| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 53 CA NF to WF swap? Topic: 53 CA NF to WF swap?

Posted: 19 May 2020 at 8:19am |

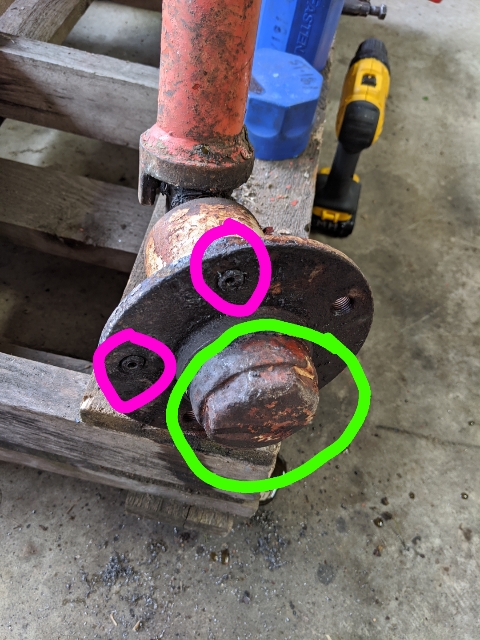

I've started to change over my narrow front to a wide front and installed the trip loader bucket. I'm not sure why but after I remove the narrow front pedestal it only has the big gear for steering on top and no post with tapered bearing on top of that (my wide front that I bought has the big gear for steering then a post on top of that and a tapered bearing on top of that?) Do I need the bearing on top of the steering gear? I'm not sure why I would need this bearing but the casting has a place for it but will require me to remove the radiator to get to this part of the raceway in the casting marked a.m. 3775 - 5... Here's some pictures to hopefully help someone give me an answer to this below.

|

|

|

Sponsored Links

|

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 9:40am Posted: 19 May 2020 at 9:40am |

So here's a quick update I removed the radiator because in my mind I could not see that I would not use the top tapered raceway on the wide front end and strangely enough the exact same casting number that can be seen in this picture that's mounted on the tractor right now does not have the same tapered raceway from the bolster that came with the wide front end? So now if I'm going to use the top bearing from the wide front end I'm going to have to change the front bolster I believe because the front bolster that's currently on the tractor has no raceway to accept or match with the wide front end...

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 9:52am Posted: 19 May 2020 at 9:52am |

i believe you are correct.........

|

|

Like them all, but love the "B"s.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 10:51am Posted: 19 May 2020 at 10:51am |

|

Okay thanks

|

|

Richardmo

Orange Level Access

Joined: 12 Sep 2009

Location: Rolla mo.

Points: 1746

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 11:51am Posted: 19 May 2020 at 11:51am |

|

Just look up the upper support no different part # is given for the bolster.

You would have to take the top gear off and need a race to go in the top of your support then put the bearing back in not less I missed something in the parts book.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 12:13pm Posted: 19 May 2020 at 12:13pm |

|

Right I believe I have all the parts I need from when I bought the wide front end luckily...

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 12:14pm Posted: 19 May 2020 at 12:14pm |

|

the casting number for the upper support on both tractors would be the same... There is an EXTRA machining process needed for the upper bearing on the wide front for the bearing on the TOP.... If that is put into ALL supports, then they have the same part number... If some were not machined for the bearing, then they SHOULD have a different part number .......... maybe yours is just rusted up too bad to see the bearing bore ?

|

|

Like them all, but love the "B"s.

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 4:18pm Posted: 19 May 2020 at 4:18pm |

On the narrow front you have a bearing on the bottom of the pedestal and top that holds the shaft straight. On the wide front requires a top and bottom in the bolster to hold the shaft straight. If you dont put the top one in the shaft will move around and gears wont mesh right.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 5:40pm Posted: 19 May 2020 at 5:40pm |

|

Ok, makes sense now

When I took the pedestal off from the narrow front oil came dumping out (which I didn't expect)

It seems like it should have grease in it but I'm not sure?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 6:32pm Posted: 19 May 2020 at 6:32pm |

|

normally REALLY THICK GREASE !

|

|

Like them all, but love the "B"s.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 6:36pm Posted: 19 May 2020 at 6:36pm |

|

Hmmmmm, ok( I thought oil was strange)looked like 80w oil mixed with 30w- consistency-

So does it get filled through the small plug on front of bolster?( Looks like maybe 3/8" diameter hole)

How much grease is needed when I rebuild it?

Edited by Hunt4Allis - 19 May 2020 at 6:39pm

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3971

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 May 2020 at 8:46pm Posted: 19 May 2020 at 8:46pm |

|

It's suposed to have oil should be 90 wt

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 2:03pm Posted: 22 May 2020 at 2:03pm |

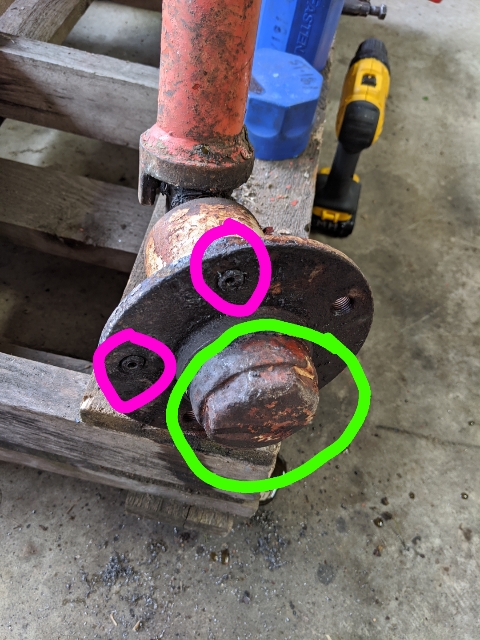

Okay thanks oh, so circled in green I need to remove this hub because two of the 5 lug nut bolts were snapped off of wide front (circled in magenta)so I plan on swapping my narrow front hubs for these but I cannot get the cap off to get to the big nut inside of it?

Edited by Hunt4Allis - 22 May 2020 at 2:04pm

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 4:01pm Posted: 22 May 2020 at 4:01pm |

|

the cap is screwed on...You put a pipe wrench on the BIG HEX and smack it... a SHOCK is much better than a constant torque on the wrench... tapping on the cap with a hammer might shock the threads and break up some old rust also.

|

|

Like them all, but love the "B"s.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 4:37pm Posted: 22 May 2020 at 4:37pm |

|

Okay that's what I was actually doing except I did not hit it with a hammer I was just on it with two pipe wrenches and could not budge it, thanks Matt 👍

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 6:11pm Posted: 22 May 2020 at 6:11pm |

|

your green circle kind of covers the JOINT between the cap and the hub... look real close for the JOINT... going around the cap and tapping on that JOINT might break the rust loose on the threads... then wrench on the HEX and SMACK hard.

|

|

Like them all, but love the "B"s.

|

|

Hunt4Allis

Orange Level

Joined: 13 Mar 2018

Location: Ohio

Points: 1172

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 6:18pm Posted: 22 May 2020 at 6:18pm |

|

Ok, so right hand thread?( Lefty loosie)

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88098

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2020 at 9:06pm Posted: 22 May 2020 at 9:06pm |

|

YEP... counter clockwise = off

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)