| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis Chalmers G, brakes and transmission Topic: Allis Chalmers G, brakes and transmission

Posted: 21 Jan 2012 at 8:51pm |

Hello, it's been a while since I've visited. I'm working on a repair of the brake system on one of two G tractors that we own (we currently use both for cultivation, and repairing mid summer is not a good option).

The brakes on this tractor have become increasingly ineffective, to the point of worry. I tightened up the yoke on the end of both brake rods mid summer, to the point where the threads bottomed out on the yoke, thereby shortening the rods to the greatest possible extent, but it didn't do much to improve braking action. I put it on my list to repair during the winter months.

Now I'm into it, and what I've discovered (at least on the left side) is that the brake shoes are covered in oil, which is apparently leaking past the oil seal at the differential bearing carrier and into the axle housing area, where it looks like the oil has combined with dirt and dust to form a sludge which has more or less plugged up the drain holes, and possibly caused the brake problem. It makes sense to me now that the brakes would be ineffective.

Here is a picture of the brake area, with the shoes removed. You can see the oil seal in the center, which is apparently damaged:

Several years ago, I had basically rebuilt the transmission of this tractor, because one of the teeth on the second gear of the transmission had broken off. I found the tooth, and was able to replace the gear. But, I never found the reason why the tooth broke off in the first place. Using my farm shop style tools and methods (I don't have a machine shop), I did what I could to check the shaft for eccentricities, but again, found nothing. In the process of rebuilding the tranny, I believe I replaced the seal which is featured in the picture above. Maybe I did it wrong...

But, on a possibly related note, following the tranny rebuild, not immediately, but during the next growing season or two, when the tractor was put to use, guess what happened? The tooth broke off again in second gear...

And so this evening I have been wondering whether this problem with the transmission could possibly be related to some eccentricity in the axle. Seems unlikely to me, but the thought crossed my mind, as I didn't examine the axles during the tranny rebuild, and there is some limited evidence that the axle may be out of round - specifically, the wear pattern on the axle at the failed oil seal location is wider on one side of the axle than the other. If, hypothetically, the axle was not straight, could this cause the failure of the oil seal? Could it cause the failure of the second gear in the transmission?

And, one other question. Can the replacement of the oil seal be done from the outside, without having to separate the tractor? I can't remember.

Any suggestions or comments would be much appreciated. Thank you.

|

|

|

Sponsored Links

|

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2012 at 8:57pm Posted: 21 Jan 2012 at 8:57pm |

|

The axle could be bent enough to cause a problem.

|

|

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2012 at 9:04pm Posted: 21 Jan 2012 at 9:04pm |

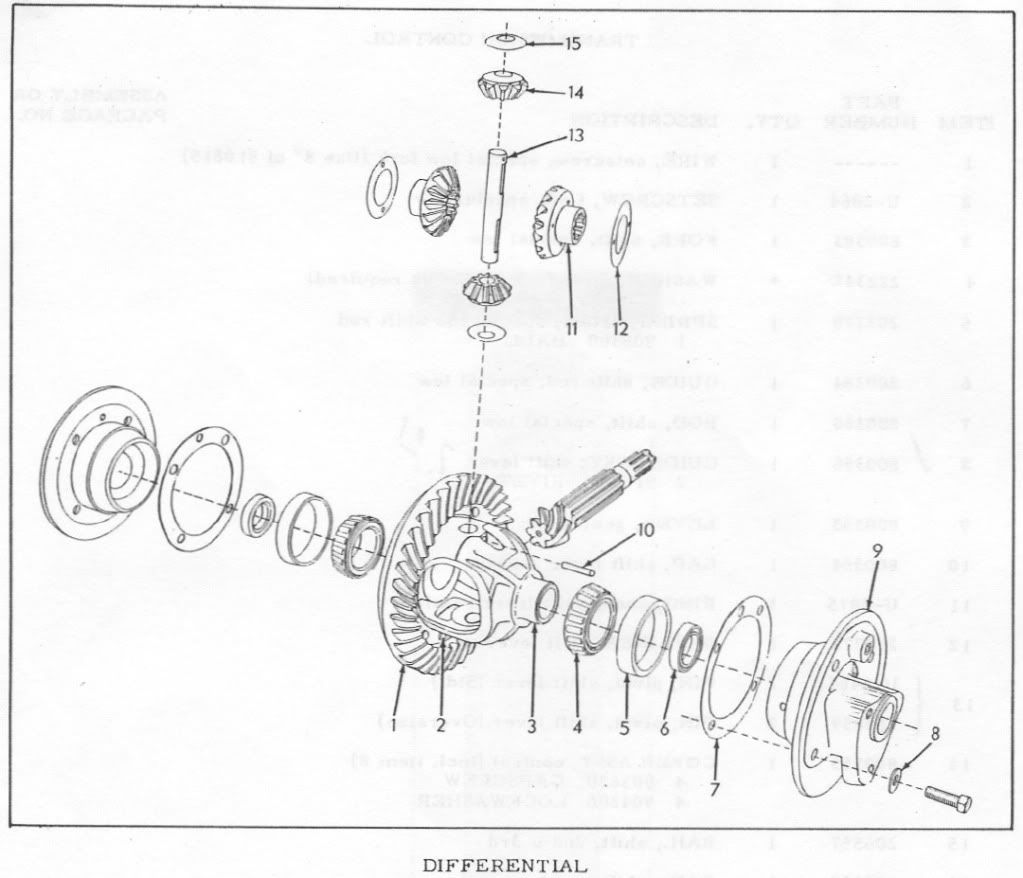

Here's the parts diagram for the Differential. I can see now that in order to replace the failed oil seal, I will need to remove the differential carrier (part 9), which is held in place with 4 cap screws. I think I'll have someone else press that in with a tool made for the purpose. If I remember correctly, I had used a large socket to do the job when I had done it myself. Must have goofed it up.

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2012 at 9:05pm Posted: 21 Jan 2012 at 9:05pm |

|

With the seal, or the tranny gear, or both?

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Jan 2012 at 9:14pm Posted: 21 Jan 2012 at 9:14pm |

|

I can't see how the axle shaft, if it were bent, could cause the problem with the second gear in the tranny. The differential carriers are bolted to the tranny housing, and thus fixed, and the carriers sandwich the differential and two roller bearings between them. If there is an eccentricity in the axle shaft, it doesn't seem probable that it could cause a significant eccentricity in the differential. But, I've been wrong before....

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:07am Posted: 22 Jan 2012 at 8:07am |

|

It's really hard to tell but it looks like the lip of the seal is facing the outside or away from the oil. That would be backwards and would make it hard to put the axle in without damaging the seal. A socket is a fine tool for installing a seal, the main thing is to put the lip facing the right direction(toward the fluid) and keep the seal "square " with the housing. Charlie

|

|

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:13am Posted: 22 Jan 2012 at 8:13am |

Alexander wrote: Alexander wrote:

I can't see how the axle shaft, if it were bent, could cause the problem with the second gear in the tranny. The differential carriers are bolted to the tranny housing, and thus fixed, and the carriers sandwich the differential and two roller bearings between them. If there is an eccentricity in the axle shaft, it doesn't seem probable that it could cause a significant eccentricity in the differential. But, I've been wrong before.... |

You're right,it wouldn't cause the gear problem in the tranny. It might cause a seal problem.

|

|

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:26am Posted: 22 Jan 2012 at 8:26am |

|

Charlie,

Thank you. I'll look at that seal this afternoon to see if I can tell whether perhaps I installed it backwards. Do you know of a diagram that shows the proper orientation?

Al

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:31am Posted: 22 Jan 2012 at 8:31am |

In the image below, the axle would be inserted from left to right, and the fluid (tranny) side would be on the right?

Edited by Alexander - 22 Jan 2012 at 8:32am

|

|

jaybmiller

Orange Level Access

Joined: 12 Sep 2009

Location: Greensville,Ont

Points: 24704

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:51am Posted: 22 Jan 2012 at 8:51am |

Yes, the clue is the text in the B column where 'extra rubber added to better seal the fluid side'

Also when you slide the axle in ,it gently rolls the rubber,then reseals.

|

|

3 D-14s,A-C forklift, B-112

Kubota BX23S lil' TOOT( The Other Orange Tractor)

Never burn your bridges, unless you can walk on water

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 8:52am Posted: 22 Jan 2012 at 8:52am |

|

Yep!!

|

|

|

|

JoeM(GA)

Orange Level

Joined: 12 Sep 2009

Location: Cumming,GA

Points: 4823

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 9:24am Posted: 22 Jan 2012 at 9:24am |

|

You've raised curiosity in me also with what broke the tooth twice. A real close look at the shaft support bearings is in order both on that shaft that the broken gear was on and the ones that the gear mates with is in order. As for the axle seal it truely looks to be in backwards. While apart, go ahead and check for wear grooves in the axle from 60+ years of wear. A "speedy-sleeve" may also be in order. When I had mine apart I went ahead and located seals that were half thickness and installed a pair in each housing. This doubled the sealing potential along with giving the seal a new place on the axle to ride. My only question with doing this is will the outer and always hopefully dry seal cause a new groove? I lubed the shaft and seals a bit hoping this might help. I guess my kids will find out in another 60 years if I was right or wrong!

Let us all know what you discover on the gear

|

|

Allis Express North Georgia

41 WC,48 UC Cane,7-G's,

Ford 345C TLB

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 4:40pm Posted: 22 Jan 2012 at 4:40pm |

Charlie and Joe,

Thanks for noticing about the oil seal. You were correct, it was installed backwards. Here is a picture of the inside of the differential bearing carrier, just after removing it from the differential case. I wasn't able to identify through the differential opening which gear was broken, and the shaft it was on, so I'm going to look up my purchase history to see if I can identify which part I purchased last time. I much appreciate the assistance, gentlemen.

Al Thorp

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Jan 2012 at 10:11pm Posted: 22 Jan 2012 at 10:11pm |

My invoice indicates that the part that I purchased from Wengers in 2007 when I performed the previous work on the tranny was part number 203210 "AC 2ND & 3RD GEAR 30T". Some additional details on this page: http://www.wengers.com/parts/Farm-Tractor-Parts/Allis-Chalmers/B/B/Transmission/Sub-Component/GEAR-2ND---3RD-SLIDING/01-203210.htm I'm not sure if its significant, but the Wengers part number does not seem to match the part number shown in the Model G Dealer Repair Parts Catalog dated August 1954.

A diagram from that catalog is shown below. I believe the part in question is identified as number 37, and the accompanying list (not shown) identifies it as part number 206542 "GEAR, sliding pinion shaft, 2nd & 3rd (30T)". I will call Wengers tomorrow to confirm that these are interchangeable part numbers.

In any case, for the moment, I would like to follow up on Joe's suggestion to check the shaft support bearings. If I understand it correctly, Joe, you're suggesting that I examine the condition of the bearings which support the pinion shaft (numbers 33 and 41) on which the failed gear slides, and also the condition of the pair of cone bearings supporting the main shaft (number 22). What sort of evidence might you be looking for in a case like this? I should mention that I did clean and examine these bearings during the previous effort, and didn't find anything which looked suspicious ( I know, that's not saying much, given that I put the oil seals in backwards!).

I'm wondering what portion of the examination could be done without having to take the transmission apart again? It was a rather big effort as I recall....Any suggestions on what sort of tests I could perform before committing to do that job?

Thanks for all the help and suggestions!

Edited by Alexander - 22 Jan 2012 at 10:14pm

|

|

Matt (Jordan,MN)

Orange Level

Joined: 12 Sep 2009

Location: Jordan, MN

Points: 3802

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 2:06am Posted: 23 Jan 2012 at 2:06am |

|

The part number for the gear in question is 206542. The number that is casted or stamped in the gear is 203210. I don't know why but the casting number and part number was never the same but they are the same part. I have any part you would need for the transmisson. Matt

|

|

CTuckerNWIL

Orange Level

Joined: 11 Sep 2009

Location: NW Illinois

Points: 22825

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 7:03am Posted: 23 Jan 2012 at 7:03am |

|

If the Timken bearings that carry the pinion shaft aren't set right, you would have excess backlash from the pinion to the ring gear and front to back end play.That would be hard on the ring and pinion I would think.

|

|

|

|

Dnoym N. S. Can.

Orange Level Access

Joined: 03 Oct 2009

Points: 544

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 7:12am Posted: 23 Jan 2012 at 7:12am |

|

Alex this may not be of any help

but to me the bolt`s in the top

picture look like there were lose

because the lock washer top left

look like it`s not flat and the tarnish

look to be all shine up the one on

the right is shine up a little as well

did you find them easy to come out ?

it mite just be me but i`am sure

someone else mite know better

HTH

B:-) dnoym

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 11:41am Posted: 23 Jan 2012 at 11:41am |

Dnoym,

Thanks for noticing, but that picture was taken after I had loosened the bolts. I believe they had been properly torqued upon last assembly, and were not unusually easy to remove, and thus I think can be ruled out as a potential cause of the problem.

Al

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 11:43am Posted: 23 Jan 2012 at 11:43am |

Charlie,

Thanks for the help. If the Timken bearings were not set right, and there was excessive backlash, would that be a potential cause of the failure of the tooth on the 2-3 pinion gear previously identified?

Al

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 11:53am Posted: 23 Jan 2012 at 11:53am |

|

I'm going to remove the side plate on the right side of the transmission, just below the shift lever, and see what I can see. I'm thinking that with the rear wheels off the ground (right side is still attached), I might be able to rotate the transmission shafts through multiple revolutions to see if I can see any evidence of eccentricities in the shafts. I'll also take a close up picture of the broken tooth. Maybe someone would be able to identify from what direction the load came which caused the failure...I'll post again soon. Thank you, all!

Edited by Alexander - 23 Jan 2012 at 11:53am

|

|

Alexander

Bronze Level

Joined: 23 Jun 2011

Points: 24

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 10:48pm Posted: 23 Jan 2012 at 10:48pm |

Well, after taking off the battery, side plate, etc. I was able to find the gear from which the tooth had broken off. Below is a picture of the gear, with the tooth missing at the end of my finger.

I was not able to find the tooth itself.....

I didn't see it while I was in the shop this evening, but I'm seeing it now. The next tooth down from the one that had broken off looks worn, doesn't it? Is there anything about the wear pattern that would suggest what's causing this problem?

Also, I wasn't able to turn either the main shaft or the pinion shaft, despite the fact that both rear wheels have been removed...Maybe that's because the clutch is engaged? (I took off the clutch rod in order to remove the left axle housing). If the clutch is engaged, would putting the tranny in neutral allow me to spin the main and pinion shafts?

Edited by Alexander - 23 Jan 2012 at 10:54pm

|

|

GlenninPA

Orange Level

Joined: 11 Sep 2009

Location: Ashley, PA

Points: 5054

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jan 2012 at 11:05pm Posted: 23 Jan 2012 at 11:05pm |

Alexander wrote: Alexander wrote:

Also, I wasn't able to turn either the main shaft or the pinion shaft, despite the fact that both rear wheels have been removed...Maybe that's because the clutch is engaged? (I took off the clutch rod in order to remove the left axle housing). If the clutch is engaged, would putting the tranny in neutral allow me to spin the main and pinion shafts?

|

Unless that MIA tooth is jammed between two gears.....

Edited by GlenninPA - 23 Jan 2012 at 11:06pm

|

|

Good judgment comes from experience. Experience comes from bad judgment.

From listening comes wisdom and from speaking comes repentance.

Wise men learn more from fools than fools from the wise.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Alexander wrote:

Alexander wrote: