AMMETER

The ammeter wasn't working, which is bad news with a manual charging control. I took off the glass cover and knocked out a bunch of grit. Now it works! The gasket came apart so I put the cover back on with some RTV before crimping it.

LIGHT TERMINALS

The insulation was crumbling in spots on the wires to the headlights. I also took the opportunity to solder a ground wire to the socket. This is likely to be more reliable that relying on the setscrew for ground. Note that you need a pretty big soldering iron to do this or VERY careful work with a propane torch.

I also had to replace one of the light wires entirely. For the terminal I used a small copper rivet soldered to the end of the wire. Here's a comparison with the original.

LIGHT SWITCH REHAB

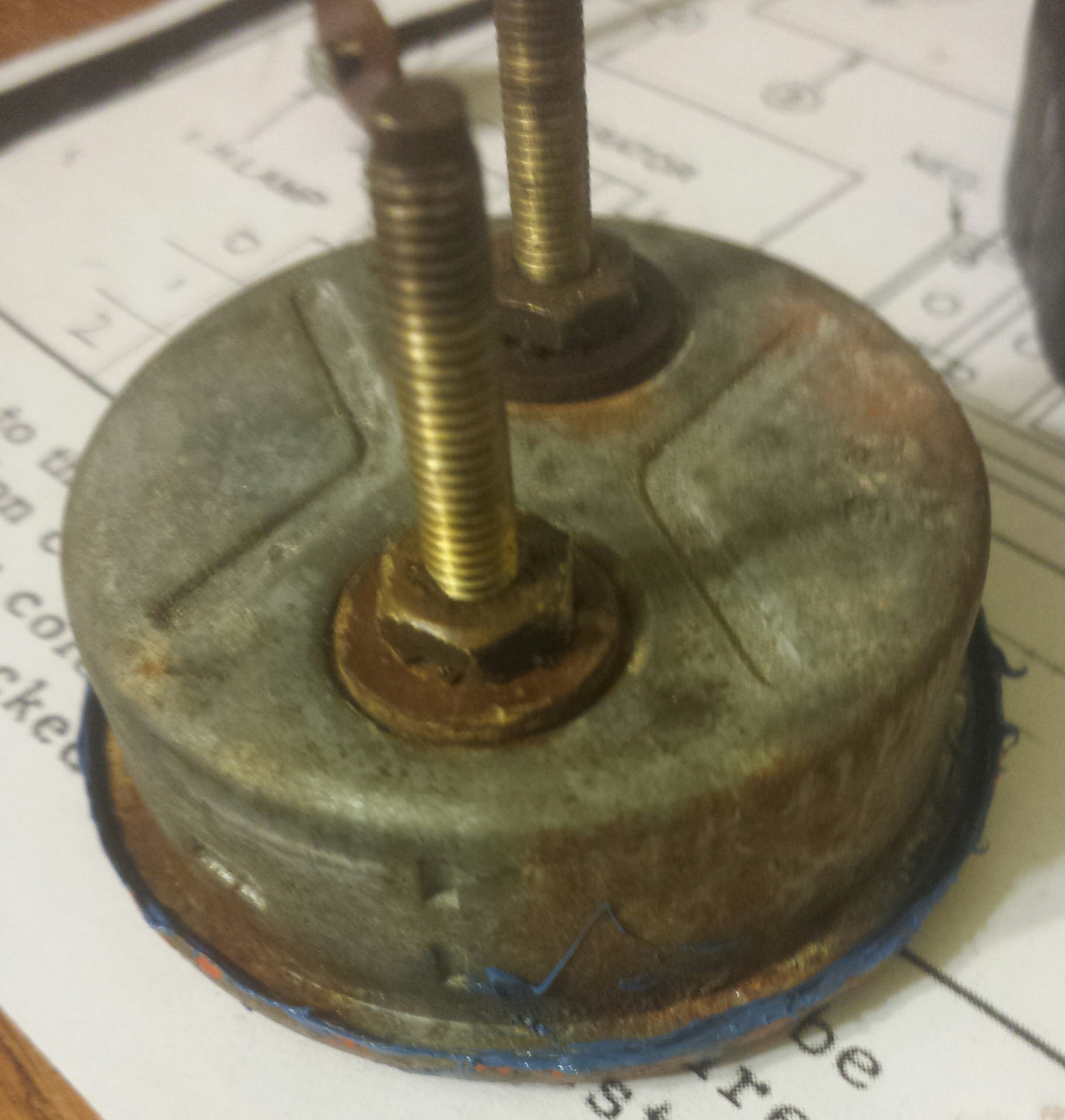

The light switch was totally inoperable when I brought it home. Fortunately I have a lot of experience with old electronics (e.g. restoring Hammond organs). The main issue with the switch was a bent and rusted actuator stem. I bent and threaded some 3/16" rod and voila....new stem.

The other issue was a broken axle lug on the plastic rotating bit inside the switch. That's the black part in this pic.

To fix it I cleaned thoroughly with acetone and built a dam of rope caulk to cast some JB weld.

I filed to shape and recut the keyway with a utility knife.

Here it is reassembled.

It works perfectly now, though I imagine Steve in NJ will have some thoughts on whether this can be expected to last very long. If not, it's not such a big deal to me since I hope to upgrade to a regulator once I figure out which genny I have. At that point a simple toggle switch will do fine turning the lights on and off.

Speaking of which, the ignition switch was a toggle when I got it. Hold your ears originality police, but as a working tractor I plan to replace that with a dead man kill switch and lanyard. I think every machine should have one, to be honest.

Thanks all,

Rob in WI

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)