| Author |

Topic Search Topic Search  Topic Options Topic Options

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: C replace crankshaft thrust bearing Topic: C replace crankshaft thrust bearing

Posted: 28 Oct 2020 at 7:05am |

1948 Model C with wide front end, magneto and MS carburetor.

I think I have the time to replace the crankshaft trust bearing. The end play is just over .030.

Can I do this this with the engine in the tractor? It is a wide front axle, will the wishbone get in the way? Pan gasket is easy? Could I/should I use Plasti-Gage to check all the bearing clearances? I have proper oil pressure so I presume the oil pump is good. Rear main does leak. Front OK. Can that rear seal be replaced from below?

I don't use it that much, but worry every time I depress the clutch.

Thank you, any advice appreciated.

|

|

|

Sponsored Links

|

|

|

GregLawlerMinn

Orange Level

Joined: 11 Sep 2009

Location: Lawler, Mn

Points: 1226

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2020 at 8:41am Posted: 28 Oct 2020 at 8:41am |

You would need to replace the front main bearing; don't know that this can be done without removing the crankshaft. The thrust bearing on the CE engine is integral with the front main bearing; ie, it is a lip off it. You can do this without removing the engine, need to remove the front axle, steering bolster, and front cover. It would be easier to remove the engine and mount it on an engine stand. That way you could inspect it effectively (laying on the back, looking up with a flashlite, and crud dripping in the eyes is no fun). Plasti-gage is good to check the clearance between the bearing and journals; however, not so good at detecting if the journals are round, a micrometer is needed for that job. Be prepared for surprises. My experience has shown me that when I opened up an old tractor, there is more wear/tear on other parts that need attention than what I opened it up for to begin with. Good luck with the repair and maybe someone else has had experience in replacing a front main bearing without removing the crankshaft and will chime in.

|

|

What this country needs is more unemployed politicians-and lawyers.

Currently have: 1 D14 and a D15S2.

With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC

|

|

Luke114

Bronze Level

Joined: 27 Aug 2019

Location: Washington

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2020 at 4:31pm Posted: 28 Oct 2020 at 4:31pm |

All the bearings can be rolled in from below. Pan can be removed while the front axle is still on, but the two rear bolts are a pain in the butt. Gasket is simple one piece cork, and it's flat...no humps at either end.

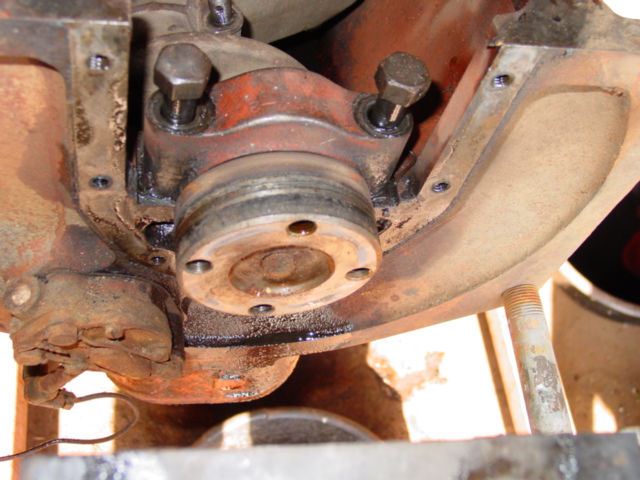

However, the rear crank seal requires the tractor to be split as the seal housing is a separate non-split piece that goes on after the crank is in place. If you are determined to change the rear seal, then it will be so much easier to wait til the engine is upside down on a stand to tackle the bearings. Complete crank removal would also require taking the front cover off. Removing the pulley can be difficult. I tapped puller holes last time to make this easier.

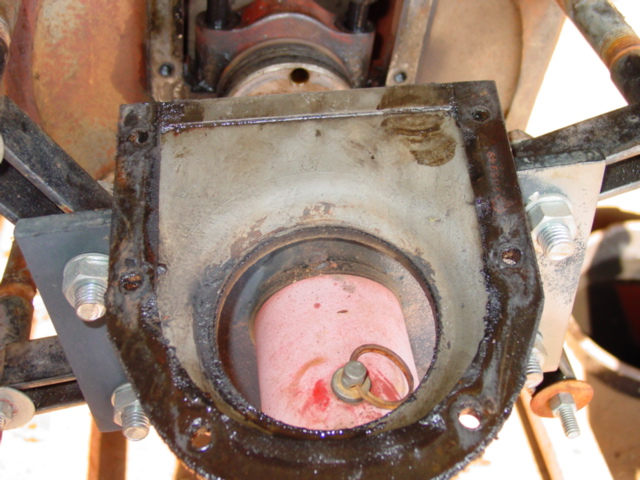

But you could still remove the pan before splitting the tractor, and even the front bearing block just to see what you are up against on that thrust bearing. You might decide rolling in one bearing isn't bad you can live with the rear seal leak. Only the half of the bearing that is in the cap has the thrust flanges. The half that would need to be rolled in looks like every other bearing half shell. The thrust bearing is captured by the crankshaft timing gear, which is pressed on.

.030" end play is a lot and I wonder if your crank gear wasn't fully pressed in place at some point?

|

|

Tracy Martin TN

Orange Level Access

Joined: 11 Sep 2009

Location: Gallatin,TN

Points: 10658

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Oct 2020 at 4:49pm Posted: 28 Oct 2020 at 4:49pm |

|

The end play is because of using the clutch a lot. Like cultivating short rows , or mowing where you stop and go a lot. I have seen worse. HTH Tracy

|

|

No greater gift than healthy grandkids!

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2020 at 5:49am Posted: 29 Oct 2020 at 5:49am |

The wear for the thrust will not only be on the thrust bearing but also on the inside thrust area on the crankshaft. You will need to inspect the crankshaft and make sure it is not rough or a new bearing will be gone in a very short time. Your rear seal housing and where it bolts fast over the crankshaft.

|

|

BrianC

Orange Level

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2020 at 10:59am Posted: 29 Oct 2020 at 10:59am |

Thank you all for the info! For taking the time to post pictures and give advice, thanks again. It was a short row cultivating tractor, that was it's life. Father and uncle bought in '49 when tractors became available again at a reasonable price. His first new tractor. An Allis was also his last new tractor (have that also). Engine is a little noisy, the valve lash is set OK.

The rear seal leak I could live with, it is not harming clutch action as far as I can see.

I presume the gear is pressed to a stop shoulder on the end of crank. With the bearing cap off, could I see, or use a feeler to check if gear is on all the way? However, the real "clutch pressure thrust bearing action" must be on the other side, against a surface ground into the end of the crank. I think this is what you all told me, do I have it in my head right?

One more, press on gear is nice, but is it a function of the front pulley to keep it from ever backing off?

Thanks.

Edited by BrianC - 29 Oct 2020 at 6:00pm

|

|

Luke114

Bronze Level

Joined: 27 Aug 2019

Location: Washington

Points: 109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2020 at 11:40am Posted: 29 Oct 2020 at 11:40am |

You are correct, the gear presses against a shoulder. Technically it is pressed on until the proper thrust clearance is achieved, which could leave a small gap to the shoulder if things aren't machined exactly. The press fit is the only thing that retains it. The front cover plate, with the front main seal, is in between the gear and the belt pulley.

And yes, the thrust wear from the clutch would take place on the crankshaft side, opposite from the gear.

One thing I've had to learn from old equipment is that seldom can you make things perfect. We forget that these antique machines once worked hard for a living and were maintained with limited time and budgets. Lots of strange things can be found when they are opened up. Sometimes repairing them to a state of "good enough" is the best choice.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Oct 2020 at 11:45am Posted: 29 Oct 2020 at 11:45am |

|

When they grind the crankshaft they clean up where the thrust bearing rides and remove enough from the gear stop to give the proper thrust clearance. If the tractor is used much after the babbit surface is gone it will eat into the crankshaft quickly.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)