| Author |

Topic Search Topic Search  Topic Options Topic Options

|

Northern Hoser

Bronze Level

Joined: 19 Feb 2020

Location: Canada

Points: 125

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 8030 MFD knuckle pin removal Topic: 8030 MFD knuckle pin removal

Posted: 25 Jun 2023 at 6:16pm |

Before I start making a mess, is there a trick to pulling the king pins out of the knuckle?  Thanks! Matt

|

|

|

Sponsored Links

|

|

|

ryan(IN)

Orange Level

Joined: 11 Sep 2009

Location: Bluffton,IN

Points: 790

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2023 at 6:26pm Posted: 25 Jun 2023 at 6:26pm |

|

There is a puller for those. Threads in the grease zerk and pulls the pin out.

|

|

ryan

1984 8070 FWA,1979 7060,1975 7040,1971 190,1960 D-17D,1957 D-14, 196? D-19G, 1975 5040,1971? 160,1994 R62

|

|

8070nc

Orange Level Access

Joined: 21 Mar 2019

Location: North Carolina

Points: 649

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2023 at 6:30pm Posted: 25 Jun 2023 at 6:30pm |

|

Take the grease fitting out. Its metric. Determine the size and thread pitch

Get a threaded rod that size and cut a piecce long enough to go through a socket that is bigger than the pin so that it is against the knuckle. Good grade threaded rod is better. With a nut and washers on the rod screwed into the pin the socket gives you a hollw place to pull the pin out. May have to use a little heat on thee knuckle

Ive got to replace mine too

|

|

1984 80780

1957 D14

DES 300 with 25000 engine

616 tractor

|

|

Northern Hoser

Bronze Level

Joined: 19 Feb 2020

Location: Canada

Points: 125

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Jun 2023 at 8:15pm Posted: 25 Jun 2023 at 8:15pm |

|

Fantastic! Thank you all!

Hopefully she's not rusted too bad

Matt

|

|

Ron(AB)

Orange Level

Joined: 27 Dec 2009

Location: Alberta

Points: 962

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jun 2023 at 12:24am Posted: 27 Jun 2023 at 12:24am |

|

I think there is another way...take out the grease nipple, then weld a nut over top (3/8- 1/2"), thread a rod into it, put a piece of pipe over it then a thick washer or two, then a nut, and tighten it and it pulls upward.

Grind off the welds when its out.

Been a while since I've done it but there was pics on here a few years back.

|

|

405, 7000, 7050, 8050, 8070, L3, 2300 & 2600 disk

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22181

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 27 Jun 2023 at 5:41am Posted: 27 Jun 2023 at 5:41am |

|

Chances are good the pin will be worn and need replacement anyway.

|

|

Northern Hoser

Bronze Level

Joined: 19 Feb 2020

Location: Canada

Points: 125

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2023 at 7:16pm Posted: 28 Jun 2023 at 7:16pm |

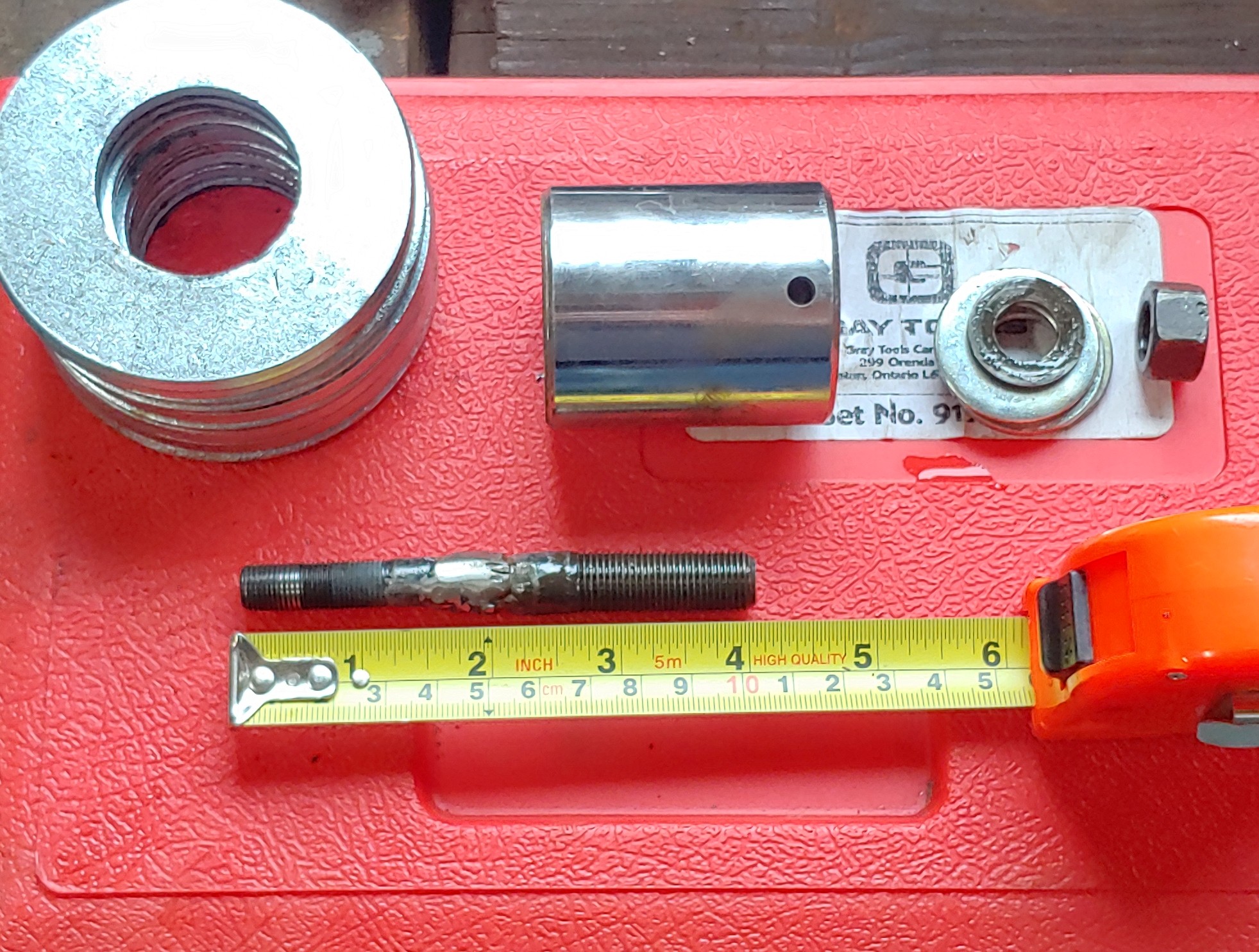

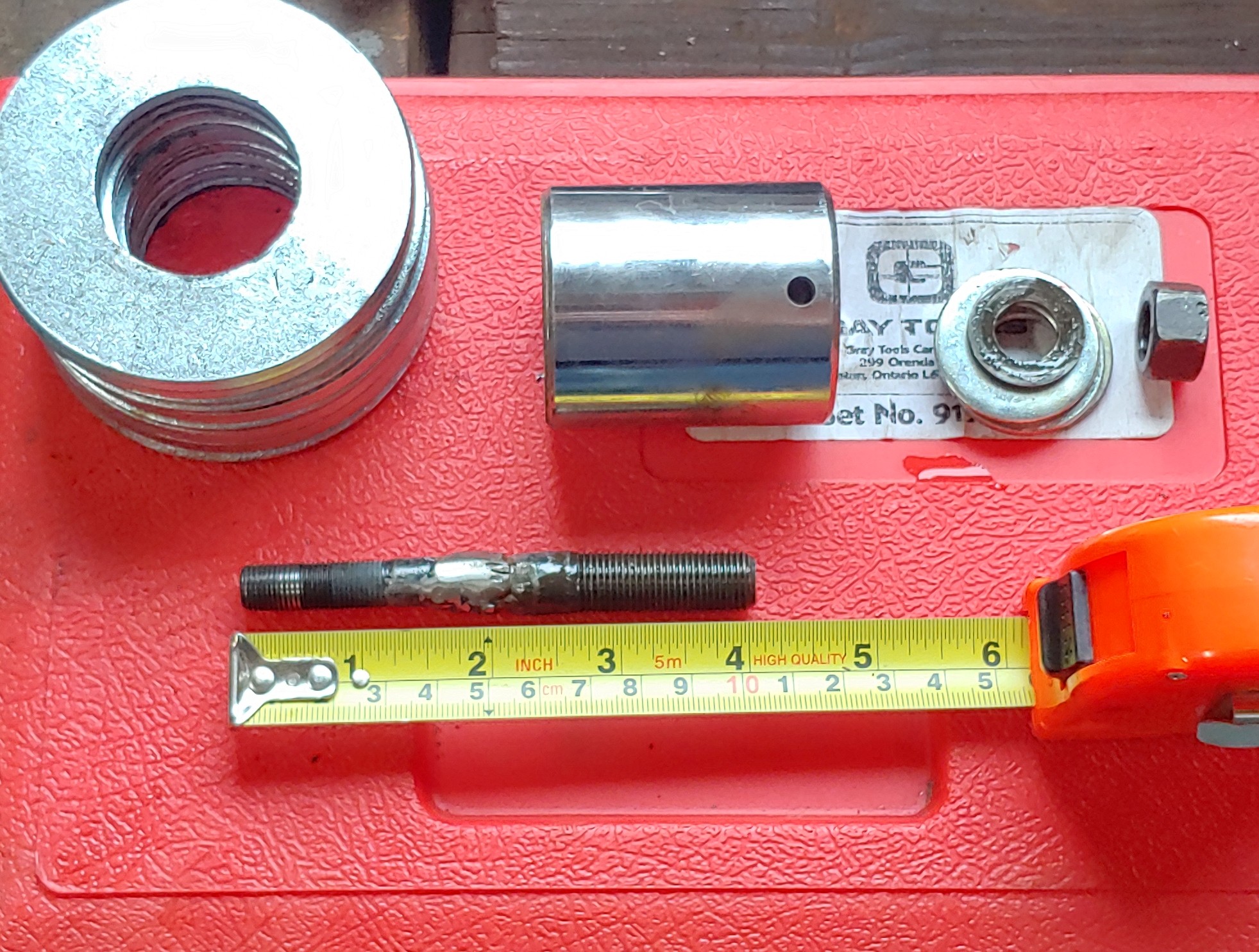

Pin internal threads for the puller are M10-1.0.. cut a bolt and welded a 1/2" fine thread to it. Worked good, kept stacking 1 1/2" washers under the socket as it came out. Pins actually in good shape. Bearing was screwed, cage half gone. Flushed the housing out can't see any metal anymore. Will change the other side now that I'm all set up to do it

|

|

Northern Hoser

Bronze Level

Joined: 19 Feb 2020

Location: Canada

Points: 125

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2023 at 7:23pm Posted: 28 Jun 2023 at 7:23pm |

|

Parts inside the axle rusted up a bit, tractor sat a lot before I got it. I suspect that helped take the bearing out.

I can see a little bit of the pinion through the drain hole and it doesn't look too great. No hardness flaking off that I can see but quite worn..

Has anyone rebuilt one of these recently? I'd rather pull it in the off season and rebuild it before it's a problem

Matt

|

|

BrianC

Orange Level Access

Joined: 16 Jun 2011

Location: New York

Points: 1619

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2023 at 7:47pm Posted: 28 Jun 2023 at 7:47pm |

Uhh, I looked up the parts cost from an Agco dealer. 4 pins and 4 bushings/bearings. About $1600. Aerospace prices.

|

|

ryan(IN)

Orange Level

Joined: 11 Sep 2009

Location: Bluffton,IN

Points: 790

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 Jun 2023 at 9:35pm Posted: 28 Jun 2023 at 9:35pm |

|

Pins,bearing, seals are gonna set you back about 2500-3000 for the whole front. We just did ours this spring. Ring and pinion from heitman is brand new and last I knew wanted about $4500

|

|

ryan

1984 8070 FWA,1979 7060,1975 7040,1971 190,1960 D-17D,1957 D-14, 196? D-19G, 1975 5040,1971? 160,1994 R62

|

|

Northern Hoser

Bronze Level

Joined: 19 Feb 2020

Location: Canada

Points: 125

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2023 at 7:43am Posted: 29 Jun 2023 at 7:43am |

|

Is Heitman the only source for a ring and pinion? I haven't checked AGCO myself.

It's all functional now, knuckle pins and bearings in good shape just the axle seals and bearings we're bad.

But if this stuff is hard to get I'll start making a parts pile for the inevitable differential rebuild in advance

Matt

|

|

ryan(IN)

Orange Level

Joined: 11 Sep 2009

Location: Bluffton,IN

Points: 790

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Jun 2023 at 8:00am Posted: 29 Jun 2023 at 8:00am |

|

Heitman is only place I know of. Hasn’t been available from agco for years

|

|

ryan

1984 8070 FWA,1979 7060,1975 7040,1971 190,1960 D-17D,1957 D-14, 196? D-19G, 1975 5040,1971? 160,1994 R62

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)