| Author |

Topic Search Topic Search  Topic Options Topic Options

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 7020 - Steering Hydraulic Cylinder Fix Topic: 7020 - Steering Hydraulic Cylinder Fix

Posted: 09 Aug 2024 at 3:50pm |

Have a bad leak on the hydraulic steering cylinder. I have bought the seal kit from agco and going to try it. Hope there isn't any major rod issues.

My only cylinder rebuild experience is that I have rebuilt the 4 cylinders on the 500 loader, buy maybe this cylinder is easier or harder? Any tricks to rebuilding this cylinder that I should know about?

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

|

Sponsored Links

|

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Aug 2024 at 6:17pm Posted: 09 Aug 2024 at 6:17pm |

|

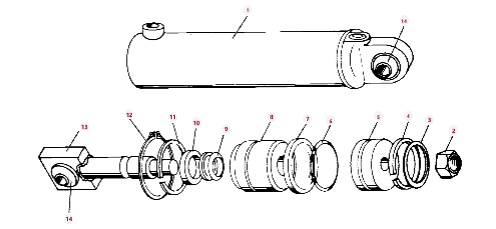

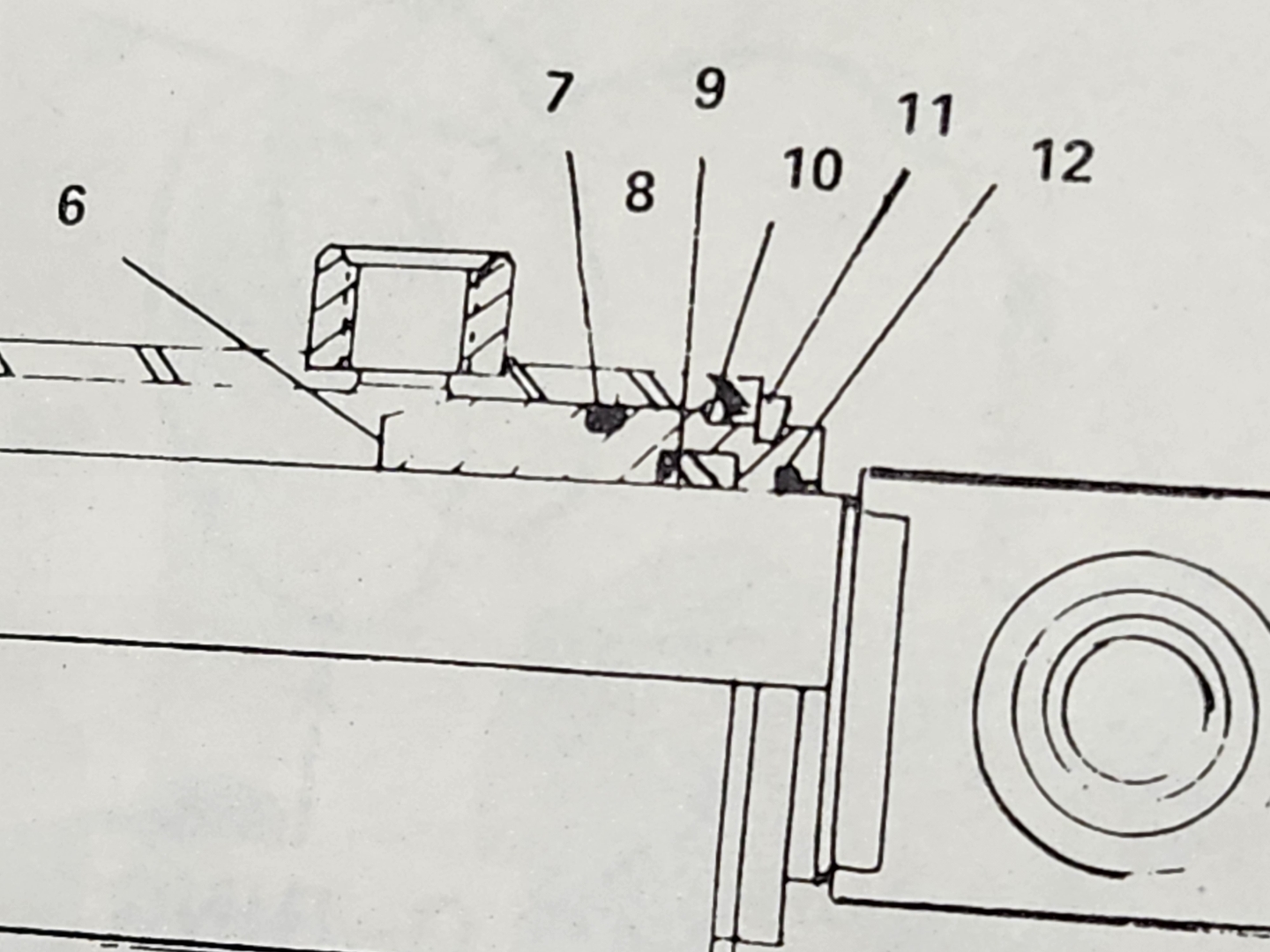

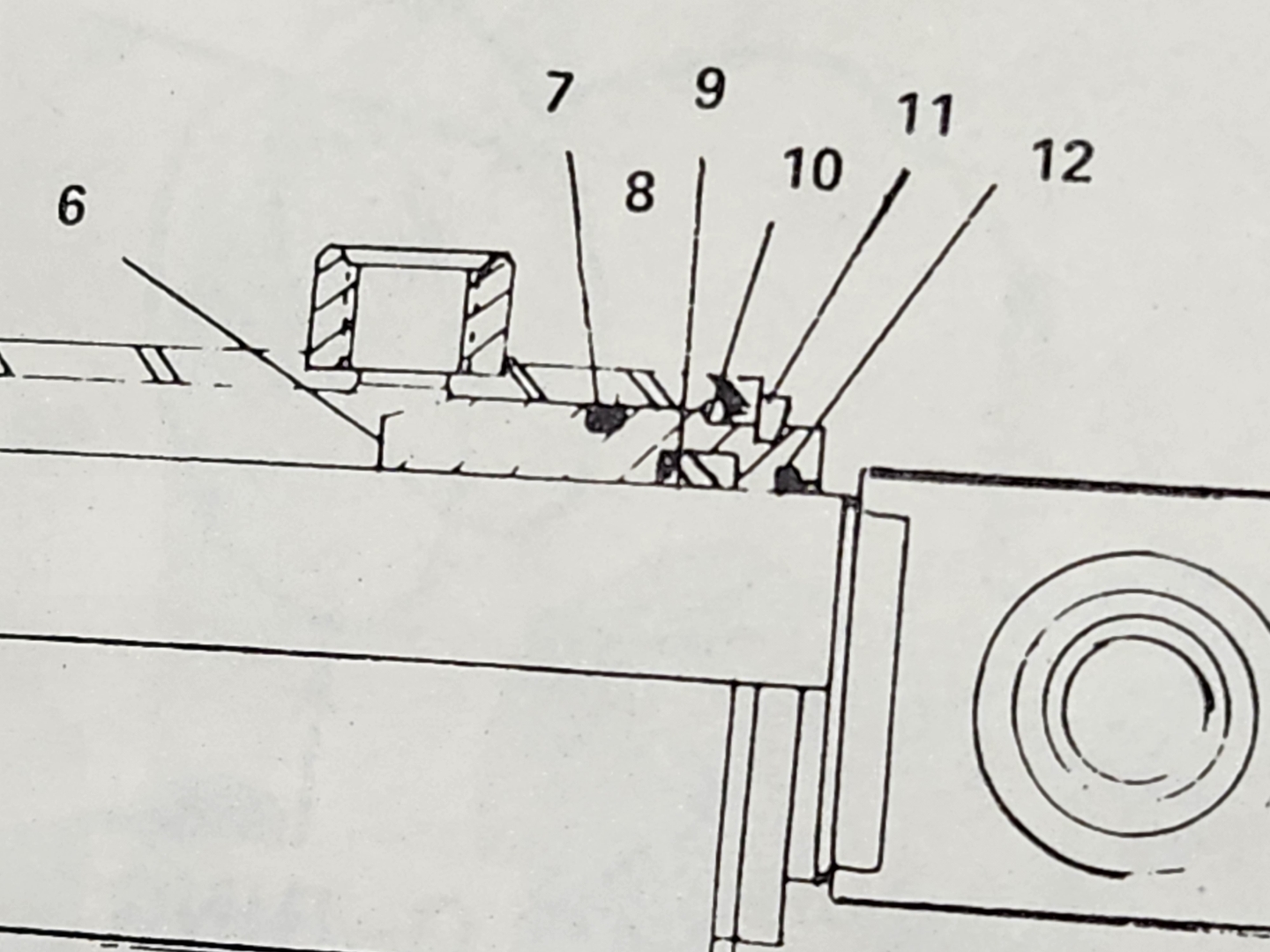

I took the retainer ring off, item 12, but I can't figure out how to pull the piston out? I don't see the snap ring they refer to which is item 11? I tried unscrewing it thinking it had threads and it just turns. So, no threads. Anyone know how does the piston come out?

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Aug 2024 at 6:23pm Posted: 09 Aug 2024 at 6:23pm |

|

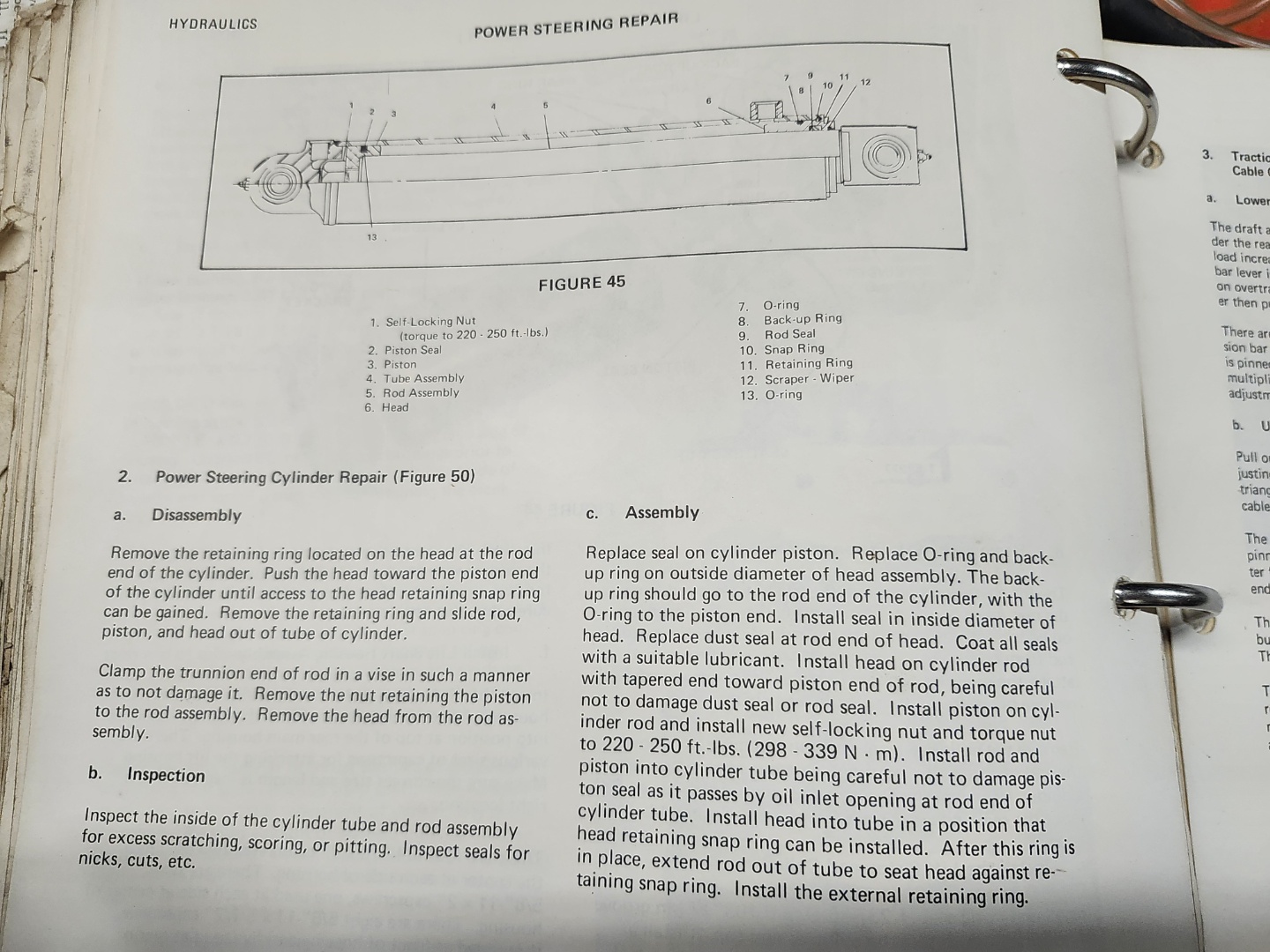

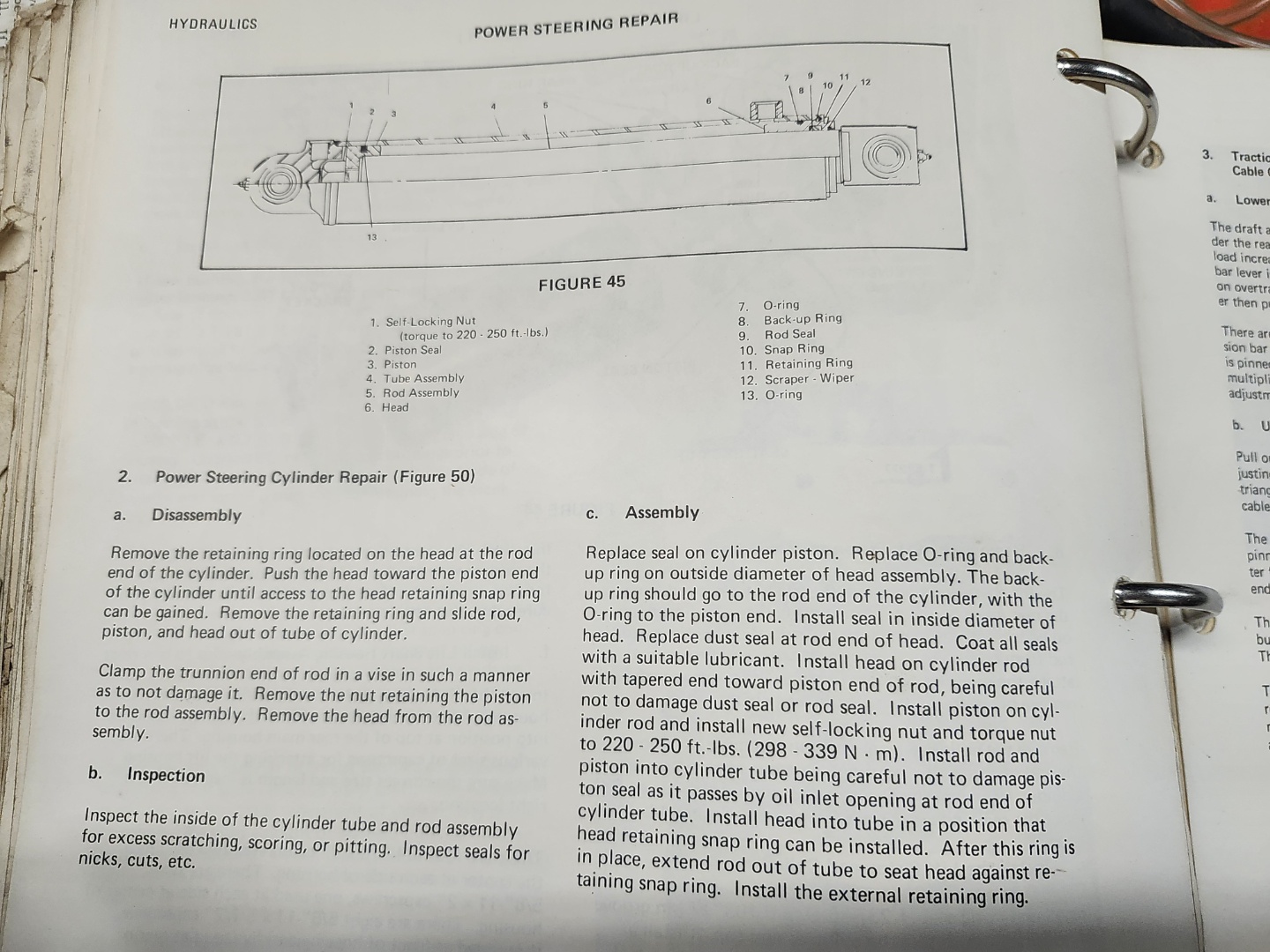

Not difficult. Will need to tap the gland head in a little to remove snap ring IIRC. Did 3 on the tractor only removing one end and the hoses. I thoroughly cleaned the dirt and rust on the end before inserting the New seals. I do not know what or if there is a torque spec for the locknut on the shaft end

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Aug 2024 at 6:29pm Posted: 09 Aug 2024 at 6:29pm |

|

So, I have tapped the gland head inwards but it stops before it exposes the retaining ring? I haven't hit it hard. Do I need to hit a little harder? It just feels like something is jammed behind it that shouldn't be there. Not sure what that could be though.

Edited by calico190xt68 - 09 Aug 2024 at 6:37pm

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2427

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Aug 2024 at 9:38pm Posted: 09 Aug 2024 at 9:38pm |

|

Make sure that the rod is partially retracted into the barrel so that the gland isn't hitting the piston, which is on the end of the rod. Yes, tap the gland into the barrel to gain access to the round ring. Then pull it out.

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Aug 2024 at 10:02pm Posted: 09 Aug 2024 at 10:02pm |

I did mine some time ago. I recently acquired a service manual and found the page in question   And lo and behold, there is a torque spec for the rod nut

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Aug 2024 at 9:24am Posted: 10 Aug 2024 at 9:24am |

Thanks for the diagram. I went out this morning and tapped the piston and it went right in and exposed the snap ring. I don't know what the problem was yesterday. I did position the rod half in the middle as Lynn suggested so maybe that was it. My new problem is getting the tube inserted into rod. The yellow retaining ring keeps wanting to get into a bind as the tube is inserted. Is there a trick to keeping the retaining ring together while inserting the tube? This is the last thing.

I noticed this pitting on the rod. Maybe I need a new rod?

This yellow retaining ring is really loose and hard to keep in place. What is the trick?

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Aug 2024 at 4:23pm Posted: 10 Aug 2024 at 4:23pm |

|

I put a hose clamp around it and snugged it down. Held it there for a while. Overnight on a couple. Put one from a skid loader in the freezer once so it would hold shape after I removed the clamp. If you have a ring compressor, even better as there is no groove for the worm gear to leave impressions in the new seal. This is why I spent cleaning any rust off the end of the bore

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Aug 2024 at 4:27pm Posted: 10 Aug 2024 at 4:27pm |

|

Pits are nasty. One of mine, the PO or his mechanic appeared to have cranked on the rod with a pipe wrench. I smoothed it up with file and sand cloth. Still have some groove marks butisnot leaking

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Aug 2024 at 9:02pm Posted: 11 Aug 2024 at 9:02pm |

|

Well. I failed. My cylimder won't move either direction. It nudges then stops. If it isn't connected it will extend but not retract. I found an oring was damaged when i took it apart. I screwed up that retaining ring too. Going to have to put the tail between the legs and get a professional.

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

8070nc

Orange Level Access

Joined: 21 Mar 2019

Location: North Carolina

Points: 649

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 1:44am Posted: 12 Aug 2024 at 1:44am |

|

You didnt fail. It just didnt work this time

|

|

1984 80780

1957 D14

DES 300 with 25000 engine

616 tractor

|

|

ValleyFarm

Bronze Level

Joined: 07 May 2022

Location: Greenleaf, Wi

Points: 22

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 7:01am Posted: 12 Aug 2024 at 7:01am |

|

Did you try cracking the lines and bleeding the air out?

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 10:31am Posted: 12 Aug 2024 at 10:31am |

|

I did, but I screwed up other parts of it. I can't get the retaining ring in no matter what.

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 1:50pm Posted: 12 Aug 2024 at 1:50pm |

After analysis by hydraulic shop, the tube needed to be honed. The pitted piston needed to be replaced or it was just going to keep ruining my seals. Seals weren't the only problem. Agco does not have pistons nor tubes for sale any longer. I know All States Ag had a used steering cylinder for sale at $209 but it could have the same problem.

Just a new seal kit would not have fixed my problems in the long run.

I need to do the same thing to the 7010 although it doesn't leak near as bad. I will see how this goes and then maybe do that one this winter.

Hope it is fixed in two days as the shop indicated. Got some hay I need to get cut and baled.

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 3:10pm Posted: 12 Aug 2024 at 3:10pm |

|

Glad you’re able to identify the cause and have it repaired. Curious as to how the rod got so beat up

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Aug 2024 at 3:50pm Posted: 12 Aug 2024 at 3:50pm |

|

I have owned the tractor for about 5 days so i dont know the history as it was bought at auction. Doesn't look like a wrench in my opinion. It was leaking really badly. After driving down road, the rear tire was soaked. We put 5 gallons in it. Hoping this is the only major problem. Thanks for your help on this!

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Aug 2024 at 5:33pm Posted: 15 Aug 2024 at 5:33pm |

|

I got the cylinder back from the hydro shop. Works great, no leaks. They said it was also bent as well as the pitting on the piston. Hard to understand how a steering cylinder would get bent? That's a heavy duty piston. Need to get the 7010 cylinder fixed next. Steering is way better on 7020.

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

plummerscarin

Orange Level Access

Joined: 22 Jun 2015

Location: ia

Points: 3989

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Aug 2024 at 5:49pm Posted: 15 Aug 2024 at 5:49pm |

|

That is a stout piston but who knows what that tractor has been through. Just ask JWingerter about his D17. Yours may have been abused in a previous life. Glad you got it back and working. Sorry it turned out to be more than a DIY fix.

|

|

calico190xt68

Orange Level

Joined: 12 Jan 2017

Location: Frankton, IN

Points: 870

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Aug 2024 at 10:20pm Posted: 15 Aug 2024 at 10:20pm |

|

I would think something else would break before that piston would bend but i don't know the history. I wasted $87 trying to fix it myself but i really wanted to use it this past weekend. It is a relief knowing it is fixed right. Should last another 45 years. I was going to lose another $100 in hydro fluid per day of use if i didnt fix it. Still shaking it out and see some small things i need to do. Fuel shutoff cable is not oem and cheap. It flexes and won't cut off the fuel everytime. It is never ending with old stuff but i like having a spare tractor and not spending $50k.

|

|

80 7010, 80 7020. 67 190XTD Series I w/500 Loader, AC 2000 Plow, Member Indiana A-C Partners, Member TAC

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)