| Author |

Topic Search Topic Search  Topic Options Topic Options

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Building a new equipment shed Topic: Building a new equipment shed

Posted: 12 Aug 2024 at 4:31pm |

I bought 2 more tractors last week and I'm out of shed space. Looking at building another shed for these 2 tractors and some of my other equipment that I need to put inside.

I've got a complete metal building that I took down for free years ago (they were going to demo it and gave it to me to take it down. I think it is 40x60, but I think I just want to put up 1 section (2 trusses), which will make the building 40x20. My issue is the foundation. What info I've found for a 40' free span building is a pretty large foundation. One thing I'm thinking about is putting a post in the middle of the truss, that should take a lot of stress off the end columns, but it's still a fairly large foundation. Does anybody know the cost difference of mixing your own concrete vs having ready mix delivered? I first thought I could mix it myself a lot cheaper (I have a mixer), but after pricing bags of Portland cement, it looks like I can have ready mix delivered for not much more than I can just buy bags of Portland for (not counting the sand and gravel). Maybe I'm just not shopping at the right places, but bags of Portland seem awfully expensive.

At the end of the day, I really don't know if this "free" metal building is worth it. The tin I took off has already ruined, and buy the time I hire equipment to set the metal building, I'm wondering if I can actually build a pole barn cheaper?

|

|

|

Sponsored Links

|

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24765

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 5:50pm Posted: 12 Aug 2024 at 5:50pm |

well we all KNOW that 40x20 is already too small,so at least pour pads for the other posts at 40' and 60'. As the building was designed for 40' span ,NO need for center posts or columns.

Concrete comes in 3 forms 1) piles of sand,gravel and bags of cement 2) one pile of 'concrete mix' plus bags of cement 3) readymix truck.

1 and 2 area LOT of work ! HEAVY slugging and HOURS of mixing. Unless you have a 1/3yd mixer, I doubt you could mix fast enough to finish the job before the 1st pours were setting up hard ! It's 'logistics'... you need a LOT of manpower and great weather. Pretty sure you're not as young as you were 10 years ago...I KNOW I ain't !!!

3 is the only realistic way to do it. It will NOT cost that much more AND be done a LOT faster. My shop, well my old shop, sniff,sniff. I had a crew come in an pour 20x48x 6 inches. they were here ALL day....did a GREAT job...floor was and still is real smooth.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88405

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 6:20pm Posted: 12 Aug 2024 at 6:20pm |

why would you need a big foundation ? Look at a pole barn... Base of posts is less than 12 inch diameter and one every 6- 8 ft ????

Granted, you only have 4 "bases" and a pole barn would have a dozen... but the TOTAL amound of concrete should be similar ??

Edited by steve(ill) - 12 Aug 2024 at 6:25pm

|

|

Like them all, but love the "B"s.

|

|

PaulB

Orange Level

Joined: 12 Sep 2009

Location: Rocky Ridge Md

Points: 5153

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 6:28pm Posted: 12 Aug 2024 at 6:28pm |

|

Around this area the "ready mix" plants are so booked up with contract work they don't even want to serve one time users and have priced their product accordingly. This has spawned a bunch of "mobile mix" outfits that will come to your site and mixt exactly what you need. Getting premixed and just add water in the bag is terribly expensive.

|

|

If it was fun to pull in LOW gear, I could have a John Deere.

Real pullers don't have speed limits.

If you can't make it GO... make it SHINY

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 9:38pm Posted: 12 Aug 2024 at 9:38pm |

steve(ill) wrote: steve(ill) wrote:

why would you need a big foundation ? Look at a pole barn... Base of posts is less than 12 inch diameter and one every 6- 8 ft ????

Granted, you only have 4 "bases" and a pole barn would have a dozen... but the TOTAL amound of concrete should be similar ?? |

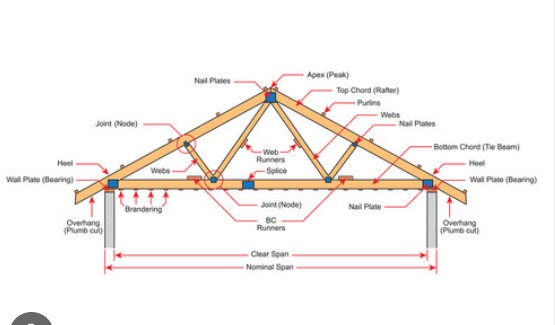

Doing my research on free span trusses, there is a lot of lateral load on the columns. Basically, the load is pushing down on the top of the truss, this causes the columns to try to kick out at the bottom, as the force tries push down on the peak of the truss, it makes the columns wanting to "kick out" at the bottom. It's a engineered foundation that has to be right or the building will eventually fall. I talked to a guy that builds these type buildings, he said they built a building a couple of years ago that was a record free span (don't recall how far). About a year after they built the building, somebody noticed the columns where trying to kick out at the bottom and the roof was trying to fall. Engineers looked at it and the solution was to cut a trench all the way across the building in the column line, install big cables between the columns, pull the foundations back into place, and fill it all back in with concrete. He said the fix cost more than the cost of the building originally.

The reason I mentioned the post in the middle was because that would hold up the peak of the truss, and essentially shift the weight of the building from a lot of lateral stress to more or less straight down onto the columns.

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 9:51pm Posted: 12 Aug 2024 at 9:51pm |

jaybmiller wrote: jaybmiller wrote:

well we all KNOW that 40x20 is already too small,so at least pour pads for the other posts at 40' and 60'. As the building was designed for 40' span ,NO need for center posts or columns.

Concrete comes in 3 forms 1) piles of sand,gravel and bags of cement 2) one pile of 'concrete mix' plus bags of cement 3) readymix truck.

1 and 2 area LOT of work ! HEAVY slugging and HOURS of mixing. Unless you have a 1/3yd mixer, I doubt you could mix fast enough to finish the job before the 1st pours were setting up hard ! It's 'logistics'... you need a LOT of manpower and great weather. Pretty sure you're not as young as you were 10 years ago...I KNOW I ain't !!!

3 is the only realistic way to do it. It will NOT cost that much more AND be done a LOT faster. My shop, well my old shop, sniff,sniff. I had a crew come in an pour 20x48x 6 inches. they were here ALL day....did a GREAT job...floor was and still is real smooth.

|

I will concede that you never can have enough buildings and they are never big enough. That being said, I already have several other sheds and a sizable shop, and the spot I want to put this shed 20x 40 is about all that will fit without a lot of dirt work.

For the concrete, I've got a nice mixer that goes on my loader that works really well. By my current calculations I'm going to need around 2.5 yards of concrete, that's not a big job for the mixer I have. Just the price of the Portland, I'm going to have $113 per yard just in Portland, not counting the sand and gravel. Now it's been awhile since I bought concrete, but pre covid I could buy ready mix delivered for $120 per yard, and I could make it myself for around $75 per yard.

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 9:58pm Posted: 12 Aug 2024 at 9:58pm |

PaulB wrote: PaulB wrote:

Around this area the "ready mix" plants are so booked up with contract work they don't even want to serve one time users and have priced their product accordingly. This has spawned a bunch of "mobile mix" outfits that will come to your site and mixt exactly what you need. Getting premixed and just add water in the bag is terribly expensive. |

Yes, buying premixed in the bag is very expensive. Pre-covid though, I could make my own concrete for around $75 per yard (mixing the cement, sand, and gravel myself). Now, the price of Portland cement is $113 per yard, not counting the sand and gravel. I haven't called the ready mix outfit to check the current price of concrete delivered. Looks like I need around 2.5 yards, I know the ready mix outfit used to have a 5 yard minimum or they charge you a outrageous delivery charge.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24765

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Aug 2024 at 6:02am Posted: 13 Aug 2024 at 6:02am |

OK, I was under the 'funny idea' that you were going to pour the FLOOR as well post/column foundations...... oospy...

Bags will still be easier and maybe be cheaper, once you factor in delivery costs ,unless you've got a '6by10' dump trailer...and in good health. There's a lot of shovels in 2.5 yds of concrete !

Crazy thing here is that Home Depot sells Sakrete bags of concrete mix and the 5000PSI bags are the SAME price as the 3500 ones ! FYI $6 CDN for 1/2cuft bag.

That brings up another kinda important item.. premixed IS the same bag to bag. when you do it,it's easy to be off the 'ratio' and probably have weak concrete.

Also up here, every 'pier' has to be poured in a bell shaped hole. I think 'big foot' is a plastic version ?

If the 'specs' call for a 12" pier, consider using 16". Not that much in extra cost but much better,esp for 'side loads' I suspect.

Foundations are kinga important, so best to make it stronger,better NOW is a good thing. Yes, costs a little more up front but well worth it ! Also, when you mark out the locations, get them within an 1/8" of an inch NOT like the clowns next door, who were off 7 INCHES in 24 feet.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Aug 2024 at 10:37pm Posted: 13 Aug 2024 at 10:37pm |

jaybmiller wrote: jaybmiller wrote:

OK, I was under the 'funny idea' that you were going to pour the FLOOR as well post/column foundations...... oospy...

Bags will still be easier and maybe be cheaper, once you factor in delivery costs ,unless you've got a '6by10' dump trailer...and in good health. There's a lot of shovels in 2.5 yds of concrete !

Crazy thing here is that Home Depot sells Sakrete bags of concrete mix and the 5000PSI bags are the SAME price as the 3500 ones ! FYI $6 CDN for 1/2cuft bag.

That brings up another kinda important item.. premixed IS the same bag to bag. when you do it,it's easy to be off the 'ratio' and probably have weak concrete.

Also up here, every 'pier' has to be poured in a bell shaped hole. I think 'big foot' is a plastic version ?

If the 'specs' call for a 12" pier, consider using 16". Not that much in extra cost but much better,esp for 'side loads' I suspect.

Foundations are kinga important, so best to make it stronger,better NOW is a good thing. Yes, costs a little more up front but well worth it ! Also, when you mark out the locations, get them within an 1/8" of an inch NOT like the clowns next door, who were off 7 INCHES in 24 feet.

|

Yes, just pouring column foundations. We don't have to worry about "frost heave" down here in TN like you folks up north have to deal with.

I'm still weighing my options. I don't need anything fancy, just enough to keep the rain off a few tractors and equipment, but I do have to make it look decent for the beautification department (wife). I could probably get by with more if you couldn't see it from the house.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88405

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Aug 2024 at 10:56pm Posted: 13 Aug 2024 at 10:56pm |

you said your buddy had the legs try to spread and so they connected them at the BOTTOM with a cable and buried in concrete.... another way would be to stretch a cable across the span at the TOP of the legs and ratchet it TIGHT so it acts with the rafter beams above to form an "A" type rafter with bottom truss ( the cable)... that is how most houses and barns keep the LEGS from kicking out..

Edited by steve(ill) - 13 Aug 2024 at 11:02pm

|

|

Like them all, but love the "B"s.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24765

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 6:37am Posted: 14 Aug 2024 at 6:37am |

That red tight cable is the bottom chord of the truss, so cable isn't needed. Had to go back to the 1st post.....he does say truss.

Now there are two major type of trusses, 'roof ONLY and 'roof with floor' roof ONLY trusses should NEVER have anything stored on top of the trusses bottom chord. Well OK, maybe 3 or 4 fishing poles but NOT WEIGHT. very,very bad things WILL happen,like the truss WILL fail. BTDT next door..... roof with floor trusses ARE designed to,well, have a floor on them and support a certain designed weight (xx pounds per square foot ).

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88405

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 9:16am Posted: 14 Aug 2024 at 9:16am |

|

many "STEEL" buildings are made with just a BEAM or TOP CORDS setting on the walls... No lower CORD turing it into a TRUSS.... If he had a BEAM in place of the RED LINE then there is NO PROBLEM with the roof trying to push the walls OUT..... I assume he DOES NOT have a beam at the RED LINE... Adding a CABLE at this point under TENSION would turn the ROOF into a REAL RAFTER with no horizoztal load on the walls.

Edited by steve(ill) - 14 Aug 2024 at 9:26am

|

|

Like them all, but love the "B"s.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88405

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 9:19am Posted: 14 Aug 2024 at 9:19am |

Edited by steve(ill) - 14 Aug 2024 at 9:24am

|

|

Like them all, but love the "B"s.

|

|

m16ty

Orange Level

Joined: 28 Jan 2011

Location: TN

Points: 1476

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 4:39pm Posted: 14 Aug 2024 at 4:39pm |

steve(ill) wrote: steve(ill) wrote:

many "STEEL" buildings are made with just a BEAM or TOP CORDS setting on the walls... No lower CORD turing it into a TRUSS.... If he had a BEAM in place of the RED LINE then there is NO PROBLEM with the roof trying to push the walls OUT..... I assume he DOES NOT have a beam at the RED LINE... Adding a CABLE at this point under TENSION would turn the ROOF into a REAL RAFTER with no horizoztal load on the walls.

|

Yes, you are correct, the manufacturers call it a truss, but it's really a engineered beam with no bottom cord. A cable across the red line would work, and I hadn't thought of that, although it would limit your headroom somewhat.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24765

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 5:34pm Posted: 14 Aug 2024 at 5:34pm |

|

would those be 'collar ties' under those 40' steel truss picture ??

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88405

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Aug 2024 at 10:08pm Posted: 14 Aug 2024 at 10:08pm |

|

i would be very temped to stretch the cable at the BOTTOM and lay it a couple inches below ground.. Gravel floor should cover that OK and no future rust if not "WET".... you could lay the cable in a small trench and pour a cover with 6 x 6 poured concrete 40 ft long if you want the cable "covered"..

|

|

Like them all, but love the "B"s.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

steve(ill) wrote:

steve(ill) wrote: