| Author |

|

smokey

Orange Level

Joined: 04 Oct 2010

Location: Michigan

Points: 287

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 7:21am Posted: 04 Jan 2012 at 7:21am |

|

pre64, in your picture of the cover I see what looks like 2 shim washers on the rail in the book does not show them, and with the wear on 1st- and reverse idler leading edge's it don't look right, the shims on the counter looks like the front spacer should be (0.868) and the rear should be (0.966)

|

|

|

Sponsored Links

|

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 8:07am Posted: 04 Jan 2012 at 8:07am |

|

This morning I took an inspection mirror and looked at mine, the spacer in front is about 3/8" wide, and the one in the rear is about 7/8" wide, these are rough guesses as I couldn't get anything in there to measure them. When the tranny is in 1st gear, the reverse gear should be all the way rearward up against the back mainshaft gear, and there was about 3/16" or maybe a 1/4" of clearance between the countershaft reverse and the reverse idler gear, with the spacers reversed, they would probably mesh.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 11:46am Posted: 04 Jan 2012 at 11:46am |

|

Well fellows we will know shortly. Just got it split and the power director off. As soon as I eat a bite I will be pulling the main shaft and working my way down. Should know something in a few hours.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 11:51am Posted: 04 Jan 2012 at 11:51am |

Dr Allis, Thanks for your tip. Don't ever recall doing one that way but it sounds possible. I have already spilt the tractor so I am going in and making sure everything else is correct as well as perform a good inspection. I am also hoping to take some pictures of the problem before and after it is corrected. Thanks Tim

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 3:39pm Posted: 04 Jan 2012 at 3:39pm |

|

I didn't realize that the top gears would't come out the front. It has been 30 years plus since I have been in the transmission part of it. I was able to get the end gear and slider off but that is it. I also notice a brand new soft plug over the counter shaft that we suspected was the culpret. Imagine that. I am done for the day so tomorrow I will pull the drives and rear end so I can remove the pinion . I am hoping to get the top main shaft out of the way so I can get a clear picture of the problem for others to see. Hopefully it may prevent someone else from going through this headache. I don't know how you could ever do a major overaul on a transmission and not check your work during assembly.

Edited by pre64 - 04 Jan 2012 at 8:33pm

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Jan 2012 at 10:07pm Posted: 04 Jan 2012 at 10:07pm |

|

some folks should'nt be parents and some should'nt be mechanics....but, that's the way it is

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 2:17pm Posted: 06 Jan 2012 at 2:17pm |

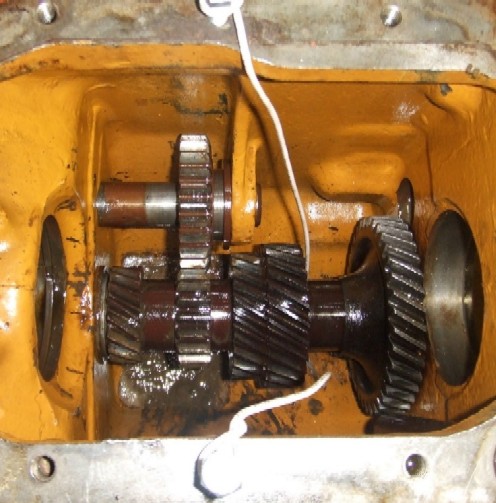

I didn't get to work on this yesterday as planned, but I got it tore down today. Take a look at this picture and tell me if you agree with me the 2 spacers are reversed? Thanks Tim

Edited by pre64 - 06 Jan 2012 at 7:53pm

|

|

Dave (Mid-MI)

Orange Level

Joined: 12 Sep 2009

Location: Hemlock, MI

Points: 570

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 3:10pm Posted: 06 Jan 2012 at 3:10pm |

|

Yup.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:08pm Posted: 06 Jan 2012 at 5:08pm |

Dr. Allis I see what you mean by driving out the counter shaft to replace the bearings and races. I think however it would be very difficult to slide the shaft out far enough to pull 2 gears and spacers off and change them around. If you work alone as I do I would say no, however if you had a couple of extra hands and they were small I would say maybe on a lucky day. Small hands and lucky days seem to flee from me however. I have posted a before and after picture of the spacers being in the wrong location. I want to thank you for all of your help. Hopefully others have learned as well. Thanks Tim

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:14pm Posted: 06 Jan 2012 at 5:14pm |

|

You'd have thought the person responsible for the mistake would have noticed it after together and groaned and fixed it.

|

|

Gary in da UP

Orange Level

Joined: 13 Sep 2009

Location: EUP of Mi.

Points: 1885

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:25pm Posted: 06 Jan 2012 at 5:25pm |

SteveM C/IL wrote: SteveM C/IL wrote:

You'd have thought the person responsible for the mistake would have noticed it after together and groaned and fixed it. |

Yes, you and I think alike, but not everyone has to sign-off on their work or feels compelled to do their work to a standard. Too bad , it causes a lot of grief for the innocent !

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:26pm Posted: 06 Jan 2012 at 5:26pm |

Here are the before and after pictures of the spacers on the counter shaft. My advise to all is to pay attention and take pictures of all of the parts if you are going to rebuild a transmission yourself. Some poor soul probably paid some several thousand dollars for this repair and it was done wrong.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8784

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:33pm Posted: 06 Jan 2012 at 5:33pm |

|

well,the bright side to the story is you didn't have to buy hard parts to fix it

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 5:54pm Posted: 06 Jan 2012 at 5:54pm |

|

Glad you got it headed to working properly, sorry you had to tear into it so far, but as Steve pointed out, no hard parts, just a few gaskets and seals.

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 7:23pm Posted: 06 Jan 2012 at 7:23pm |

I want to thank all of you for your input and help on this. Normally we always say it should be something simple....this time we proved the theory wrong. Other than buying some gaskets and seals cost wise won't be so bad but if I add my 4.50 per hour shop rate to it I will have to sell my dog. :) . Thanks again Tim

|

|

allischalmerguy

Orange Level

Joined: 11 Sep 2009

Location: Deep River, IA

Points: 2894

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 10:13pm Posted: 06 Jan 2012 at 10:13pm |

|

I have been following this post, it has been educational and very interesting to me. Thanks for all the information and way to go Tim on getting it solved!!!!

Pastor Mike

|

|

It is great being a disciple of Jesus! 1950 WD, 1957 D17...retired in Iowa,

|

|

Orange Blood

Orange Level

Joined: 29 Nov 2010

Location: ColoradoSprings

Points: 4053

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 Jan 2012 at 10:25pm Posted: 06 Jan 2012 at 10:25pm |

Hey Tim,

Where do you get $4.50, an hour from, I am lucky if I don't have to pay to work in my own shop? :-)

|

|

Still in use:

HD7 WC C CA WD 2-WD45 WD45LP WD45D D14 3-D17 D17LP 2-D19D D19LP 190XTD 190XTLP 720 D21 220 7020 7030 7040 7045 3-7060

Projects: 3-U UC 2-G 2-B 2-C CA 7-WC RC WDLP WF D14 D21 210 7045 N7

|

|

Chalmersbob

Orange Level

Joined: 11 Sep 2009

Location: Pennsylvania

Points: 2122

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Jan 2012 at 9:05pm Posted: 07 Jan 2012 at 9:05pm |

At $4.50 per hour, you can work in my shop any time you want to.

Glad to hear that you solved your problem, now on to the next. Bob

|

|

Pat the Plumber CIL

Orange Level

Joined: 11 Sep 2009

Location: Springfield,Il

Points: 4982

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 2012 at 7:46pm Posted: 08 Jan 2012 at 7:46pm |

|

Thanks for posting subject and pictures. This is why this is the best site on the internet

|

|

You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails

1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF.

|

|

DaveKamp

Orange Level Access

Joined: 12 Apr 2010

Location: LeClaire, Ia

Points: 6109

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Jan 2012 at 7:57pm Posted: 08 Jan 2012 at 7:57pm |

|

Hee hee... isn't it cool that we can live vicariously through eachother's tribulation? Better yet, we can post pictures showing it, just as we found it, and after, we fixed it...

Congratulations, Tim- job well done! It may take small hands, but then again, it may be a case where special tools MAY knock that rascal out without breaking it all down.

I'll be working on a WD transmission in the future... the experiences shared here, along with the photos, will help me immensely. Thanks Everybody!

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 2012 at 6:39am Posted: 09 Jan 2012 at 6:39am |

Thanks everyone for the comments. Had it not been for this site and everyones willingness to aide a fellow Allis collector, things may have turned out much different. I will be posting a couple of more pictures this week of assembly and some pointers for doing the entire job alone that will hopefully aide some of you in the same situation. I work alone 99% of the time so I am use to developing tools and tricks for helping me through it. I have now assembled the counter shaft gears and reinstalled the pinion shaft and main gears, and tried all gears to assure they are working correctly. I know a couple of you are wondering if I cleaned out the crud down in the housing that shows up in the picture and yes I did. I am at a stand still now waiting on seals and gaskets and hopefully will have them by the weeks end. More to come! Tim

Edited by pre64 - 09 Jan 2012 at 6:57am

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24931

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 2012 at 7:51am Posted: 09 Jan 2012 at 7:51am |

Man , what a painful learning experience( even from the sidelines ) !

I've always been impressed with the knowledge that you guys freely share and those 2 pictures showed WHY we should always take pictures before we tear into something and ASK before commiting to putting it all back together with fingers crossed, hoping this is the right way

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

TomMN

Orange Level

Joined: 13 Sep 2009

Location: Elbow Lake, MN

Points: 858

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 2012 at 9:09am Posted: 09 Jan 2012 at 9:09am |

|

Those pictures are worth a thousand words for sure. I like to have the manuals when I tackle these things. I just checked and with either the parts book or the service manual this shouldn't have happened. The service manual for the WD45 even gives the width of these spacers, the two wider ones are .966 wide and the small one is .654 wide. I remember I had to shim mine up to tighten the countershaft properly. The only adjustment is different width snap-rings to set the end play at .000 to .004. Thanks for the great detail on what this problem turned out to be.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Jan 2012 at 4:17pm Posted: 09 Jan 2012 at 4:17pm |

D17 Transmission Disassembly Tools and Techniques I was going to start a new thread for tips

and tools for splitting and disassembly of the D17 transmission, but I am going

to inlcude it here.

If the moderator wishes to have it moved let

me know. This is not a complete instruction guide and may vary between

applications. This is merely some things that

I have done that have helped me when no help was around.

First thing is get a good manual and do your homework.

When you find things left out or issues, come here to get your answers! You won’t find a better helping forum.

When you are ready to begin make sure you

have adequate tools and room to complete

the task. This is where the books don't help much. Many of us do not have expensive

state of the art equipment just sitting around waiting to be used. I am

fortunate enough to have a small shop with mills lathes and drill presses etc

and normally a fair supply of iron around.

If you don't have these items then it will take you just a little more time is

all.

This method is only as safe as the person performing. Please keep safety

in your work at all times.

For my method the following tools are needed to complete the task. Your list may

vary but the basics will be similar: At least 1 large floor jack, 2 large jack

stands, engine hoist and some misc blocking and a digital camera (your very best friend).

I like to use the engine stand for

splitting, moving parts around, and pulling the rear differential housings and

axles. Also a tip for working alone, I spent about 100.00 bucks and put an air

lift cylinder on my engine hoist which gives you great control and allows you

to multi task.

Once you have read your manual and

you feel comfortable or brave enough to proceed you will probably discover that

it doesn't always go as planned. The "book" says support both parts

of the tractor being split, remove the bolts and just roll the tractor away.

That is all fine and dandy when they wrote the book 50 years ago, but things do

weather over time and changes the way we do things. You may very well notice

that after doing all of the things the book says the tractor is still stuck

together and won't budge. You can't hook you 4 wheel drive pickup to it and

yank it apart, there is no opening for you to get a prybar or a screwdriver between the housings so what next? I do not recommend lowering your front half

down to try and break it away that way, you are asking for trouble. If all else

fails this is what I do: (I may get some fellow mates to disagree on this but

it does work). Find an inconspicuous place on the side of the housing close to

the bottom and take your angle grinder with a thin cut off blade on it, and

make a small indentation (cut) between the two housings. This will allow you to

get a small prybar or similar between the cracks and force

the gasket apart.

The next thing you will discover when

splitting is you will begin to run out of jacks, jackstands etc to support all

of the heavy parts. Rather than getting a bigger stack of 2x4's and trying to

support a couple of ton of iron with the risk of killing yourself, here is what

I do for very little money. Once you have the transmission split from the

differential I start rounding up to 2 or 3 inch angle iron long enough to fit

to the top of the transmission housing around 3 feet or so. Next if you don't

have an end mill to make exact holes, measure the distance between one of the

top holes on the side and one of the

bottom holes on the same side and drill you a couple of "oversize

holes" in the angle to match these. Your not going to get them exact so

over drill them at least two or three sizes too big so you can offset the

difference, you don't care how they look just so they are safe. Now put bolts

through both holes and tighten them up and the same for the opposite side of

the transmission. You now have your front supports and eventually will free up that floor jack.

Using the same technique make two more in the same fashion for the other half

you just split and bolt them in place. Now you can ease your floor jack off and

free it up. When you move to the rear to remove your Lift Arm Housing ,place your jack in the center back and remove your lift arm housing. Get a good long strap and secure a loop around the lift arm housing from your engine hoist and center it so it doesn't get away from you when it breaks loose. You read your book right? So you have already pulled your pto shaft and unhooked and removed your lift cylinder. Now if the housing is stuck and you can not get a pry bar in anywhere then you may have to use your angle grinder again as we did before. Once it is down and out of the way you can access the differential components. Before you proceed you need to make at least one more angle iron leg brace to place on the the back of the housing so you can get your jack out of the way to clean up all the oil that leaked out. This leg you can get by using one bolt and line up the other hole with the guide pin sticking out. This will save you a little time and work and once you tighten it, it will be safe and secure. Keep following your book and remove the rear axle housings very carefully, preferably with the engine hoist and strap and move aside. If the drum came out with it pull if off the shaft and put aside. With both axles removed you are ready to remove the ring gear assembly. Before you start get you a couple of large dowels, broom handle etc and put in the ends of the ring gear assembly through the side holes so it doesn't fall when you remove the bearing housings next. Follow the book and remove the bolts from the axle housing bearing retainers. These housings have an oring seal and are

about 2 bucks from Allis so don't consider reusing them. You will need to take

a brass punch or small block of wood inside the differential housing and tap

out the bearing housings outward until they are free. Once the oring is out of

the housing they will come off easy. Make sure you replace the seals in the

housing before reinstalling. Your ring gear assembly is now free. It is heavy

and sharp so some gloves may be nice. You will need to hold it up and pull the

dowels at the same time. When you remove it bring it straight back out the

rear. There is not much clearance here!

Next you will be ready to remove your hand

clutch and the main input shaft according to the instructions. You will notice

that most likely your will encounter snap rings that have no holes in them to

remove them and not enough room to get anything else in their to aid in getting

them off the shaft. What I do now is get a small, good sharp center punch and

mark each side of the snap ring and drill the two holes in them. Keep it under

an 1/8" and centered or it will be too close to the edge. Now you can use

your regular snap ring pliers to remove it and possibly save it. The material

of the ring is a little hard so make sure you have a good fresh bit to drill

with, but a regular steel bit will work.

The book says to just tap the main shaft

out the rear housing. Hope yours comes right out but I bet it don't. It may

take a lot of tapping to drive it out. Mine came out hard all the way to the

end. You have a double roller bearing with a couple of inches of surface so a

normal tap isn't going to cut it. If you do not have a large brass shaft or

punch you will probably need to find a small oak 4x4 and a 3 lb hammer. Before

you begin this so called tapping I would advise that you put some type of a

shim wedge between your 2 piece split ring collar and the rear part of the main

shaft. I broke one half of my split ring from driving on it and could have prevented

it by putting a wedge between it. Once you have moved it about 3/4" you

can slide the collar back and remove the split rings. Now is a good time to get

you a shaft, broom handle or something similar a couple of feet long and clamp

it to the rear differential somewhere close so when the pinion shaft comes out

you can start taking your gears off and sliding them right onto the shaft so

you don't mix up how they go. Also if you are working alone it would be a good

idea to stuff something in the differential incase the pinion comes flying out

or drops and dings up your bearing. I put a bunch of my dirty rags in mine. Any

comments or criticism is welcome. If we can improve this no hard feeling here!

I will begin to write some assembly tools and tips as well in the next few

days. Also are a few small images to clarify some of text.

Tim

Edited by pre64 - 10 Jan 2012 at 6:53am

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2012 at 9:08am Posted: 13 Jan 2012 at 9:08am |

D17 Transmission

Assembly Tools and Techniques

As promised I am adding a few pointers for assembly of this

project. Once you have received all your new gaskets, bearings, seals etc and

double checked to make sure they are right we will proceed.

You will find

that some of the gaskets come off very hard after the years. I still prefer

using a razor blade scraper to get down to the metal surfaces. You will notice

that some of the casting flaws will catch on your blades every now and then and

break your blades (make sure you have your safety glasses on for this) so make

sure you have a handful of razor blades before you start. Once you have all of

your gaskets cleaned off, clean out all the junk from the housings and swab it

out good.

Now get

all your pinion and main shaft parts and gears ready to go. Here is a tip for

putting the pinion shaft in yourself . Get you a couple of feet of good wire

and put two bolts in your top transmission housing straight across from one

another near the front of the transmission. Wrap one side of the wire 2 or 3

turns around the bolt farthest from where you are standing and leave the other

end of it hanging. Get your pinion shaft and place it through your back housing

all the way to the bearing edge and hold onto the shaft with the other hand.

Now with one hand free start feeding your gears etc onto the shaft. Then in

order to free up your other hand grab your wire and loop under the front part

of the shaft and lift it up until it is nearly centered in the front housing

and give it a couple of wraps around the other bolt on the top housing. This

will temporarily hold it in place while you go to the rear and get your pinion

started up into the bearing housing. When you get ready to do your so called

“tapping” your shaft into the housing you will need a hard block or similar to

tap in the center of the pinion and drive into place. When you get within about

¾” or so from being into place, you will need to put on your “split ring”. I

usually grease them up good with some heavy grease so they will temporarily

stick into place and not fall out. Slide your retainer over the top of them

when done to hold it together. Don’t be afraid to put a wad of grease on this

as well to help hold it in place. Keep checking after each tap to make sure it

doesn’t come apart. Note; when tapping your shaft into place you will need to

keep slacking your wire that is holding the end of your shaft up. Once you have

started the pinion into that bearing housing I realize the shaft holds it self,

however the wire at this time serves to hold the gears from flying off the

front of the shaft during the tapping process. This image is on the bottom

shaft assembly but the same technique is used on the top:

Once you

have your pinion and gears in place make sure your gears all turn freely and

each gear functions properly and is free. If your pinion shaft is binding at

all you probably drove it in a little to far. If this happens make sure you

have your snap ring on the front of the shaft and then give it a good tap

backwards and it should free right up. If all is well and you get your rear

bearing retainer plate on and all bolts tight, you will need about 18-20” of

steel wire .050” or less in diameter to put through the bolt heads as the

book indicates. End up with your splice for the wires where you have room to

work and about ½ way in the middle of two bolts. This will give you enough room

to twist the ends together. Once done clip off any excess and flatten all wire

down tight against the flange. This will prevent it from getting caught in your

ring gear.

With all of your parts cleaned good install all of your seals. When you are

installing the new orings, especially the ones on the rear axles bearing

holders, do not roll them into the grooves they fit in, but rather start one

side of it down into the groove and “carefully” stretch it just enough to get

the remainder of it into the groove. This will prevent the oring from twisting

that you get from rolling it into position. You want it to lay straight when it

is in the groove to prevent from catching during assembly, since it is a real

tight fit. Right before assembly put a little Vaseline on it all the way around

to help it go together.

When working alone and installing the ring gear assembly into the housing you

will need a couple of dowels, broom handles etc to fit though the axle housing

into the rear end to hold it up during assembly. Once you have it suspended

then you can get your bearing housing and shims and slide them over your

dowels, line it up and carefully push them into place. Make sure all of your

shims are lined up with the bolt holes during assembly. Don’t use the retainer

bolts to draw your bearing housing into place. If it is clean and lubed you

will be able to put them in by hand by turning them a little during assembly.

This will prevent you from pinching one of the orings. Once they are in place

tighten them up, Check now and insure it rotates freely and your ring gear and

pinion gap are good. If you have kept all of your shims straight on each side

it should go back to where it was. If you don’t have the dial indicators etc.

to check exact clearance make sure that there is a little play back and forth

between the ring gear and pinion. I would say no more than 1/8” back and forth

just as a guideline. When you are ready to install the rear axle housings I like to use the engine

hoist and put the strap as far out as it will go and it will be balanced then.

Make sure your brakes are spread clear apart and put a little grease on the

ends of the splines to help it to go together easier. Once you are lined up and

ready to start the axles into place, go easy and not bump the inner seals. If

you have it lined up it should go in a good ways and stop. At this point turn

your outer wheel hub a little back and forth and it should go all the way in.

Never draw it in with the bolts, it should always go together fairly easy by

hand. Also keep an eye that your don’t catch on your brake shoe linings going in.

Edited by pre64 - 14 Jan 2012 at 7:35am

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2012 at 7:41am Posted: 14 Jan 2012 at 7:41am |

|

Finally got back to work on this yesterday. I now have the pinion shaft and all the gears and input shaft as well as the rear axles in place. I manually shifted all the gears into place one at a time and they all function properly now. Hope to have it back to together this weekend so I can move the tractor around and make some room.

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

wjohn

Orange Level

Joined: 19 Jan 2010

Location: KS

Points: 2319

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2012 at 9:37am Posted: 14 Jan 2012 at 9:37am |

Awesome job, pre64! I haven't been into a tractor transmission yet and this write-up looks extremely helpful.

I really wish we had a "Stickies" section of the forum, so everyone could easily find this sort of thing later. Many members have done great write-ups like this that should be easy to find.

|

|

1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2012 at 11:52am Posted: 14 Jan 2012 at 11:52am |

It would be nice to be able to categorize some of the post on this forum so you could find them in the archives later, maybe by main categories: ie; engines, transmissions, clutches, electrical etc. and then break it down into sub categories even if it is broad for instance all D series tractors, W series or maybe even broader by years like 1930 to 1950 or whatever. This wouldn't need to be done for all post, but the ones that relate to specific areas of interest that would help a member solve a problem or do a specific task. At the same time I have ran several websites myself and know that it is very time consuming to make modifications etc. Especially for those that operate primarily on donations. As soon as I finish the final on this thread I plan on starting one to help others get motivated to make a donation and keep this great forum going. Breaks over....time to see if I can put two halves together and make a whole tractor again. More later... Tim

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

pre64

Bronze Level

Joined: 04 Oct 2010

Location: Cable OH

Points: 34

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2012 at 8:11pm Posted: 15 Jan 2012 at 8:11pm |

The tractor is back together now and everything works as it should. Other than a little more painting and some finishing touches it is done. Once it is all done I will post a final picture of it. I want to thank all that helped on this. This is a great forum! Not sure what will be next, but maybe another D17. It needs an engine over haul. Tim

|

|

Coming up in the near future: another D17, 2-B's,WC styled, WC unstyled,2 snap coupler 3 bottom plows, pull type shredder,and 2 belly mowers.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

SteveM C/IL wrote:

SteveM C/IL wrote: