| Author |

Topic Search Topic Search  Topic Options Topic Options

|

ecarmich25

Bronze Level

Joined: 09 Apr 2020

Location: north carolina

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: 6080 rebuild Topic: 6080 rebuild

Posted: 09 Apr 2020 at 6:52am |

|

new to site i am rebuilding my grandpas old AC 6080 4wd tractor. had been sitting in the shop after he passed and went to turn it over and engine is locked up. took the head off water must have gotten down the stack because the valve is cracked. my uncle bought another 6080 2wd with bad trans, and were looking to do an engine swap and possible repair trans on 2wd but just focusing on one thing at a time at the moment. is there any advice anyone can give me before getting started. possibly tools i might need or things i should check or do once i have the engine apart?

|

|

|

Sponsored Links

|

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2876

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2020 at 7:02am Posted: 09 Apr 2020 at 7:02am |

|

From what I understand they had 14:1 and 16:1 compression ratios. 16:1 starts much much better.

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

lowell66dart

Orange Level

Joined: 10 Jul 2013

Location: Paulina La.

Points: 964

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2020 at 7:16am Posted: 09 Apr 2020 at 7:16am |

|

So if you need pistons go with the higher compression ones if possible.

|

|

AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear.

|

|

AC720Man

Orange Level

Joined: 10 Oct 2016

Location: Shenandoah, Va

Points: 5013

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2020 at 11:58am Posted: 09 Apr 2020 at 11:58am |

|

Sounds like you have multiple projects happening. If you are going to do a engine swap, the hood, radiator and anything else upfront will need to be removed. Anything that will be in the way of the engine being pulled. Do you have any idea what condition the main clutch and pto clutches are in? It would be wise to replace both at this time especially if it has quite a few hours on it. The clutches don’t hold up that well if not kept adjusted or abused. They are not that expensive. They are a bear to line back up if you split the tractor. What ever you do never try to force it back together or you will bend the clutch...trust me I know. It should slip back together with some wiggling. Make sure you use a clutch alignment tool. Good luck.

|

|

1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2020 at 2:09pm Posted: 09 Apr 2020 at 2:09pm |

|

As Doc said in the past,put 8010 piston kits in it

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8175

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 09 Apr 2020 at 3:47pm Posted: 09 Apr 2020 at 3:47pm |

|

Is there a way to tell if you have 16-1 pistons?

|

|

ecarmich25

Bronze Level

Joined: 09 Apr 2020

Location: north carolina

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 8:34pm Posted: 11 Apr 2020 at 8:34pm |

|

thanks everyone for the replies. finally had the chance to work on it this weekend me and my dad. ill post some pics later. but i got both tractors tore down. removed front grill radiator. next question is i have a cherry picker up there and was going to try and pull it with that. my dad says he has a gantry i think its called but would have to dig it out. would it be easier with that or shouldn't have a problem with cherry picker? also do i have to take the front wheels off? or does the two halfs seperate then as the cherry picker has engine just need another person and then just roll the frontend forward? and has anyone worked with 4x4 as far as the front driveline shaft linking to the rear? does anyone know how to take that off?

|

|

ecarmich25

Bronze Level

Joined: 09 Apr 2020

Location: north carolina

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 8:39pm Posted: 11 Apr 2020 at 8:39pm |

|

lowell66dart

i would think this one is 16 to 1 ratio... its the 433I. i know when i took the head off valve number 2 is cracked so where just going to replace all of them. not sure the best way to do that thinking going to have to have a big press to put the sleeves in

Edited by ecarmich25 - 11 Apr 2020 at 8:42pm

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 8:55pm Posted: 11 Apr 2020 at 8:55pm |

|

That's a wet sleeve engine. When the block is cleaned GOOD you can push them in by hand.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 10:00pm Posted: 11 Apr 2020 at 10:00pm |

The front driveline has a coupler at the front and middle of it. There is a snap ring against each of them. Loosen the snap ring on each and slide it to the end of the splines then you can slide the collars toward the center of the driveline and it will drop out.

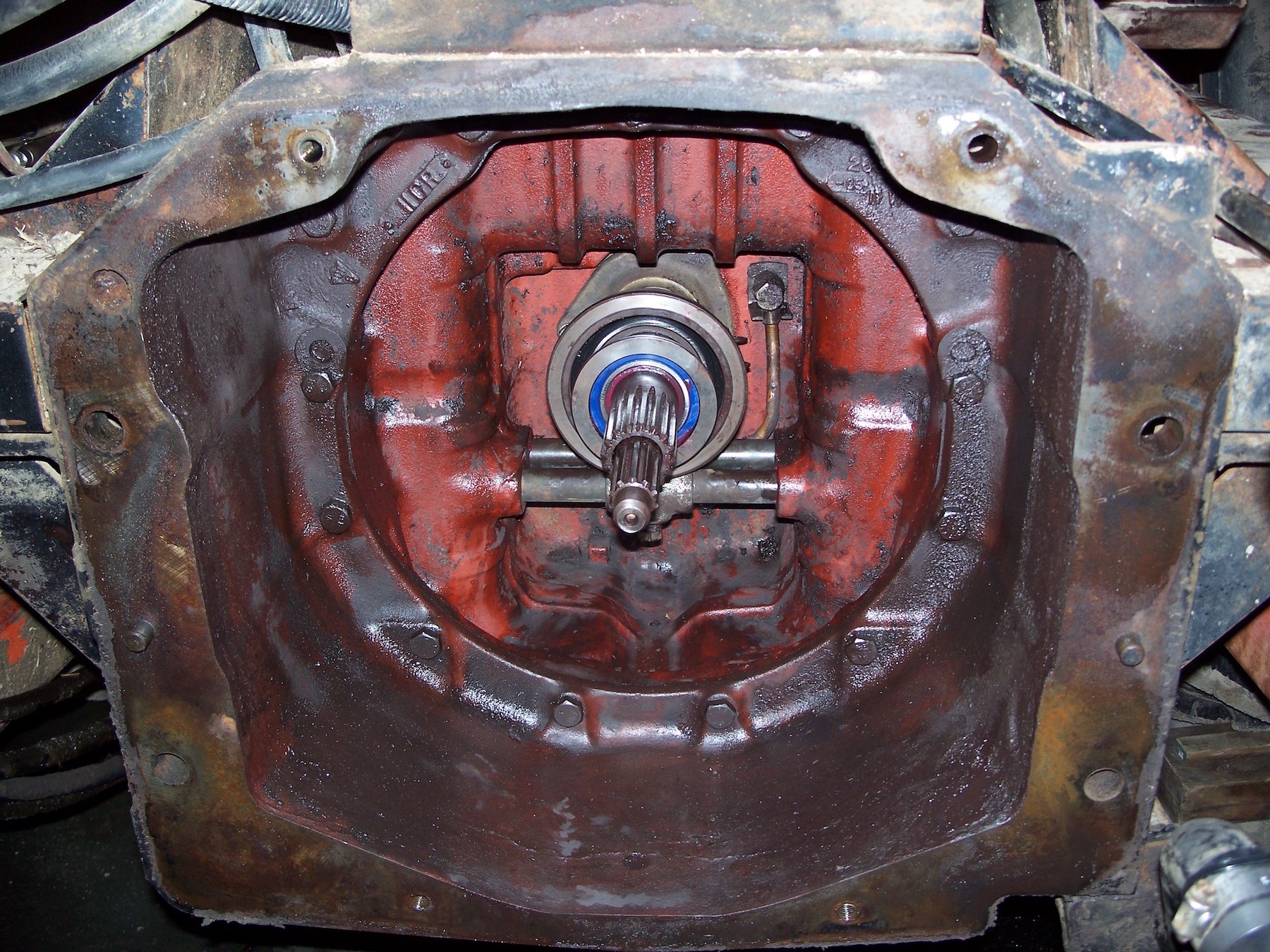

The 433 is not too heavy (compared to the 6 cyl diesels). Here is one on an engine stand, although it is a 2000lb rated stand. It handled it just fine.

If you are going to switch motors I would pull the front end then the engine. If you split it with the front wheels on still and then try to swap the motors around it is going to be a lot more work. I used a regular engine hoist on this one. I pulled radiator then the front off at the front frame rails, rolled it ahead and left the engine bolted to the trans then pulled it off. To me it was really easy to work on that way. It was one of the easier tractors I have taken apart, nothing much in the way or hard to get to. If I remember right the frame rails aren't even that heavy, once that front end is off.

If you were just doing a clutch then a normal split would be easier.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8477

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Apr 2020 at 10:22pm Posted: 11 Apr 2020 at 10:22pm |

|

Ok so if you were to buy an engine kit for 6080, can you get a 16-1 kit for 6080.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 10:14am Posted: 12 Apr 2020 at 10:14am |

Mikez wrote: Mikez wrote:

Ok so if you were to buy an engine kit for 6080, can you get a 16-1 kit for 6080. |

Go to the parts book and compare pistons from 6080,F3,8010. If 16:1 was available for 6080 it should match up to something....

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 1:20pm Posted: 12 Apr 2020 at 1:20pm |

|

Book list same piston for all 3. If they ever had a lower one it has been superceeded to to the higher.

Edited by SteveM C/IL - 12 Apr 2020 at 1:22pm

|

|

LeonR2013

Orange Level

Joined: 01 Jan 2013

Location: Fulton, Mo

Points: 3500

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 2:06pm Posted: 12 Apr 2020 at 2:06pm |

Use guide bolts on each side to align the block to to clutch housing. Cut the heads off and slip engine into place. Makes a world of difference. Leon

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8477

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 Apr 2020 at 10:36pm Posted: 12 Apr 2020 at 10:36pm |

|

Thanks Steve, is there a kit part number, I'm not able to get on agco site. Thanks

|

|

farmboy520

Orange Level Access

Joined: 22 Jun 2016

Location: Beason, IL

Points: 553

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 13 Apr 2020 at 8:00am Posted: 13 Apr 2020 at 8:00am |

|

Click the log in as guest

|

|

On the farm: Agco Allis 9695, 7060, 7010, R66, Farmall H, and Farmall F20 (Great Grandpa's)

|

|

ecarmich25

Bronze Level

Joined: 09 Apr 2020

Location: north carolina

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 6:02am Posted: 15 Apr 2020 at 6:02am |

|

thanks leon, does anyone know how to take out the throwout bearing? the 2 bolts on the inside of the bearing ( fork screws) i believe are seiezed up or something. aren't giving at all. but good news got both the motors out yesterday hopefully after i get throwout bearing replaced im gonna throw it back in.

|

|

LB0442

Orange Level

Joined: 27 Dec 2014

Location: Boise ID

Points: 767

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 9:07am Posted: 15 Apr 2020 at 9:07am |

Yes you have to loosen the bolts on each of the bearing forks then rotate them out. Soak them with your favorite lube and let it set and work in. I would sure replace both of the release bearings and the pilot bearing while you have it apart, if you don't know how old they are.

|

|

JohnColo

Orange Level

Joined: 03 Apr 2020

Location: Niwot, CO

Points: 1263

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 12:42pm Posted: 15 Apr 2020 at 12:42pm |

|

I'm trying to remember some history. Did AC buy the rear end from Fiat and build the rest of the tractor or did they buy the entire tractor, minus the engine and just install it at the US plant?

|

|

DougG

Orange Level

Joined: 20 Sep 2009

Location: Mo

Points: 8175

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Apr 2020 at 6:24pm Posted: 15 Apr 2020 at 6:24pm |

|

Good question , Im pretty sure by pics , they bought the stuff from Fiat and assembled them in West Allis

|

|

ecarmich25

Bronze Level

Joined: 09 Apr 2020

Location: north carolina

Points: 48

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 7:20am Posted: 30 Apr 2020 at 7:20am |

|

update. got the engines swapped over bearings replaced, everything put back on and loader on yesterday. finally!!! question??? so fuel pump is leaking and constantly have to open and close shut off valve to tank. i forgot to open and crank tractor and then dies, then i have to go back and crack heads and pump to get it to prime then tractor will crank. i talked to my dad and he thinks theres a vapor lock in the system. does anyone know what rebuild kit i need for the fuel pump or had this problem before? also my dad said that the fuel pump is timed, does anyone know once i take the pump off and repair it; how i do the timing once i put it back on because i have never done it before?

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 20899

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 7:27am Posted: 30 Apr 2020 at 7:27am |

|

Fiat provided the chassis from the flywheel housing on back, including the clutch assembly. A-C did the engine, adapter plate, side frames, hood, radiator, air cleaner, batteries, front support, front axle, etc. Some of the hydraulic system was AC and some was Fiat. I think the platform/fuel tank/fenders were A-C.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8348

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 8:01am Posted: 30 Apr 2020 at 8:01am |

|

remove timing window on side of pump....turn engine advanced till 2 marks line up in window. Remove pump and don't turn the engine until pump is replaced

|

|

victoryallis

Orange Level

Joined: 15 Apr 2010

Location: Ludington mi

Points: 2876

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 8:07am Posted: 30 Apr 2020 at 8:07am |

|

Make sure you don’t have parts of the flex ring plugging things up. I’d also change out the o ring on throttle shaft. You also need to pull tank and clean it out. 6080’s are famous for getting crap in the fuel.

|

|

8030 and 8050MFWD, 7580, 3 6080's, 160, 7060, 175, heirloom D17, Deere 8760

|

|

injpumpEd

Orange Level Access

Joined: 13 Sep 2009

Location: Walnut IL

Points: 4953

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Apr 2020 at 8:11am Posted: 30 Apr 2020 at 8:11am |

|

finding the timing line may be difficult, so to make it a little easier start watching when you get close to the 18* mark on front pulley. If no mark there, turn crank one turn, then look close as you approach the 18* mark. Spraying brake cleaner inside may cut the gummy coating if it is not nice and clean. The mark can be hard to see in a dirty pump.

|

|

210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers!

|

|

tbran

Orange Level

Joined: 14 Sep 2009

Location: Paris Tn

Points: 3369

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 May 2020 at 10:02pm Posted: 03 May 2020 at 10:02pm |

|

First thing I would have done is check the crank end play - these engines should have had a front brg setup on them to relieve the thrust from the clutches - few understood this and fewer are maintained. The latest production had a wide thrust flange and different crank, these would wear out as well if the foot clutch and pto were depressed while cranking. No use starting a swap unless the crank is good. My 2 cents worth... over .008 ,,,, bad news..

|

|

When told "it's not the money,it's the principle", remember, it's always the money..

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

Mikez wrote:

Mikez wrote: