| Author |

Topic Search Topic Search  Topic Options Topic Options

|

eamoore1984

Bronze Level

Joined: 31 Mar 2021

Location: Stanton, KY

Points: 2

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis Chalmers D14 Starter Failure Topic: Allis Chalmers D14 Starter Failure

Posted: 31 Mar 2021 at 11:08am |

Hey All,

I have read through several threads on the forum here. Thank you for all the contributions. Sadly my issue still transcends all the advice given. My father has an Allis Chalmers D14 1957 model (this is according the serial number stamp). It has been converted to 12 volt prior to his coming to own it in 2005. We used the tractor for many years with NO issues with the starter but about a year ago it failed. My father had it "rebuilt" in Lexington, Kentucky and so starts the tale. The newly rebuilt starter failed on install, he then had it rebuilt again, failed shortly after install. Purchased a new starter, failed shortly after install. Purchased another new starter which worked for longer but failed within a month.

I am now involved on the repair. I'm obviously trying to eliminate any misleading information. This is what I know at this point. A 10 tooth will not engage at all (its seems they are clockwise turning but I'm not sure) so I'm 90% sure it is a 9 tooth counter clockwise. After the starter failure the bendix is usually stuck in the engaged position which makes me think it's getting stuck in the flywheel but upon tooth inspection through the hole manually turning the tractor over, everything looks fine. The teeth on the starter bendix are always fine with no signs of chewing or marring. The tractor is a 1957 so it would have been 6 volt originally but has always been 12 volt since my family has come to own it so we are putting on 12volt starters (the most recent from Complete Tractor started the tractor 4 times without issue and smoked on the 5th). Side note the pertronix kit for this tractor is amazing! I have another new starter coming from DB Electronics that says its for 59-60 but client support insists that its a 9 tooth counter clockwise 12v starter which "should" work.

The install is literally one bolt with a check nut, it does not appear there is any adjustment in the positioning of the starter. What am I missing??

|

|

|

Sponsored Links

|

|

|

Richardmo

Orange Level Access

Joined: 12 Sep 2009

Location: Rolla mo.

Points: 1746

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 11:31am Posted: 31 Mar 2021 at 11:31am |

|

The 6 volt and 12 volt starters do have different teeth counts.

How bad does the ring gear appear to be on the flywheel

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8524

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 11:36am Posted: 31 Mar 2021 at 11:36am |

Ok Lets step back: -The tractor came from the factory and worked for many years, Maybe with out a starter being changed for a long time. - Your tractor is now 65 years old. My starter doesn't work as well now either! - You have had several "starter" failures, some rebuilds and more failures. - There is a problem and it may not be fixed with another starter? - You have examined the ring gear. - You have determined the correct rotation and the correct gear teeth numbers. My gut says the ring gear may be worn considerably, maybe in one spot? But that my best guess from here on the couch! I had a worn ring gear and starter issue on one of the WD's.

Please try to describe the failure mode in as much detail as you can remember. That may help us help you.

Stick your camera in the starter hole and take a picture of the ring gear teeth. I dont know which is the correct tooth number for the starter but remember ring gears can get changed to? Not sure that's feasible on yours as I just don't know those tractors well, But Mack and Dr Allis will be along with less talk and more actions! Regards, Chris

Edited by Sugarmaker - 31 Mar 2021 at 11:40am

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21919

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 11:48am Posted: 31 Mar 2021 at 11:48am |

I have one question. Whenever you've installed a "good" starter, has the engine ever turned over and started ??? because if it has never turned over and started, it's because you need a 6-volt starter Bendix to match the teeth pitch on the flywheel. You cannot use a 12-volt starter where a 6-volt used to be without splitting the tractor and replacing the ring gear on the flywheel. Converting over to 12 volts never meant changing the starter over from 6-volts.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8524

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 11:58am Posted: 31 Mar 2021 at 11:58am |

And there you go! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8637

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 1:10pm Posted: 31 Mar 2021 at 1:10pm |

|

My 6V WD45 starter has worked fine for 40 yrs on 12V. Some have the fields/coils/armature? changed to 12V in the old 6V starter but seems unnecessary to me.

|

|

john(MI)

Orange Level

Joined: 12 Sep 2009

Location: SE MI

Points: 9262

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 7:10pm Posted: 31 Mar 2021 at 7:10pm |

I had my 6v starter converted to 12v. It always ground when it was 6v, now it works great. The 14 has a change at S/N 19001, yours would be before that change. There is also a change on the starter at engine s/n 149-19070. The part # for the original starter is 0231935-8, that has probably changed at some point.

When I had my starter converted to 12v, the starter man put a new solonoid on it. He said it had the wrong one on it.

I guess you need to determine which engine is in it, the ring gear had a different tooth count from one to the other. The bendix had a different tooth count as well. If you decide to change the ring gear, you will need to pull the engine. You don't need to split the tractor just remove one side rail. If you go that far you might as well change all of the other parts in there at the same time.

|

|

D14, D17, 5020, 612H, CASE 446

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 7:52pm Posted: 31 Mar 2021 at 7:52pm |

|

Dr. has it right... You had a 6 volt system, you need a 6 volt starter... you can run it for YEARS on 12 v.... The tractor does not care.... thats what was on it when you bought it.

|

|

Like them all, but love the "B"s.

|

|

KJCHRIS

Orange Level

Joined: 21 Dec 2015

Location: WC Iowa

Points: 960

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 8:02pm Posted: 31 Mar 2021 at 8:02pm |

Been 25+ years since had D14, still have D15, so may be wrong. Didn't the early D14 gas w/ 6 V use a 10 tooth drive and then when later D14 & D15 gas w/ factory 12V use a 9 tooth drive?

|

|

AC 200, CAH, AC185D bareback, AC 180D bareback, D17 III, WF. D17 Blackbar grill, NF. D15 SFW. Case 1175 CAH, Bobcat 543B,

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21919

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar 2021 at 8:19pm Posted: 31 Mar 2021 at 8:19pm |

|

I do not remember the tooth counts. All I remember is the 6 volt starter has a different ring gear tooth count and Bendix tooth count than a 12 volt system. Combining a 12 volt starter with a 6 volt ring gear is like using a #60 roller chain on a #50 sprocket. It doesn't work.

|

|

JCC

Bronze Level

Joined: 11 Apr 2021

Location: Kansas

Points: 4

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 9:11am Posted: 11 Apr 2021 at 9:11am |

|

Can someone show me a diagram of the wiring for the solenoid?

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24697

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 9:18am Posted: 11 Apr 2021 at 9:18am |

All '6 volt' D-14 starters I've had, have a 'brush inspection band' bolted to them. My one true 12 volt starter doe NOT have this band.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 12:41pm Posted: 11 Apr 2021 at 12:41pm |

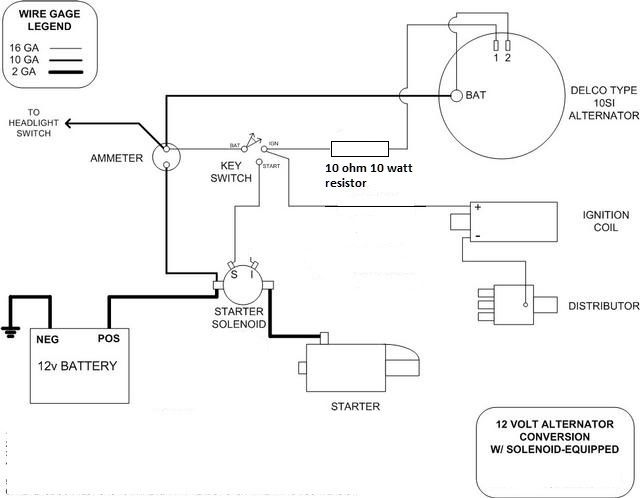

Jill, im not sure what tractor you are working on. Some did not have a SOLENOID, they had a PUSH ROD.. If you have a tractor with a solenoid, then it also has a key or push button to engage the solenoid to put power to the starter motor... something like this... you may not have an alternator .... the solenoid wiring is like this.

|

|

Like them all, but love the "B"s.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 12:55pm Posted: 11 Apr 2021 at 12:55pm |

Here is the wiring diagram for the original D14 6 volt positive system from a D14 Operator's manual, which includes the solenoid and wiring.

|

|

JCC

Bronze Level

Joined: 11 Apr 2021

Location: Kansas

Points: 4

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 4:34pm Posted: 11 Apr 2021 at 4:34pm |

|

It is a D14, and has been converted to an alternator. It has both a kill switch and a key ignition.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2021 at 7:03pm Posted: 11 Apr 2021 at 7:03pm |

|

A D14 originally had a key switch and a push button for the starter.

Kill switches I'm familiar with are generally used with a magneto, they ground the magneto out to stop the engine, D14s didn't have magnetos. A D14 should have just a key switch to shut the power off to the distributor.

I wonder if your kill switch was installed as part of the conversion to the alternator. Depending on the alternator, and how it was wired, it can back feed the ignition which will prevent stopping the engine with the key switch. A switch in the excitation wire can be used to break that circuit and allow the engine to stop. Can you tell where the wires on that switch go? Will it run but not charge if you don't turn that switch on?

Does your key switch normally operate the starter solenoid or does it have the push button for the solenoid?

Given yours has been converted to an alternator there is no official drawing since it is not OEM. Conversions are similar but different due to different alternator and components used, as well as the person doing it, so it may take a bit to sort things out.

Edited by Jim.ME - 11 Apr 2021 at 7:04pm

|

|

JCC

Bronze Level

Joined: 11 Apr 2021

Location: Kansas

Points: 4

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 1:41pm Posted: 12 Apr 2021 at 1:41pm |

|

The key switch operates the solenoid. The tractor won't run or start when the kill switch is off.

|

|

JCC

Bronze Level

Joined: 11 Apr 2021

Location: Kansas

Points: 4

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 3:18pm Posted: 12 Apr 2021 at 3:18pm |

|

I'll go out and see if I can track where the kill switch wires go, then get back with you. It will be later.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 3:23pm Posted: 12 Apr 2021 at 3:23pm |

|

kill switch should be on the hot wire going to the coil.

|

|

Like them all, but love the "B"s.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 4:03pm Posted: 12 Apr 2021 at 4:03pm |

|

Unless it is a battery power kill switch.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87910

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 5:28pm Posted: 12 Apr 2021 at 5:28pm |

|

If the alternator is connected to the coil with a hard wire and no resistor or diode in the line, the tractor might continue to run after the key is off.... I assume thats why they added the switch ?

|

|

Like them all, but love the "B"s.

|

|

Jim.ME

Orange Level

Joined: 19 Nov 2016

Location: Maine

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2021 at 7:14pm Posted: 12 Apr 2021 at 7:14pm |

|

That is why I was asking where the wires from it go. It could be wired in several ways for a few different reasons.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)