| Author |

Topic Search Topic Search  Topic Options Topic Options

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Cllutch Woes Topic: Cllutch Woes

Posted: 25 Jul 2019 at 2:24pm |

Posted once before about this on the Allis forum, but this seems to be a more appropriate place for it.

(BTW, this is the same thing I need to replace the widow maker rims on)

Questions relate to a Deweze Hay Monster, which was a commercial made contraption used for hauling small square hay bales. Built in the early 70's from a variety of sourced parts, but centered around a Chrysler 318 engine, New Process 540 truck transmission. Similar to a 30' school bus chassis with flat deck on top. But as for those parts.....there is no parts book for this thing. It could be anything. Cast number on the engine shows it to be a "race engine", with no VIN stamp on it. So just a generic small block 318 that could have been in anything. Worse, this isn't the original 318.....it is a replacement engine. No idea what was replaced......just the block, or an entire engine found somewhere. I suspect just the block, but hard to know for sure.

But now roughly 50 years old and passed down through who knows how many owners and now an accumulation of untold numbers of modifications......often of the hurry up variety to get it running ASAP by shade tree mechanics working without the benefit of the shade tree.....and for as little cost as possible. It came to me with no fewer than 3 bundles of baling wire lashed near the engine and cockpit, ready for instant use when needed. I'm in the process of restoring it to usable condition......and trying to do it right without the baling wire or chewing gum.

So we got engine running, but quickly found the clutch to be stiff to the point of being almost unusable. Dangerous......if so stiff you can't push in the clutch to stop it.

About the clutch......when it left the factory in Harper, KS, it appears to have had a hydraulic clutch. That had been replaced at some point with a mechanical clutch cable, running through a series of high friction blocks and turns.

Before it came to me, it had sat idle for the past 4 or 5 years. Throw out bearing and shaft looked "gummy" from old engine oil....so was stiff. Hit it with brake cleaner, then some Free All and it has loosened up a bit, but is still stiff.

Plans are to go back to the hydraulic clutch system. Found a match for master and slave.....but hit a snag on the install. Clutch yolk is apparently not right.

Should be a ball type clutch fork similar to this one........

http://www.brewersperformance.com/proddetail.php?prod=CF-BALL

Ad suggests that is 13 1/4" from tip to tip. Existing clutch fork is only 11 1/4" and because it is used with a cable system, does not have a ball end for the push rod from the slave.

As near as I can tell it is also reversed. Most of these clutch bell housings have the clutch yolk on the left (driver) side. This on is on the right. So probably not off a Dodge.....could be just about anything.

So looking for advice. This has to be viewed almost from the standpoint of this being something like an off road or pulling truck or something shop built (which for all practical purposes it is).

I'm thinking the existing yolk is probably off a car or something, and if I replaced it with the one that is 2 inches longer, the extra leverage I'd gain would help ease the clutch pedal pressure?

Or.....does anyone have a truck transmission of this type to confirm what it is I have or what I need to get this working as it is supposed to?

(PS: Working with this thing makes a guy appreciate the Agco Parts Book website. Parts may no longer be available for your D15, but at least there is a schematic to show you what it was supposed to look like. I have found some Mopar parts sites, but many of the older models are not included.......1984 is as far as some of them go back).

|

|

|

Sponsored Links

|

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24878

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2019 at 2:32pm Posted: 25 Jul 2019 at 2:32pm |

|

hmm.. how about finding a 'donor' to supply a complete bellhousing and internal parts ?

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

iowallis

Silver Level

Joined: 04 Jun 2017

Location: North Iowa

Points: 376

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2019 at 5:04pm Posted: 25 Jul 2019 at 5:04pm |

Is there any other agucultural equipment that may have used a 273/318/360 engine and clutch, combines maybe? Self-propelled windrower or silage cutter?

I think Massey-Harris-Ferguson used Chrysler engines but they may have been 6 cylinder flatheads.

Best bet would be to find a big Dodge Truck (D400-D700) or Dodge LCF series which was more of an over the road semi from the late 60s,early 70s that would have a hydraulic clutch. But then again these are not just sitting around like a Ford from the same vintage.

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2019 at 5:32pm Posted: 25 Jul 2019 at 5:32pm |

Found this guy's website in which he documented his rebuild of a Chevy C60 dump truck.

This truck used the same 540 tranny as the hay monster. So a lot of good ideas there.

Worst case scenerio, a guy could buy a running C60 and part it out. Saw several sell for peanuts at consignment auctions last winter. But runs against my grain to take a good running truck and trash it.

But might be able to get an axle off that too.

|

|

DiyDave

Orange Level Access

Joined: 11 Sep 2009

Location: Gambrills, MD

Points: 54684

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2019 at 5:43pm Posted: 25 Jul 2019 at 5:43pm |

If I were you, I'd find a good mopar boneyard, near you, and get in touch with them, I have one near me, but it won't do you much good, as far apart as we are. Answer is probably to take it apart, and take the parts you have, and explain what you want... Good old fashioned boneyards are becoming a thing of the past, though...

|

|

Source: Babylon Bee. Sponsored by BRAWNDO, its got what you need!

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4792

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jul 2019 at 8:29pm Posted: 25 Jul 2019 at 8:29pm |

Starting to get a better picture of what your working with. Not that I have much to add. But I do have the remains of a New Holland 1048 bale pickup machine. For a lot of years with the NH it was Ford 2 ton truck parts. At this point I don't know if it matters what brand truck parts you look for they are getting harder to find.

For what ever reason there where never many of the bigger Dodge truck here since the early 60's. I would start looking at ever old truck and see which has the most parts in common. Is Dew-eze still in business to ask if they could tell you what it started with.

Not to keep you from changing the clutch linkage, but a new push pull cable that in not rusted up may fix the current problem easier than finding parts to change. I soaked the parking brake cable from my NH in a bucket of diesel all winter one season and it never worked as it should. So any cable that is bound up is never going to work right without spending way more time on than is worth.

|

|

TimNearFortWorth

Orange Level

Joined: 12 Dec 2009

Points: 2014

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2019 at 5:45am Posted: 26 Jul 2019 at 5:45am |

|

Consider Bunker Hill Cables in OH, 330-893-0242 as they make replacements for many industrial and ag apps. If you send them the existing cable, maybe a heavier duty replacement will work for you?

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2019 at 9:09am Posted: 26 Jul 2019 at 9:09am |

TimNearFortWorth wrote: TimNearFortWorth wrote:

Consider Bunker Hill Cables in OH, 330-893-0242 as they make replacements for many industrial and ag apps. If you send them the existing cable, maybe a heavier duty replacement will work for you?

|

Existing cable system is heavy enough.....cable and all the blocks are about 1/4" in size. Problem is it is a high friction system, including one turn in which they used a 4 inch section of steel pipe to make about a 10 degree turn......so is rubbing on the ends. Also no sure if this is a stiff cable, or one with a soft lay that will easily make those 180 turns through the blocks.

Neighbor who is helping me is a semi-retired engineer who works for a company that makes auto component parts, including cable systems. He cringes when he looks at it.

He said we could replace it with a low friction system, but would still be worse by far than going back to the hydraulic clutch as designed. Not entirely sure of this one, but it seems to me there is some mechanical advantage to be gained by using a master of one size and a slave of a smaller sized piston, which I think is how this was setup.

There is also some mechanical advantage to be gained if the clutch yolk is made 2 inches longer. Need to find out if what is on it is the correct one for this clutch, or if they put a shorter one on it because it was available.

And don't want to sound too doomsday on this.......while not what I want for the long run, clutch would work as is. Axles, tires and wheels too. The only thing preventing me from using it as is are the brakes, and we have the new brake master, and I've got the bleeders working.......so all I need now is someone who knows how to bench bleed the master, bleed the brake lines and get the brakes working. Do that and we can install the pickup snout and I would be in business!

The rest are long term / winter projects getting this ready for next year and beyond.

|

|

Ray54

Orange Level Access

Joined: 22 Nov 2009

Location: Paso Robles, Ca

Points: 4792

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2019 at 10:52am Posted: 26 Jul 2019 at 10:52am |

You have peaked my curiosity what years was this machine made,  your best guess.

