| Author |

Topic Search Topic Search  Topic Options Topic Options

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis 415 loader to a D17 Topic: Allis 415 loader to a D17

Posted: 25 Nov 2024 at 5:55pm |

|

Hello all! I bought a 415 loader off a D15 I'm picking up this weekend. Can anyone provide me with some pictures of how it will mount to the axles. It's going on a series 4. Others have said it would fit, just need the D17 brackets for the rear axle. Also it comes with everything to use a front mounted pump but I believe the pump is missing. Can anyone recommend a front pump to use with it, I kinda like the idea to keep the rear remotes free. Any pics of mounts,pump ideas, or pictures of a manual would greatly be appreciated TIA-Josh

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2024 at 5:58pm Posted: 25 Nov 2024 at 5:58pm |

|

Why would you want to use a front pump on a series 4 ??? Only have one remote valve ?? instead of two ?? I'd get a second remote valve.

|

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2024 at 6:28pm Posted: 25 Nov 2024 at 6:28pm |

|

It has both rear remotes currently, but for the ability to run my disk, and other implements that take hydraulic rear remotes itd be nice not to have to unhook, hook when ever it's needed. I'm not set on this decision just looking at different ideas and such. Especially since the loader and hoses are already set up for a separate pump.

Edited by JoshDay94 - 25 Nov 2024 at 6:29pm

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2024 at 6:41pm Posted: 25 Nov 2024 at 6:41pm |

|

I'd be getting a couple of shut-off valves for the bucket and make that work. Move the bucket couplers back with a tee in-between. Then, connect buckets hoses to the bottom of the tee. Place shut-offs wherever you want. The upkeep of a second pump and drive shaft and it takes some HP/fuel to run a second pump. You also haven't priced a new pump or mounting plate or drive shaft or drive hub or chain coupling to make it all work.

Edited by DrAllis - 25 Nov 2024 at 6:47pm

|

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2024 at 5:29pm Posted: 28 Nov 2024 at 5:29pm |

|

I will probably go that route.

|

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2024 at 5:30pm Posted: 28 Nov 2024 at 5:30pm |

|

Bump for pictures of how other 400 series loaders are mounted please.

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5905

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2024 at 7:02pm Posted: 28 Nov 2024 at 7:02pm |

|

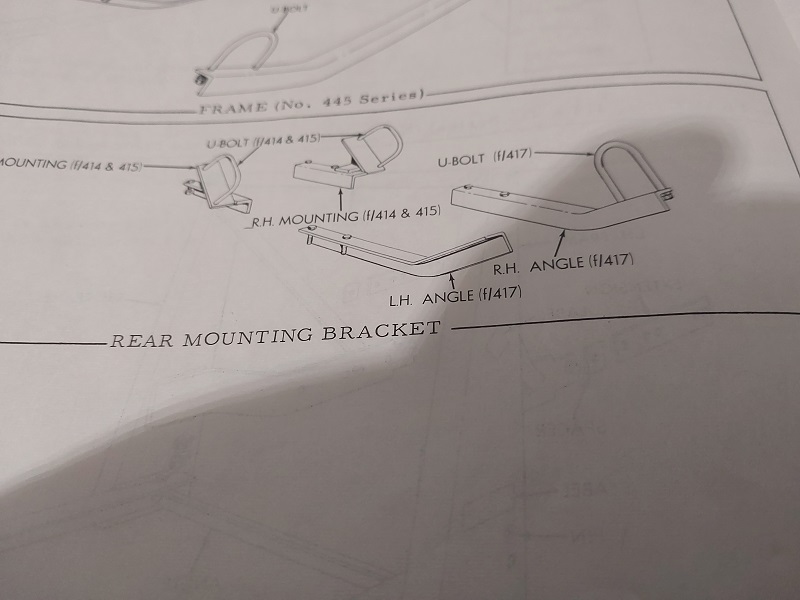

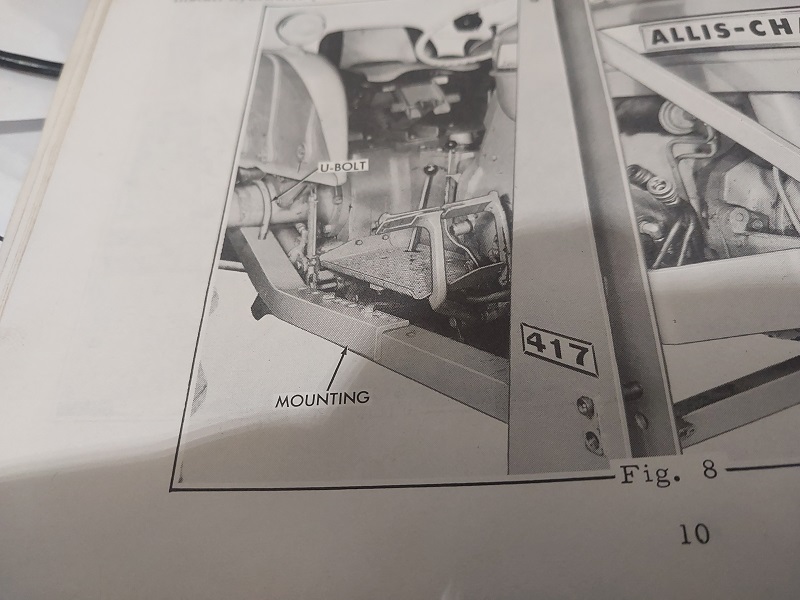

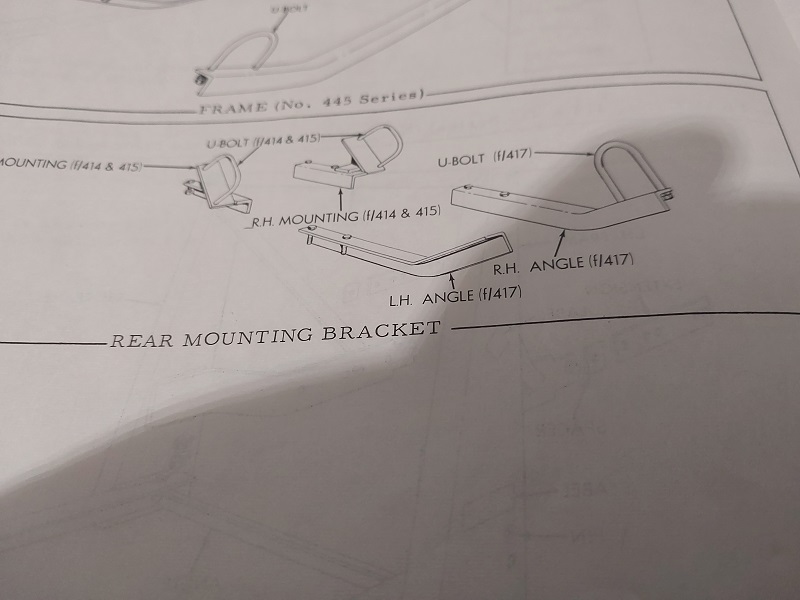

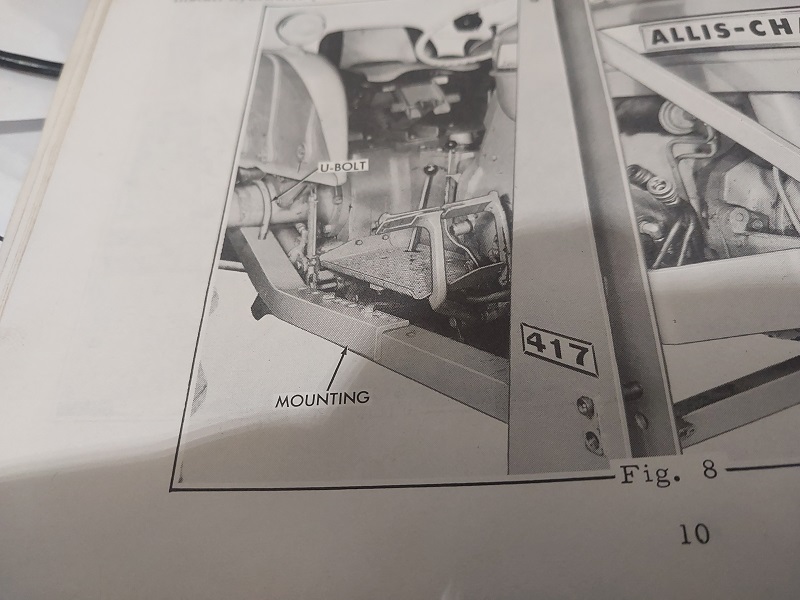

D-15 and D-17 are attached similarly at the Rear.

Both are an Angle Iron clamped to the underside of the Rear Axle with a 3/4" 'U' Bolt.

G

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2024 at 7:11pm Posted: 28 Nov 2024 at 7:11pm |

|

An operators or parts manual is needed. either will answer your questions.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5905

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Nov 2024 at 7:28pm Posted: 28 Nov 2024 at 7:28pm |

|

An original Allis Operating Instructions and Parts Illustration

400 and 500 Series Hydraulic Farm Loaders TM328

would be the ideal Manual with lots of illustrations.

G

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2024 at 2:26am Posted: 29 Nov 2024 at 2:26am |

Couple of pics.

|

|

Kenny L.

Orange Level Access

Joined: 12 Sep 2009

Location: NEIOWA

Points: 1363

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2024 at 2:30am Posted: 29 Nov 2024 at 2:30am |

|

I made my brackets to put a 415 loader on my D17, if I get out to the shed today I'll try to reminder to get some pics.

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5905

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2024 at 12:57pm Posted: 29 Nov 2024 at 12:57pm |

|

Yes Kenny those are the sketches and pictures I was referring to.

G

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88624

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2024 at 1:36pm Posted: 29 Nov 2024 at 1:36pm |

|

|

|

Like them all, but love the "B"s.

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5905

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Nov 2024 at 7:58pm Posted: 29 Nov 2024 at 7:58pm |

|

Wow, I only had to watch this Video a few minutes and I thought to myself what an idiotic Redneck way to complete what is really a simple Task.

Simple that is if you have been shown the correct procedure, OR you have the Allis 'Operating Instructions and Parts Illustrations Manual'.

The Manual clearly states and illustrates you first install the Left and Right Frames loosely to the Tractor.

Then you install the 'Frame Spacers' between the Left and Right Frames.

After you have tightened all the Frame bolts, you install the Lift Cylinders with hoses attached.

After completing the installation of the front Pump, guard, hoses, etc.,

only then do you attach the Boom and Bucket.

So in the Original Posters case, he would perform the above Tasks IN REVERSE.

1) Remove the Loader Boom and Bucket.

2) Remove lift Cylinders

3) Remove Left and Right Frames.

Use a chain hoist, Engine Hoist, or another Tractor Loader to support the Frames.

Forget removing Rear Tires and Wheels, Fenders, the need for Jack Stands, blocking front wheels, pulling on the whole loader assembly trying to drag it forward.

The whole Task really is quite simple if you follow the Reverse Procedure of installing the Frames, Loader Boom, Lift Cylinders, etc. to the Tractor.

AND much Safer as well!

Gary

|

|

DaveWisc.

Orange Level

Joined: 11 Oct 2009

Location: Wisc.

Points: 1015

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Nov 2024 at 11:02am Posted: 30 Nov 2024 at 11:02am |

|

The brackets are different angles got 15-17

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Nov 2024 at 4:20pm Posted: 30 Nov 2024 at 4:20pm |

|

It is important on a D-17 series to make sure that small angle iron clip is attached to the big U-bolt and on a fender mounting bracket bolt to keep the U-bolts from spreading apart.

|

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 6:19pm Posted: 01 Dec 2024 at 6:19pm |

|

Thanks guys for the info. I got the loader home today, only has 1 patch weld on the left tower where angle iron to axle attaches needs all new hoses and cylinders re packed. But for $450 bucks I thought that was a pretty good buy especially with everything, including the front mounted hydraulic pump, mounting brackets, drive shaft and guard. I will get pictures tomorrow.

|

|

Dragfluid

Bronze Level

Joined: 30 Nov 2024

Location: Pillager, MN

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 8:00pm Posted: 01 Dec 2024 at 8:00pm |

DrAllis wrote: DrAllis wrote:

Why would you want to use a front pump on a series 4 ??? Only have one remote valve ?? instead of two ?? I'd get a second remote valve. |

Doc, does the Series IV main pump have that much more volume? I've got the III and I know the loader would be slow as snails on it. Mine came with the 417 loader with the frt pump. Used it for many years and never had a issue with the pump.

Edited by Dragfluid - 01 Dec 2024 at 8:00pm

|

|

Series III D-17

Many others in my life.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22170

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 8:07pm Posted: 01 Dec 2024 at 8:07pm |

|

Series 4 factory hydraulics easily match a front pump tractor for speed. So, why use a front pump on a series 4 ??

|

|

Dragfluid

Bronze Level

Joined: 30 Nov 2024

Location: Pillager, MN

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec 2024 at 11:19pm Posted: 01 Dec 2024 at 11:19pm |

DrAllis wrote: DrAllis wrote:

Series 4 factory hydraulics easily match a front pump tractor for speed. So, why use a front pump on a series 4 ?? |

That's what I was asking. OK, thanks!

|

|

Series III D-17

Many others in my life.

|

|

darrel in ND

Orange Level

Joined: 22 Nov 2009

Location: Hebron, ND

Points: 8735

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2024 at 5:16am Posted: 02 Dec 2024 at 5:16am |

Dragfluid wrote: Dragfluid wrote:

DrAllis wrote: DrAllis wrote:

Why would you want to use a front pump on a series 4 ??? Only have one remote valve ?? instead of two ?? I'd get a second remote valve. |

Doc, does the Series IV main pump have that much more volume? I've got the III and I know the loader would be slow as snails on it. Mine came with the 417 loader with the frt pump. Used it for many years and never had a issue with the pump.

|

Just to elaborate a little on what Doc said; series one, two, and three all had the high pressure, low volume hydraulic pumps, that were internally mounted, and dead when you stepped on the clutch. Series 4 went to low pressure, high volume pump, that was externally mounted in what was previously the mounting spot for the belt pulley, and was full on "live', even when stepping on the clutch. Darrel

|

|

Dragfluid

Bronze Level

Joined: 30 Nov 2024

Location: Pillager, MN

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2024 at 5:09pm Posted: 02 Dec 2024 at 5:09pm |

darrel in ND wrote: darrel in ND wrote:

|

Just to elaborate a little on what Doc said; series one, two, and three all had the high pressure, low volume hydraulic pumps, that were internally mounted, and dead when you stepped on the clutch. Series 4 went to low pressure, high volume pump, that was externally mounted in what was previously the mounting spot for the belt pulley, and was full on "live', even when stepping on the clutch. Darrel [/QUOTE]

Yes, I've seen that pump on units at shows. The Series IV was nicer all around.

We tried running a log splitter off the main pump many moons ago. Took forever. Wasn't very economical. Didn't do that very long.

|

|

Series III D-17

Many others in my life.

|

|

JoshDay94

Bronze Level

Joined: 18 Nov 2024

Location: Logansport, Ind

Points: 110

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Dec 2024 at 1:06pm Posted: 09 Dec 2024 at 1:06pm |

|

Would anyone have a set of the 17 brackets they would be interested in selling? Or would someone be willing to help me in getting a set made at a fab shop based off an original set. Thanks!

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

DrAllis wrote:

DrAllis wrote: