| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 8050 670I main bearing issues Topic: 8050 670I main bearing issues

Posted: 25 Jan 2025 at 3:04pm |

|

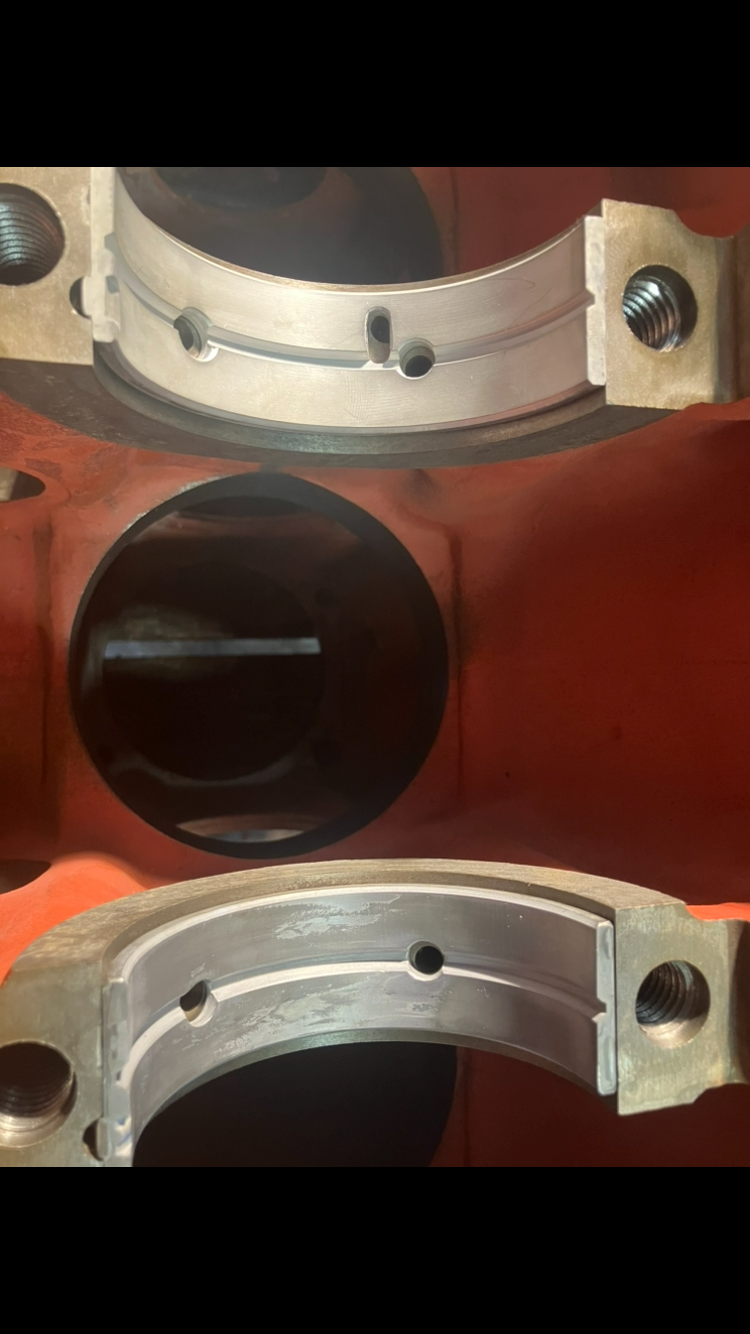

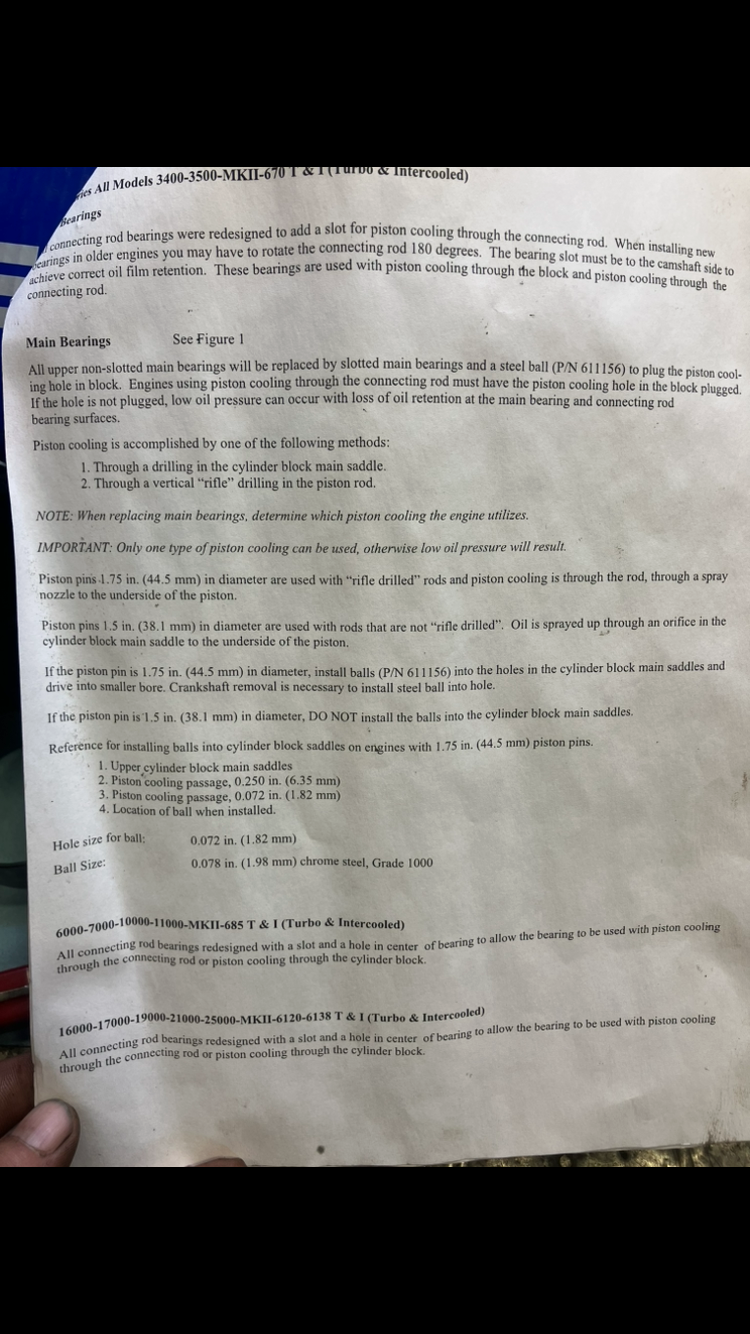

Complete out of frame overhaul on my 8050. Long story short due to an injector failure on number three piston it cooked the piston and wrist pin bushing and cracked the block deck and the crack went down and followed the counter bore, block is junk. Using a 670T block but it has the piston cooling jets in the web where as the 670I has the piston cooling jets in the top of the rod as the wrist pins are pressure oiled.

Reliance kit was all I could source and all their main bearings have the slot for main bearing piston cooling where the Clevite bearings from a previous inframe do not. Reliance supplies 6 steel balls to drive in the main bearing piston cooling orifices, which went in fine on mains 1-5, however main 6 for piston 6 Allis Chalmers has drilled the orifice too deep leaving barely a ridge for an orifice and the steel ball drops right in and there is no material to drive it down into to keep it in place. What would be the best solution? I don't have any hardened steel balls the correct diameter for the small hole that is there, and don't really like the idea of drilling it out to fit. A 3/32 drill bit fits loose and a 7/64 won't go in. I do have some brass and bronze bushing stock, I could turn up a plug the correct size and drive that in which is what I'm leaning towards. Does Clevite/Mahle still have main and rod bearings available without the piston cooling slots? Agco? The cam bearings I sourced are Mahle and not Reliance but I have a feeling that even Mahle mains would have the oil slot.

I've got pictures but it won't bring up the upload page to post them

Edited by Dave7060 - 25 Jan 2025 at 3:05pm

|

|

|

Sponsored Links

|

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2025 at 3:08pm Posted: 25 Jan 2025 at 3:08pm |

|

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2025 at 3:09pm Posted: 25 Jan 2025 at 3:09pm |

|

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2025 at 3:10pm Posted: 25 Jan 2025 at 3:10pm |

|

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2025 at 3:10pm Posted: 25 Jan 2025 at 3:10pm |

|

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8684

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jan 2025 at 9:45pm Posted: 25 Jan 2025 at 9:45pm |

|

Welcome to the club. How hard would it be to make both bearings? To my knowledge you can NOT buy unslotted bearings. How good are you old uppers? Reuse them with new lowers? At least you have the crank out. Doing inframe don't give you a choice. My dual cooled 8070 runs 45psi hot and loaded at full throttle with 15w40. You could plug 5 and go but since you're there I'd figure out a way to plug 6.

|

|

NEVER green

Orange Level Access

Joined: 28 Feb 2013

Location: MN.

Points: 8703

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Jan 2025 at 8:27am Posted: 26 Jan 2025 at 8:27am |

Fill it with JB weld, the bearing partially covers the hole so it wont fall out, or tap it for one of them allen wrench plugs.

|

|

2-8050 1-7080 6080 D-19 modelE & A 7040 R50

|

|

Dave7060

Bronze Level

Joined: 12 Nov 2009

Points: 184

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Feb 2025 at 9:21am Posted: 03 Feb 2025 at 9:21am |

|

I had thought about using the old uppers but really didn't want to start mix and matching bearings, especially since the new mains all plastigauged at .003". I ended up drilling and tapping part way for an 8-32 set screw, then before putting the set screw in the last time I gave the threads a smack with a hammer, slathered on the locktight and wound it in till it got tight in the partial threads from the tip of the tap. Then I staked the top of the threaded hole with a punch. If that won't keep that set screw in nothing will and I'll put a 516 in it.

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)