This is the first I have heard of this brand of small bale pickup. The Dew-eze brand itself is not new to me,but don't know that I have ever seen any of there equipment in person. In the west NH has owned the market forever,with a Freeman brand machine every one in a 100 or maybe a 1000. Now with big bales there maybe a few more options.

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2019 at 12:22pm Posted: 26 Jul 2019 at 12:22pm |

Ray54 wrote: Ray54 wrote:

You have peaked my curiosity what years was this machine made,  your best guess. your best guess.

This is the first I have heard of this brand of small bale pickup. The Dew-eze brand itself is not new to me,but don't know that I have ever seen any of there equipment in person. In the west NH has owned the market forever,with a Freeman brand machine every one in a 100 or maybe a 1000. Now with big bales there maybe a few more options. |

Deweze was the brainchild of one Dewey Hostetler.......one of those barnyard engineering geniuses that pop up now and then. This was one of the first of many of his ideas that went into production around 1968 and lasting to around 1975.

https://harperindustries.com/heritage/

The hay mover became know as the Hay Monster. Deweze was the first, but was copied by Kent and United Technologies. All were made in the vicinity of Wichita, KS. Of the surviving examples, most are located in SE KS and NE OK. These were made for maybe 5 or 6 years......from late 60's into mid 70's. At the time, they were hands down one of the best methods ever devised to move small square bales. Simple in design and concept. So simple in fact that it is likely that for every commercial made unit, 10 were made in farm shops out of school bus and 2 ton truck frames. Kid who hauled for us made his out of a truck frame. His had tandem rear axles. They could easily lap the next best option (haul double).

The reason they didn't last long was that almost simultaneous with the development of the hay monsters, Vemeer starting making the large round balers, which rendered them instantly obsolete.

But if you need to haul small squares like I do, this is one of the best ways that has ever been devised to do it. I'ts only drawback is it requires a minimum of 2 to operate. But 3 guys who are trying can move 2,000 bales a day with one.

NH stackliners won't work for me. My storage barns are not setup for them, plus I'm selling hay in a 10 mile radius to folks who also can't handle bales from a stackliner.

BTW, Deweze brand is still being made, but it's for equipment to handle large round bales, but has been bought and sold a few times since it was founded. I suspect if you called them, they might acknowledge the company started making hay monsters, but they know nothing about them, nor do they support them.

|

|

iowallis

Silver Level

Joined: 04 Jun 2017

Location: North Iowa

Points: 376

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jul 2019 at 7:40pm Posted: 26 Jul 2019 at 7:40pm |

modirt wrote: modirt wrote:

NH stackliners won't work for me.

|

I always found it odd that my dad "discovered" these machines after my brother and I moved off the farm. He also said I was special 'cause I got to work up in the the barn in the shade.

Would one of these that was self propelled have they clutch system you are looking for?

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2019 at 10:19am Posted: 27 Jul 2019 at 10:19am |

I also found it curious that the first tractor with cab and AC showed up about the same time as I left home (1973). As per dad, mom had to take my place doing tillage work and it was the only way to get her on a tractor. But that didn't last long either......wasn't but a few years later a hired hand showed up to take her place.

Back to the monster........found this site that documents the Dodge medium duty trucks of the period and it looks to me like what the monster was built from is a near perfect fit for one or two variants of a Dodge D600 truck. Same engine, transmission and rear axle. So that will be a good place to start. Only problem being good luck finding one. Don't know that I've ever seen one. Only trucks of that size from that era I've seen in that category were GM, Ford and International. Good news is from the bell housing back to the axle, most builders probably used the same transmissions and axles.

But clutch master and slave I took off the monster is an exact match for Dodge D200 trucks from the 60's.

Things are starting to come into focus.

|

|

Rick

Orange Level

Joined: 11 Sep 2009

Location: Jonesburg,Mo.

Points: 3695

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2019 at 12:38pm Posted: 27 Jul 2019 at 12:38pm |

|

That pressure plate is a 12" Borg & Beck unit found in many models of the Chevy and GMC trucks from the late '60's to the late '80's. Also, used in some of the Chryslers in and around that same time frame, depending on what the clutch disc splines were...10 spline in the GM's and 23 spline's in the Chryslers. I'm saying that it probably has the Chrysler engine, clutch and slave cylinder. Rick

|

|

desertjoe

Orange Level Access

Joined: 23 Sep 2013

Location: New mexico

Points: 13744

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jul 2019 at 4:00pm Posted: 27 Jul 2019 at 4:00pm |

Hey Rick,,, Hopin you been doin OK,,had not heard from you here in quite some time,,,,You gotta check in more often, Guy,,,,,,  Say,,thet pressure plate and heavy duty clutch you talked me into is doing many wonderfuls in my D14 Industrial,,,  A couple three days ago,,there was a fellar from overseas can't remember the country that was lookin for contact info for you. Wasn't for sure he wasn't a bounty hunter or anything,,  ,,but did not give out any info but I had lost your contact info AND could not find in the Members List either,,,,,,Did he find you,,??

|

|

ac fleet

Orange Level

Joined: 12 Jan 2014

Location: Arrowsmith, ILL

Points: 2337

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jul 2019 at 9:09am Posted: 28 Jul 2019 at 9:09am |

|

If you have room for longer arm,----could always weld a heavy extension on yours, IF it came down to that. I have done that to a couple over the years.

|

|

http://machinebuildersnetwork.com/

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jul 2019 at 6:32am Posted: 31 Jul 2019 at 6:32am |

Plot thickens.......

Mounted up the clutch slave to the clutch housing and it aligns directly to the existing clutch fork.......which is 11 1/4".

So I called around and found a junk yard that had a dodge pickup from the 60's era that left the factory with this same clutch master and slave and clutch setup, and sure enough, clutch fork on that was 11 1/4". And has the ball end to match.....so hope to pick that up tomorrow.

|

|

ocharry

Silver Level

Joined: 26 Jun 2016

Location: missouri

Points: 288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jul 2019 at 10:42am Posted: 31 Jul 2019 at 10:42am |

hi modirt

hey maybe i can help you out with the break bleed thing

all you need to do to bench bleed the master cylinder is clamp it in a vice and make some lines to run from the fitting holes back into the reservoir,,,,so it makes a circle of fluid,,,the end of the line needs to stay UNDER the fluid level so it does not suck air back into the line,,,fill the reservoir with fluid and push the piston in and out a few times till you dont get any bubbles coming out,,,,take the lines out and put your plugs back in and you are ready to go,,,,,do the pumping slow,,,if you leave the top off,,,,,or you will have break fluid all over the place,,,,lol,,,,go ahead,,,ask me how i know this,,,,lol

as for bleeding the breaks,,,after you get the master back on and the lines hooked up,,,,,MAKE SURE TO KEEP THE MASTER CYLINDER TOPPED OFF,,,,go to the farthest bleeder from the master cylinder,,,put a short hose on the bleeder so the fluid can run into a pan or bottle to catch it,,,,,,open the bleeder valve and let the fluid run for a while,,,the longer the better,,,,it will push out all the old fluid and the air,,,,when you think it has run long enough,,,( i like to let it go for at least 12 hours ),,,close that bleeder and move to the next longest line,,,do the same with it,,,and the next longest line,,,,and then the last line,,,,,just make sure to keep an eye on the fluid level in the master,,,,at this point you should have new fluid in the system and have breaks,,,,until you blow one of the old rotten lines out that is,,,,,but the gravity bleed will get you good breaks and it is pretty easy to do

hope this can help you out on your project and get you running till you can get your hay in

my daughter lives in Ohio and has a horse operation,,,she was telling me hay is really high,,,,they have around 40 horses and i think they use about 4000 bales a year,,,,wheeew ,,,i dont want that feed bill

hope this helps you out,,,good luck with your project

ocharry

Edited by ocharry - 31 Jul 2019 at 10:45am

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jul 2019 at 8:16pm Posted: 31 Jul 2019 at 8:16pm |

Thanks for the walk through. We did something like that.....except for the 12 hour part......more like 12 minutes, with me pumping and expert knowledge bleeding. But at any rate, an hour later and we had brakes! Good thing too......got to feeling frisky and decided to take her for a joy ride on the public gravel road.......got to the end of the driveway and sure enough, here comes some lady in a bright red new pickup. I stomped down hard on the brake pedal and she came to a stop. Otherwise, it was looking like T bone city.

|

|

Ken(MI)

Orange Level

Joined: 14 Sep 2009

Location: Lansing, MI

Points: 619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jul 2019 at 8:30pm Posted: 31 Jul 2019 at 8:30pm |

|

If it was mine, I'd throw that whole fork and slave cylinder in the weeds and put a Tilton release bearing set up in there, problems solved, but it will cost you about 300 bucks.

|

|

ocharry

Silver Level

Joined: 26 Jun 2016

Location: missouri

Points: 288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Jul 2019 at 11:28pm Posted: 31 Jul 2019 at 11:28pm |

|

Yep you can do the pump thing....that works if you have a helper...I usually dont...

So the gravity thing works while I'm doing something else

But you got her to stop...all that matters in the end

Ocharry

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2020 at 10:34am Posted: 29 Apr 2020 at 10:34am |

Finally got around to putting together a video on the monster......

[TUBE]onIsfsSXRXc[/TUBE]

Got the brake lines bled and purged.....so working brakes....if you keep the reservoir topped up. Still working on the parking brake and replacement clutch fork. Came with an electronic mico parking brake system, but NP 540 transmission has a band type parking brake on the back......and I have a source of a manual "over center" parking brake lever and cables, so thinking of going that route. Previous owner just chocked the wheels.......cement block, hay bale.....whatever was handy.

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2020 at 10:43am Posted: 29 Apr 2020 at 10:43am |

Currently working on replacing all wiring for lights and turn signals. I think existing wiring may have more linear feet of butt splices than actual wiring.

Amazing that all 6 headlights and all turn signal lights were actually working.

|

|

tadams(OH)

Orange Level Access

Joined: 17 Sep 2009

Location: Jeromesville, O

Points: 11147

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2020 at 2:14pm Posted: 29 Apr 2020 at 2:14pm |

|

Altenator looks loose

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2020 at 3:50pm Posted: 29 Apr 2020 at 3:50pm |

Yes, the alternator is a concern. Nothing about it is "stock". Oversized for the engine.....not sure why unless more amps were needed to keep the battery up while running the 7 head lamps at night....... and somebody got creative in devising a method to mount it. Also suspect the belt is a bit too long, which is why it is flopping around....along with the fact that there is no more tension to take up.

May have mentioned it before.....but if not, engine starts and runs out ok.......except when you "rev" it.......it stalls out......and if you keep your foot down.......it will die. Also seems to lack power under a load. In the video......road trip shown was idling downhill. To get back up a steep hill, gotta gear down and get engine cranked up to 2,500 + RPM to pull a good hill.....and that is empty.

Have been testing a lot of theories....but none of them have helped.

Edited by modirt - 29 Apr 2020 at 3:58pm

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 May 2020 at 2:04pm Posted: 16 May 2020 at 2:04pm |

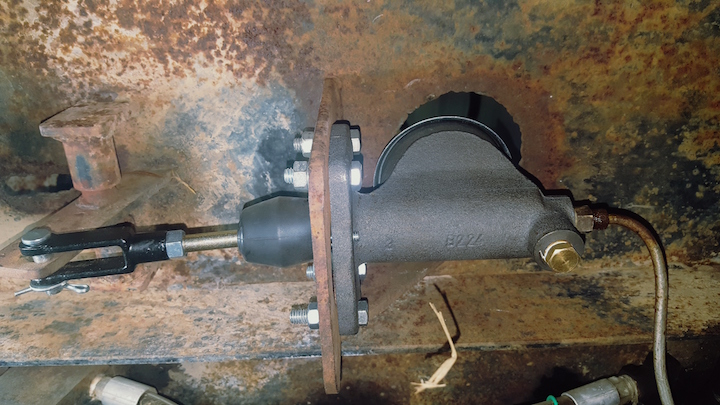

Clutch issue has finally been resolved.

History is previous owner had abandoned the hydraulic clutch in favor of a high friction, high effort cable system due to a strong clutch spring. I was able to find replacements for the clutch master, clutch slave and the lines were found to be clogged, but still OK, so once I got those cleaned out, it went back together and all worked.

Complication for me was bad advice from a guy at the NAPA store who told me I'd need to use a cutoff bolt on the slave. That would have meant the clutch fork was wrong. It wasn't. All I needed was the correct type linkage bolt for the clutch fork. Discovered that when I found this replacement clutch fork.....which is identical to the one already on it. That simplified things greatly......

What I needed was that bolt. But then ran into problems when I found out the bolt wasn't long enough. Likely the guy who took it off the salvage yard truck didn't get it all. There is another piece that is needed for that bolt to be long enough to reach the clutch slave cylinder when fully compressed. Like 4 inches too short. That came with a clutch fork adapter kit.....which included a yolk for the clutch master, push rod for that, plus parts for the slave that I didn't know I needed. These parts....

Universal push rod end on top would have worked, but was too thick to fit through the slot in the fork, but could have been dressed down on the grinder to make it work. Once I could finally see how it was all supposed to work, lights came on and things went together pretty fast.

Before.....

And after.....

And the clutch master installed and rigged.......

As previously stated, although I've got a small selection of wrenches, it has been over 40 years since anybody paid me to use them on things mechanical.......so as long as it is simple, I can do it. But with any of it, helps to know what you are doing. I didn't before.....but do now. Mostly.

But as for the clutch, it's working......and is less than half the effort of the cable system. A guy had to stand on that pretty hard to get it to work. Much easier to use now.

By end of day tomorrow, it may also have an Orschlen over center mechanical parking brake installed on it.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24878

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 May 2020 at 2:36pm Posted: 16 May 2020 at 2:36pm |

|

NICE !!!! Looks like real good 'bodging' back to OEM standard !!!

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 May 2020 at 2:53pm Posted: 16 May 2020 at 2:53pm |

|

Good news about the monster.......ain't nothing hidden. All the moving parts are out there in plain open sight for all to see. And for the most part, easy to get to if you don't mind rolling around on the ground.

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 May 2020 at 3:00pm Posted: 16 May 2020 at 3:00pm |

BTW, I have since located a 70's era Dodge D600 parts donor parked on the side of the road. Probably hasn't moved in 10 years, but still has some stuff that would be valuable to me.....things like the tire rims (not widowmakers), possible spare 318 engine, plus drive train parts, etc. Has not moved in over 10 years. Stake bed is rotting out. Gas tank has been removed. But sheet metal and glass all look good, so may be some valuable parts on it to make up for any salvage cost.

What I can't seem to find is the owner. I have a phone number, but he won't answer it. Can't find an address or I would write.

Guess I could tow it off and leave a note on where to find it.........that might get his notice.......or me arrested.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8731

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 May 2020 at 10:34am Posted: 17 May 2020 at 10:34am |

|

Check with local sheriff...may know who owns it...unless you're gonna help yourself....then less is more

|

|

modirt

Orange Level Access

Joined: 18 Jul 2018

Location: Missouri

Points: 8992

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 May 2020 at 12:05pm Posted: 17 May 2020 at 12:05pm |

Town isn't that big. He has 2 or 3 old trucks and some old farm equipment......including a Gleaner K......all on small commercial lot at edge of town. I know several locals......several folks know "of him"......few seem to know much about him. Kind of a ghost.

Part about nicking it was a joke. Few things get me revved up more than sticky fingers.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Starting to get a better picture of what your working with. Not that I have much to add. But I do have the remains of a New Holland 1048 bale pickup machine. For a lot of years with the NH it was Ford 2 ton truck parts. At this point I don't know if it matters what brand truck parts you look for they are getting harder to find.

Starting to get a better picture of what your working with. Not that I have much to add. But I do have the remains of a New Holland 1048 bale pickup machine. For a lot of years with the NH it was Ford 2 ton truck parts. At this point I don't know if it matters what brand truck parts you look for they are getting harder to find. TimNearFortWorth wrote:

TimNearFortWorth wrote: