| Author |

Topic Search Topic Search  Topic Options Topic Options

|

BH Reinen

Bronze Level

Joined: 02 Nov 2009

Location: Wi

Points: 22

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: WD 45 Loader Topic: WD 45 Loader

Posted: 29 Jun 2010 at 9:38pm |

|

What do I need to repack the rams on my WD 45 front end loader? Thanks Bart

|

|

|

Sponsored Links

|

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2010 at 9:51pm Posted: 29 Jun 2010 at 9:51pm |

Maybe Danny will see this and get on here and give you the low down on repacking them.

Don

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

dannyraddatz

Orange Level

Joined: 12 Sep 2009

Location: Plainfield, Ill

Points: 848

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2010 at 5:47am Posted: 30 Jun 2010 at 5:47am |

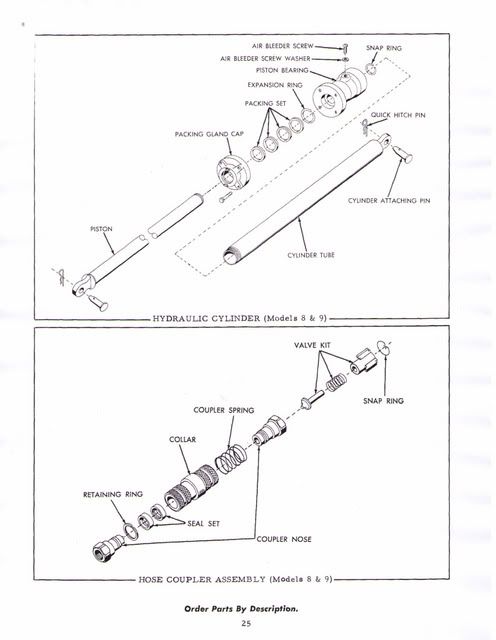

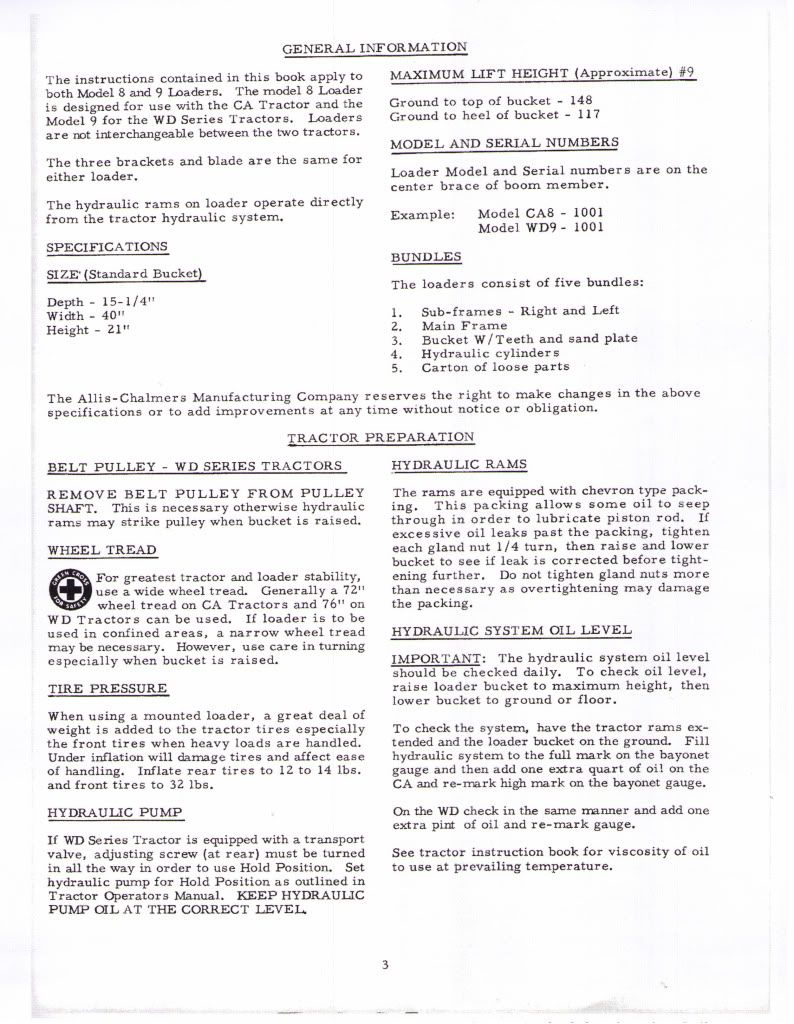

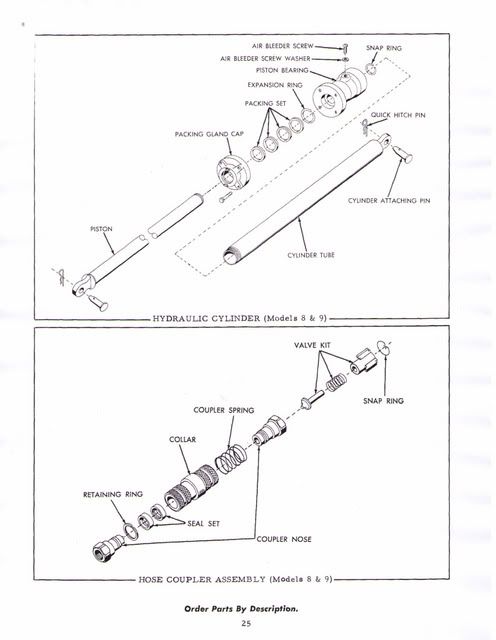

Bart, ******Check with your dealer to make sure this information is correct.********* All you will

need is 8 of part # 72000650 (packing) they cost me from a local ac

dealer 27.51 shipped to my house. Here's the link on rebuilding them, select slide show in my link when you get to photo bucket if you have any questions pm me. Danny Here is the pictures of rebuilding of the loader cylinder for a WD9 today! http://s577.photobucket.com/albums/ss212/dannyraddatz/?newest=1

Edited by dannyraddatz - 01 Jul 2010 at 7:41am

|

|

Danny Raddatz

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2010 at 6:09am Posted: 30 Jun 2010 at 6:09am |

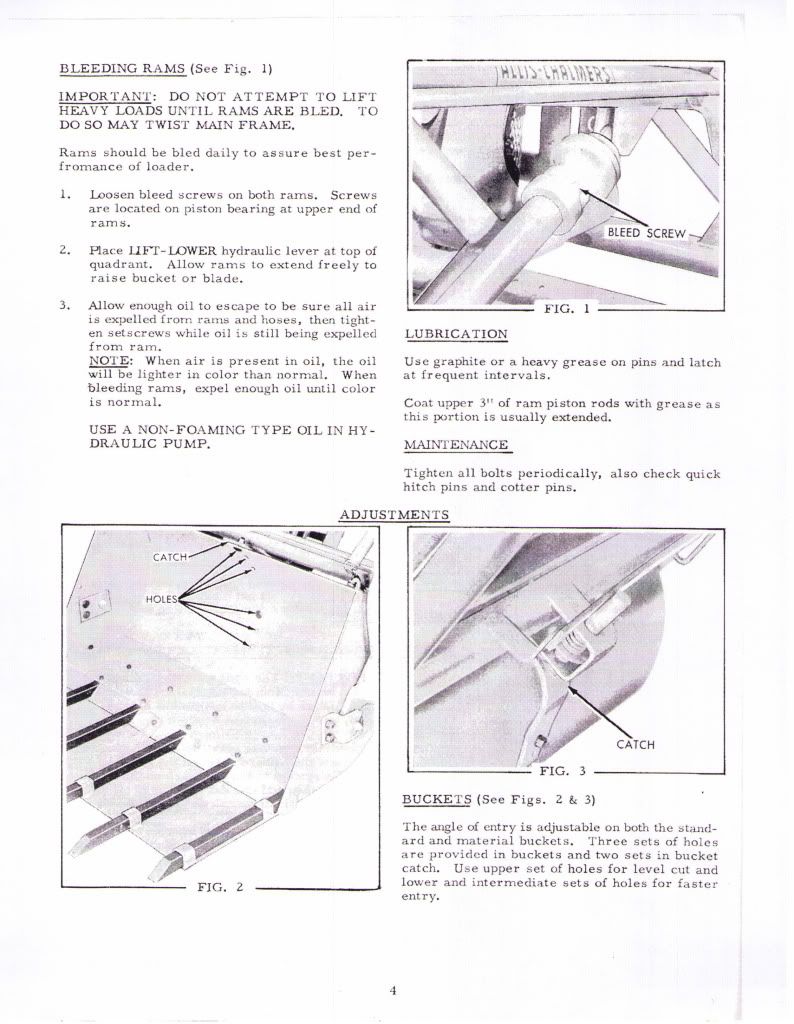

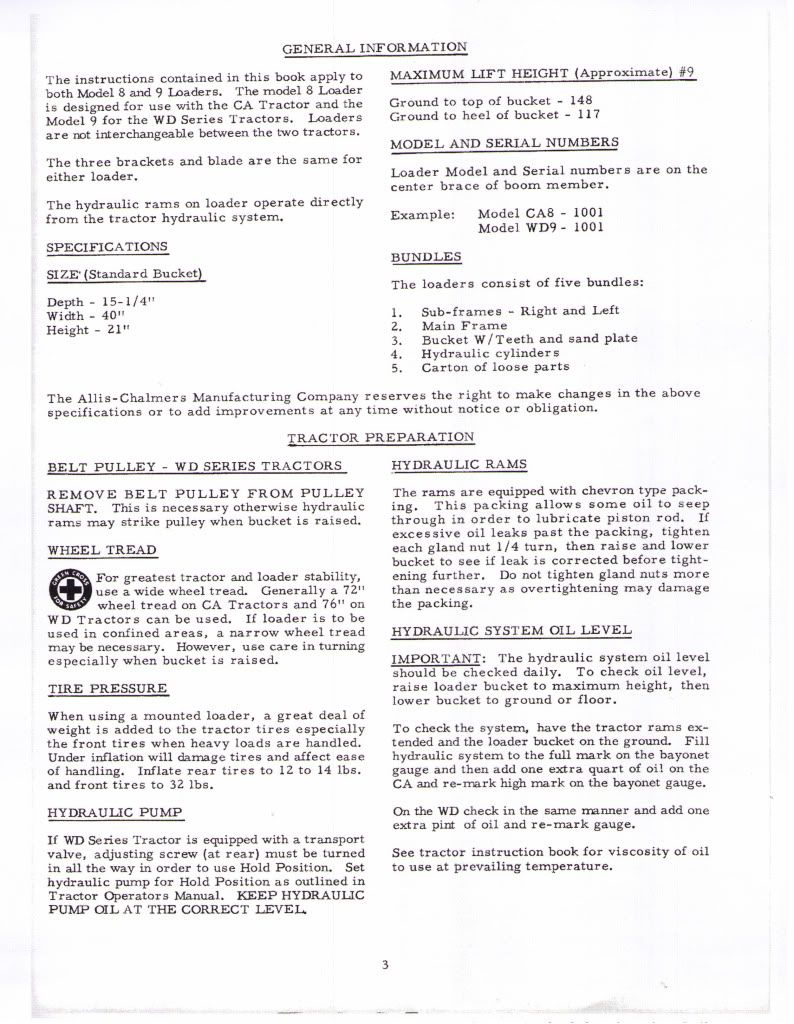

If the cylinder looks like this picture, you can tighten the packings by closing up the gap shown. Do not over tighten. Some oil must weep through to lubricate the packings. If the rods are pitted or have deep scratches they will eat up seals no matter what you do. The options then are, get new rods made, live with the leak, or buy different cylinders. (credit picture to Danny)

|

|

|

|

tbardell

Bronze Level

Joined: 30 Jun 2010

Points: 4

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Jun 2010 at 11:21am Posted: 30 Jun 2010 at 11:21am |

Good thread so far. I just re-packed mine last week- and it worked very well, the old rams seem to be fine holding 100% now with the new packing. I was worried about the rams being out of round or pitted, but they seem to be good. One Question: How tight should I pull the end caps down? I am afraid I may have them too tight now, possible starving the outer-most packings of oil.

Thanks! Trale

|

|

dannyraddatz

Orange Level

Joined: 12 Sep 2009

Location: Plainfield, Ill

Points: 848

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Jul 2010 at 8:20am Posted: 01 Jul 2010 at 8:20am |

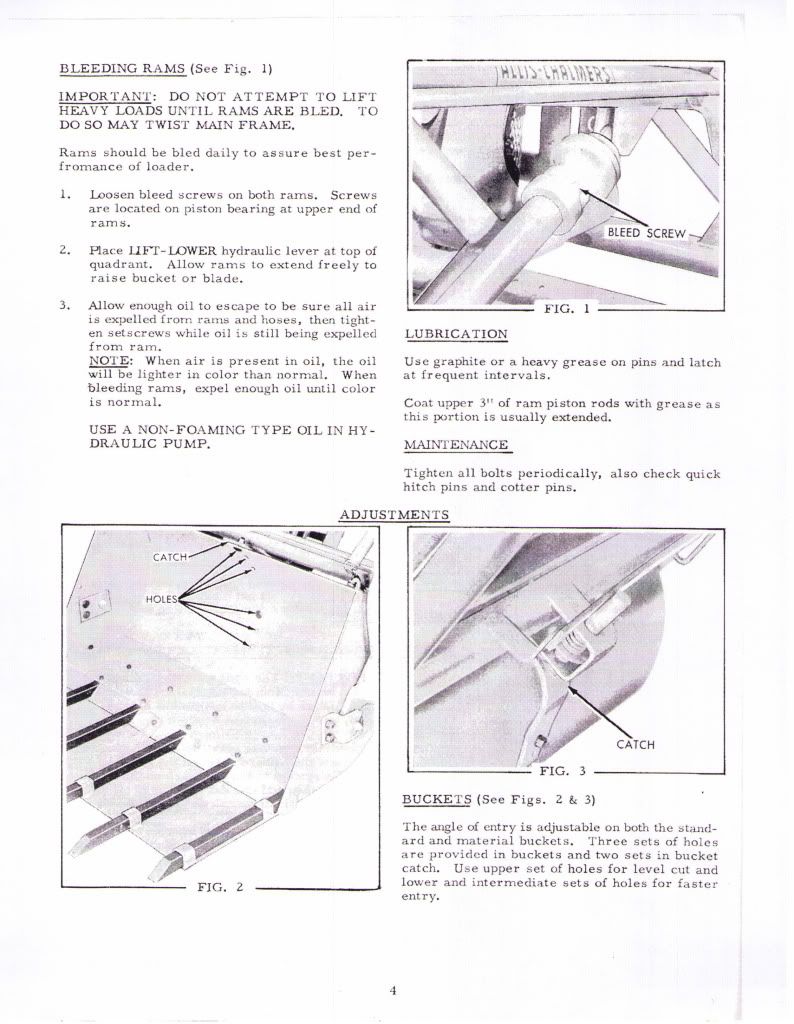

Did you bleed the piston bearing at the bleeder screw, remember it should be done each day before you lift. The problem is if you have air in the cylinder and try to lift the air will escape, this will cause heat friction between the ram piston and seals and cause a friction burn. Then over time the the seal develops a leak, in the picture Tucker posted you will see the bleeder screw. Make sure you know what your doing when you bleed the cylinder, Hydraulic fluid is very harmful to the human body, wear PPE. Back to your question that is a paint stirrer I used as my gauge for the first tightening down the cap. You should see a fine film on the piston but not a leaking from the top of the cap. Danny Here are 2 pages from the owners manual for the loader, you should try to get one, this should answer your question.

Edited by dannyraddatz - 01 Jul 2010 at 9:19am

|

|

Danny Raddatz

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)