| Author |

Topic Search Topic Search  Topic Options Topic Options

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Topic: HD6EP REPAIR Topic: HD6EP REPAIR

Posted: 24 Apr 2017 at 3:26pm |

Ok, Merv and Peter are looking for a 6EP story. I started looking for a post that I had done several years ago about this tractor. Couldn't find it , Uhhh guess I didn't do it, but this is what it would have looked like.

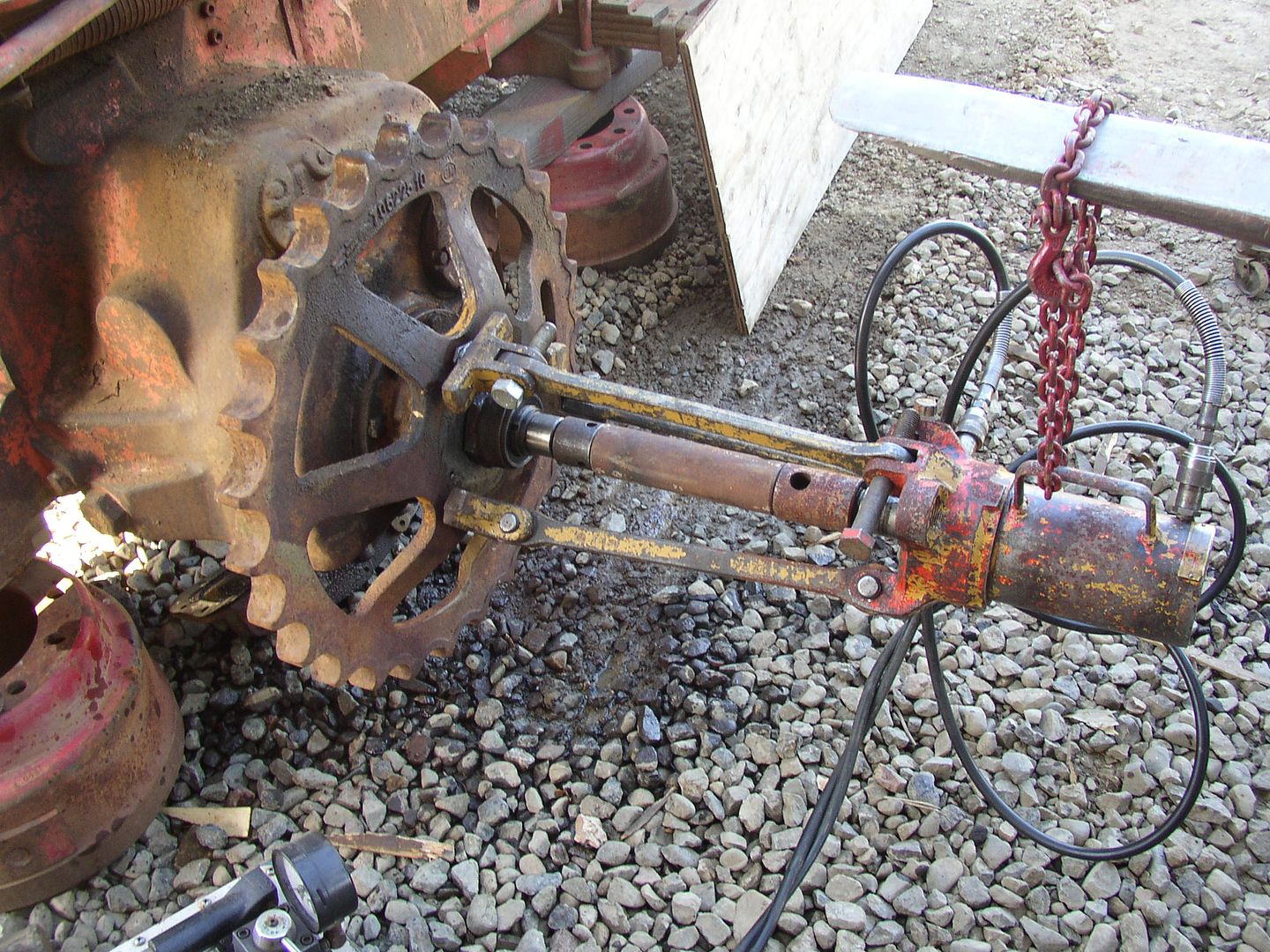

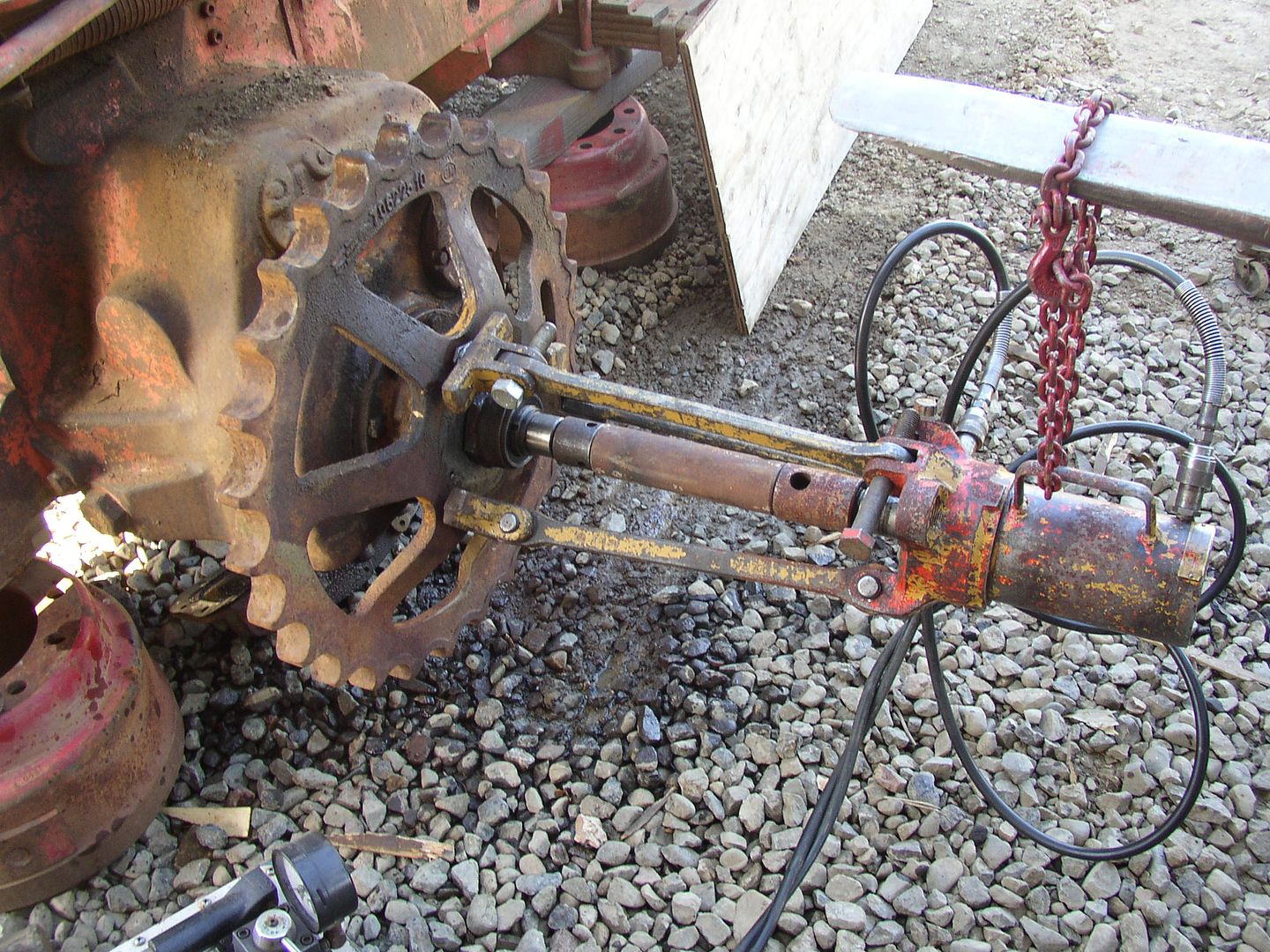

We got this tractor 5 or 6 years ago from a contact that we'd been working on for several years. He finally agreed to part with it after the right side quit working ,(he also bought a new CAT D4 for his projects) We went and picked it up with our boom truck to help pull it on. We suspected a broken sprocket shaft or other issues, he knew he would have to spend way more money than it was worth since he didn't do his own mechanics. At the end of this post I will be appealing for help on a problem.  So it sat in our yard for a year or so before we got around to looking for the problem. Used the 745 to drag it to the shop. Got the blade of and put in in the shop in a position we could get the forklift to it. So it sat in our yard for a year or so before we got around to looking for the problem. Used the 745 to drag it to the shop. Got the blade of and put in in the shop in a position we could get the forklift to it. So this is what we found, right on que. So this is what we found, right on que. So I went out to our parts depot out in the front drive way to section #6 (as in HD6) to look for the best donor tractor specimen and found a good choice. So I went out to our parts depot out in the front drive way to section #6 (as in HD6) to look for the best donor tractor specimen and found a good choice.

I checked some serial numbers to try to stay close to the same parts. The closer the better. This was a direct drive farm tractor with pretty poor undercarriage. So the sprocket puller press was still on the ground from pulling the EP sprocket. The closer the better. This was a direct drive farm tractor with pretty poor undercarriage. So the sprocket puller press was still on the ground from pulling the EP sprocket.

This was done 4 years ago. The pictures say 4/24/2013 Every thing appeared to be in very good usable condition. Every thing appeared to be in very good usable condition. So after we got it back together we put it up on some blocks with all the belly pans of to pressure was and change oils. It sat on these blocks for probably a year cause we were busy. So after we got it back together we put it up on some blocks with all the belly pans of to pressure was and change oils. It sat on these blocks for probably a year cause we were busy. The reason it sat there was because we have to go back in and fix a leak. So yes, it's turboed The reason it sat there was because we have to go back in and fix a leak. So yes, it's turboed  It is a very, very nice specimen. It is a very, very nice specimen. It has a CARCO PS winch and hydraulic tilt on the blade. It has a CARCO PS winch and hydraulic tilt on the blade.

Ok so going back to this picture this is our problem. We have a leak that comes out of the outboard bearing seal. It seems that it is the 2 metal sealing rings (maybe not touching? I have taken the sprocket nut off and redone the seal and checked it , I have checked the outboard bearing housing and the sealing ring. It's very hard to feel any drag on the sealing rings after you have everything tight. The sprocket shaft and bearings are all shimmed accordingly. Can't tell any difference in sprocket nuts? Parts books don't indicate any different nuts or out board bearing housings. It's very hard to get a measurement at the sealing rings? So we'll be standing by for ideas from forum members. I will be going back in there with or without ideas as soon as we get the HD7G back in service. We have a leak that comes out of the outboard bearing seal. It seems that it is the 2 metal sealing rings (maybe not touching? I have taken the sprocket nut off and redone the seal and checked it , I have checked the outboard bearing housing and the sealing ring. It's very hard to feel any drag on the sealing rings after you have everything tight. The sprocket shaft and bearings are all shimmed accordingly. Can't tell any difference in sprocket nuts? Parts books don't indicate any different nuts or out board bearing housings. It's very hard to get a measurement at the sealing rings? So we'll be standing by for ideas from forum members. I will be going back in there with or without ideas as soon as we get the HD7G back in service.

|

|

|

Sponsored Links

|

|

|

JC-WI

Orange Level Access

Joined: 11 Sep 2009

Location: wisconsin

Points: 34384

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 4:43pm Posted: 24 Apr 2017 at 4:43pm |

|

YEOUCH!!!! Broken sprocket shaft... not good.

Tried to use plastigage to check to see if it even touches?

|

|

He who says there is no evil has already deceived himself

The truth is the truth, sugar coated or not. Trawler II says, "Remember that."

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 6:20pm Posted: 24 Apr 2017 at 6:20pm |

|

Were there not two series of outboard bearing types? One that fed off final oil and one that used its own supply? Is the shaft from the first plugged and the second open bored?

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 9:43pm Posted: 24 Apr 2017 at 9:43pm |

|

JC, That's a good thought, it will be part of our reentry plan unless we hear of another smoking gun first.

Dave, I know what you're talking about, but I'm pretty sure we're all right there too. But we'll revisit that also.

|

|

donoman

Silver Level

Joined: 18 Feb 2015

Location: New Zealand

Points: 117

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 10:39pm Posted: 24 Apr 2017 at 10:39pm |

Great pic's Mel, I fitted the turbo today ,the oil pipework is a different setup from the photo, this one came off a military motor and the oil feed comes from the relief valve, its a tight fit but it all lined up. Which sprocket are you fitting ,could be the splines are worn and the sprocket is sitting further in on the splines and the nut if wound it in a couple of extra turns you may lose the pressure on the sealing rings. Otherwise it would work to pack the bellows out with an extra neoprene ring. there are two different size nuts ,prior to tractor 13595 which was the same for later HD5'S but all the later tractors on have one size. Cheers Peter

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Apr 2017 at 10:53pm Posted: 24 Apr 2017 at 10:53pm |

|

Peter,Very sure that the splines and sprocket are in good enough condition not to cause the problem. Have you used an extra neoprene gasket to fill the gap before? Also sure I have the right nut. (but will check that too).

|

|

donoman

Silver Level

Joined: 18 Feb 2015

Location: New Zealand

Points: 117

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2017 at 2:16am Posted: 25 Apr 2017 at 2:16am |

No I haven't but the HD6 I'm working on is leaking the out board seal so I will keep you posted, I have spare sprocket nuts and seals so I will see how they measure up.

|

|

HD6 Merv

Silver Level Access

Joined: 03 Aug 2010

Location: New Zealand

Points: 498

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Apr 2017 at 2:56am Posted: 25 Apr 2017 at 2:56am |

|

Great pics thank you for posting Mel

Certainly a very tidy 6EP, even more special with the 7000 engine and E30ps winch.

|

|

tits tyres and tracks

they all cost you money

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Apr 2018 at 12:21pm Posted: 18 Apr 2018 at 12:21pm |

Ok...Thought I would revisit this post and appeal for help before we start this project. We will probably be doing a salvage logging job on our ranch property that became toast back on October 9th...not a lot of timber...but we'll be doing it all ourselves ...of course it will be an AC show. We have ready to go currently..1 HD11Bseries/with grapple...1 HD11EP/with winch...1 HD6B with winch....1 745C loader (way to big) waiting for repairs...1HD11B series/w grapple &winch...1HD6EP/w winch.

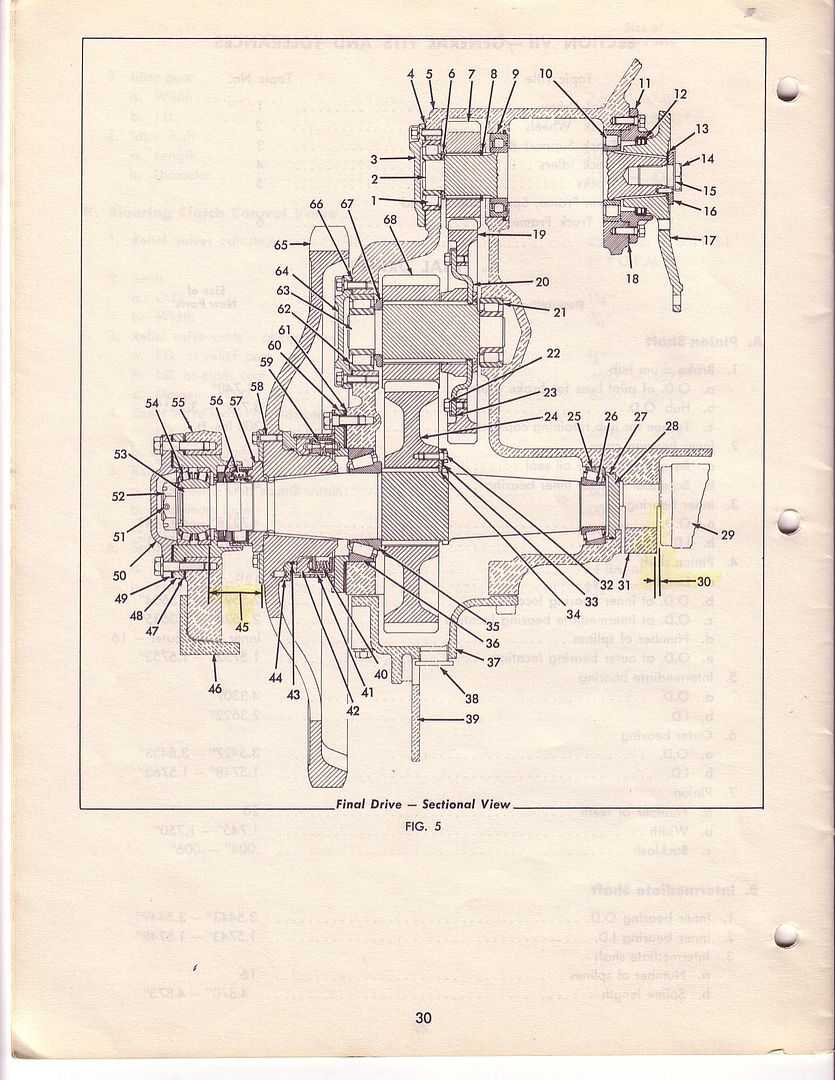

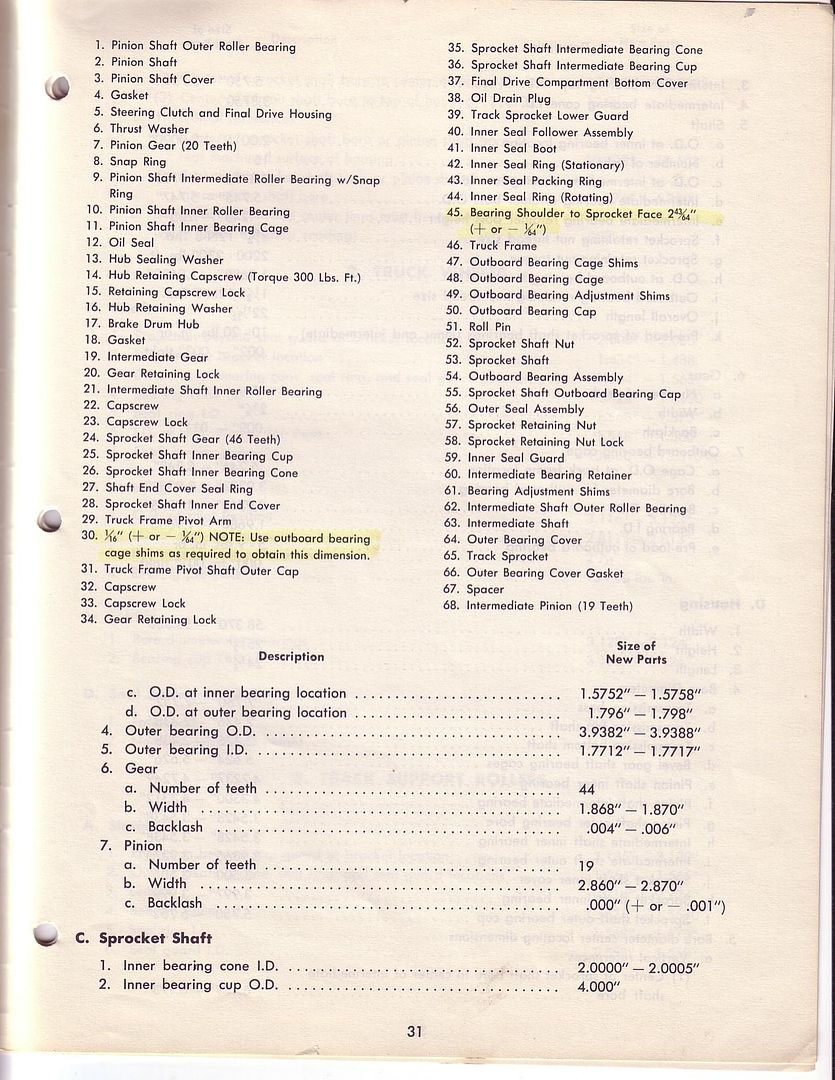

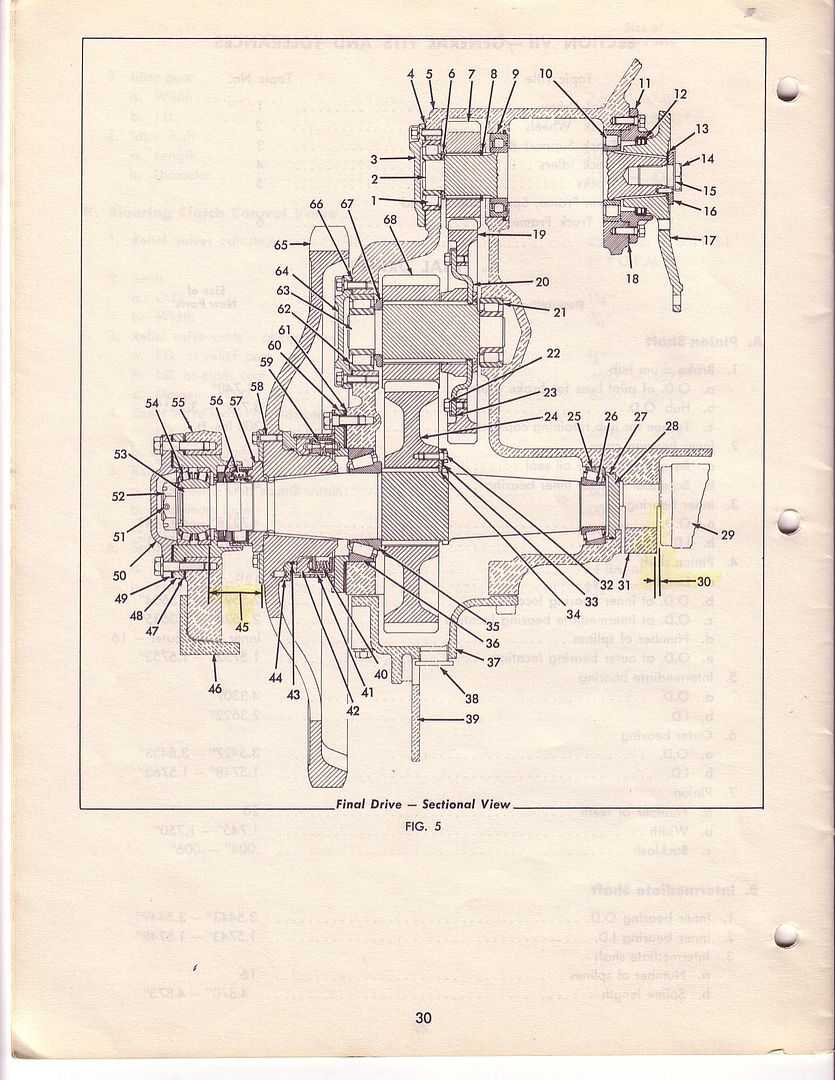

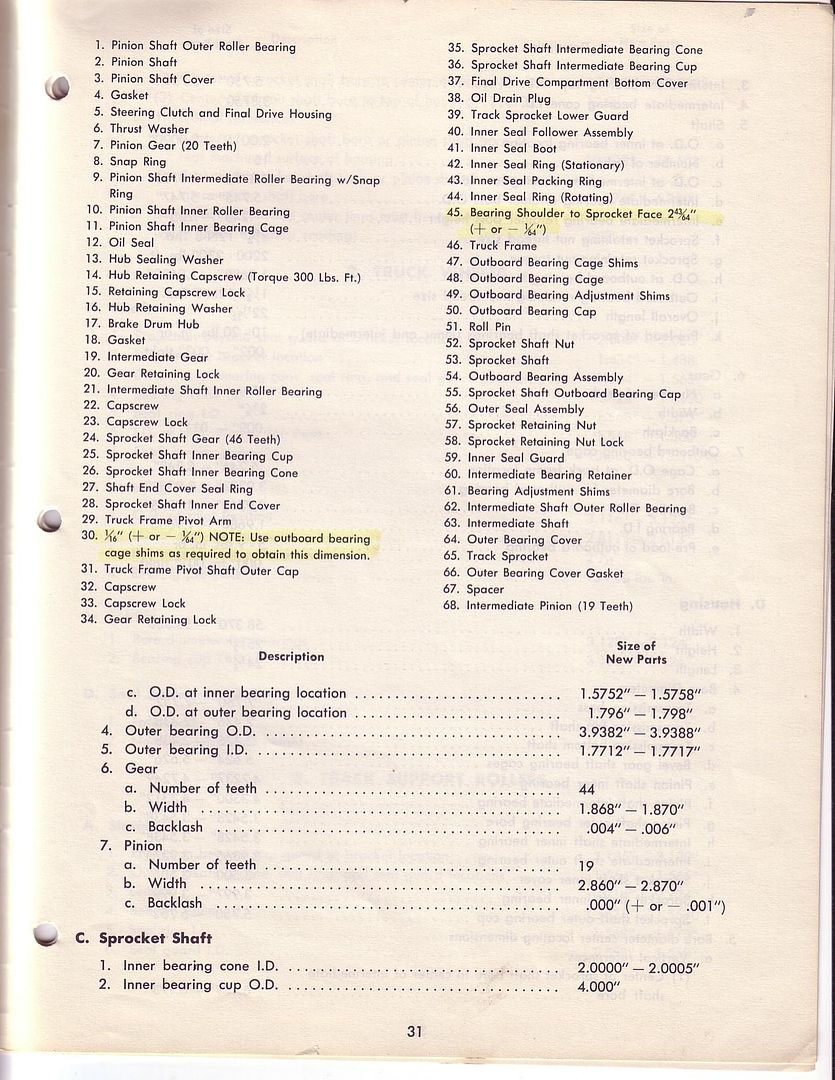

So this 6EP has been sitting for some time..nothing has been done since this last post. The outboard bearing seal rings leaked after all of it was put back together. We have done a lot of these on different size tractors over the years and have never had this problem. Digging through our library I recently found a'' MODEL HD6EP TRACTOR FIELD SERVICE INFORMATION BULLETIN" I would like to call your attention to dimension #45 & 30. When we get this puppy back in the shop we will be trying to check these to see if this has led to our problem? Any thoughts? Any other experiences? We're listing.

We will check the swing frame dimension first #30. We will check the swing frame dimension first #30.

|

|

CAL(KS)

Orange Level

Joined: 18 Sep 2009

Location: Chapman, KS

Points: 3804

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Apr 2018 at 8:09am Posted: 19 Apr 2018 at 8:09am |

|

no experience with this model at all but with the seals being spring loaded you wouldn't think being off a little would cause a leak. I would sure check it, but man alot of work for an oil leak!

|

|

Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20

Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jan 2024 at 1:03pm Posted: 18 Jan 2024 at 1:03pm |

Ok....thought I would dust of this post....maybe put it to bed....with a happy ending and start a new post as this tractor travels on it's next journey. So it was several years ago that I went back into the outboard bearing seal...replaced it....couldn't find anything wrong with it ...it quit leaking. But after that it would not steer. After we got a roof on our big shop a couple of years ago we moved it inside out of the weather...thinking we work on it. Well that didn't happen until last week...Brannen thought he would tackle the steering oil problem and get the tractor out of the shop to have the space for trailer repairs that need to be done. So what he learned was the suction line screen in the transmission supplys oil to both the steering pumps and the transmission charging pumps...through different ports at the strainer. The screen was pluged so bad....yes so bad that the steering pumps could not pull oil...but the transmission charging pump would still pull oil allowing the transmission to function.  So this picture is even after he started cleaning it. We have never run this tractor any where...so the previous owner probably was trying to operate this with those conditions. So this picture is even after he started cleaning it. We have never run this tractor any where...so the previous owner probably was trying to operate this with those conditions.

|

|

DMiller

Orange Level Access

Joined: 14 Sep 2009

Location: Hermann, Mo

Points: 34639

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jan 2024 at 6:14pm Posted: 18 Jan 2024 at 6:14pm |

|

That is really hard on those little

Steer pumps.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Jan 2024 at 7:10pm Posted: 18 Jan 2024 at 7:10pm |

|

How's it steer now?

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

HD6 Merv

Silver Level Access

Joined: 03 Aug 2010

Location: New Zealand

Points: 498

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Jan 2024 at 12:18pm Posted: 19 Jan 2024 at 12:18pm |

Yes steering and transmission both suck from same screen. Andwe yes pumps are abit light. Tractors after an 18000 number have a bigger steering pump. And after 19800 ?? there was an update from hydreco to cessna steering valves. Am told the cessna is a better steering valve. Also that little drive tang that drives steering pump and winch pump can wear and break over time, something else to be aware of. Ok, your final drive problem. . .Had a mate went down this same road The inner sprocket shaft bearing is different from wet backend tractors to dry backend tractors. Shaft is same, but inner bearing cup, and or cone, or both are different. if you just swapped shafts and didn,t use original bearings, i bet this is what problem is. Love your posts Mel and Dave; take care boys, cheers from the bottom of the world, Merv

|

|

tits tyres and tracks

they all cost you money

|

|

HD6 Merv

Silver Level Access

Joined: 03 Aug 2010

Location: New Zealand

Points: 498

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 Jan 2024 at 3:19pm Posted: 19 Jan 2024 at 3:19pm |

|

Had a look in parts book. Yes both inner cup and cone for sprocket shaft are different on a wet backend HD6E/EP compared to a dry HD6B

|

|

tits tyres and tracks

they all cost you money

|

|

AC Mel

Orange Level Access

Joined: 23 Jan 2010

Location: N.Ca.

Points: 1186

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Jan 2024 at 7:14pm Posted: 19 Jan 2024 at 7:14pm |

Yes....that's a work load for those little pumps...it does seem to steer alright now. Merv...I think I have the leak stopped also. BUT....I don't remember what I did with those bearings....the donor shaft was out of a dry deck 6. I was very careful looking at serial number breaks...and looked at all the parts books....been a long time. I know I didn't have any trouble preloading the shaft

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2269

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2024 at 10:16am Posted: 21 Jan 2024 at 10:16am |

|

Thanks for the video. It looks and sounds awesome.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(1)

Thanks(1)