| Author |

Topic Search Topic Search  Topic Options Topic Options

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D15 II Head Gasket Trouble Topic: D15 II Head Gasket Trouble

Posted: 20 May 2021 at 5:38pm |

Following the engine rebuilt, we been putting her all back together and making good progress. Last thing we did yesterday was put in some engine oil to test the pump...(worked perfect), with the head on and all holes plugged, we added enough water to the block to make sure nothing was leaking.

So pulled the drain plug this morning and first thing to come out was about 1 cup water. That was disappointing.

So we pulled the head back off and found a wet head gasket, that delaminated when we pulled it off. Best guess is coolant was wicking past gasket and on into the block. But we have also filled block back up to top to see if any coolant is getting past O rings of the sleeves.

Head gasket came with rebuild kit from Reliance. Rumor has it (now.....after the fact) those are suspect. So looking for a Fel-Pro replacement.

Main question, however is the head bolts, which come in two sizes. One group is 3/8".....4 bolts on right side are larger. My service manual shows torque for all head bolts to be the same.

Have been told that on the WD45 and maybe D17, same thing exists....head bolts are two different sizes but torque for those goes up. Is greater for the larger bolts.

What is the best plan for the D15? Leave them all the same or increase torque for the larger ones?

Edited by modirt - 20 May 2021 at 7:13pm

|

|

|

Sponsored Links

|

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2021 at 6:35pm Posted: 20 May 2021 at 6:35pm |

|

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 May 2021 at 9:17pm Posted: 20 May 2021 at 9:17pm |

|

I made steel orings for my D15 engine in forklift. No more head gasket problems. MACK

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 7:08am Posted: 21 May 2021 at 7:08am |

You made steel O rings?

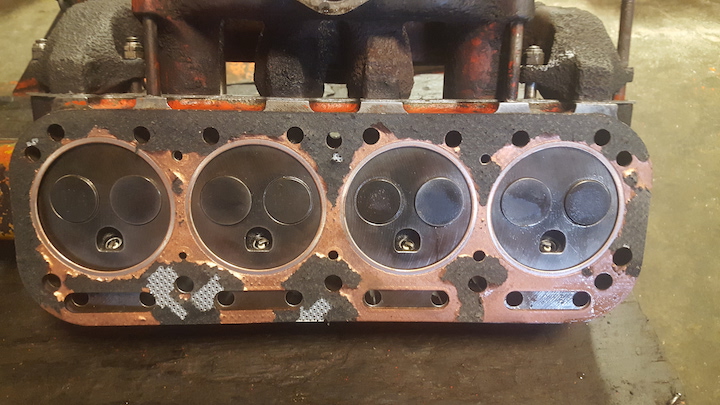

Not sure what that means. The head gasket shown included metal fire rings around each cylinder, which I hear is far better than one without.

The copper color is the permatex spray on sealant sold for head gaskets.

Just looking at the gasket, pathway coolant may have taken was lower left in photo.....from coolant channel to one or both of the slots used for the push rods. Just wicked through.....which is where it was wet and where it delaminated when head was pulled off. Where metal core of the gasket is showing.

Still looking for thoughts on the head bolt torque.

|

|

orangeman

Orange Level

Joined: 12 Sep 2009

Points: 1868

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 9:21am Posted: 21 May 2021 at 9:21am |

This is a good topic on the head gasket issue associated with the G-160 gas engine and head gasket failure. If memory serves the original G-160 engine head gasket had steel fire rings laminated into the gasket.

Am wondering if a person could secure a mill sheet of copper of the appropriate thickness and mill there own gasket then use copper sealer as a work around?

Orangeman

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5316

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 1:07pm Posted: 21 May 2021 at 1:07pm |

|

We just did our D15 engine rebuild 2months ago and so far no head gasket issue so I’m hoping we should be good, Torquing the bolts in the correct sequence and in steps per the manual is key. A light coat of the copper coat is all that is needed.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 1:29pm Posted: 21 May 2021 at 1:29pm |

|

The smaller bolts were a different lb rating than the bigger ones if I remember right.

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 3:31pm Posted: 21 May 2021 at 3:31pm |

Interesting. My D15 II has always leaked coolant externally out of the head gasket since the rebuild. I regret not using the copper coat. Will use next time.

If I recall the book has the big bolts and the little bolts torqued to 85 ft lbs??? Which I thought was pretty light but I followed the book regardless. I did however take them up after the fact trying to get rid of the leak. Not sure how far I torqued. But it did not stop the leak.

|

|

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 4:25pm Posted: 21 May 2021 at 4:25pm |

|

We copper coated ours

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 8:42pm Posted: 21 May 2021 at 8:42pm |

In the D15 service manual, the Series II (160 engine) has all bolts torqued to 85 ft. lbs. But the service manual for the 160 engine is pretty brief compared to the info for the series 1. It could be right, or could be an oversight.

I hear from some better informed guys than me that a couple other AC engines like the D17 and maybe the WD 45 do use more torque for the larger bolts. Not sure what they are, but more. The large bolt side appears to be where the leak occurred.

So more torque might be right, or it could be all the same. Trying to find somebody who knows.

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 May 2021 at 8:57pm Posted: 21 May 2021 at 8:57pm |

Ive had same head gasket problems on a D17. You can identify the bad head gaskets by the following: the width of the steel fire rings on the BAD gaskets are the same width on both sides of the gasket.

The good head gaskets have a wide width fire ring on the block face, and a narrow width fire ring on the CYLINDER HEAD side. These bad aftermarket head gaskets started to hit the market last December from what i can tell. They do not compress enough under torque to seal. This, in combination with too much sleeve standout from aftermarket sleeves causes coolant leakage! Anywhere you see copper still showing on the gasket means it did not seal under torque on those areas! The head bolts should be 2 different torques for different sizes I believe although the factory manual says 80-85 for the 7/16 bolts, doesn't mention the 1/2" bolts. The original D15 head gasket didn't have fire rings, but most use the D14 gasket with fire rings.

Edited by Alex09(WI) - 25 May 2021 at 9:27pm

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 6:59am Posted: 22 May 2021 at 6:59am |

As near as I can recall, the fire rings on this gasket were the same. I wasn't looking for different sized fire rings, but was looking for any other differences to find a top or bottom. As I recall, both sides looked to be the same.

Will look at the flange on the sleeves to see if they bed flush or remain a bit proud. I remember having concern about those, and fire ring on top of them and if it would allow you to compress the gasket enough to seal it. Assumption was it was made that way so it must?

We followed the book as far as torque amount and pattern, except we did it in steps. Started inside to 40 pounds, then worked our way out. Then started at # 1 again...this time to 85 pounds and worked our way out. Then when back and tested them all a 3rd time.

Back to fire ring......wide side to block side vs cylinder side? Aren't those the same side?

So does wide side of the right fire ring go to the block or head?

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 7:43am Posted: 22 May 2021 at 7:43am |

All head bolts on ALL of the 138/149/160 engines are the same diameter on all engines, just 2 different lengths. The smaller 3/8" bolts hold the rockershaft. The gasket should have "This Side up" embossed on it. It really isn't possible to get it on wrong as there is a long and a short distance from the bore to the edge of the block front and back.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 8:33am Posted: 22 May 2021 at 8:33am |

As I study the bolt pattern again, PaulB is correct. Only one way to put the gasket on.

As for the bolts, 4 are shorter, but are also larger. This is the 160 engine.

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 8:49am Posted: 22 May 2021 at 8:49am |

|

I would check the sleeve protrusion and other question is did you get it up to temp, let it cool and retorque? I learned the hard way that even with the newer gaskets that claim retorque not necessary you need to retorque.

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 8:57am Posted: 22 May 2021 at 8:57am |

|

To correct myself, all the head bolts are to 80 to 85 ft lbs

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 May 2021 at 8:57am Posted: 22 May 2021 at 8:57am |

|

We never got far enough to get it up to temp. Filled the block and head with water to test for leaks, let it set overnight, and found about 1 cup of water in oil sump next morning.

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2021 at 7:36pm Posted: 25 May 2021 at 7:36pm |

|

If you have a mix of 7/16" & 1/2" head bolts on a 160CID engine, you must have the Red Headed Stepchild that snuck past the QC at the engine plant. Every 160 CID engine I've ever had apart as well as the 2 empty NOS 160CID blocks I have, all have nothing but 1/2" head bolt threads. Now the 149,138, as well as the BE & CE engines have a full set of 7/16" bolt from what I've worked on. Yes there are long bolt to one side and shorter bolts to the other side.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5316

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2021 at 8:46pm Posted: 25 May 2021 at 8:46pm |

|

That’s not true, our D15 series II has never been apart and it had 2 different size head bolts when we rebuilt it 2 months ago. I know, I torqued the head with 2 different sockets. The head bolts were removed and placed in a piece of cardboard as they were taken off, marked front and rear and with the proper alignment of the bolts of the head.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2021 at 9:30pm Posted: 25 May 2021 at 9:30pm |

Alex09(WI) wrote: Alex09(WI) wrote:

Ive had same head gasket problems on a D17. You can identify the bad head gaskets by the following: the width of the steel fire rings on the BAD gaskets are the same width on both sides of the gasket.

The good head gaskets have a wide width fire ring on the block face, and a narrow width fire ring on the CYLINDER HEAD side. These bad aftermarket head gaskets started to hit the market last December from what i can tell. They do not compress enough under torque to seal. This, in combination with too much sleeve standout from aftermarket sleeves causes coolant leakage! Anywhere you see copper still showing on the gasket means it did not seal under torque on those areas! The head bolts should be 2 different torques for different sizes I believe although the factory manual says 80-85 for the 7/16 bolts, doesn't mention the 1/2" bolts. The original D15 head gasket didn't have fire rings, but most use the D14 gasket with fire rings.

|

The good head gaskets have a wide width fire ring on the block face, and a narrow width fire ring on the CYLINDER HEAD side.

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

Alex09(WI)

Orange Level

Joined: 15 Mar 2012

Location: CECIL WI

Points: 1768

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 May 2021 at 9:35pm Posted: 25 May 2021 at 9:35pm |

|

|

|

www.awtractor.com

A&W TRACTOR 920-598-1287

KEEPING ALLIS-CHALMERS IN THE FIELDS THROUGH THE 21ST CENTURY

|

|

structures

Silver Level

Joined: 28 Feb 2011

Location: Beggs, OK

Points: 336

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 12:00am Posted: 26 May 2021 at 12:00am |

|

My 64 d15II head had 7/16” and 1/2” bolts too.

|

|

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5191

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 6:18am Posted: 26 May 2021 at 6:18am |

|

Maybe there was an update at some point that increased the size of the 7/16 to 1/2. As I mentioned I have 2 NOS blocks that have never been used, that a 1/2" bolt fits all holes. I've also have a few other 160 engines apart that had all 1/2" head bolts. I've never encountered a 160 engine that had a mix of sizes for head bolts.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 7:21am Posted: 26 May 2021 at 7:21am |

So imagine our frustration when we uncork one that does have a mix of bolts. And even the parts book is no help......they only mention various numbers.....some lengths, no sizes.

But since this engine does have a mix of bolts, we are leaning towards borrowing the concept of giving the larger bolts more torque, same as is done on other AC engines where there is a mix of bolts. The question will be how much.

Another thing that is a puzzle.....how we found it and as shown in the parts book. ONE....and only one....head bolt / cap screw has a washer under it. Why is that?

|

|

Tom IA

Silver Level

Joined: 17 Sep 2009

Location: Donahue IA

Points: 255

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 8:08am Posted: 26 May 2021 at 8:08am |

|

Did you clean the bolts and holes and use a good sealer on the bolts as some bolts go into the water jacket

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 May 2021 at 8:21am Posted: 26 May 2021 at 8:21am |

If memory serves, all the head bolts go into blind holes. Two of the manifold studs go into water.......and I would love to know why. (Those are sealed with teflon tape).

And if memory serves, the two manifold studs that go into the water jacket broke off and had to be drilled out to extract the remnants. Again, would love to have a sit down with the engineer that came up with that one.

Lot of curious things about this engine and tractor I would love to have explained to me by the guys who designed it.

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jun 2021 at 8:38pm Posted: 08 Jun 2021 at 8:38pm |

Epilogue......

Replacement head gasket

ordered through a local supplier. Gent who is about 80 dropped off a new

Fel-Pro gasket. He happened to be the same guy who was trusted to turn down the crankshaft, and is well respected by locals when it comes to engine rebuilds. He is the man.

However, before that showed up, as luck would have it, a

pair of alternative head gaskets showed up in shop where wrenching is

taking place. Should probably mention that the building is about 45

years old and has been used almost exclusively as an AC repair shop. On

any given day, there are from 6 to 8 AC tractors in there in various

stages of undress. Currently holding a C, pair of 185's, pair of 190XT's

a WD and a 7010.....plus a D15. While sorting through one of several

piles of various surplus gaskets, two different Victor head gaskets

showed up. No clue as to their origin or history, but there they were.

One is what is

believed to be similar to what she was wearing when she left West

Allis.....thin and no fire ring. Alternative was a thicker Victor with

ring.

When gent who brought new replacement in

saw the Victors, his mood improved. Said at one time they were A#1 first

choice if you wanted the best. Would be using those if it was

his......and no sealant. Says so right on the gasket. He confirmed that

was right.

So thicker gasket with fire

ring went in, no sealant, smaller bolts torqued to 80 ft pounds, larger

bolts to 90 ft pounds and that did it. Held head water for about 5 days

with no leaks, so buttoned her up and she is now back together and

running.

Getting discharged tomorrow.

|

|

ACinSC

Orange Level

Joined: 16 Dec 2015

Location: South Carolina

Points: 3165

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2021 at 5:47am Posted: 09 Jun 2021 at 5:47am |

|

Good news Howard . Thanks for the update .

|

|

Charlie175

Orange Level

Joined: 11 Sep 2009

Location: Shenandoah, VA

Points: 6369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2021 at 6:02am Posted: 09 Jun 2021 at 6:02am |

|

Great news

|

|

Charlie

'48 B, '51 CA, '56 WD45 '61 D17, '63 D12, '65 D10 , '68 One-Ninety XTD

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jun 2021 at 7:10am Posted: 09 Jun 2021 at 7:10am |

Pile of gaskets were replacements were found. Lucky to have access to such parts.....

And for future reference.......part number for the gasket used was Victor 3145. Those can be found on ebay and a few other places. Now sold under the name of Victor Reinz. Not sure if quality of those is still the same as the one we used.

Have heard from a few sources that the head gasket included with the Reliance rebuild kit is suspect. If that one is used, I might suggest putting some water in the block and head after torquing it down to test it overnight before going much further.

Also confusing as to what to do about using sealant on the gasket. D15 service manual says use it. The Victor gasket had the words "Use no sealant" printed right on it. The D17 has head bolts of two sizes and service manual for that says to torque larger bolts about 15 pounds more. D15 manual for 160 gas is silent on torque for different sized bolts. Only gives one torque (80 to 85 foot pounds) for all. Again, hard to know which is right. Pretty much forced to pick one and go with it and hope it works out.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Alex09(WI) wrote:

Alex09(WI) wrote: