| Author |

Topic Search Topic Search  Topic Options Topic Options

|

KidFarmer87

Bronze Level

Joined: 26 Aug 2013

Location: Northern IL

Points: 40

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 226, to overhaul or not overhaul?? Topic: 226, to overhaul or not overhaul??

Posted: 01 Feb 2018 at 7:22pm |

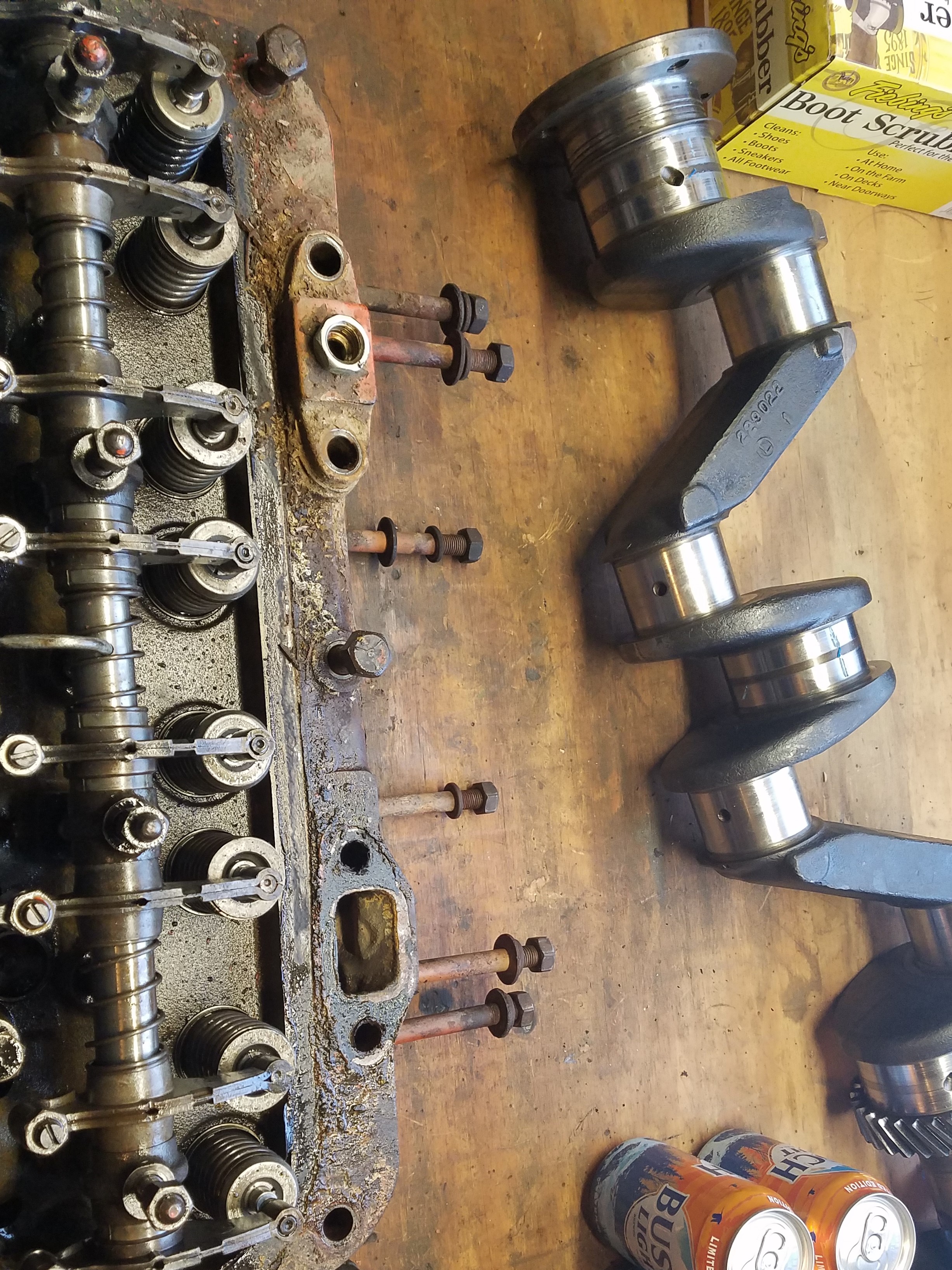

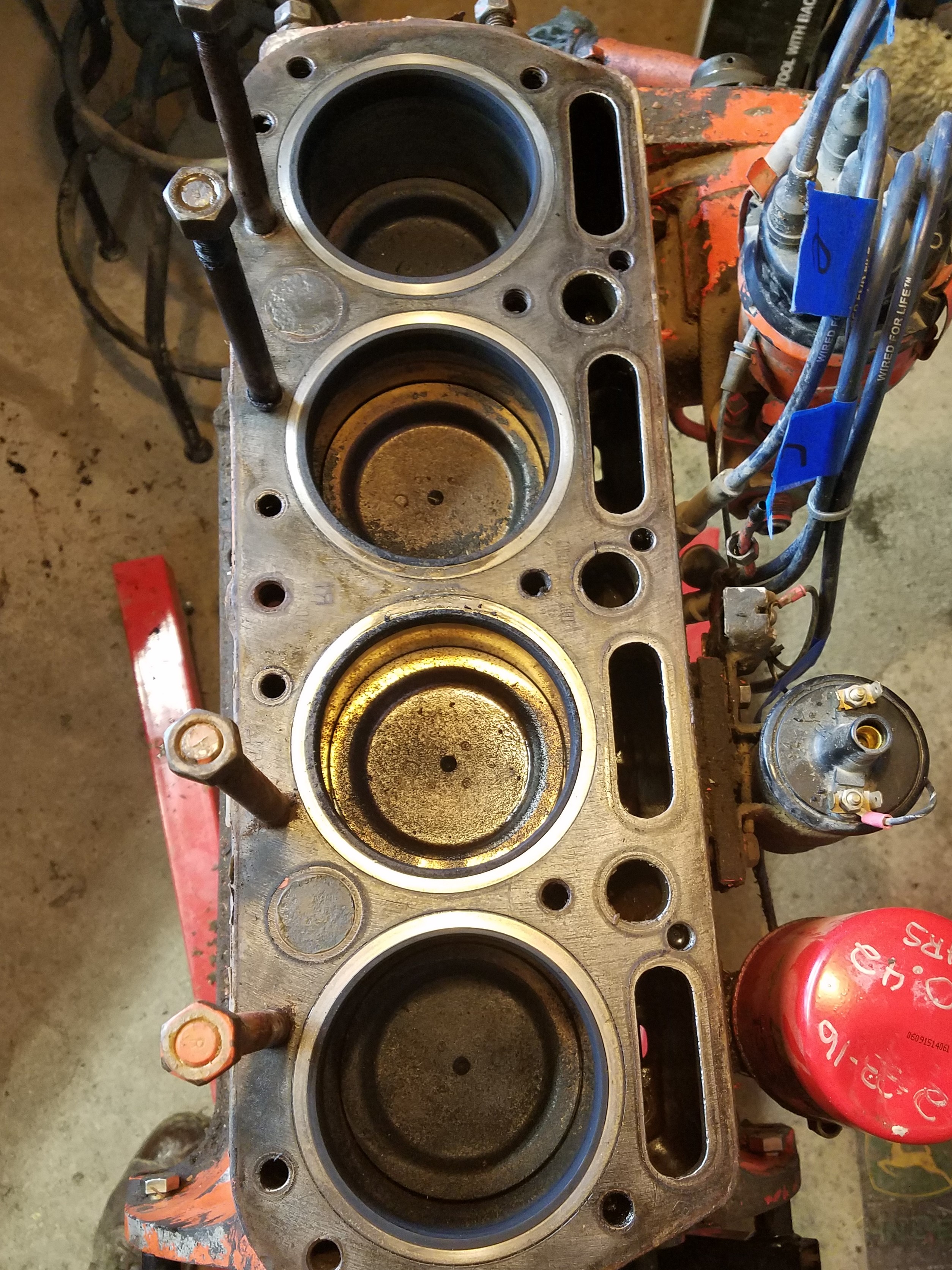

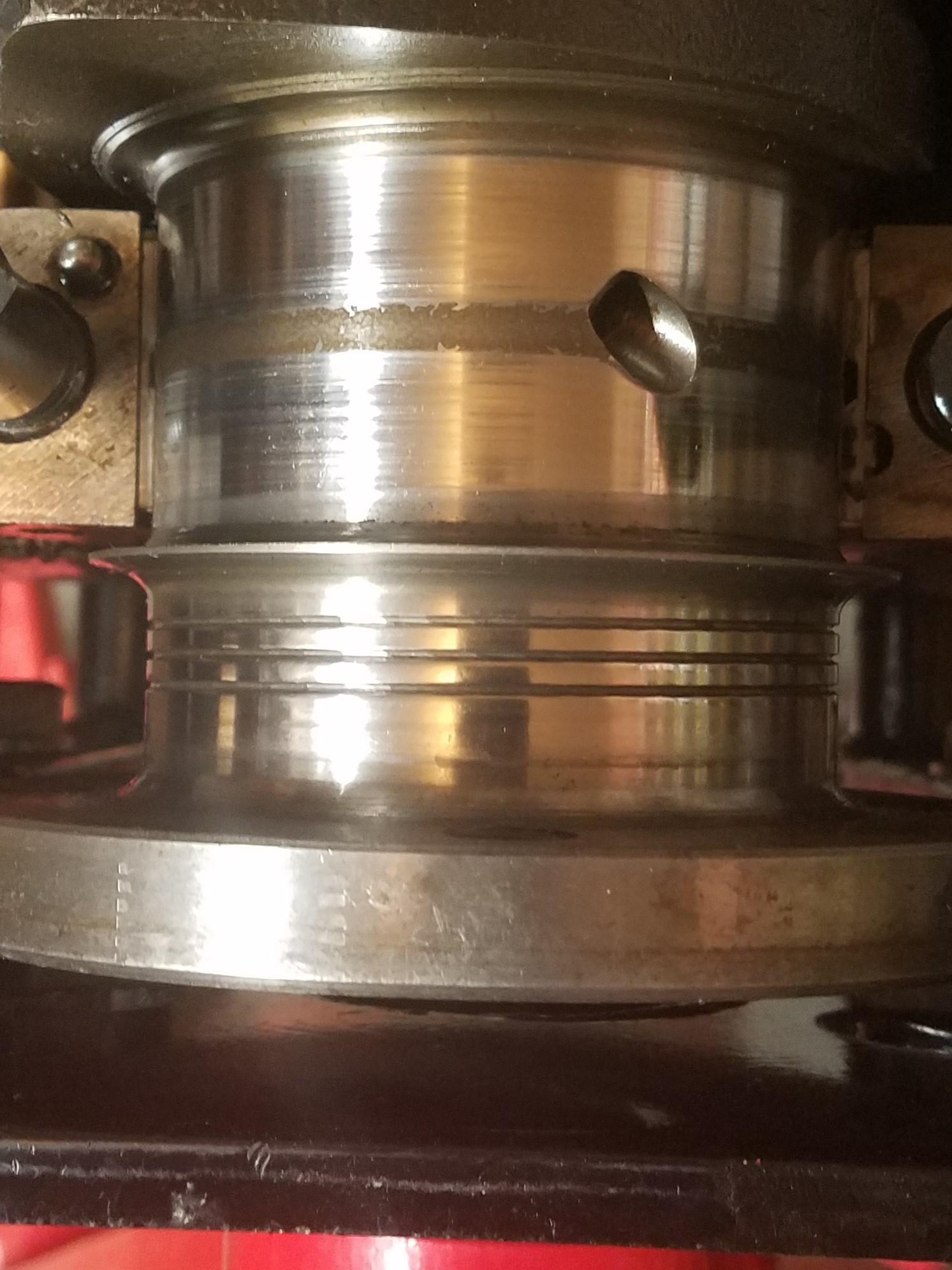

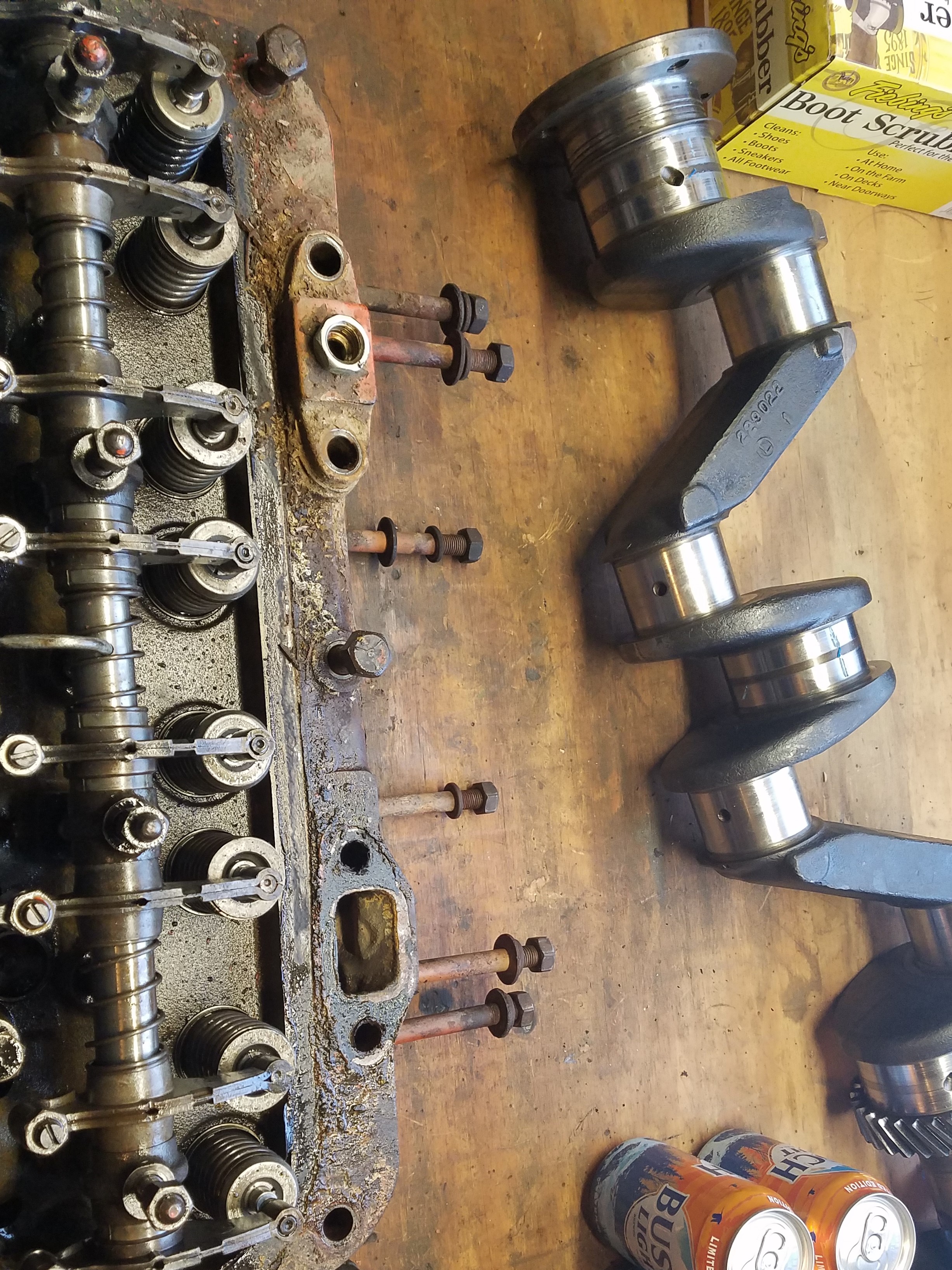

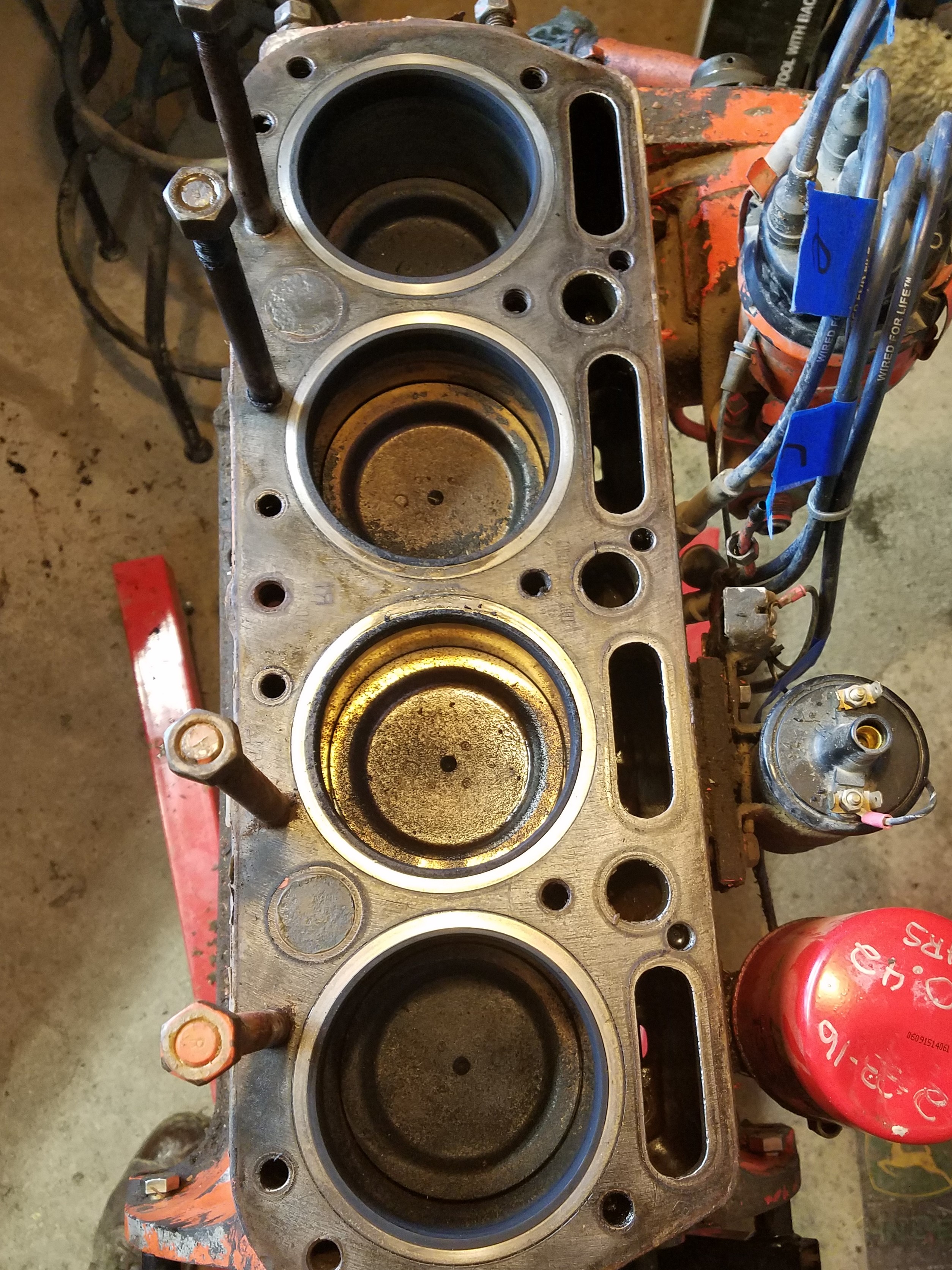

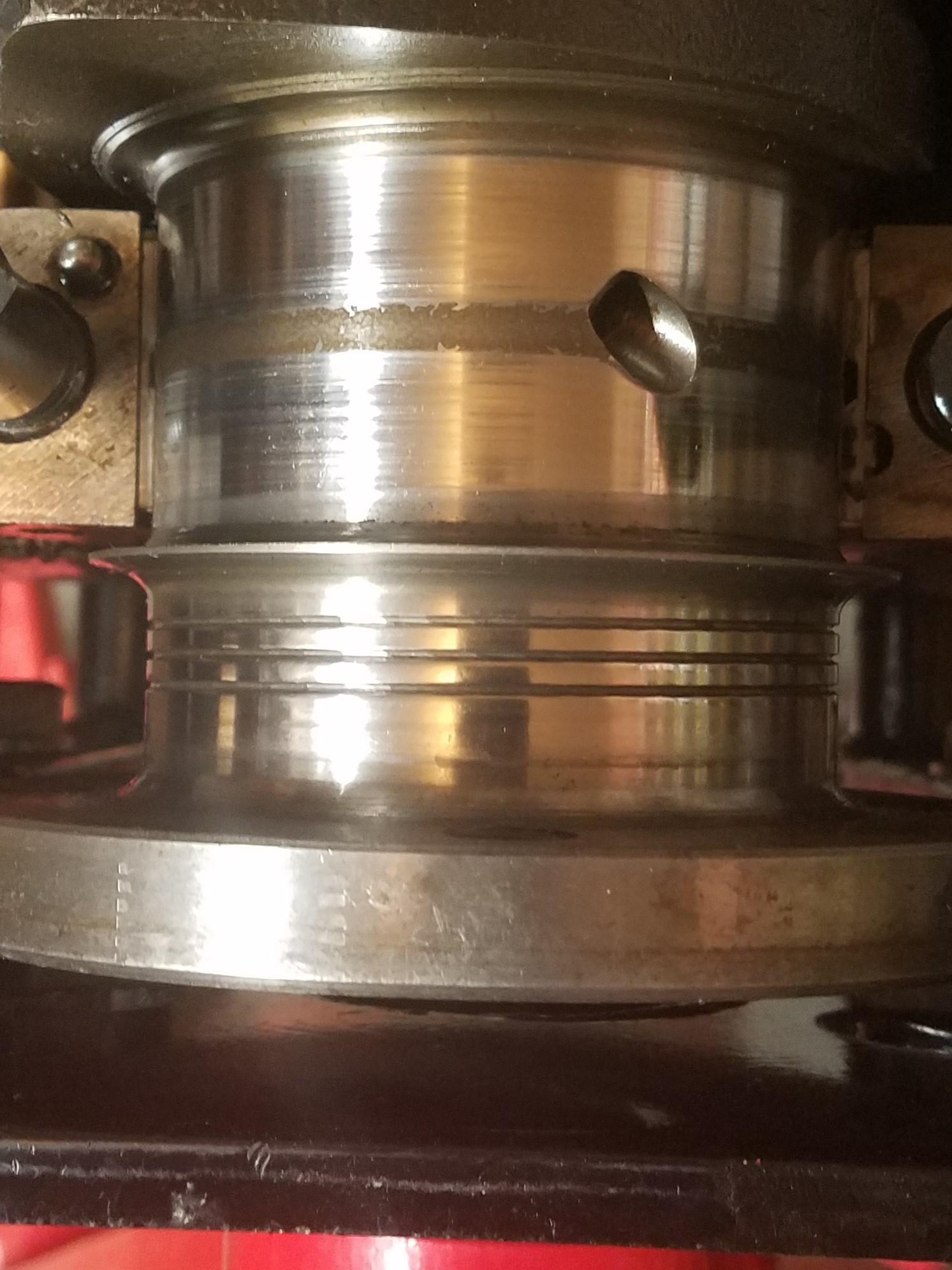

So I split my early D17 because of an oil leak at the rear of the motor, also thinking it needed a clutch. (Witch it does) Now that I've got the pan off and watched Don's very informative video on how to do the rear main I have just a couple questions. 1) ?Is the crank supposed to have grooves in it where the rear main seal sits??? ?I really hope I don't need to track down a newer one. I've also got some pictures of the cylinders, that I think look pretty good, and a picture of the main bearing on the rear cap that I removed. And 2) Should I just do an overhaul? (Rod's, main's, rings?) I'm going to get some PlastiGauge and see what what the main bearing checks out at.  I think this was the main source of my oil leak. Look at the gap between the gasket and the block.  Grooves where the rear main seal rides  Rear main cap bearing  Looking inside the cylinder.

|

|

|

Sponsored Links

|

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8616

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2018 at 9:21pm Posted: 01 Feb 2018 at 9:21pm |

|

the grooves keep the oil in the engine.

|

|

CrestonM

Orange Level

Joined: 08 Sep 2014

Location: Oklahoma

Points: 8455

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2018 at 10:00pm Posted: 01 Feb 2018 at 10:00pm |

|

Cross hatching looks good to me (but what do I know). I'd say if it ran good before (good compression, no blow by, etc.) let it be. No sense spending money if it runs good.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 87694

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Feb 2018 at 10:15pm Posted: 01 Feb 2018 at 10:15pm |

|

Im with Creston.......... liners and piston look great... Bearings look like dirty oil has gone thru them , but I don't see babbit gone. Clearance check on 1-2 might be a good idea. What was oil pressure when running ?

|

|

Like them all, but love the "B"s.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3042

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2018 at 6:54am Posted: 02 Feb 2018 at 6:54am |

It looks good to me too. plastigauge the mains and a couple rods and see how they look. Should be .002-.004. Might be a good time to do a coolant flush on the block. They can get a lot of junk in them over the years. Make sure to put a little glue on the main seal to hold it in it's groove. I've heard sometimes they want spin. Lookup username "Rick" on here. He sometimes post in the classifieds. He sells great clutch parts at a great price. He relines the clutch and brake pads himself.

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2018 at 7:04am Posted: 02 Feb 2018 at 7:04am |

|

How much end play do you have on the crank? Admittedly I'm not getting the clearest picture but things look rough to me. And it looks like a lot of junk laying around. A good cleaning is needed or you can ruin the new parts you put in, but if everything else is good you may not need a complete tear down.

|

|

Unstyled

Bronze Level

Joined: 27 Nov 2017

Location: missouri

Points: 30

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2018 at 9:11am Posted: 02 Feb 2018 at 9:11am |

Some things to keep in mind, The bottom of the bore where the rings never touch will almost always look good. As mentioned above if it had good power and did not use oil, probably OK. With the work required to get the engine torn down to this point, why not replace the bearings? I would not chance it. Use assembly lube on the bearings (new or used) at final assembly so you don't have a dry start. Good time to replace the front seal. Use a speedi-sleeve if there is a grove at the front seal.

|

|

Brian Jasper co. Ia

Orange Level

Joined: 11 Sep 2009

Location: Prairie City Ia

Points: 10508

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Feb 2018 at 3:11pm Posted: 02 Feb 2018 at 3:11pm |

My guess is that engine had an "in frame" repair done to it, meaning new pistons, sleeves, probably rod bearings too. I say that because I see no varnish buildup on the under side of that piston or on the edges of that sleeve where nothing ever touches. It could also have been an overhaul that set without running for quite a few years and there was enough moisture present to discolor that crank journal. Either way I'd be having that crank reground with all new bearings if it were me.

|

|

"Any man who thinks he can be happy and prosperous by letting the government take care of him better take a closer look at the American Indian." Henry Ford

|

|

KidFarmer87

Bronze Level

Joined: 26 Aug 2013

Location: Northern IL

Points: 40

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Feb 2018 at 6:00pm Posted: 03 Feb 2018 at 6:00pm |

|

Thanks so much for the input guys. I should've mentioned that at some point prior to me getting it had some engine work. I talked to the man who did it and he remembers doing it, but not exactly what they did to it. (As he's done many) I've owned and lightly worked it for about 4 years and it really runs great. However after working for an hour, not real hard the oil pressure drops, not all the way, I wish it was a number gauge, as I cant remember what letter the needle ends up on, without going to look. Just the oil leak is what really concerned me, then the clutch went. I still need to plastigage it, and I'll report back.

|

|

Fred in Pa

Orange Level

Joined: 13 Sep 2009

Location: Hanover Pa.

Points: 9210

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Feb 2018 at 9:42am Posted: 04 Feb 2018 at 9:42am |

|

If it was a in frame then cam bearing where not replaced .

|

|

He who dies with the most toys is,

nonetheless ,still dead.

If all else fails ,Read all that is PRINTED.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8616

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Feb 2018 at 9:50am Posted: 04 Feb 2018 at 9:50am |

Fred in Pa wrote: Fred in Pa wrote:

If it was a in frame then cam bearing where not replaced . |

....and loose cam brgs cause loss of oil pressure in these engines....not every one knows that

|

|

KidFarmer87

Bronze Level

Joined: 26 Aug 2013

Location: Northern IL

Points: 40

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Feb 2018 at 6:11pm Posted: 04 Feb 2018 at 6:11pm |

Well I spent most of the day out in the shop, Plastigage shows .006 on the front and rear main bearing, and .005 on the center bearing. Needless to say I tore the whole motor apart. It's already got .010 over bearings in it, so my guess is it had to be an out of frame, and the crank was already ground. How much of a bugger is it to put a new cam bearing in it? I haven't pulled the pistons yet, but if I've gone this far I might as well put new in. So who sells a good overhaul kit??

|

|

wekracer

Orange Level

Joined: 13 Oct 2009

Location: Tebbetts, MO

Points: 1590

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2018 at 6:14am Posted: 05 Feb 2018 at 6:14am |

|

I would use agco. You might check with Minnpar. They had the best price when we did the 8050. And the machine shop will put cam bearings in for you.

I would also put your hunters edition Busch Light back in the fridge before they get warm. Lol.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3042

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2018 at 8:35am Posted: 05 Feb 2018 at 8:35am |

Reliance sells good kits. I bought mine a couple years ago from "Fred in PA" who commented on your post above. Did you happen to do a compression test before you tore down? What is the bore size of the sleeves? The main bearings in these motors are shimmed. It's possible that the last guy didn't shim them well, and that why you have .005. Take it to a machine shop and they can tell you for sure. It's hard to tell from the pictures. The oil pressure issue does sound like Cam bearings need replaced.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2018 at 9:09am Posted: 05 Feb 2018 at 9:09am |

|

Main and rod bearings on a G-226/ D-17 engine are NOT shimmed.

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 3042

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2018 at 9:22am Posted: 05 Feb 2018 at 9:22am |

Oops, Thanks for clarifying Doc. I thought the shims went away in the 170-175. So it probably does need the crank ground and new bearings.

Edited by Allis dave - 05 Feb 2018 at 9:22am

|

|

Don(MO)

Orange Level

Joined: 12 Sep 2009

Location: Bates City MO.

Points: 6862

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Feb 2018 at 9:46am Posted: 05 Feb 2018 at 9:46am |

|

Might look the crankshaft timing gear over and have the shop check the mains on the crank when you have the cam bearings changed.

|

|

3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Fred in Pa wrote:

Fred in Pa wrote: