| Author |

Topic Search Topic Search  Topic Options Topic Options

|

lenholm

Bronze Level

Joined: 26 Dec 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D17 Loader Identification/Failure Topic: D17 Loader Identification/Failure

Posted: 26 Dec 2022 at 4:19pm |

I am new to this site and tractor ownership. I have a 1961 D17 with a front end loader (see below). I can't find any information on this loader. It appears to have been installed by Sandhill Equipment, Bassett, NE, based on the almost obscure sticker.

Today the loader failed after operating fine for an hour. The hydraulic tank is mounted on the right side of the loader and runs off a pump attached to the front of the tractor. If anyone has any information on this loader set up that might help me diagnosis the problem I would be greatly appreciative.

|

|

|

Sponsored Links

|

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 4:25pm Posted: 26 Dec 2022 at 4:25pm |

|

Failed totally?? Make sure the drive shaft on the pump is turning when the engine is running OR stays turning when you try and lift the loader. Might take two people to confirm.

|

|

DaveWisc.

Orange Level

Joined: 11 Oct 2009

Location: Wisc.

Points: 1015

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 4:27pm Posted: 26 Dec 2022 at 4:27pm |

|

Looks to be 400 series loader.As to problem I think it mostlikely comes from pump if all hoses are in good shape no pinched and it has oil in the tank then I should work

|

|

lenholm

Bronze Level

Joined: 26 Dec 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 4:31pm Posted: 26 Dec 2022 at 4:31pm |

|

Yes it quick working entirely and suddenly. I dumped a load of rock and then couldn't move the bucket in any direction except down. There are no blown hoses or leaks so I am assuming it's the pump - it is turning. Where do I begin looking for a new pump? I can't find any information and it appears to be unique - running off the front of the engine - PTO?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89106

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 4:39pm Posted: 26 Dec 2022 at 4:39pm |

|

im suprised the pump is turning and not pumping.. I would have guessed it was the coupling driving the pump..

|

|

Like them all, but love the "B"s.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 4:42pm Posted: 26 Dec 2022 at 4:42pm |

|

Not unique. There are thousands of them. OK. If the shaft is turning when the engine is running AND while you are trying to raise the loader, the system is out of oil, or the pump has failed or the key on the pumps drive shaft has sheared, which means even tho you see the shaft turning, the pumps shaft (hard to see) may not be turning. I would think, if oil level is correct and with no load in the bucket, that the bucket would work both ways (maybe slowly) with the engine throttled up even if the pump has failed..

Edited by DrAllis - 26 Dec 2022 at 4:56pm

|

|

lenholm

Bronze Level

Joined: 26 Dec 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 5:14pm Posted: 26 Dec 2022 at 5:14pm |

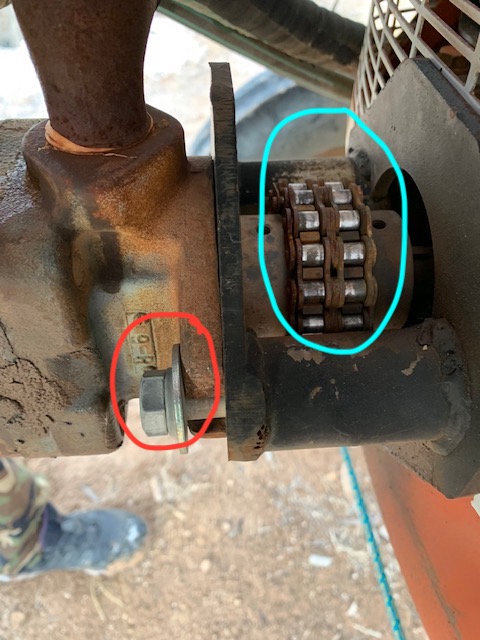

This is all very helpful and I'm grateful for the information. Here are pictures of the pump - the chains are turning when the entire is running. Final stupid question for the night - checking the hydraulic fluid level - is that done via the plug 1/2 way up the tank mounted on the right hand side of the loader?

Edited by lenholm - 26 Dec 2022 at 5:40pm

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54656

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 5:38pm Posted: 26 Dec 2022 at 5:38pm |

lenholm wrote: lenholm wrote:

This is all very helpful and I'm grateful for the information. Here are pictures of the pump - the chains are turning when the entire is running. Final stupid question for the night - checking the hydraulic fluid level - is that done via the plug 1/2 way up the tank mounted on the right hand side of the loader?

|

Take the pump loose, see the set screw holes in the last picture? check to see if there are set screws and keys underneath them. Take the chain off by finding the jesus clip of the master link of the chain. You can see the ML, in that last picture, if the set screws are at 12 o'clock, the ML is at 11:50. Pry up on one ear of the jesus clip, at the split end, hang it on the pin, and press down on the other ear, getting them off the pin slightly. Then ever so carefully, slide the jesus clip off. (needle nose pliers and a medium flat screwdriver) If you do it wrong the clip will fly off in a random direction, hence the name jesus clip.

Assuming something IS wrong with the pump, and not the drive hardware, Surplus center has a good selection of pumps. Others may chime in with the operating specs of that loader and the cylinders, and you will need that info to find out what GPM/pressure of the system should be. Other than that, you may want to visit surpluscenter's hyd tech page to get schooled on pump mount terminology. Halfway up the tank is as good an estimate as to how much oil as any.

I don't shill for anyone. I give zero f's where you buy. The above link has info that is handy, that is all...

One last thought, you may want to dump some 10w30 motor oil on that chain, when you finally re-assemble, it looks kinda dry...

Edited by DiyDave - 26 Dec 2022 at 5:43pm

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3987

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 6:33pm Posted: 26 Dec 2022 at 6:33pm |

|

do the lift arms still go up and down ? if so then it is possible that one of the tilt cylinders blew the piston packing making it dead head

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 3987

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 6:35pm Posted: 26 Dec 2022 at 6:35pm |

|

or just return to tank

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22285

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 7:02pm Posted: 26 Dec 2022 at 7:02pm |

|

To Mr. Lenholm: Your hydraulic system for the loader is a homemade creation of someone. Not saying it's bad, just none of the parts will come from AGCO or Allis-Chalmers, except maybe the drive shaft and chain coupler to the pump. If you need a pump, you are looking for something that is CCW rotation and 10 GPM at 2,000 RPM and is capable of 2,500 PSI. Measure your mounting holes spacing and the pilot hole in the pump mount bracket and find a similar sized mounting. Probably an SAE "A" or "B" mount pattern.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 8:17pm Posted: 26 Dec 2022 at 8:17pm |

|

I have a pump that looks just like yours. Mine came off a early A Gleaner combine. Pump is also for sale. MACK

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54656

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 8:46pm Posted: 26 Dec 2022 at 8:46pm |

DrAllis wrote: DrAllis wrote:

To Mr. Lenholm: Your hydraulic system for the loader is a homemade creation of someone. Not saying it's bad, just none of the parts will come from AGCO or Allis-Chalmers, except maybe the drive shaft and chain coupler to the pump. If you need a pump, you are looking for something that is CCW rotation and 10 GPM at 2,000 RPM and is capable of 2,500 PSI. Measure your mounting holes spacing and the pilot hole in the pump mount bracket and find a similar sized mounting. Probably an SAE "A" or "B" mount pattern. |

Quite correct, possibly the dealer built it out of scrap parts laying around, common practice. Get close up pics of the name and any numbers on the pump, and someone here might recognize what its from. If it were mine, and I had to put a new pump on, I would do it with a lovejoy coupling, its much quieter...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6103

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 9:18pm Posted: 26 Dec 2022 at 9:18pm |

So there's several things that will cause this failure mode.

pump not turning (and in the case of that coupling, I've got this gut feeling that the pump drive side of the double-chain is actually a ROUND shaft, stuck on a splined pump, with that grub screw run down 'tween splines (and probably sheared off)

Valve's pressure relief section has become stuck open by virtue of some crud that shouldn't be in there... dumping all pressure back to tank

Pump's suction line interior has become delaminated from the rest of the hose, and gotten sucked shut, meaning, the pump is now drawing NOTHING...

The valve stack has developed some internal problem and is bypassing all incoming flow to tank...

There's not enough fluid in the reservoir...

The pump has melted down it's gears, scored up it's wear plates, and is now bypassing all it's flow...

The pump is sucking air in through some leak in the suction hose plumbing

|

|

Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest.

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 9:48pm Posted: 26 Dec 2022 at 9:48pm |

The pump is a vane pump, not a gear pump. Vanes may be stuck or broken. It looks like an SAE A mount. Make sure the pump shaft is turning. It could have a key sheared on the pup shaft. A gear pump would be better. If you get a new pump, you will probably have to slot the mount holes. The SAE A bolt spacing is 4.188. The mount holes on the D series is 4.500.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

D19Dillon

Bronze Level

Joined: 26 Dec 2022

Location: West Virginia

Points: 3

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Dec 2022 at 11:00pm Posted: 26 Dec 2022 at 11:00pm |

|

Looking for some info on putting a ts500 front loader on 1963 d19 what modification I need too look out for

|

|

Gary

Orange Level Access

Joined: 13 Sep 2009

Location: Peterborough,On

Points: 5909

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2022 at 8:48am Posted: 27 Dec 2022 at 8:48am |

I never knew you could have a chain coupling with a cover enclosing it to contain the lubrication inside and keep foreign debris etc. outside. See attached Link at the 3:00 minute mark. G https://www.youtube.com/watch?v=3AR9TnrUlBI&t=43s

|

|

lenholm

Bronze Level

Joined: 26 Dec 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2022 at 5:47pm Posted: 27 Dec 2022 at 5:47pm |

I hope to quit bothering all of you but I'm very appreciative of the responses and possible solutions. I have some questions on the pump.

Am I correct that the two bolts at the 3/9 o'clock positions (circled in red) are used to remove the pump from the tractor without disassembly of the pump or leaking fluid?

I am at a loss for the purpose of the chain (circled in blue) and how it interacts with the shaft. I have been searching the web but can't find any diagrams or information. Should this chain have a cover surrounding it?

|

|

Joe(TX)

Orange Level

Joined: 11 Sep 2009

Location: Weatherford. TX

Points: 1682

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2022 at 6:21pm Posted: 27 Dec 2022 at 6:21pm |

It's a chain coupling. Two separate sprockets and a double chain. Try a google search. The two bolts just hold the pump to the plate. Pretty obvious to me.

|

|

1970 190XT, 1973 200, 1962 D-19 Diesel, 1979 7010, 1957 WD45, 1950 WD, 1961 D17, Speed Patrol, D14, All crop 66 big bin, 180 diesel, 1970 170 diesel, FP80 forklift. Gleaner A

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89106

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2022 at 6:35pm Posted: 27 Dec 2022 at 6:35pm |

Two sprockets back to back.. ONE on the tractors "motor shaft extension" and one on the "pump"... The chain is wrapped around the two, and then a master link couples them together.. The chain allows some MISS- ALIGNMENT between the two shaft. If you had a solid sleeve and the pump was miss-aligned 1/16 inch, you would tear up the pump.

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89106

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Dec 2022 at 6:46pm Posted: 27 Dec 2022 at 6:46pm |

watch this movie at at 2:15 mark ............ if you have never put oil on the chain, it could have rusted up and have NO miss - alignment ability ... and that can damage the shaft / key / pump.

Edited by steve(ill) - 27 Dec 2022 at 6:52pm

|

|

Like them all, but love the "B"s.

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4792

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Dec 2022 at 1:16pm Posted: 28 Dec 2022 at 1:16pm |

lenholm only way your going to learn is to ask, most of us are not bothered by your asking. Some are much better about explaining it out than others, just because we know doesn't help you, if we don't explain it so you understand.

Can be a fine line to not sound like we are talking down to you if you know more than we guess sometimes. So the first step in hydraulics is you need fluid in the system. If you have fluid it needs the pump to move it.

So take it apart like you where thinking. Once chain is remove should be able to tell if couplings are driving the pump. Could be so simple as the set screws came lose.

Good luck. But come back for more if this is not enough.

|

|

lenholm

Bronze Level

Joined: 26 Dec 2022

Location: Colorado

Points: 12

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Dec 2022 at 2:47pm Posted: 28 Dec 2022 at 2:47pm |

|

Thank you Ray54 - I appreciate your comments and patience. The weather is crappy here and the tractor is sitting out in the mud so I'm going to wait a few days for the weather to clear and then work on it. All of this information has been very helpful. I will reach out if I have more questions. Thank you again.

|

|

brkfldj

Bronze Level

Joined: 13 May 2010

Location: Sharpsburg, MD

Points: 168

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Dec 2022 at 12:16am Posted: 29 Dec 2022 at 12:16am |

|

Welcome to the forum. There are many members with years of experience and knowledge willing to help you. Please, when you do find the answers, share the solution.

Jim

|

|

Democracy is two wolves and a lamb voting on what is for lunch. Liberty is a well-armed lamb contesting the vote. ——— Ben Franklin

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54656

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Dec 2022 at 4:42am Posted: 29 Dec 2022 at 4:42am |

lenholm wrote: lenholm wrote:

I hope to quit bothering all of you but I'm very appreciative of the responses and possible solutions. I have some questions on the pump.

Am I correct that the two bolts at the 3/9 o'clock positions (circled in red) are used to remove the pump from the tractor without disassembly of the pump or leaking fluid?

I am at a loss for the purpose of the chain (circled in blue) and how it interacts with the shaft. I have been searching the web but can't find any diagrams or information. Should this chain have a cover surrounding it?

|

To remove the pump, remove the jesus clip(it's inside the blue circle, see the extra length pins?), push the ML toward the radiator, and the chain is then removable... Yes the 2 bolts on the pump hold it to the mount. Might need a few mallot blows to loosen up the pump from its mount. Use a rubber or plastic faced mallot so you don't damage the pump.

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 10127

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Dec 2022 at 10:38am Posted: 29 Dec 2022 at 10:38am |

We put an occasional squirt of chain lube on the double chain. Our tractor has had the same coupling on since 1970. Most of the time, the tractor sits outside. Never had a problem with the coupler chain.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

lenholm wrote:

lenholm wrote: