| Author |

Topic Search Topic Search  Topic Options Topic Options

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Allis B sleeve oring Topic: Allis B sleeve oring

Posted: 11 Jan 2020 at 2:23pm |

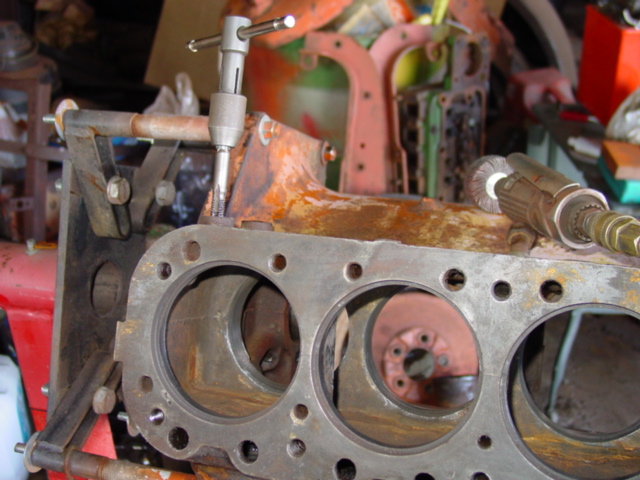

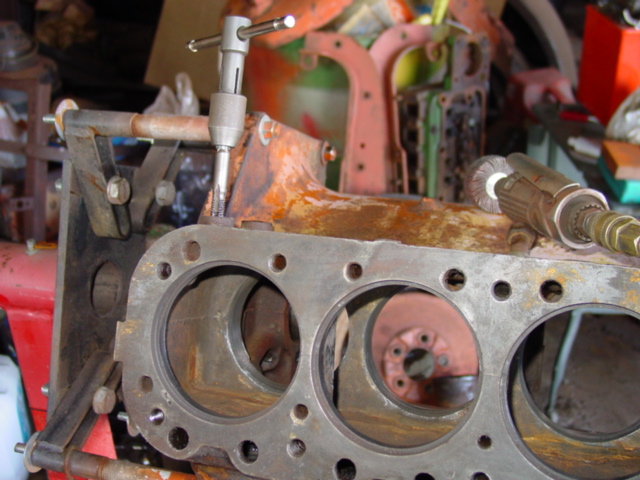

I started this project of repairing my old 1940 allis B because it was leaking rad fluid into the oil. Soon found the sleeve O-rings to be leaking. OK so I commence to tear the engine down and fix/repair what needs to be fixed and repaired with a lot of help from this forum. Much thanks. Today I had some time to install my new sleeves and while cleaning the block webbing where the sleeve o-ring would seat I notice somewhat massive corrosion on the surface where the O-ring's may be seated. My question is by looking at the pics do you think this is a issue? is there a product I can use to build this area up. I suppose I could do an exact measurement to see exactly where the o-ring surface should be but looking at the groove in the sleeve there is a lot of movement for the o-ring. I guess I am looking for some advise from the experienced.

Edited by gman54313 - 11 Jan 2020 at 2:24pm

|

|

|

Sponsored Links

|

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 2:25pm Posted: 11 Jan 2020 at 2:25pm |

|

I should mention all four holes look pretty much the same.

Edited by gman54313 - 11 Jan 2020 at 2:25pm

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 4:31pm Posted: 11 Jan 2020 at 4:31pm |

|

Pitting doesn't look that bad in the pic. Should be able to install new o-rings and run it. I've used Devcon, which is a liquid steel similar to JB Weld, to fill pits. If they get real bad a machine shop can bore the block and install a new lower deck.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 8:40pm Posted: 11 Jan 2020 at 8:40pm |

|

Thanks boss man do you have any idea of the temp. inside the block? The devcon I looked at says 250 F is this the same devcon you used to fill in.

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 9:02pm Posted: 11 Jan 2020 at 9:02pm |

|

Do you all see the pictures I see? Looks like a cylinder head with one valve removed. Or M I loosen it? MACK

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 9:59pm Posted: 11 Jan 2020 at 9:59pm |

|

Mack, it sure looked like a burnt valve but it can't be because it's the block and not the head. Wonder if there is a timing issue?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 21905

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 11 Jan 2020 at 10:24pm Posted: 11 Jan 2020 at 10:24pm |

|

The temperature of those O-rings should pretty much be whatever the coolant is...…….160 to 180 degrees F.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 7:14am Posted: 12 Jan 2020 at 7:14am |

If you can put the sleeves all the way down and rotate them 360 degrees by hand you can fill the voids with bondo or JB weld and sand/ flapper wheel back to where you can again rotate the sleeves 360 degrees. It looks very clean but does not look like it has been flapper wheel sanded.

Edited by Dick L - 12 Jan 2020 at 7:18am

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 7:15am Posted: 12 Jan 2020 at 7:15am |

MACK wrote: MACK wrote:

Do you all see the pictures I see? Looks like a cylinder head with one valve removed. Or M I loosen it? MACK |

I see a upper deck with the counter bore, the lower deck with the next sleeve exposed. Not sure how you're getting valves. Need a bigger screen maybe? lol

|

|

Boss Man

Orange Level

Joined: 03 Mar 2018

Location: Greenleaf, WI

Points: 617

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 7:16am Posted: 12 Jan 2020 at 7:16am |

gman54313 wrote: gman54313 wrote:

Thanks boss man do you have any idea of the temp. inside the block? The devcon I looked at says 250 F is this the same devcon you used to fill in. |

Been a few years, but it sounds right. Like Doc said temp should be about the same as the water.

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8522

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 9:55am Posted: 12 Jan 2020 at 9:55am |

gman, To me the block looks very very clean! Nice work. (Mack ,I also see a block with the sleeve removed.) I must admit that I am not a good judge of the corrosion vs sealing, but from the pictures I might use the recommended sealer and fill those voids. sand smooth. You will probably sleep better at night. Thanks for the update on your B! Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

IBWD MIke

Orange Level

Joined: 08 Apr 2012

Location: Newton Ia.

Points: 4087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 10:03am Posted: 12 Jan 2020 at 10:03am |

MACK, bit of an optical illusion. I saw the same thing until I studied it awhile.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 11:41am Posted: 12 Jan 2020 at 11:41am |

|

The rough edge of the chamfer could very well tear the O ring going in. That should all be smooth. The sleeve does not want to be tight going in without the O rings.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 11:50am Posted: 12 Jan 2020 at 11:50am |

DrAllis wrote: DrAllis wrote:

The temperature of those O-rings should pretty much be whatever the coolant is...…….160 to 180 degrees F. |

You put wet sleeves in at 160 to 180 degrees? I never had a problem removing them from the pack and installing them at the room temperature I was working in at the time be it winter or summer..

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8628

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 3:09pm Posted: 12 Jan 2020 at 3:09pm |

|

LOL! First MACK,then Dick. You guys are loosing it! Doc was referring to what temp the repair patching mat'l needed to stand,nothing about installing temp.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 5:40pm Posted: 12 Jan 2020 at 5:40pm |

|

Thanks to everyone for their input and recommendations. This afternoon I fired up the propane heater in my garage and mixed up some JB weld and applied to the surface to fill in the rough surface. I will let it cure and take the round flapper sander to it and refit my sleeves. Incidentally I had all four sleeves fitting in the block nicely and was able to rotate them 360 degrees very easily. I will just have to re-sand the JB weld to get them to fit again, but as mentioned earlier I will sleep better.

Cheers

Greg AKA Gman

|

|

MACK

Orange Level

Joined: 17 Nov 2009

Points: 7664

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 9:09pm Posted: 12 Jan 2020 at 9:09pm |

|

The JB weld will not stay in the groves. If it don't fall out when you smooth the surface, it will later. MACK

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8522

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Jan 2020 at 9:21pm Posted: 12 Jan 2020 at 9:21pm |

Greg, MACK and others have way more experience than I do. I would at this point be pondering my next moves?? I have done these same things. I move out on something that I think is right and along comes a different idea. From what you have said and done you will get through this issue! Your work fitting the sleeves and checking the fits is right on. Good job! Its a lot of cleaning to get them to fit and seat properly. I had a question. The inside to your water chamber (block) looks way cleaner than the ones I have seen. Anything special you did in there? Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2020 at 7:28am Posted: 13 Jan 2020 at 7:28am |

|

Chris,

the water chamber was basically flushed and air blown I was amazed at how rough the casting is but I guess that's the way it was 80 years ago.

Greg

|

|

Fred in Pa

Orange Level

Joined: 13 Sep 2009

Location: Hanover Pa.

Points: 9210

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2020 at 11:42am Posted: 13 Jan 2020 at 11:42am |

HYLOMAR gasket sealer n maker . Do a search on it and get the correct type u need for ORINGS n LIGUIDS . Used it for over 30 years it works if you use it correct way on the gas engine . Diesels I always do repair sleeves in bottom if ate out to bad .

|

|

He who dies with the most toys is,

nonetheless ,still dead.

If all else fails ,Read all that is PRINTED.

|

|

Dick L

Orange Level

Joined: 12 Sep 2009

Location: Edon Ohio

Points: 5087

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2020 at 4:29pm Posted: 13 Jan 2020 at 4:29pm |

|

The Oliver Company sent a bulletin to all there dealer in the 1960's to use bondo to repair the bottom bore. This was when they were having a problem with deep eating out of the top of the bore. Uncle owned an Oliver dealership and I was installing new sleeves and ask him if the block needed to be replaced. I personally have not seen an Allis block eat out as bad as a couple Oliver blocks I worked on. I have also used JB weld on both Allis blocks and an Oliver block with out a problem. I am sure they're several other types that will work just as well. These happen to be two I have used without any problems.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2020 at 9:19pm Posted: 13 Jan 2020 at 9:19pm |

|

Fred,

Thank you for your feedback I went to Hylomar's website and I think the Hylomar RED 100 is the right product, but I will call them tomorrow to make sure.

Thanks

Greg

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Jan 2020 at 9:23pm Posted: 13 Jan 2020 at 9:23pm |

|

Dick L.

Thank you for your feedback. I asked my machinist today what he would use and he told me JB or similar. I am interested in the Hylomar red 100 this might be an option if when I sand out the JB if it falls out.

Thanks

Greg

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8628

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2020 at 1:55pm Posted: 14 Jan 2020 at 1:55pm |

|

Belzona dealer told me their product was under Cat part# used to "repair" counter bores.

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 9888

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Jan 2020 at 6:37pm Posted: 14 Jan 2020 at 6:37pm |

I have used Belzona Super Metal to do many counter bores. My dad and I did our 180 diesel back in the mid 80's. Still working great with no leakage.

|

|

gman54313

Silver Level

Joined: 23 Nov 2019

Location: Green Bay WI

Points: 66

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Jan 2020 at 8:55pm Posted: 15 Jan 2020 at 8:55pm |

|

Fred,

I managed to contact the Hylomar customer service and after 10 minutes of detailed information of what I was looking for Hylomar recommended the Hylomar RED 100. Thank you for the tip

greg

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

MACK wrote:

MACK wrote: