| Author |

Topic Search Topic Search  Topic Options Topic Options

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 892

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: AC Letter Series Comparison Topic: AC Letter Series Comparison

Posted: 25 Nov 2023 at 2:18pm |

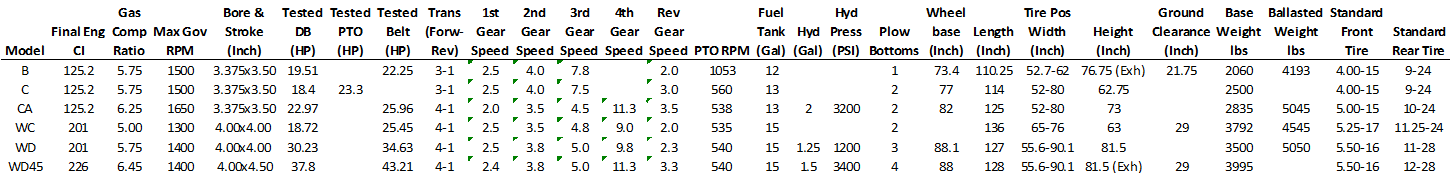

I was bored today so I put together a little comparison spreadsheet...

Mostly from tractordata.com. I know there are errors and measurement method issues for some items. I just find it messy to try to compare with the tractordata.com data format.

Don't really know what the ballasted weight means. Is that the max you should reasonably be able to achieve or max used for a particular pulling test?

Edited by dfwallis - 25 Nov 2023 at 2:32pm

|

|

|

Sponsored Links

|

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5250

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2023 at 2:55pm Posted: 25 Nov 2023 at 2:55pm |

|

My guess would be weight achieved once fluid was added to the rear tires? I’m sure there is a formula for tire and rim size for the amount of gallons each tire would hold. I’m not sure what that is though? Did they add fluid at the Nebraska proving grounds?

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 892

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2023 at 7:33pm Posted: 25 Nov 2023 at 7:33pm |

AC720Man wrote: AC720Man wrote:

My guess would be weight achieved once fluid was added to the rear tires? I’m sure there is a formula for tire and rim size for the amount of gallons each tire would hold. I’m not sure what that is though? Did they add fluid at the Nebraska proving grounds? |

I don't think it can only refer to tire ballast. For the CA, my 13.6x24 tires would hold a max of 400lbs each at 75% fill. That would only get it up to 3635lbs. And I doubt any of the Nebraska tests had 13.6 tires installed.

Edited by dfwallis - 25 Nov 2023 at 7:43pm

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 88653

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Nov 2023 at 8:22pm Posted: 25 Nov 2023 at 8:22pm |

ballast weight is normally the weight of a machine plus additional weights added so that you can get the max draw bar horsepower at a given ground speed.... probably determined to get the most WORK out of the machine...with a fixed amount of wheel SLIP... Normally that is about 130 pound per HP for a tractor...

so a 20 HP at the drawbar should be loaded to weigh 2600 pounds.... and a 40 HP tractor should be loaded to weigh twice that or 5200 pounds....... but that does not seem to jive with the above chart....

also this should be at a GIVEN ground speed... that could be a fixed 3 MPH, or it could be what ever ground speed you can get in 1st gear at the max drawbar HP point on a curve.

Edited by steve(ill) - 25 Nov 2023 at 8:23pm

|

|

Like them all, but love the "B"s.

|

|

jvin248

Silver Level

Joined: 17 Jan 2022

Location: Detroit

Points: 482

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2023 at 6:58pm Posted: 02 Dec 2023 at 6:58pm |

.

How accurate are the plow bottoms?

Bottom cut width and soil type, what are the typical standards?

I have a 52 WD, mostly clay, and curious what plows I should watch for or avoid.

.

|

|

dfwallis

Orange Level

Joined: 09 Mar 2023

Location: DFW

Points: 892

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Dec 2023 at 8:06pm Posted: 02 Dec 2023 at 8:06pm |

jvin248 wrote: jvin248 wrote:

.

How accurate are the plow bottoms?

Bottom cut width and soil type, what are the typical standards?

I have a 52 WD, mostly clay, and curious what plows I should watch for or avoid.

.

|

I can't personally say for sure. A CA can handle a 3-14 in good conditions. I used to plow even in some areas with tree roots with the CA (with overbore kit so tiny HP increase over stock) and a 2-14 without too much difficulty. I think a WD was billed as a solid 3 bottom capable tractor. So I'd say 3-14 in good condition, properly adjusted and traction booster properly adjusted, necessary ballast, should be able to handle just about any soil type. I've seen various specs from 5-8 HP per bottom for the 50 and 60 series plows (and one source as high as 13HP)

Edited by dfwallis - 02 Dec 2023 at 8:52pm

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

AC720Man wrote:

AC720Man wrote: