| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Connecting rod tang positioning Topic: Connecting rod tang positioning

Posted: 12 Jan 2017 at 4:47pm |

|

I was putting together my ca engine and I know that the mark on the Piston goes towards the front of the engine . But when I am putting the rod on the piston should the tang run to the exhaust side of the engine or the intake side or does it matter thanks william

|

|

|

Sponsored Links

|

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2017 at 6:05pm Posted: 12 Jan 2017 at 6:05pm |

|

On those engines the exhaust side and intake side are the same.

It does matter which way the rod faces, but not sure what "tang" you refer to on the rod.

Edited by wbecker - 12 Jan 2017 at 6:08pm

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2017 at 6:20pm Posted: 12 Jan 2017 at 6:20pm |

|

Yes you are correct I'm sorry I just looked at my head. The thing I'm referring to as a Tang is that indent in the bearing. Just wondering what side it should be on the manifold side or the spark plug size.

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2017 at 6:35pm Posted: 12 Jan 2017 at 6:35pm |

|

-

Edited by Whtbuch - 12 Jan 2017 at 6:36pm

|

|

wbecker

Orange Level

Joined: 29 Oct 2009

Location: STL

Points: 837

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2017 at 6:53pm Posted: 12 Jan 2017 at 6:53pm |

|

Notice that the rod big end has an offset from the center-line of the rod.

from the manual "To assemble piston and rod to engine,the long offset side of the rod must be turned away from the nearest main bearing." So the rods are not all facing the same direction in this engine.

Bill B

|

|

Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 4:04pm Posted: 15 Jan 2017 at 4:04pm |

|

Thank you very much Billy B. Since you seem to be very knowledgeable guy about this I have to ask I have a ton of crankshaft end play is there shims something to adjust with.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 4:38pm Posted: 15 Jan 2017 at 4:38pm |

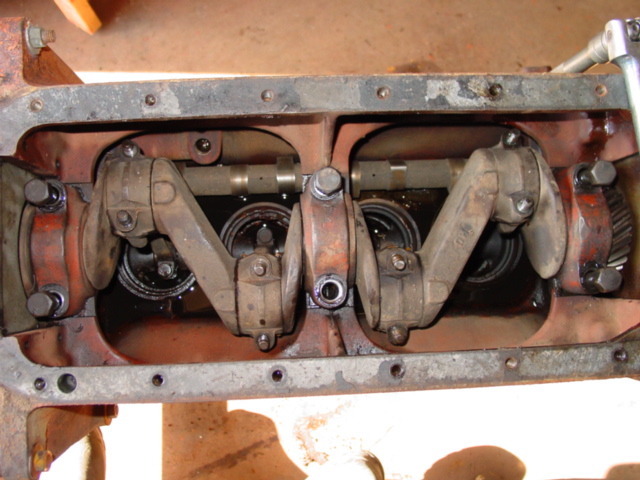

This picture will show which way the rods caps go. If you look under the bottom as you push the piston down

to be correct the rod will centered on the wrist pin as the rod bearing is centered on the journal. If they are not they need to be turned around so they are. If not correct the rod will bind on the crankshaft.

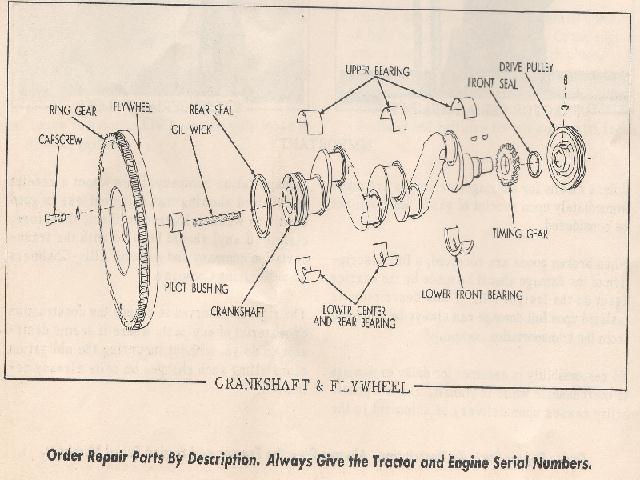

If you have a new thrust bearing the rides on the crankshaft gear and have more than .005 end play the crankshaft needs repair. The thrust bearing slides over the main cap that is at the front of the engine.

Because of the offset of the rods the caps will only go one way

Closely inspect all parts. Don't forget to measure the end gap of the rings down in the cylinders before installing them on the pistons. Just because they are new does not mean they fit.

Edited by Dick L - 15 Jan 2017 at 4:42pm

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 4:46pm Posted: 15 Jan 2017 at 4:46pm |

|

Thank you very much. I have my crankshaft turn still has too much end play I was reading

now I can have it cut right behind the timing gear to get my tolerance back in Spec does this sound correct to you guys. Thanks william

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 5:01pm Posted: 15 Jan 2017 at 5:01pm |

|

One of the check points that a crankshaft grinder is suppose to check and bring into spec when grinding the crankshaft. They do grind back the stop step behind the gear. If you have the thrust bearing in the correct place and have the end play I would take the crankshaft back to the grinding shop. Most grinding shops also do complete rebuild and assembly and this spec would be something that would be on the must set properly while the crankshaft is set up on the grinder. I have had several crankshafts ground for several makes and they never have missed these kinds of specs.

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 5:44pm Posted: 15 Jan 2017 at 5:44pm |

|

Thank you very much for the wealth of knowledge. I have also read that the new bearings can sometimes be thinner than the old ones and this is why you have the end play Problem sometimes . So I guess my next move is a trip back to the machine shop. I'm hoping they can just cut back so that gear will slide back 2 spec. Because as I say they were have to add to the crankshaft to make up the play I believe that would be much more expensive there than just cutting back behind the gear. As for this is just to mow Lawns with no heavy work

Edited by Whtbuch - 15 Jan 2017 at 5:45pm

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 6:34pm Posted: 15 Jan 2017 at 6:34pm |

|

Not seeing the crankshaft I would not know if it needed welded on the edge of the journal or what the conversation was between you and the grinder. It is always done as to the condition of the crankshaft. If you pay for a regrind it should be in spec at all points or the grinder should reject even starting on it. I am sorry you having problems but a green customer should not be taken advantage of. I never heard of bearings being out of spec/ thin. Quality control is quite tight on bearings.

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 6:49pm Posted: 15 Jan 2017 at 6:49pm |

|

Thank you much . First time I have ever worked on a tractor engine .I'm very used to working on chevy engines. But will have a very long conversation with him tomorrow morning.and yes paid very good to have work done. Yes I believe you're correct to say it would need welded on the end of the journal and then bring back into spec. But again thank you for your time . William

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2017 at 6:55pm Posted: 15 Jan 2017 at 6:55pm |

|

Yes I feel I shouldn't have to explain his job to him when you drop it off to machine shop as you say it should be bring back to within specs are not touched at all!!!!

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2017 at 2:58pm Posted: 16 Jan 2017 at 2:58pm |

|

Hi mr. Dick I was wondering is there such a thing as a washer that goes in between the timing gear and the thrust bearing to make up the play my machine shop says there should be one there that should not ride on the timing gear is this true or does it ride on the timeing gear thank you

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5093

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2017 at 3:29pm Posted: 16 Jan 2017 at 3:29pm |

No washer! the Thrust bearing rides on the crankshaft timing gear.

The G does have a washer type thrust bearing that sets on pins so it does not rotate. That is a Continental engine.

Print this for him.

Edited by Dick L - 16 Jan 2017 at 3:35pm

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2017 at 4:00pm Posted: 16 Jan 2017 at 4:00pm |

|

Thank you very much. I will show him this as I have the same exact manual to the ca. I just hate when people think you're stupid!!Again thank you very much for your time and expertise.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89201

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Jan 2017 at 4:22pm Posted: 16 Jan 2017 at 4:22pm |

|

I have measured the "GAP", then pulled the gear off and cut the backside of the gear around the crank so it will slide on further ( .020 ?) to get back to the proper clearance........ this was on a crank that I just cleaned up, not turned by machine shop.

|

|

Like them all, but love the "B"s.

|

|

Whtbuch

Bronze Level

Joined: 16 Aug 2015

Location: Ohio

Points: 32

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2017 at 5:12pm Posted: 21 Jan 2017 at 5:12pm |

|

Thanks guys now I got these problems taken care of I have a new one. Is there a secret to installing timing chain cover with the seal in it the seal keeps on popping out when I go to the shove it over top of the crankshaft ? And the second question would be should the felt side of the seal go towards the crankshaft or facing out ?. Thanks william

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)