| Author |

Topic Search Topic Search  Topic Options Topic Options

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 8:29am Posted: 20 Aug 2025 at 8:29am |

|

Took me 20 minutes to type my short story and TBran beat me to it !!!

|

|

|

Sponsored Links

|

|

|

SteveM C/IL

Orange Level Access

Joined: 12 Sep 2009

Location: Shelbyville IL

Points: 8866

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:14am Posted: 20 Aug 2025 at 11:14am |

|

Lol there pokey....starting to look like guides may be the culprit.

|

|

TedN

Bronze Level

Joined: 30 Apr 2025

Location: Central WA

Points: 140

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:18am Posted: 20 Aug 2025 at 11:18am |

|

First post said it doesn't turn over at all - does it now turn with the head removed? It looks like the pistons are in different positions, so I would guess it does. I think I would bolt the head back on and see if I could get a pushrod straight enough to give a decent indication, then roll it over by hand until you see what stops it. I think the suggestion of valve guides is correct, because it would be difficult to time the cam to bend ALL of the pushrods so severely, maybe half of them. Be interesting to see the cause.

Ted

Edited by TedN - 20 Aug 2025 at 11:18am

|

|

190XTD seriesIII, 190XTD seriesI, maroon belly 7000, 190XTD series??? project(or maybe parts)

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:28am Posted: 20 Aug 2025 at 11:28am |

|

There's a dimension given in the service manual as to how far to press the valve guides in BELOW flush of the top surface of the cylinder head (where the valve cover gasket contacts). This is the most likely cause of 8 destroyed push rods.

|

|

Clay

Orange Level

Joined: 11 Sep 2009

Location: Udall, Kansas

Points: 10288

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:30am Posted: 20 Aug 2025 at 11:30am |

Improperly knurled or honed valve guides? Valve guide bores measured for the proper tolerance? Condition of valve stems? Valve seat depth? Rust or deposits on the valves? Excess fuel or water in the cylinders? Engine way out of time? Mud daubers? Gremlins? These and many other mysteries need to be answered.

Edited by Clay - 20 Aug 2025 at 11:32am

|

|

HudCo

Orange Level

Joined: 29 Jan 2013

Location: Plymouth Utah

Points: 4050

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:36am Posted: 20 Aug 2025 at 11:36am |

|

my red flag is it said that the head was done twice it was split three times three places or the same place three times

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:45am Posted: 20 Aug 2025 at 11:45am |

The front crank pulley was never pulled… Was just about every thing my puller could pull without heating it up. The seal looks original. The engine does turn over after I got all the push rods out (that was really fun getting one out  ). The valve guides look to be good with being just pass even with top of head.    Valve that I pulled doesn’t appear to be in the best shape but looks like it should run.

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 11:52am Posted: 20 Aug 2025 at 11:52am |

|

I'd have to look in my service manual at home to tell you the guide height, but it's below flush of the top of the head, not flush. I'm thinking 1/8" inch below. When one used Allis/AGCO guides they had a mark on the guides that was the proper dimension so you pressed them into the head from the top until the mark was flush with the guides bore.

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89931

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 12:15pm Posted: 20 Aug 2025 at 12:15pm |

|

that valve face looks like it was cut with a body grinder !! ....... is it just a bad picture, or is it really that bad ?

|

|

Like them all, but love the "B"s.

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1557

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 1:36pm Posted: 20 Aug 2025 at 1:36pm |

steve(ill) wrote: steve(ill) wrote:

that valve face looks like it was cut with a body grinder !! ....... is it just a bad picture, or is it really that bad ? |

My 14 year old grandson does a better job than that using my 100 year old Van Norman valve grinder. Seriously.

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 4:17pm Posted: 20 Aug 2025 at 4:17pm |

|

The stem also looks like its an old valve not new one

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 6:39pm Posted: 20 Aug 2025 at 6:39pm |

Gary Burnett wrote: Gary Burnett wrote:

The stem also looks like it’s an old valve not new one |

you are right, rust pits everywhere. Just noticed today that the bottom of the sleeves are pitted pretty bad… If I was to planing on running it a lot I’d probably go ahead and put new sleeves in due to burning a little oil.  I didn’t realize that someone could do a job like this and still get business while charging full price..

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 6:42pm Posted: 20 Aug 2025 at 6:42pm |

Les Kerf wrote: Les Kerf wrote:

My 14 year old grandson does a better job than that using my 100 year old Van Norman valve grinder. Seriously.

|

He probably could run a paint gun a lot better than what this guy did too!!! The back wheels are full of runs… and the front axle was painted with a brush it looks like to me….

Edited by 55allis - 20 Aug 2025 at 6:43pm

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 7:02pm Posted: 20 Aug 2025 at 7:02pm |

|

Intake guides to be at least 1/8" (.125") below flush with the top of the head and exhausts are flush.

|

|

Dirt Farmer

Silver Level Access

Joined: 15 Sep 2020

Location: Illinois

Points: 461

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Aug 2025 at 9:22pm Posted: 20 Aug 2025 at 9:22pm |

|

Just wondering, what are the chances that the last time it was worked on the guy put the wrong push rods in out of another project he had been working on and there is another project out there that has no power or cranks but won't start. Just thinking outside the box. Too long, totally collapsing the spring and bending the push rods.

|

|

Gary Burnett

Orange Level Access

Joined: 11 Sep 2009

Location: Virginia

Points: 3164

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2025 at 1:28am Posted: 21 Aug 2025 at 1:28am |

Dirt Farmer wrote: Dirt Farmer wrote:

Just wondering, what are the chances that the last time it was worked on the guy put the wrong push rods in out of another project he had been working on and there is another project out there that has no power or cranks but won't start. Just thinking outside the box. Too long, totally collapsing the spring and bending the push rods. |

Also seems to me I remember some of the rocker assemblies being different heights on the 201/226 motors.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2025 at 11:35pm Posted: 21 Aug 2025 at 11:35pm |

|

Valve guides do not appear to have been replaced…

But they don’t seem to be even…

Plan is to go ahead and rebuild the head, going to local engine shop tomorrow and he will check and or replace valve seats, some appear to have pits and or sunk in.

Some of the original valves have a little bend to them, not bad but figured with the rust pits that fresh ones won’t hurt it.

Going to replace the clutch shaft seal and front crank seal due to leaking. Need your opinion, should I replace the rear crank seal again? The guy supposedly replaced it all ready…. Did he do it correctly I have no clue until I get it apart.

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

Dirt Farmer

Silver Level Access

Joined: 15 Sep 2020

Location: Illinois

Points: 461

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2025 at 11:57pm Posted: 21 Aug 2025 at 11:57pm |

|

Better safe than sorry while you have it this far along and if it starts leaking he'd probably blame you. I'd try to figure out why the bent push rods before I dove in too deep. Could turn into a money pit but that's not on you, you are working with what you have and connecting the dots like any good mechanic would do. While the head is being checked over have them check it for being true and flat and ask if there is a way to measure if and how much it may have been planed down. Be sure to check valve/rocker arm settings when reassembling. Keep us in the loop cause we all learn something on here from others experiences.

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2469

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 7:34am Posted: 22 Aug 2025 at 7:34am |

|

I'm sorry, but what a mess. If I scratch my head anymore over these problems, I'm gonna have another bare spot. Replaced clutch shaft and now the clutch shaft seal is leaking?? The head has supposed to have been went through twice already and looks like that?? As for the push rods, I don't think that the starter could have even turned the engine over after a piston hit the first valve. Maybe someone tried to pull start it and could have done the damage. It would still have to be seriously out of time with the cam position. If you're going to replace the front crank seal, I'd pull the front cover and have a look.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 8:44am Posted: 22 Aug 2025 at 8:44am |

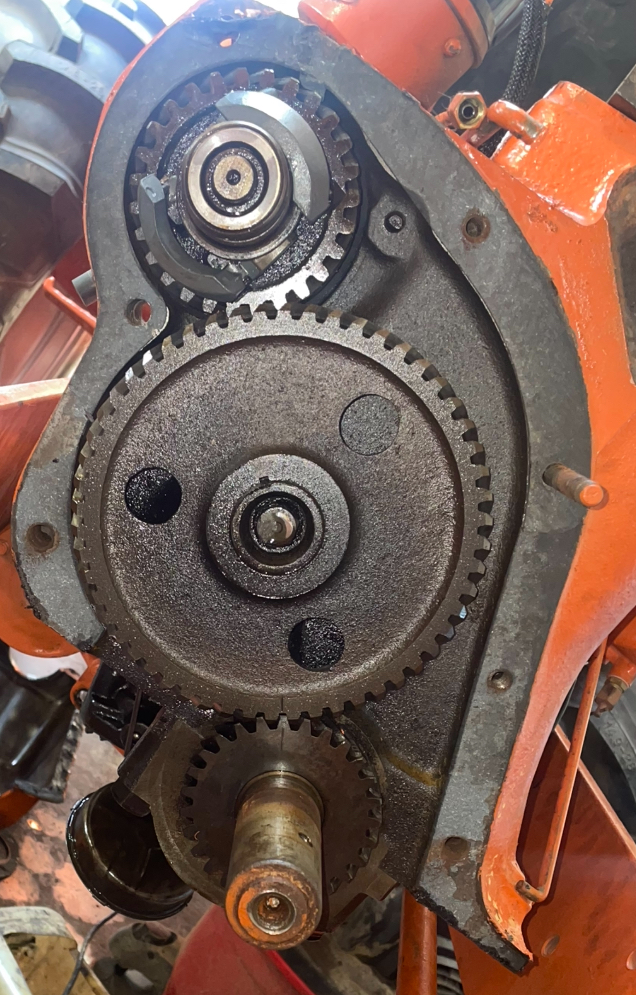

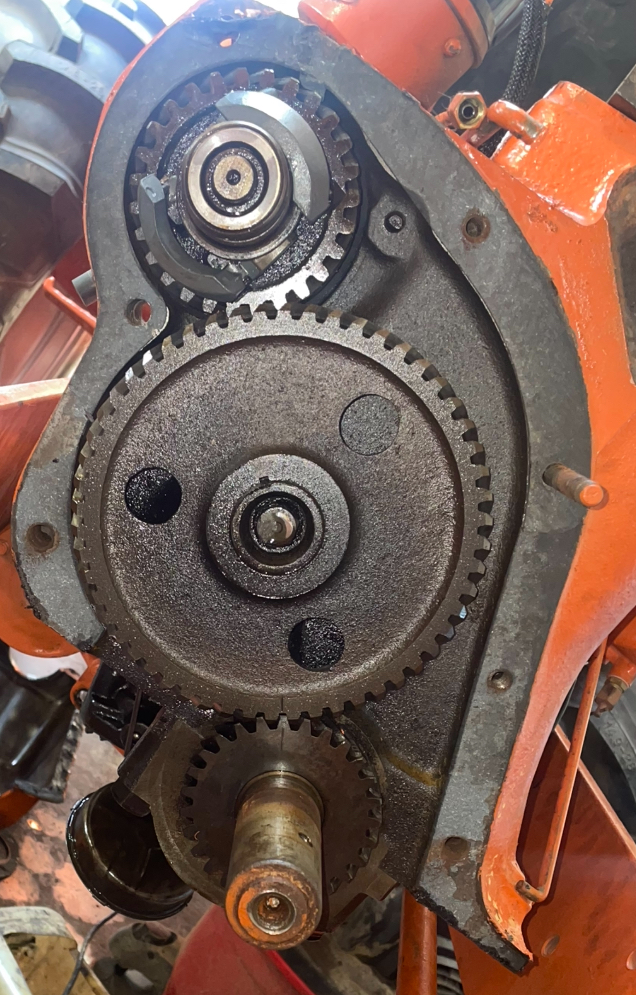

Looks to be in time.. Very confusing because front pulley doesn’t appear to have been removed and the seal too, but the gasket seems like it has gasket maker on it… I’m starting to get bald spots from scratching my head….

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2469

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 9:37am Posted: 22 Aug 2025 at 9:37am |

|

Is the #1 piston at top dead center in that photo?

|

|

steve(ill)

Orange Level Access

Joined: 11 Sep 2009

Location: illinois

Points: 89931

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 9:48am Posted: 22 Aug 2025 at 9:48am |

cam is in time and the governor is OK...... and the valves bent... So valves were stuck in the guides, or the engine had oil on top of the pistons and came up on compression when full of fuel / oil ?

he said it was in the shop for 7 years... maybe the rings stuck in the piston and no compression, or stuck to liner and no rotation.. so they put a few oz of oil in each cylinder and let it set, then installed plugs without removing the oil ??

Edited by steve(ill) - 22 Aug 2025 at 9:54am

|

|

Like them all, but love the "B"s.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 11:13am Posted: 22 Aug 2025 at 11:13am |

Lynn Marshall wrote: Lynn Marshall wrote:

Is the #1 piston at top dead center in that photo? |

Yes it is

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 11:18am Posted: 22 Aug 2025 at 11:18am |

steve(ill) wrote: steve(ill) wrote:

cam is in time and the governor is OK...... and the valves bent... So valves were stuck in the guides, or the engine had oil on top of the pistons and came up on compression when full of fuel / oil ?

he said it was in the shop for 7 years... maybe the rings stuck in the piston and no compression, or stuck to liner and no rotation.. so they put a few oz of oil in each cylinder and let it set, then installed plugs without removing the oil ?? |

There only was some grease, in previous posts I had a picture of the cylinders right after I removed the head. I sprayed some JD multipurpose oil down the spark plug holes to prevent cylinder scoring when I got it here. But it was still stuck until I removed all the push rods.

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

Les Kerf

Orange Level

Joined: 08 May 2020

Location: Idaho

Points: 1557

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 10:33pm Posted: 22 Aug 2025 at 10:33pm |

|

Even though the timing marks are lined up, at this point I would put a degree wheel on the crankshaft and verify the actual cam lobe events. I have seen engines that had the timing gears installed incorrectly.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Aug 2025 at 11:48pm Posted: 22 Aug 2025 at 11:48pm |

|

To me it looks like it has a key in the cam shaft, so there’s only one way for it to go on…

I will look at the distributor and see if it’s right but I don’t think that the cam or cam gear has been removed… I could be wrong but I will look into that.

I have the head in the head shop for inspection so it will probably take him a few days to do that. Hoping it won’t need anything but rather safe than sorry.

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2025 at 12:28am Posted: 24 Aug 2025 at 12:28am |

So I looked at the distributor and here’s what it looks like at tdc

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

Lynn Marshall

Orange Level Access

Joined: 13 Sep 2009

Location: Dana, Iowa

Points: 2469

|

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 24 Aug 2025 at 6:41am Posted: 24 Aug 2025 at 6:41am |

|

The distributor is just what the name implies. It distributes the spark to the proper cylinder at the proper time. With the cap back on, the rotor should be pointing approximately, to the #1 cylinder wire. Nothing in the distributor is going to cause that carnage with the push rods.

|

|

DrAllis

Orange Level Access

Joined: 12 Sep 2009

Points: 22564

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2025 at 7:00am Posted: 24 Aug 2025 at 7:00am |

|

TDC on #1 is also TDC for #4, only one full turn different. The problem ain't there.

|

|

55allis

Orange Level

Joined: 30 Jun 2020

Location: Griswold Iowa

Points: 1265

|

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 Aug 2025 at 10:38am Posted: 24 Aug 2025 at 10:38am |

|

I was meaning if the cam time was off the distributor could be off too…

Edited by 55allis - 24 Aug 2025 at 10:39am

|

1955 AC WD45 diesel with D262 repower, 1949 AC WD, 1963 A-C D17 series 3, several Allis garden tractors

|

|

Topic Options

Topic Options

Post Options

Post Options Thanks(0)

Thanks(0)

).

).

steve(ill) wrote:

steve(ill) wrote: