| Author |

Topic Search Topic Search  Topic Options Topic Options

|

fartwhif

Bronze Level

Joined: 18 Jun 2023

Location: TN

Points: 6

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: D15 cracked block, seized, how does it look? Topic: D15 cracked block, seized, how does it look?

Posted: 18 Jun 2023 at 7:11pm |

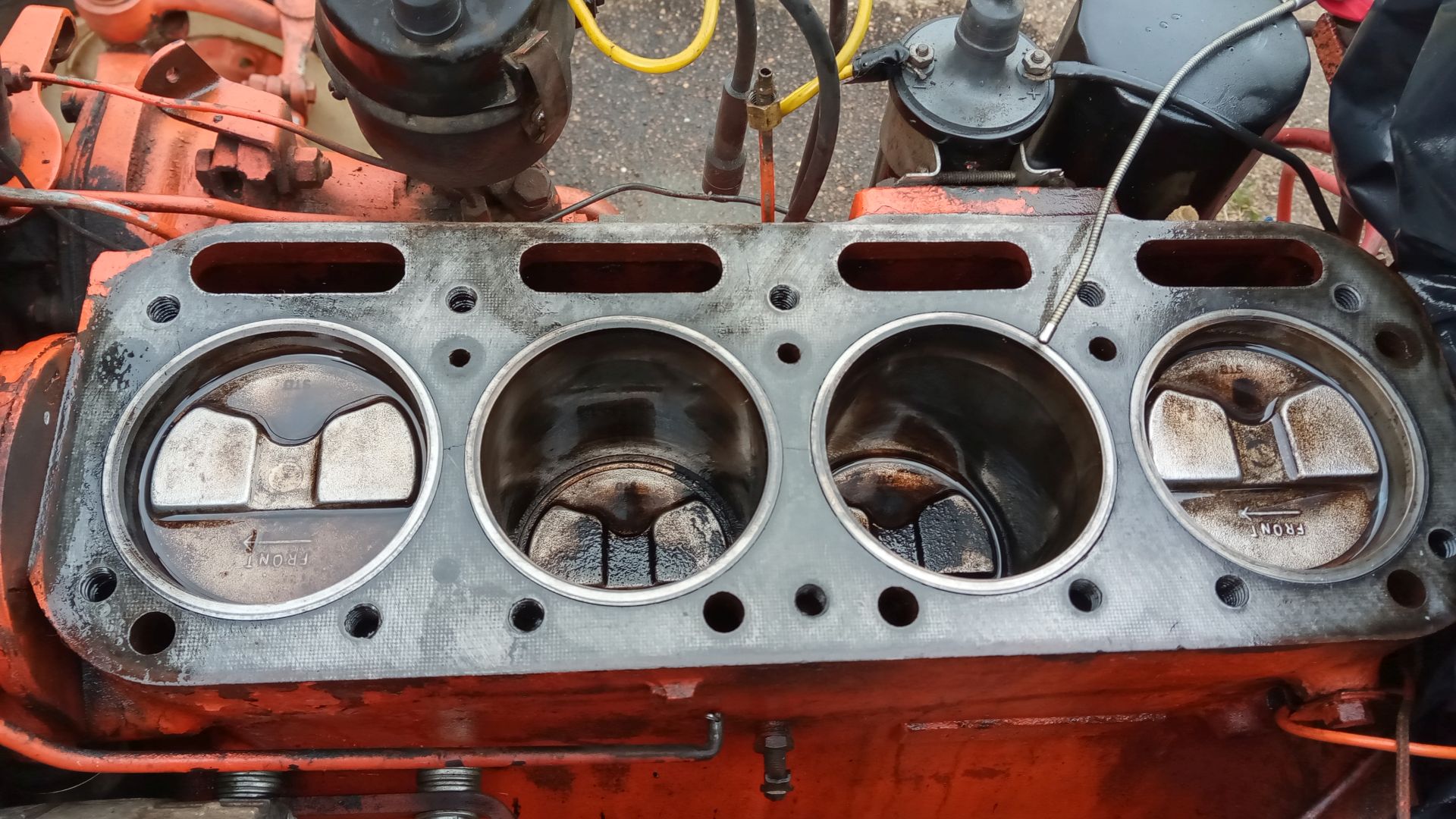

It was pleasing to see that a forum like this exists. I really appreciate it. I think I seized it a few weeks ago. Right now, I'm chalking it up as overheated seized and cracked due to lack of coolant, but with a 20% chance of something else. The first start of the year, I let it idle for 2-5 minutes until I heard a weird sound and before I could get back to it to shut it down the RPM had gone lower and lower until it stopped, over about 5 seconds. I forgot to check the coolant and it was down a half of a jug.

I let it soak for 2 weeks full of 50/50 acetone/ATF for 2 weeks, it all went down, every cylinder was dry when we looked at it 2 weeks later.

When in high 4th gear we can rock it forward and back and the fan blades turn 2-5 inches on a good budge (but the pistons don't seem to move unless it's a very small amount that can barely be seen). When rocking it when the fan spins a couple inches there's a "bad bearing" sound. Kroil + dead blow hammering says piston 1 is in a different state than 4 but it's too subtle and I'm too inexperienced to be sure or speculate why. We tried pull starting it but it's far too seized (or jammed?) to turn. I still don't know what the bottom end looks like so I'm not ruling out the idea that something broke down there and is jamming it.

About the cracks, is it possible that it was like this before? Is this totally defunct, unusable, or this is perhaps common to find in a running capable effective D15? Is there a possibility it was already cracked like this before? I'm trying to hold onto the hope that I can fix it restoring last year's performance, and if I do that it won't be crippled by being cracked because if it already was cracked last year then I didn't even notice it. They are cracks, right? - this is my first 4-cylinder teardown so I can't be sure that it's just hopeful ignorance that they're not cracks or that it runs fine that way.

Edited by fartwhif - 18 Jun 2023 at 7:33pm

|

|

|

Sponsored Links

|

|

|

Gary(VA)

Silver Level

Joined: 13 Sep 2009

Location: Troutville, VA

Points: 341

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jun 2023 at 7:29pm Posted: 18 Jun 2023 at 7:29pm |

|

The cracks are probably not a big deal. They normally seal with the head gasket. If the bottom web is cracked then that's a issue. I would drop the oil pan and see if there's anything obvious going on. I don't think being only that low on coolant for less then five minutes would be an issue

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10850

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jun 2023 at 7:48pm Posted: 18 Jun 2023 at 7:48pm |

|

Sounds like it spun a bearing. Could be a rod or crankshaft bearing. If you decide it is more than you want to tackle. I would be interested in tractor. I live in Gallatin, TN Thanks, Tracy

|

|

No greater gift than healthy grandkids!

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22181

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jun 2023 at 9:02pm Posted: 18 Jun 2023 at 9:02pm |

|

I'll bet the oil pump lost it's prime and you didn't notice the oil pressure was zero. Low on coolant 2 quarts under no load was not the problem.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88672

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jun 2023 at 9:47pm Posted: 18 Jun 2023 at 9:47pm |

I ran a B motor low on coolant ( about a gallon) and it "slowed down and locked up" as you said... The liners got hot and the rings "STUCK" and froze the motor...... Since you said you put penetrant into the bores and it ran past the rings into the crankcase, you COULD have the same problem i had..

Your oil system may be OK if you just overheated the liners / rings and they STUCK... Cracks in the block are OK in the top.. I would pull the connecting rod bolts and lift the crank shaft out... then smack each piston on the top and see if they will pop loose from the liner... I got by with honing the cylinders, same piston , new rings... If you can get it apart without breaking a piston or liner, that would be good...

When liners are out, check the bottom o-ring seal in the block as mentioned to see that this area does not have a CRACK that could leak coolant later on..

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88672

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 18 Jun 2023 at 9:51pm Posted: 18 Jun 2023 at 9:51pm |

|

Either way, your not going to know anything until your remove the crank, look at the bearings, and get the piston out of the liners...... but YES.. those cracks will be OK.

|

|

Like them all, but love the "B"s.

|

|

WF owner

Orange Level

Joined: 12 May 2013

Location: Bombay NY

Points: 5060

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 19 Jun 2023 at 6:36am Posted: 19 Jun 2023 at 6:36am |

|

Before you get into the oil pan, do yourself a favor and remove the engine and put it on a stand. It may be a little more work right now, but it's a heck of a lot easier to be able to turn the engine upside down to work on it.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7542

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 20 Jun 2023 at 4:12pm Posted: 20 Jun 2023 at 4:12pm |

ATF and Acetone is for rusted engines. It will not do anything for an engine that became seized in another manner. As others have said, remove the engine and taken apart. It seized for a reason, now you have to investigate why.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

fartwhif

Bronze Level

Joined: 18 Jun 2023

Location: TN

Points: 6

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 11:08am Posted: 04 Jul 2023 at 11:08am |

|

A ton of thanks for all the experienced guessing and tips. I've taken off the journal bearings. All the pistons are free. Please correct me if I'm wrong, but I'm 70% confident it's spun main bearing(s). I don't have the resources to do an out-of-frame rebuild so I'm hoping that I can use the cotter pin trick to replace those bearings. I don't have the funds for crankshaft grinding. If I replace the main bearings without getting the crank shaft ground first then what is the chance it would just spin again? I would measure the crank and get the thicker bearings if needed (is that even possible?), would it be in danger of spinning even if graduating the bearing thickness because the crank isn't ground? An unground crank and new bearings, what often happens? Unground leaves it in between sizes and perhaps also having weird shapes? How important is grinding? Is it absolutely required? Will they definitely spin again or have some other failure without?

Edited by fartwhif - 04 Jul 2023 at 12:59pm

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22181

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 1:47pm Posted: 04 Jul 2023 at 1:47pm |

|

If the crankshaft has spun/failed a main bearing, it is probably due to zero oil pressure. This is only a guess. You are money ahead to do nothing and wait until you can fix it right. A reground crankshaft will surely be needed for a proper repair. You MUST determine WHY there was a failure. My guess is the oil pump, but I'm not there looking at the damage. Where I live, probably $600 bucks to regrind the crank and get new main and rod bearings. Also need cam bearings while you are there. This is just to make it run.

|

|

DSeries4

Orange Level

Joined: 12 Sep 2009

Location: Ontario, Canada

Points: 7542

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 3:21pm Posted: 04 Jul 2023 at 3:21pm |

You can either fix it cheap and then fix it again 6 months down the road, or fix it right and not have any problems for the next 40 years. If it was me, I would save up some money and fix it right.

|

|

'49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88672

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 6:22pm Posted: 04 Jul 2023 at 6:22pm |

|

You may not have to spend a fortune to fix it... but you CAN NOT just roll in bearings.. When a bearing spins it may DEPOSIT metal onto the crank journal... You have to have the crank OUT of the engine and at a minimum run fine emory cloth around the journal to cleanup and get off any "deposits"..... You will need a new set of bearings and a new gasket set... I would pull the liners and replace the o-rings and a new RING set would help.. You do not necessarily need new liners and pistons... they need to be measured and see if they are within reason to reuse.... I have reused many pistons and liners that were " close to spec"... but always hone and put in new rings.. You would be surprised how well that works... Your not building a race car.

Edited by steve(ill) - 04 Jul 2023 at 6:23pm

|

|

Like them all, but love the "B"s.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2427

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 8:24pm Posted: 04 Jul 2023 at 8:24pm |

|

Most often, a spun main bearing will damage the block and require line boring.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88672

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 8:29pm Posted: 04 Jul 2023 at 8:29pm |

Either way, your not going to know anything until your remove the crank, look at the bearings, and get the piston out of the liners.......

|

|

Like them all, but love the "B"s.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8688

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 04 Jul 2023 at 11:26pm Posted: 04 Jul 2023 at 11:26pm |

|

You can't really measure the main journals with the crank in the block. The half baked way you are talking a bout fixing is going to bite you in the a$$ and make it even more expensive to fix right. You have "precision" bearings and things have to be precise to work long term. If a shell slipped in the main bore it removed metal requiring line boring.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22181

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 05 Jul 2023 at 6:50am Posted: 05 Jul 2023 at 6:50am |

|

The clearance between any crankshaft journal surface and each precision bearing surface is approx .002" to .003" of an inch. This clearance is for oil to fill to keep the parts from touching. An average human hair is .001". Very close tolerances and must be perfectly ROUND and smooth !!!

Edited by DrAllis - 05 Jul 2023 at 11:29am

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)