| Author |

Topic Search Topic Search  Topic Options Topic Options

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: WD 45 Hydraulic Control Lever - Wear or as made? Topic: WD 45 Hydraulic Control Lever - Wear or as made?

Posted: 15 Nov 2018 at 10:22am |

I'm having trouble with the hydraulic lift on my WD45. I rebuilt the pump 2 years ago, and things seemed to be okay for awhile, but a month or two ago it just stopped working. Readjusting the linkage per the manual didn't fix anything. Even when it was running, it still didn't seem great.

That brought to mind something I noticed when I rebuilt the pump. One of the pieces of the control linkage had what I though was some interesting machining done to it. But as I thought about it, I realized that could be the source of my troubles. I pulled the pump off and that part out.

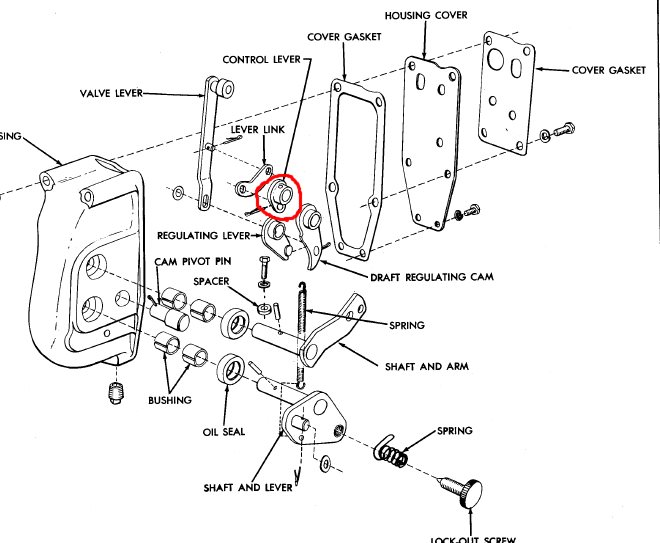

If it's wear, it wore so nicely. But it seems like it would have been a strange way to design the part. So I thought I'd see if anyone could confirm that indeed the pin is worn, and it's not like it should be, before I repair it. It's the part referred to as the "Control Lever" in the parts diagram, circled in red in the image below. The suspected wear is squared in red in the next two photos. Thanks for looking!

Scott

|

|

|

Sponsored Links

|

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 2939

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 10:40am Posted: 15 Nov 2018 at 10:40am |

|

I had mine apart about 8 years ago and rebuilt. I wish I could remember how it was but I can't... It seems like a weird piece. It's inside the housing right? That Control compartment is filled with oil so it seems like it'd be really hard to make it wear that much. Hope someone else can remember better!

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 10:57am Posted: 15 Nov 2018 at 10:57am |

Yes, it's inside the control housing on the back of the pump. I've wondered if the hydraulic fluid level was too low? It would definitely cause the piston rod to not go in as far, therefore not opening the valves as much. But maybe that's by design?

Scott

|

|

DougS

Orange Level

Joined: 03 Nov 2011

Location: Iowa

Points: 2490

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 11:25am Posted: 15 Nov 2018 at 11:25am |

|

Wear over time usually doesn't suddenly stop something from working. Generally things begin to get sluggish first. I smell something in the pump instead of something in the controls.

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 11:38am Posted: 15 Nov 2018 at 11:38am |

It indeed was getting sluggish. For awhile after rebuilding the pump, things worked. Then it got to where if I left the control rod in the lift position long enough (or revved the engine) it would start lifting, slowly. Or sometimes I could get it to by moving the control rod back and forth a bit. Scott

|

|

Dakota Dave

Orange Level

Joined: 12 Sep 2009

Location: ND

Points: 3960

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 3:53pm Posted: 15 Nov 2018 at 3:53pm |

|

that's the regulating lever. I welded a new pin on mine. I had problems With my CA till it didn't work it whet up and wouldn't come down till I listened the Hyd line and let the fluid out. That pin was completely gone. I welded a new pin on and it worked better than it ever had. the pin cant be any longer than the original. I didn't know that the first time until I had assembled it.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8479

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 4:55pm Posted: 15 Nov 2018 at 4:55pm |

|

Have an nos one here, I think

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 5:19pm Posted: 15 Nov 2018 at 5:19pm |

Looking at it, it seems like the pin was pressed in. My plan is to press is out with my press, and then press in a new one I'll make.

Mike, if you can confirm how yours looks, or even post a photo, that would be great!

I think it should be a pretty easy fix. I just don't want to fix something that ain't broke (but then I'd have to figure out what the real problem is).

Scott

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 6:31pm Posted: 15 Nov 2018 at 6:31pm |

Well, I don't have the answer, but I do plan to take my pump apart in the near future I will check mine. I have had one of these apart. but it just doesn't look like wear. Regards, Chris

|

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

Mikez

Orange Level Access

Joined: 16 Jan 2013

Location: Usa

Points: 8479

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Nov 2018 at 10:30pm Posted: 15 Nov 2018 at 10:30pm |

|

Ok will see if we can lay a hand on one

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Nov 2018 at 8:16am Posted: 16 Nov 2018 at 8:16am |

Chris, I agree, it definitely doesn't look like wear. And yet, it seems like a strange way to machine a piece. It doesn't seem like it would be strong enough. However, I don't see any wear on the mating piece. Perhaps one is heat treated, the other not? Although, again, seems odd.

Scott

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2018 at 3:53pm Posted: 20 Nov 2018 at 3:53pm |

I sent an email to Sandy Lake Implement, asking them about this. This was their response: "...that is quite typical for wear on that part. He also said they would normally weld them up. You could also knock the pin out and replace it."

So I will continue on with my repairs. Hopefully this fixes my problem. And props to Sandy Lake Implement for a quick response!

Scott

|

|

Sugarmaker

Orange Level

Joined: 12 Jul 2013

Location: Albion PA

Points: 8332

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2018 at 5:03pm Posted: 20 Nov 2018 at 5:03pm |

Scott, I use Sandy Lake for a lot of issues. They have a great tech staff. And in sales don't forget that Brenda wrenched on these AC units at some point in here work at Sandy Lake. They are the real deal, and can help with more than just AC parts! I will be looking at my pump when I tear into it in the next few weeks. Thanks for the warning! I think I have a spare pump some where from the old parts WD.

Regards, Chris |

|

D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet.

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8353

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2018 at 8:01pm Posted: 20 Nov 2018 at 8:01pm |

|

I believe the draft regulating cam was changed to different profile in the WD45's.

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2018 at 8:03pm Posted: 20 Nov 2018 at 8:03pm |

SteveM C/IL wrote: SteveM C/IL wrote:

I believe the draft regulating cam was changed to different profile in the WD45's. |

Is this related to traction boost? Or am I getting concepts mixed up here?

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8353

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Nov 2018 at 8:15pm Posted: 20 Nov 2018 at 8:15pm |

|

Yes it is. I don't remember the deal but it seems like it was to soften up the reaction of TB or something like that. The 45 had enough more snort that it wanted to move the hydraulics to much/quick. I could be all wet but i'm sure it got changed.

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Feb 2019 at 4:55pm Posted: 25 Feb 2019 at 4:55pm |

I just wanted to follow up on this.

I made an adapter to hold a punch onto my shop press.

Those of you with experience with cheap hydraulic presses will probably guess what happened.

The piece that the hydraulic jack sits on shifted, causing the punch to get bent. While trying to straighten it, it broke. So I made a new punch, that had a much shorter section that was narrow. And used some shims between the piece and the frame, so it couldn't shift. This worked much better.

Some of the pin stayed in the hole, so I wonder if perhaps there was some sort of threadlocker in there? If I were to do it again, I would heat it up with a torch to break down any compound in there.

I turned a new pin, which had to be two slightly different diameters, one to fit the hole that it was pressed into, and a slightly smaller one to fit into the linkage that it attached to.

I pressed the new pin in along with a bit of threadlocker just to make sure.

The pump was reassembled, and along with rebuilt cylinders and new hoses, was put back on the tractor. After messing with trying to bleed the cylinders as specified in the manual and ending up with the packing sliding back out of the ram, I decided it was good enough. At first you could tell that at the end of it's travel it was compressing the air in there, but the air seems to have worked it's way out and doesn't appear to be a problem anymore.

With the repaired piece, I could actually adjust the linkages so that there was a definite spot where it raised, held, and lowered, unlike the 'ranges' that it used to have. The repair seems to have worked, and I'm happy with the result.

Thanks for your help.

Scott

|

|

Allis dave

Orange Level

Joined: 10 May 2012

Location: Northern IN

Points: 2939

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 26 Feb 2019 at 10:22am Posted: 26 Feb 2019 at 10:22am |

|

That looks like a good fix!!

|

|

garden_guy

Orange Level

Joined: 05 Jul 2013

Location: Illinois

Points: 1137

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Sep 2020 at 9:29am Posted: 26 Sep 2020 at 9:29am |

Just ran across this. Wow, that is an impressive fix. Going to have to remember this.

Any chance the pin was actually threaded, given some stayed behind in the hole? Or just seemed to have something to hold it in place with a loose press fit?

Edited by garden_guy - 26 Sep 2020 at 9:30am

|

|

applescotty

Bronze Level

Joined: 27 Feb 2013

Location: Wellsville, KS

Points: 16

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Sep 2020 at 10:09am Posted: 26 Sep 2020 at 10:09am |

|

I don't think it was threaded, I didn't see any signs of threads otherwise.

Scott

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

SteveM C/IL wrote:

SteveM C/IL wrote: