New member..grandfather's HD5

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=60854

Printed Date: 01 Feb 2026 at 4:31pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: New member..grandfather's HD5

Posted By: heron

Subject: New member..grandfather's HD5

Date Posted: 01 Dec 2012 at 10:16am

|

Hello all! Finally after many years my dad is letting go of his father's 1955 HD5. This was the last small grading machine he bought new for his company in 1955. Basically the machine has probably 2000 total hours on it, undercarriage is like new, clutches good, motor great, hydraulics great. The only issue is it has sat and has had no TLC. I was probably the last person to change the oil 30 years ago and probably has a total of 15 hours on it since then. So, I'm having it shipped from CT to TN and I'll be getting it this week. I have work to do with it(light) around my new house and I want to do some over all maintenance. Problem is I don't know where to get filters. Oil, air, fuel...where o where can I find them? My goal is to change oils, filters, coolant, grease rollers, idler, put oil in all the points and once I'm done with the final grading around my house I want to take her in the shop and restore her. One issue right now is my dad took the two huge 6v out and replaced with a 12v 800CCA battery. The generator does not work and I'd like to get that rebuild if possible but can I still use the 12v battery or is that generator designed for the two huge 6v batteries? Also, it needs a seat and arm rests. Is this something I should just build and wrap myself with some sort of covering? Final drives do leak and one track adjustor spring is frozen...not sure what kind of job this entails but will probably have to wait for some real time to fix. It will run fine but have to avoid deep sand, mud turning. Any advice would be much appreciated as I think I'll need plenty in the near future. TY |

Replies:

Posted By: Coke-in-MN

Date Posted: 01 Dec 2012 at 11:23am

|

It will start fine on one 12V battery with no problem . the starter will draw over 1200 A but a large capacity modern 12 V battery will supply enough to start it . I have been using this for 20 or more years . As far as generator finding a good cutout relay is the main problem and not the generator . I changed out the generator to a 10SI alternator but had to make my own front pulley from a cast iron pulley from a alternator from 70 series GM truck and opening up belt area to accept a wider belt. The generator is a 12 V and does not care what is down line as long as it accepts 12 V. Rollers , front idler, and top roller all take oil and not grease to lube the Timken bearings, they are not gun grease. Oil filter and the fuel filter should have the number of the filter needed stamped into the cover plate. I used filters from early Chrysler product when I could not find the Fram filters i needed. The battery box covers or arm rests are something you will have to make yourself. I raised the seat platform about 4" to make it easier to fit into position for comfort when operating. I also built a plywood box about 2" high and attached to the metal plates over battery boxes. Over the years these deteriorated so i just use plain metal plates now for covers. I have a couple of photo-copies of the HD5 manual left to sell if you do not have the manual . cover service and repair of full machine, from the 2-71 engine to the track and tractor itself. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 01 Dec 2012 at 12:21pm

|

So the generator cannot be rebuilt? What is the easiest fix for this...what you did with the GM alternator? Not sure I can fab that up...? My dad said there was some type of nozzle to oil the rollers. What type of oil do you use in those if you don't use grease? 50wt or 80/90 gear oil? What is the easiest way to add it to the rollers? As far as oils and coolant. I would use fleetcharge for the coolant. Are there any particular oils that I can run that are better than straight 30 wt for the motor? How about transmission? Any new improved oil I can run? The final drives weep. My dad has run 80/90 in them but pulls it out when he is not using it which is pretty much all the time. Is there an additive or something(brake fluid, lucas) that will swell the seal and seal it up? I remember the seals on those Allis's were always problematic. I think it led to the downfall of the 41..I know at least the larger allis's we had all had issues. If there are any "modern/better" things I should add as far as any fluids please advise. I pretty much don't have access to the good old shops I used when I lived in the North East. I'm pretty much stuck with the auto stores, walmart, northern tool. Have you got working guages? I'd like to get all the guages working properly but I'm at a loss as to what I can replace them with, sending units etc...? I may be interested in the books, my dad says he has all the old books but he cannot find them right now. I'll let you know b/c I'm sure I'll need them. |

Posted By: darrel in ND

Date Posted: 01 Dec 2012 at 12:53pm

| Heron, sounds like you got yourself a little jewel. I love them little five's. As far as your generator goes, it can be made to work, and may very well work now, just has a bad voltage regulator, or cut out relay as coke says, just that an alternator is a better deal. Myself, for originality sake, I would probably stick with the generator. As far as oil additives, I like lucas, and add it to about everything. There are a lot of good informants on this site, so be patient and you'll get lots of info. Darrel |

Posted By: Coke-in-MN

Date Posted: 01 Dec 2012 at 1:31pm

|

The generator will work fine -if, all components are there . I was using my machine with lights and it would pull down battery and later the cutout relay went bad so as i had alternator here it was easier to put that on at no cost/. I use a 15/40 Rotella oil in engine, transmission can use SAE 50 or a oil with a 1200 SSU rating or 85/120 gear oil . Final drives also a 90/120 gear oil. As your temp range there is not as extreme as it is here in MN the heavier weight should work. On the rollers and under carriage there is a plug on the center of the retaining cap remove that and insert a small tube into center of roller then pump in oil form a grease gun like pump until it flows out around the tube - then replace plug. Leaks from the final drive area can be a problem - as can the lube in the outboard bearing on the axle shaft (bearing bolted to truck frame). Early axles were drilled to allow oil to flow to this bearing . I have seen many machines where a standard grease zerk has been added to this bearing for lube. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: dadsdozerhd5b

Date Posted: 01 Dec 2012 at 4:47pm

|

i have been using john deere corn head grease for the rollers as it is 00 grade grease i believe. it flows very easily and is almost a liquid and have had no problems. it does not leak like the oil does. i have been running 15w40 engine oil and 80w90 gear oil. the biggest thing is to keep them full. i agree with coke about the outboard bearing, i put grease fittings in them after destroying an axle from no lube and i had the newer axles in to allow the oil out to the bearings. they got dirt in them and clogged the passages. one thing to look out for is mice getting into the steering clutch compartment either through the lower drain plug hole or they chew through the rubber boot that seals the brake rod. nothing ruins a day more that frozer steering clutches. post aome pics once you get it. good luck and happy dozing! ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 01 Dec 2012 at 6:54pm

|

First off, sorry for all the questions. I'm kind of in a hurry as I am in the process of building a house and if we don't get some gravel in the driveway it is going to get muddy. I have a 42hp tractor with FEL and backhoe but it does not weigh enough to cut and I need to box out around this house up to 16" in the front in order to get gravel in and have pitch away from the house. So, I'm going to try to get on this maintenance ASAP so I will not worry like crazy once I start using the dozer some. I'm not planning on working the old girl hard but just nice and slow. I probably have a day of dozing to do if all goes well. I just hate to use it and then find out later I messed something up during the course of boxing out the driveway. Onward... Is it worth fixing the outer final drive seals if they will just leak again? In other words has there been any improvement in the final drive seals over the years. Again, this is a 55 so it's the last year they made them(I think). I need to know more about the zerks and where/how to put them in the outer bearings. Something I'd like to do right away. As far as oil I'm planning on using the 15/40 and the 80/90 gear oil since I can find it anywhere. Have any of you had issues with the spring pack on the track adjustor freezing up. My dad said it happened over 35 years ago and it would throw a track if you turned hard in deep sand or mud but as long as you go easy it is fine. Any easy way to fix this? I imagine I need torches and more which I don't have access to anymore. Never heard of the John Deere CORN OIL? Only place to get it is John Deer I suspect? Sounds like the best option for the rollers. Not sure on how to put the oil in the rollers. I have one of those oil suction things you use to pull oil out of a sump..Has a plastic hose on it...Is that what I use to put oil in? I'm still a bit concerned about where I'm going to get all and I mean all the filters. Poor thing has not had a new filter in 30 years..again it has not been run much at all but old is still old. What do you guys think of literally draining all the oil and putting a couple gallons of Marvel Mystery oil in and letting it warm up on that and then drain it back out..just to clean it up a little on the inside..? How about seats? I looked at some at Northern Tool today. I'd like to go original but even my dad said he never liked the stock seats and said they could always have been about 6" higher. Has anyone had experience retrofitting a "newer" seat and if so which type? Now, on to batteries. My dad just got a 850CCA Deka battery for it. Is this adequate? I really want to make this dozer to where it's not a hassle every time I go to start it. What is the best way to set it up so it's easy, I can get the guages going again or get new ones. I'm just not sure if the Generator is designed to charge the newer 12V battery. About the fuel filter system; can I just buy a filter head and bypass the old stuff and add a Cat 2 micron to the setup. I've done this on my diesel pickups and it works flawlessly and the filters seperate water and are cheap. (01749 I think, $17). I'm looking forward to having this one thing from my grandfather. Other than this I just have a harmonica so it means a lot. I'm hoping my two young boys will jump on board with learning to wrench on this much like I did growing up with heavy equipment everywhere. I'd rather see them doing this then playing video games like every other kid now a days. I'll get pictures up as soon as I get it. Just awaiting the dispatcher to call me regarding pickup on Monday in CT. Thanks for all the replies fellas! |

Posted By: Coke-in-MN

Date Posted: 01 Dec 2012 at 9:08pm

|

I used a bucket seat from a Suburban for many years , vinyl cover and high back - put a 4" lift under it . Then had a Ford seat for a while from van. Now have a another botten seat from Northern . Changing the seals is a job as the truck frame has to come off or the frame cut near the rear bearing . On a dozer it isn't as hard as it is on HD5G loader . The grease he is talking about corn head grease is a #00 or #000 semi-fluid grease. You would use a standard grease gun filled with this and a tube small enough to fit inside hole in roller when the plug is removed- You then run pipe or tube into center of roller and pump in fluid until it comes out around tube . the battery should be fine in that size - remember way back a high amp battery was large size - they have gotten smaller and more power from batteries with new technology . No need to run clean up solution through engine - just run good oil and change it. If you look back through this listing of posts you will also find a lot of information on the HD5 as it is a popular post . The HD6 has the same track, sprockets, rollers, seals in the udrcarriage. One thing is to be sure the leak on seals is not from loose sprocket as you can be in for big problems down the line if As far as outboard bearing there are a couple ways to get grease to it, there is a flat spot on the housing where a grease zerk can be drilled and tapped into or the outer cover can be drilled and tapped but a guard needs to be welder on to protect the zerk ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: darrel in ND

Date Posted: 01 Dec 2012 at 9:16pm

| The John Deere grease is "CORN HEAD GREASE." Not to be confused with corn oil. That does sound to me like a pretty good idea. As far as the battery, the generator will charge the one big 12 volt battery just as easily as 2 sixes in a series if (as coke says) all of the components are functional. Oh, the John Deere grease would have to be bought at a John deere dealer. Darrel |

Posted By: Coke-in-MN

Date Posted: 01 Dec 2012 at 9:19pm

|

couple filter ideas ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Dozer

Date Posted: 02 Dec 2012 at 10:10am

| The concerns you have about your grandfathers HD5 are common and have been covered in the past on this forum. There was considerable discussion about the frozen track adjusters. If you need to tighten the chain to get work done now there are several ways to avoid throwing the chain. You can install shims between the yoke and the front idler bracket, you can raise the support roller or lower the truck rollers with shims. I am curious about the cost of shipping the HD5 a long distance. I have found machines I would like but I didn't consider them because of shipping. Did you find a reasonable long distance shipper? |

Posted By: heron

Date Posted: 02 Dec 2012 at 10:46am

|

Hartford CT to Chattanooga TN about 1350. Yes, my dad said the same thing about the shims. It's been so long since I've even seen the dozer that once I get it I'll have a look and see what I am able to do. I lack the tools that I had access to 30 years ago so it may be more of a challenge to do the heavier stuff with this machine. As far as the rear seals is there any additive that would help with the seal weeping? At least for now until I can really go thru and fix it up. My plan is to run 85/90 gear oil in it but is there anything better in this situation. Not sure where to get a straight 50wt oil in my area. |

Posted By: Coke-in-MN

Date Posted: 02 Dec 2012 at 11:03am

|

From just sitting static for a long time the seals may weep , it depends if the boots on the seal spring area is damaged or what else might be wrong. The seal itself is 2 brass plates which are held together by a spring plate that is enclosed by a rubber boot. This assembly is bonded to the seal base and held in place with 3 dowel pins. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 02 Dec 2012 at 11:17am

|

I've been trying to find some NON GL5 gear oil around me..none. I've read the 80/90 has too many additives and that it can harm internals. Are there readily available oils I can use in the dozer or do I need to order 50wt? I think the dozer calls for 50 wt in everything except hydraulic and motor...right? Can I use the universal tractor...transmission/hydraulic for the hydraulics? Not sure why the seals leak but I will find out. |

Posted By: Coke-in-MN

Date Posted: 02 Dec 2012 at 11:20am

|

I have been using the 90/120 in everything except trany . think the Universal fluid might be a little thing for the trany but it might work or add something like STP to it to make it cling better. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 02 Dec 2012 at 11:47am

| Where do you get the 90/120? I've looked locally and none of the 80/90 wt says it's yellow metal safe. Cannot find the 90/120 anywhere. |

Posted By: Dozer

Date Posted: 02 Dec 2012 at 3:07pm

|

Here is a picture of the outboard seal from my HD6G. Somethin got in there and cut the boot. |

Posted By: heron

Date Posted: 02 Dec 2012 at 6:35pm

Posted By: heron

Date Posted: 02 Dec 2012 at 6:37pm

| Wow, I definitely need to check them when I get the 5. I have never seen them apart on any of our old dozers. |

Posted By: dadsdozerhd5b

Date Posted: 02 Dec 2012 at 8:31pm

|

depending what brackets you have on the dozer rear pivot, installing the grease zerk for the outboard bearing could be easy or a little removal. once you get it, post some pics and we can advise. i had the rear pivot off to change the axle and drilled a hole to access the zerk without removing the dozer pivot. there were several designs so a pic is worth a thousand words. i will find my roller grease adapter and post a pic. the air filter is oil bath and fuel and oil filters readily available. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: Dozer

Date Posted: 03 Dec 2012 at 7:24am

|

Heron I sugest that when you get the HD5 home you check that everything that needs oil or greese has it. Then use the machine. Do not be too quict to take it appart because replacement parts take time to find. When you get a parts book look at the seal assembly. The AC seals are like a clutch with 2 lubricated steel rings that try to keep the oil inside. The boot covers the spring assembly. The spring assembly is like the pressure plate on a clutch. I understand you were thinking of an automotive crankshaft or wheel bearing seal when you asked about swelling the seals. Use your machine. Check the lubrication often. The parts you have to repair will become apparent. Post pictures. Good luck |

Posted By: heron

Date Posted: 03 Dec 2012 at 7:55am

| Yes, my plan is to get the essential oils and filters changed. Once I do all that I'll work it a bit and see what I think. The rear seal and the frozen left idler are not something I can tackle right now as I'm in the middle of building a house. I want to avoid running it until I know for sure all is well. Talked with my dad last night and from his memory the transmission fluid has never been changed. I have to find some 50 wt for that and some MT-1 80/90 for the final drives. Not sure about what to use for hydraulic yet but I'd like to change that also. He did tell me the serial number was 27578 and from what I've read they only produced 29K of these machines. |

Posted By: Dozer

Date Posted: 04 Dec 2012 at 8:00am

| When you deal with hydraulic oil try to empty the hydraulic tank because over the years there is probably a lot of condensation and dirt in the bottom of the tank. I have an electric pump from an old pressure washer with a filter on the output. The pump input is a hose that I can use like a vacuum cleaner in the bottom of the tank. You can reuse the oil if you allow the dirt and water to settle out. |

Posted By: heron

Date Posted: 04 Dec 2012 at 1:07pm

|

On the roller oil/grease. I cannot find any corn head grease or 00 grease in my area. There is a Dynalife L-e but if I put that in there without washing out the roller there could be compatibility issues from what I was told from a tech. So, what is the next best thing as I will be checking the rollers this weekend. I'd like to have something ready to go to fill them up with even though I don't have the device to load them with as my dad cannot find the "tube" they used many decades ago. My plan is to change out the final drive to GL1 mineral base gear oil and use it in the transmission also as an oil person told me today it's the same thing as the 50wt motor oil that was spec'd for the machine in the 50's. Not to mention the GL1 is less expensive. The same oil guy suggested an 46wt hydraulic...thoughts? How about direct filter numbers so I can pick them up on my way to the dozer? Is the PH8A a direct replacement? It's been so long since I worked on that dozer I forgot how all the filters are situated. How about fuel filter...anyone have a number or is it the C3 that Coke has pictured? Dozer will be here on Thursday morning. I'd like to literally drop the oil and coolant right away and have the filters ready to go right on without having to run around at that point. Can anyone give me some exact numbers I can source at the auto parts store? I did order some Corn Head Grease online so I should be set with the rollers...now just have to figure out how to get it in there...guess grease gun...? |

Posted By: Ray54

Date Posted: 06 Dec 2012 at 2:20pm

|

Sounds like you have a really nice machine there.Have always run 85-140 gear oil in my transmission.As for the filters Cokes picture looks like what was original,but was thinking the number was CP4 but I do know was the same as Ford 8n tractor.The primary fuel filter is the same as oil unless it has been changed. The secondary fuel filter was originally a sock type,but after looking I think Fram C1173PL is what I have been using.Bin lucky and have not had much water in that ones tank lately.If you have 45 PSI leave it alone,just drain water from tank before each us if not used often.Also have always used a lite grease in the rollers rather than oil.If they are OEM rollers they have a bearing rather than a bushing, so it is better to have the tool pump new clean grease into the bearing.Don't know were you would find a new one though.Any non foaming oil will work for hydraulics. For a cheap seat a piece of 3/4 plywood, foam from old sofa or mattress,some heavy canvas or vinyl and a staple gun, fold like raping a package. And as Coke said for arm rests.Gauges are generic until you get to the restoration,any mechanical from auto parts store. If it is important the old can be rebuilt,but something like $500 a pop.As for the battery here everyone uses one 12 volt.I used the pulley from the generator on the alternator when I changed. Under stand how you feel about this tractor as I would like to get my grandfather's first tractor.Ninety year old aunt by marriage will not sell so far.Her grand kids will likely cut it up for scrape.Good luck with your project. Ray |

Posted By: heron

Date Posted: 06 Dec 2012 at 8:20pm

|

Thanks for the reply Ray! Got the dozer delivered today. Spent most of the day running around and ended on a bad note. The fuel filter on the side of the machine was disconnected by my day 35 years ago b/c it would lose prime unless he kept the tank full which he didn't b/c it was never used regularly after 1962. Then I went to check the "only" little fuel filter on the machine and it was LOADED with junk. I cannot believe the machine runs sooo well. But the issue is not only that but the filter does not sit evenly on the bottom of the housing and the manual I have shows the little cup and washers going on the bottom of the filter yet they were installed on the top of the filter with a little square piece of metal holding the filter down. There is NO way the filter can do it's job the way it's been installed for over 4 decades..at least. One idler is stuck..my dad said they put too many shims in it years ago and it seems they have frozen up. The track adjustors look like there is no way they will move although I've coated them with PB blaster. The final drives leak, one piston is leaking and the tranny feels sloppy when shifting although engages well. So now I'm looking at adding a Napa 4770 filter head and a cat fuel filter. I'm waiting for a new oil filter from Napa. Coolant is drained and I need a new cap for the radiator....ANY IDEAS on that? I'll probably pull the generator after I get some work done with it and have it rebuilt. I bought a seat from Tractor supply that will raise the operator up a little bit. My plan is to cut a piece of 3/4" Advantek, put that on the base in the rails screw the seat to it and cover the battery trays with diamond plate. Down the road I'll look at doing things more original when I have the time. I do have the 85/140 for the final drives ready to go and once I get it hot I'll drop the tranny fluid and put GL1 mineral oil 90wt in it. Are the guages difficult to install as far as sending units fitting, things stripping out? I'd really like to have a temp guage.. :) |

Posted By: heron

Date Posted: 06 Dec 2012 at 8:47pm

|

Ray, forgot to ask about the rollers...I don't have the stem/nozzle for the rollers as my dad has misplaced it. :(( Any idea what to use to put oil in the rollers since it probably has not been done since 1962. I've got tubes of corn head grease on the way(8) that go into a grease gun. I also found a 000 grease/oil today, old stock from this lube company but we couldn't figure out how to pump it in to the rollers without spending $200 on a pump that would fit the 5 gallon pail and pump something like that. |

Posted By: Coke-in-MN

Date Posted: 06 Dec 2012 at 9:15pm

|

That cup belongs on the bottom of the filter and the top of the filter presses against the top casting to seal. That Fram C 3 filter is what I use to be able to get easily at Farm Supply store - Chrysler product oil filter. I used it both on fuel and on oil . Those PH8A filters in the other picture are the bracket I made up to use spin on filters now. That other white filter material in 10 Micron filter tubes that I cut down to make 2 filters for the one on engine , use them rather than the honeycomb woven filters as had a problem finding them. (Some oil burner guns use them ) For the rollers the GL1 should work also to fill them . Be sure to clean out the cup on the air cleaner - it is a oil bath unit and you will probably find the cup full of dirt . A #30 engine oil or that hydraulic oil will work fine there . Clean out pre-cleaner cup also. A sloppy shift lever has a couple problems and can be fixed. If you remover the boot over shift tower then the 2 - 15/16 head bolts on each side the shifting lever will lift out of case. Inside you will find a bushing and a pin which attach to the shift pin which has a ball end. That cross pin wears or breaks, the bushing wears, and the bolts which have a turned end wear. I made up a new bushing , new bolts with longer reach, new cross pin which is larger size and ground 2 flats into it . The hole for the cross pin in the shift pin were fitted to new cross pin size. So now the bolts reach the cross pin and keep it from moving and tension on pin is set by shims under bolt heads. I welded up the ball end and ground back so it fits tighter into shift rails. Lever now moves side to side for gear selection, and fwd and back - but no slop in other directions or turning to jump out of rails. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 06 Dec 2012 at 10:23pm

|

Yes, I just spoke to my dad and he swears he never put it in that way...must have been a senior moment. Anyway the cup is still on top as the spring is missing also that goes on the bottom...probably why someone installed it wrong back in the say...they must have lost the spring. I may just get a Napa 4770 filter head and run a large cat filter on it. The Primary filter and parts are gone and my dad does not remember where he put the parts. Question is if does the filter head have to be level with the bottom of the fuel tank? If it does can I run a small lift pump to help keep pressure in the system..only about 3-4psi. The oil filter; where can I cut and mount a filter head for that? I would like to eliminate the old large one on the left side of the machine and use an updated better filter. On the rollers; how can I fill them if I don't use the corn head grease? Can I use a funnel with a flexible tube? Will the rollers take about a cartridge of grease each if I use the corn head? Great advice on the shifter. I don't have any way to weld or fab something up so I'll see what I can do b/c it definitely needs help. Also good advice on the air filter as my order is air, fuel, oil, coolant, transmission, hydraulic tank cleaned, rollers, working temp guage, seals on piston(?). seat, generator... All gems of experience with these things are welcome. I don't mind doing the work...I actually miss it but I hate having to figure things out when I still don't have the right manuals(dad is sending them) and I'm fixing things that should never have been let go! What year machines do you all have? The online manual I have been using is not accurate and Allis didn't seem to make a differing year manual...? This machine was produced at the end of the HD5 series. |

Posted By: JohnCO

Date Posted: 07 Dec 2012 at 12:23am

|

You should be able to get any filters for it at a NAPA store or a parts place that sells WIX as wix makes filters for NAPA. I'm sure you could get the JD corn head grease on line from JD, if not from a dealer. Could be Case NH or AGCO has a similar greas/oil for their corn heads. Have fun with your machine! ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: Ray54

Date Posted: 07 Dec 2012 at 10:08am

|

The rollers were always called 1000 hour rollers.The grease from the day was a off white,put the pipe in and pump the new grease in until old brown grease was out and the new white was coming out around the pipe.I would guess that would be 1/4 to 1/2 tube of grease.We only did it once a year.For the us you are talking as long as there is anything in there you should be ok. As for the filters many have been changed to the spin on.With the bigger better element you could get away without the secondary element as modern equipment only uses one filter.They can be a little hard to prime some time,so it helps to pressurize the fuel tank.A old inner tube cut with the valve stem and a large hose clamp put it on the fuel tank filler works really well. For the temperature gauge you want a mechanical with a short capillary tube.As it is only a foot or so from rear of engine to the dash. Ray |

Posted By: Coke-in-MN

Date Posted: 07 Dec 2012 at 10:33am

|

The manual was printed early in production or before - It stays the same all through the years . The parts manual is revised for the years of production so later manuals show the updated parts . As the 2-71 uses a engine driven gear pump to pressurize the injectors - no lift pump should be needed - if this pump is worn - you will not have right pressure to injectors and proper flow for cooling as well as for running. Should have around 40 PSI through system. I bought a mechanical gauge for a IH tractor from TSC and have had it in for 30 years now and still works fine. I replaced the fuel pressure gauge with a Stewart Warner mechanical gauge- You need a restriction in line (snubber) or the gauge will pulse as fuel moves through system. Some filters like the ones used on HD4 diesel have primary and secondary in same can but I would not do away with the 2 filters unless you are sure the new one has that . Rebuilt HV7 Detroit injectors can be expensive IF. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 07 Dec 2012 at 11:14am

|

With the 24770 fuel filter head there is no priming screw so I'm not sure how it will prime. Also, I'd like to remove the large canister on the right side of the machine and simply put the housing within that frame work but the priming is the issue. Great idea on the tube, wondering if I could find a fitting at a big box store that would screw on to that and allow me to drill a hole for a shrader valve. I'm wondering if I can find the "correct parts" for the secondary fuel filter. I'm missing the spring that goes on the bottom. I'm wondering how that cork seal actually seals on the bottom of the fuel bowl. When you look at the bottom it's got dimples that would not allow it to seal up well...? I found some 000 grease at a local lube store. Any idea how I can get that into the rollers without some specialized pump? On that mechanical temp guage; will the sending unit that goes into the block hook right up? My plan is to run a Cat 1R-0749 filter. It has an absolute micron down to a 4 and it's what I use as a primary on my truck. Very cheap and easily found. It has lots of room in it for water also. |

Posted By: Coke-in-MN

Date Posted: 07 Dec 2012 at 11:48am

|

I have run my machine dry many times and no problem priming or getting it to fire again . The fuel pump is not a injector pump it is simply a transfer pump. If you will notice in the picture of the filters I have on my HD5 the filters are inverted so priming them is hard to do but the machine will run and transfer fuel fine . I do fill the filter mounted on the engine (small honeycomb) with fuel, then use WD 40 or either to start the engine and run a few seconds until the fuel transfers. ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 07 Dec 2012 at 4:11pm

|

If I take off the canister on the right side of the machine and mount the fuel head and have the filter to where the bottom is almost at the bottom of the tank do you think it will still prime fine? Your is close in and there is no way I can get that in there on this machine. I'll try to get pic's on Saturday if it's not raining too hard. I can always use the secondary housing on the engine to prime it if it needs it. Is there a better hose to run to connect everything up. I'll have to go and get fittings for the fuel head. I was going to use barbs and I guess 3/8 fuel line. I've never heard of using WD40 for ether...wow. Yet another use for that stuff. |

Posted By: Coke-in-MN

Date Posted: 07 Dec 2012 at 4:17pm

|

When you talk of canister on RT side of machine - If a large round housing mounted to battery box - that is a LUBE-FINDER engine oil filter , Not a fuel filter . The machine used 2 canisters mounted on left side of engine for oil and fuel filters and 1 canister on right side of engine for fuel . The round canister on back Rt side is lube filter .  ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: Coke-in-MN

Date Posted: 07 Dec 2012 at 4:29pm

Here is a HD5B with the filter on the Left side (photos by John Ford Queensland AU) ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 07 Dec 2012 at 5:57pm

| Nope...not on this machine. The oil is on the left and the fuel is on the right. There has never been two on the left. This is a 1955 machine. How old are the machines in the pic's...46..? I'll get some pic's on Saturday. It's nice to see that cable machine. I remember as a small kid the cable backhoes, northwest shovels..80d and 180d's. The first dump truck I drove was a Diamond T(reo) with chain drive. Grandfather push started me down a hill...couldn't turn the steering wheel and ran right into a pile of sand...luckily! I think I was 9. My grandpa had a little too much Jim Beam that day. |

Posted By: Coke-in-MN

Date Posted: 07 Dec 2012 at 7:51pm

|

Mine is also a 1955 HD5G Srl # 26784 Both those machine are Down Under - AU ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

Posted By: heron

Date Posted: 07 Dec 2012 at 9:17pm

| Wow, wonder why it is different...? Cannot imagine why they did it other than maybe the one you have is some severe duty model that needed extra filtering...? I know for a fact this machine has never been hacked on by anyone except my dad who disconnected the fuel filter on the right hand side of the machine. He is trying to find the parts he took out of the canister this weekend. I'd put it back to stock if I had everything although I think if I can mount this new filter head and put the Cat filter on it that is 15" long it will do a better job than the original. |

Posted By: dadsdozerhd5b

Date Posted: 11 Dec 2012 at 6:46pm

|

i have several of the canisters that you are talking about. i will look this weekend and see what is inside of them and will sell them to you cheap. i will post pics this weekend of what i have. i will also find the tube to grease the rollers. it looks like a 1/4" piece of pipe with a square block in the middle to put back pressure on the grease to force it into the bearings before it comes out. there is a pic of it in the back of the parts book but i will find mine and post it. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: dadsdozerhd5b

Date Posted: 11 Dec 2012 at 7:12pm

here is a pic of the greaser. the gun goes on one end, the grease comes out the other and the squares put back pressure to get the new grease in where it goes while allowing the old grease to come out past it. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 11 Dec 2012 at 8:10pm

Well, greased them up tonight with Corn Head Grease and a standard grease tube, pumped it in and as it came out I pulled out the tube so hopefully I got enough in there. Any ideas where I can get one of these?

|

Posted By: heron

Date Posted: 11 Dec 2012 at 8:44pm

|

How many qts of oil does the 5 take? Book says 2 gallons. Put that in and nothing on the stick. Put in about 3 1/4 and she shows full...? Also, big issue; the left steering clutch had about 5 gallons of water down in the sump. I vacuumed it out but there is all kind of rust down there. It was steering ok when I pulled it off the trailer but is there anything I can dump down there that will not hurt the fiber plates but yet clean everything up..esp. the moisture. Is there some type of drain plug under the machine? I could not see one. Planning on going over to the dozer on Thursday and cutting a driveway in. First I have to replace the tranny check plug, make sure the transmission is filled up and then do a little dozing so hopefully working the clutch will keep it from freezing up. FYI. if you guys like your tools I picked up a Kobalt (lowes) cordless 1/2" lithium impact. Unreal how handy this thing is on the dozer since I cannot get my compressor out to it. Great investment! Also, the Wix 54470 filter head works great and I now have a large Cat 2 micron spin on fuel filter along with water seperator under the seat. Sorry, have to shrink my pic's... i'll get them on here later. |

Posted By: Dozer

Date Posted: 12 Dec 2012 at 2:53pm

| There is a pipe plug under each steering clutch. Go back to August 19th on this forum "What is the tensil strength of a mouse nest?" It is about the steering clutch repair on my HD6G. |

Posted By: heron

Date Posted: 12 Dec 2012 at 3:11pm

|

Great to hear! I'll be removing that tomorrow morning...if I can since it's probably been in there since 55! Any ideas on where to get one of the grease tools for the rollers? |

Posted By: Dozer

Date Posted: 12 Dec 2012 at 3:34pm

| Greese tool. Get some 1/8th pipe from your hardware store and a greese fitting with 1/8 NPT thread. When you are looking underneath for the steering clutch drain plugs, don't remove the center plug or you will get an oil bath. The plugs are supposed to be removed unless you are working in water. |

Posted By: DMiller

Date Posted: 12 Dec 2012 at 4:13pm

|

Luberfiner is a brand for heavy equipment/trucks and available thru any major parts house, the canisters come in varied sizes and configurations but all work essentially the same, even the unit on the tractor now, it is a excellent fiter unit with a new cartridge. They also have filter base assemblies for other styles as fuel filters or spin on units. http://www.luber-finer.com/" rel="nofollow - http://www.luber-finer.com/

|

Posted By: heron

Date Posted: 12 Dec 2012 at 4:30pm

Doesn't the standard grease gun tube with the coupler off work the same...b/c that is what I used. I would think the rectangular piece is needed to help pressurize the inside to get the grease into the bearings...? I'll have to check but if the plugs are removed there is probably too much junk in the bottom and the water could not drain out. Great to know! And yes, I do know about the tranny plug. My goal on Thursday is to top off the transmission oil, go on and do some dozing then drain the transmission and add GL-1 oil back into it. Can anyone confirm the tranny takes 5 gallons? Crankcase oil said 2 gallons and it was not. |

Posted By: heron

Date Posted: 12 Dec 2012 at 4:30pm

I'm on hold with them right now...didn't know they were still in business. |

Posted By: heron

Date Posted: 13 Dec 2012 at 7:36pm

|

Okay, ran the dozer for about 30 minutes today. Here are some issues: The spool valve under the blade lever is leaking right under where it spins..."O" ring possibly...easy fix or not? Also, right piston is dripping fluid down the piston shaft. Tried tightening "evenly" the two 3/4 inch bolts. Still dripping. Are the seals easy to find and replace with the piston on the machine? Dropped the tranny fluid. Looked like brown water..Yuck. Poor fluid has probably not been changed in 45 years. Shifter is definitely sloppy. Will have to open that up at some point. I dropped about 3 gallons of diesel thru it and let it all drip out real well and added back GL1 90wt gear oil. Hope that is the right stuff as I heard from the oil company that the GL1 is the same as the 50wt motor oil. (no detergents and that is what make it different...?) Hope that was the right advice. Planning on changing out the water temp guage on Saturday. Any special fitting needed? I assume the stock guage is mechanical...hope so! |

Posted By: dadsdozerhd5b

Date Posted: 15 Dec 2012 at 7:36am

|

i have several of the blade controls if you need one but i have not had one apart. i would flush the tranny/bevel gear with the diesel only move it back and forth a few times to really wash it. check the gasket on top of the bevel gear as they dry out and allow water into the system. pistons use a packing that is available at a hydraulic shop. you can tighten them fairly tight until they stop leaking. used packig usually weeps. do the cylinders have pits or scores? you will have trouble if they do. i believe the water temp gauge threads into the head with pipe thread. a new gauge should come with the adapter. keep soaking and tapping the track adjusters to get some of the lube in there to free them up. it is some work to get them unstuck but use the time to your advantage and spray them as often as possible. i will find a pic of the packing and post it. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: dadsdozerhd5b

Date Posted: 15 Dec 2012 at 7:47am

here is a picture of packing. there are 3 sets in this pic as each cylinder uses 5 or 6 pieces. the ram does not need to be removed to replace the ram end packing. if the cylinder leaks down, then the inside gland packing needs to be replaced whic requires complete cylinder disassembly. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 15 Dec 2012 at 8:02am

|

The piston has some scores but they have been there forever. I'll have to see today if tightening it had any positive effect. On the tranny I did not remove the top plate, just removed the fill plug and dumped diesel down and out. I figured I would do that, run the new oil for a little bit and simply drain and refill again. Yes, I will keep applying the PB blaster to the track adjustors. Not sure if it will free up those shims. My dad thinks the track has to come apart but we lack the right equipment and a really good mechanic. Not sure on the blade control what has to be done. It works fine but just leaks. I may disassemble it and have a look. Seems like it would be some type of packing in there also as it's leaking out from underneath the swivel point of the lever. There is no leak down in the blade so hopefully the packing will solve the issue. It's not so bad and it may seal up the more the dozer is used. |

Posted By: DMiller

Date Posted: 15 Dec 2012 at 8:12am

| NAPA dealers should also have access to basic fuel filer spin of heads, the Allis head on my 7G is designed to draw thru the primary(vacuum or tank gravity), to the fuel transfer pump then from it to the secondary(pressurized) then to the injection system but mine has a Allis 4 stroke in it. The old Detroit style filters were similar on trucks, you could get a combination or separate head(s) from dealers that sold AC( not Allis Chalmers but General Motors AC) fliters and housings. |

Posted By: DMiller

Date Posted: 15 Dec 2012 at 8:23am

|

Found this site, go to filter bases, P/N FK1304, is a direct conversion set for Detroit cannister to spin on. Have others too as a OB1303 for spin on oil. http://www.adiesel.com/subcategory.html?id=18550" rel="nofollow - http://www.adiesel.com/subcategory.html?id=18550

|

Posted By: heron

Date Posted: 15 Dec 2012 at 10:02am

Yes, I put the Wix filter adapter on last week. Works great and allows me to run readily available Cat 1r-0749. Not sure on the oil filter though. The one on the left side of the machine is still working fine and the Napa/Wix are easy to get. I may convert that in the future to a spin on but for now I'm leaving it alone. Bigger fish to fry right now with this dozer. I'm just lucky the motor runs great! No smoke and she will push a full blade like nothing. If I can get the track adjustors freed up and the final drives sealed up the machine will be great. |

Posted By: heron

Date Posted: 15 Dec 2012 at 9:34pm

|

Hey guys, I began to take the 9/16" bolts off the top of the blade lever housing and it made the lever get really stiff so I stopped and screwed them back in. I'm afraid there are a bunch of springs etc..that will come apart as soon as I try to lift it off.  Does anyone have any illustrations or anything regarding the lever valve. The fluid is coming out right underneath where it spins. I'm hoping it's just a simple packing or "O" ring that needs to be replaced but I did not want to open up a can 9pm and rain coming in. Also, hooked up the temp guage tonight and lost some coolant. I'm puzzled because once I got the machine running and dozing the temp only went up to 160 and yet the fluid did not look down at all in the filler cap...? Could the thermostat be bad or water pump not circulating the coolant. It should have been down a half gallon or so. I'd think if the pump was bad the machine would heat up...  One thing I did not do is open the vent valve on the thermostat when I filled it up. It took almost 4 gallons so I thought it was good. Now I'm reading the manual and wondering if maybe I didn't close the vent valve and that is maybe why it's not heating up much. |

Posted By: heron

Date Posted: 18 Dec 2012 at 6:29pm

|

Has anyone seen this AW CASH COMPANY valve or know how to work on them. The blade works great but it's leaking fluid from right under where the round disk is that swivels. I'm thinking I need to use a puller and get the disk off, then the 9/16" bolts should come off and then hopefully there is some packing or something right where it swivels...? |

Posted By: dadsdozerhd5b

Date Posted: 18 Dec 2012 at 8:20pm

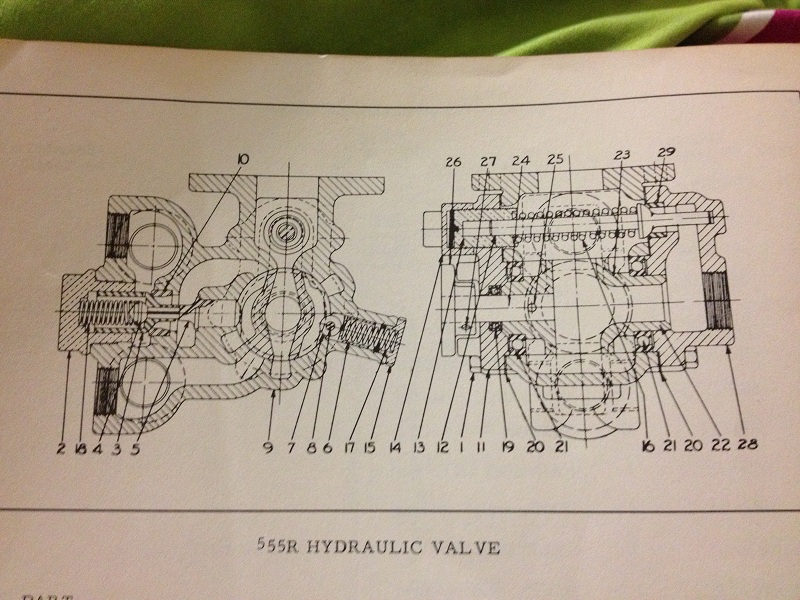

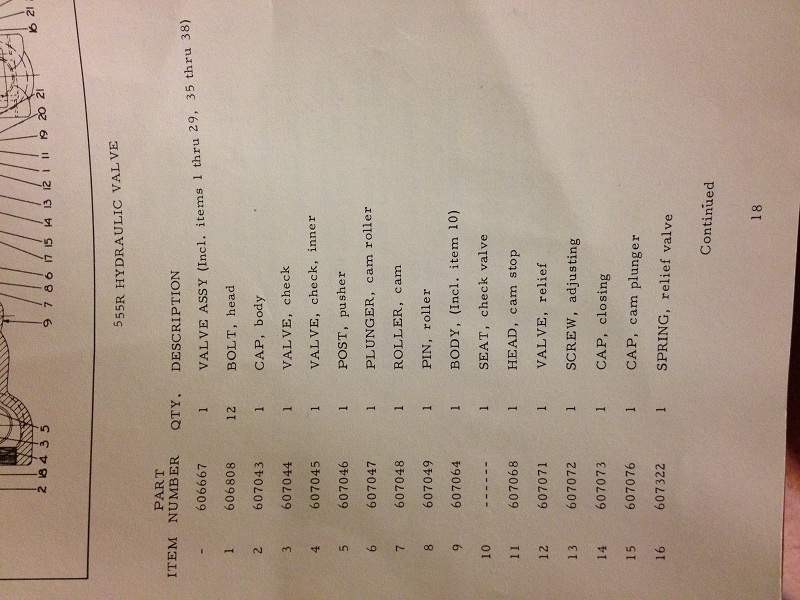

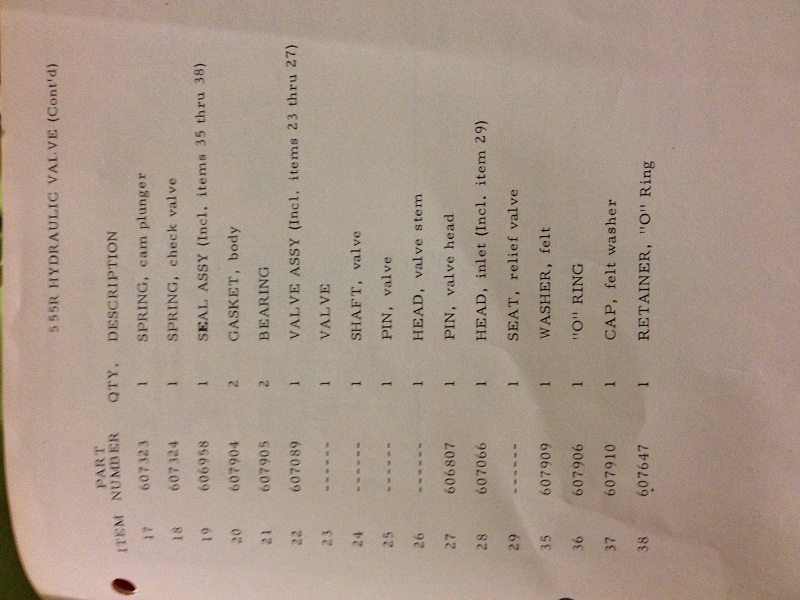

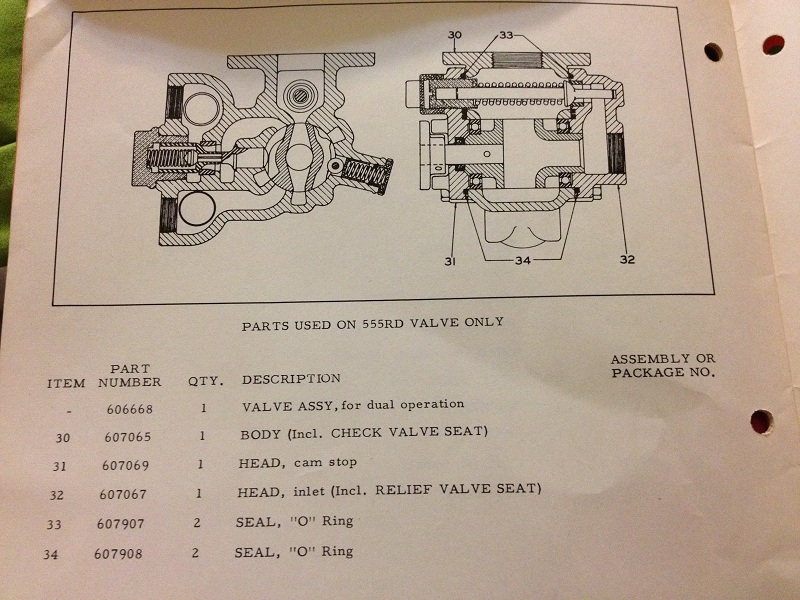

here are pics of the valve assembly and diagrams. these come from the model 5abf and 5bbf bulldozer and 5agf and 5bgf gradebuilders manual. if you see one online, buy it. it is worth it. does not look too complicated but i have not had one apart.    ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: dadsdozerhd5b

Date Posted: 18 Dec 2012 at 8:26pm

|

looks like you take the pin out of the top, pull the round adapter off and the top plate should come off and then you can replace rthe seal. there is an assembly number but not sure where to get one. maybe minn parr? let me know how you make out and post some pics. i have a few of these valves if interested. i am scrapping an almost identical hd5 that is fairly picked over. if you need any other parts, let me know, i may still have it. good luck ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 18 Dec 2012 at 8:30pm

|

Thank you...now I see why I couldn't pull it off...I looked for a pin but could not see one, must have to turn it to see it. Am I reading it right but if it is leaking out from under where it swivels then number 19 should be the one that is bad. Question is can I find the parts for that? If you do (Dozerdad) have that valve I'd definitely be interested as I really don't like dealing with this thing leaking. Let me know if you have one like this. On the other hand I'm not sure if I could break the fittings needed without destroying something else... :(( |

Posted By: dadsdozerhd5b

Date Posted: 18 Dec 2012 at 9:12pm

|

I definitely have several of these valves. I will get a pic ASAP for you. Number 19 is the seal. Try to find one if you get it apart. Mine leaks a little and I do not worry about it. How much is yours leaking? It is a low pressure system so it cannot be a great seal, and actually the seal group shows an oring which you may be able to replace. The key is to get your apart. Try some of the parts sponsors on the site as they may be able to steer you in the right direction. ------------- HD5B, HD5G, (2) FARMALL A's, CUB. DO IT RIGHT THE FIRST TIME, IGNORE THE LAUGHTER. FLANNEL IS ALWAYS IN STYLE. |

Posted By: heron

Date Posted: 18 Dec 2012 at 9:48pm

|

Now that I know about the pin I won't waste time trying to remove it. I'll probably just use some blue goo to seal up the case once I remove the bolts to get to the seal. Hopefully I can find a quick replacement for the seal. It's leaking pretty good. Not sure why all of a sudden. My dad says it literally started the day before he got it ready to throw on the trailer for it's trip down south. I just don't like anything leaking if I can repair it. Although I don't want to open up a can. Do you run the universal tractor transmission/ hydraulic in your dozer? Not sure what to put in there. I've got extra of that around and it's the easiest to find. I think my biggest struggle will be to fix the left track adjustor and free up the shimms that are rusted. Motor purrs and she has got oodles of power. Almost afraid of breaking something if I run it full out. I'm just waiting for the hydraulic hoses to start breaking. :(( Thanks for all the help! |

Posted By: heron

Date Posted: 22 Dec 2012 at 10:21pm

|

Got the valve off the top. Pin pounded out with no problems. I'll have to make a new gasket for the top casing. I'm thinking the leak must be from the spool not sealing properly b/c there does not seem to be a "real" seal to keep oil from coming up and out from where the top rotates. It seems like what is in there was simply a wiper to keep dirt out but it doesn't seem to be a tight seal to keep oil in. I'm going to try to source a seal Wednesday and hopefully find something better than what was in there. Wish me luck! Let me know if you come up with anything dozerdad! |

Posted By: heron

Date Posted: 21 Sep 2016 at 11:36am

|

Long time since I've posted. Finished building a house, having another child and now it's time to put some time into this HD5. I've got all the manuals but I'm not sure on some things. I did add some universal hydraulic/transmission fluid to it. Not sure if that is what did it but as I posted earlier the valve for the blade has been leaking out of the seal on the top under where it swivels. Could it be... 1 The fluid is too thin? 2. The fluid is over filled? Should I open up the butterfly on the tank to let the fluid weep out? My goal this week is to take the blade off and move it under an RV port. Then I plan on changing out the Hydraulic fluid with fresh fluid, adjusting the clutch band on one side and sizing up track removal. To make this machine perfect: Replace final drive seals, fix track adjustors and fix loose linkage in transmission. Are the final drive seals do-able for someone who has no torch? I just purchased some large impact sockets(1-2"), I do have 1/2 impact but nothing larger. I'm planning on getting some additional larger wrenches and some socket adapters to adapt from 1/2" to 3/4". Other than a bottle jack (20ton) what else should I have in tools to make this happen? With the tools in mind where can I find the seals and other parts to fix this machine up? I during this discussion you guys asked for pics. I do have some pics and will try to attach. Thanks for any help with this! Aaron

|

Posted By: wayneIA

Date Posted: 22 Sep 2016 at 3:15am

|

The hydraulic fluid isn't the problem, the seal hardening from the age and wear from use are the most likely causes for the leakage. I'm not 100% sure on what is leaking from your description, but I'm assuming you mean it is leaking around the spool, which should have either a seal or an o-ring to seal it and just needs to be replaced. As for the final drive seals, you need some large tools to get things apart. Start with breaking the track (takes a very large hammer and drift punch at the master pin with backing behind the chain so it doesn't bounce when you hit it). It's better to break the chain near the drive sprocket and lay it out ahead of the machine so that you can roll the under carriage ahead on the track chain (may need to jack the frame of the crawler higher to clear some of the truck frame as you roll it ahead, be aware the truck frame alone is probably around 1500 pounds on a 5 roller long frame for a loader. Then when you get the outboard bearing housing and seals off (recommend replacing the outboard seal when you reassemble), you'll need a very large wrench to get the sprocket nut off (I don't remember what the size is since we made our own wrench, but the torque spec is 1500 foot pounds). You'll also need a big puller (most likely will need a port-a-power) to break the sprocket loose too since it is seated on tapered splines. After getting the sprocket off, it's a fairly easy process to remove the final drive seal then and replace. Make sure you get the drive sprocket properly torqued again when going together too, mine were both loose and had ruined the axles. Also on the engine, I know a lot of people say that they run 15w-40 oil with no issues, but I've read in the manuals and heard from other people that you should only use straight weight oil in the engine since it is a 2-stroke. I use 40 weight diesel rated oil from NAPA in both of my 2-strokes (2-71, and 6v92TA). |

Posted By: HD6GTOM

Date Posted: 22 Sep 2016 at 8:26am

| Herron a very good pal of mine ran AC dozers all his life. He used straight STP in his final drives. Claimed it did not leak out. He had retired when I bought my first HD6 and gave me a lot of advice. He bought the STP in 5 gallon pails from someplace in Omaha Ne. I bought a porta power with a cylinder to pull tracks back together, works easier than a come a long, a set of 1" sockets, a 1" air wrench, and a bunch of other larger stuff at harbor freight. As I was not using the equipment to make a living I figured the cheaper tools would work for me and they did. This was his advice to me. Just passing it on! Have fun with your tractor. |

Posted By: heron

Date Posted: 22 Sep 2016 at 12:18pm

|

Interesting on the STP. I'm wondering what that is as STP is generic for many things these days. I did grab some 1" sockets and some socket adapters for my 1/2" gun. I can get my small compressor out to the dozer but my larger compressor is too far away. I may try my 1/2" electric gun to see if it can break anything on that dozer. My main concern is to buy a bunch of things and then find when it comes right down to it doing anything serious with this machine at this point is just too much for my budget. From what my dad and grandfather said the final drives on the AC were always issues and that eventually they always leak. I appreciate the input and will try to find out more about the STP in the 5 gallon pails. TY!

|

Posted By: LeonR2013

Date Posted: 22 Sep 2016 at 4:00pm

| Heron you had mentioned brake fluid way back there, and I can tell you, I've had amazing success with it on dried seals. So get yourself some pint cans of it and try one can in a final, run it and see what happens. If it works put it in the other places you have leaks. Being that the 2 cycle engines were leakers, I'd sure put it it in the engine. Won't hurt a thing. Also about the engine oil, run the best straight weight oil you can find. In hot weather always run 40 weight. I used to run Delo 100 in mine, but I'm sure there's something a lot better now. Do you have a Orscheln or farm and home store in your town or close by? They have some fine oils for what you need. Oh, you were wondering how you were going to get oil in the rollers? They make a gun that looks like a grease gun but with only the stem that goes down the middle. Has about a foot long hose on it, so just stick it in the oil and suck it from the container and squirt it wherever you want to. Easy as pie. |

Posted By: DavidnTenIll

Date Posted: 22 Sep 2016 at 4:09pm

|

Carquest 85010 oil filter element. Baldwin PF 906 secondary fuel filter. Have to look up primary. All available thru Carquest or Baldwin dealers |

Posted By: DavidnTenIll

Date Posted: 22 Sep 2016 at 4:56pm

| Carquest 85010 lube. Baldwin PF 906 secondary fuel. 15 w 40 diesel oils are not adequate for older detroit diesels. Should be 30 or 40w rotella T1 or equiv.Forget 1st fuel filter number but it was available also. Hope this helpful. |

Posted By: DMiller

Date Posted: 22 Sep 2016 at 6:02pm

|

I prefer 40w for Detroits as they get thin on lube anyway, 30w is fine for cooler weather.

Most of the engines I worked on were worn slick, the heavier oil helped keep some lubrication when the engines heated up. I get my Baldwin filters online the Filter Associates, they have had all the oddball Allis specific filters I have needed to date.

|

Posted By: wayneIA

Date Posted: 23 Sep 2016 at 5:07am

| The final drive seals are actually a rubber wrapped spring loaded cage that puts tension on 2 machined flat steel plates. Either the steel to steel surface is worn and leaking, or there is a hole through the rubber cage wrapper, in either case a rubber expanding compound probably isn't going to fix the leak. |

Posted By: heron

Date Posted: 24 Sep 2016 at 10:44pm

|

Yikes, not sure why I wasn't receiving any alerts to your posts...? I got the blade off today, pressure washed her up, I've never seen this machine so clean. The old yellow paint job(my dad did in 71) was flaking off and I found the HD5 AC Diesel on the back of the fuel tank. I know my grandfather would be happy. Now the bad, when I went to move the machine into the RV port noticed lots of oil coming out the bottom. Turns out one of the oil lines from the lubefiner oil filter canister rotted away and opened up under the floor pan. So, spent the good part of the evening removing the lines from the 90 right under the battery on the left up to the engine. All original stuff, never had a wrench on it in it's lifetime. Here is a question: Can I replace the metal lines with rubber tranny lines as the original lines literally came apart when I tried to work them out from under the clutch lever. OR, would the machine be better served if I eliminate the large lubefiner filter and mount a new oil filter head and use and updated oil filter? If so, any suggestions on filter head size and micron ratings I should look for in a filter? A few years back when I got the dozer I learned from a member the final drives seals won't expand with brake fluid. I wish there was an easier fix. This machine really has lots of life left, not to mention it's not all beat up like many I've seen over the years. I'm just hoping I can get the tracks off and fix those seals. I'm also really afraid the track adjustors will take a lot without the right setup(torches esp.) I think when I start to try to turn the nuts things will begin to round off pretty quickly. Any advice would be appreciated fellas!

|

Posted By: heron

Date Posted: 24 Sep 2016 at 10:50pm

|

David, Not sure what you are replying too. I've got a large primary Cat filter I installed under the seat. Are you saying the Baldwin 906 will go in the original fuel filter housing on the motor? Currently I have nothing in there. If memory serves on this thread I posted I was missing a spring or something in the factory secondary fuel filter..

|

Posted By: heron

Date Posted: 24 Sep 2016 at 11:22pm

|

Sorry I missed this post. I'll get 40 wt from Napa and get away from the 15W40. I'll have to look over the track removal as my dad says they always had torches and things to work on the machines. Closest thing I have is a hand held torch. I think the spool leakage is because the hydraulic was over filled before the machine was delivered to me. When I opened up the butterfly on the tank lots of fluid came out. It still seems to be leaking but I'm hoping it's residual from the over fill. Plus it was filled with the univeral tractor fluid, I'm not sure if that stuff is too thin for this machine.. plus it was mixed with who knows what and it's been in there for at least 50 years. One of my simple goals was to change out the hydraulic but now I have to fix my oil filter lines.

|

Posted By: shameless (ne)

Date Posted: 25 Sep 2016 at 3:08am

| I had numerous hyd hoses that replaced the steel lines on my HD5. worked all the years I owned it. and I ran 30 wt non detergent oil year around in it. and like any other motorized machine to this day, I always check the oil level before starting any engine. |

Posted By: shameless (ne)

Date Posted: 25 Sep 2016 at 3:11am

| oh....also....on the track tighteners, I had a machine shop cut the screw tighteners, and weld a new section on, and that lengthened the tightener screw more for more adjustment. worked very well. don't take much. |

Posted By: heron

Date Posted: 25 Sep 2016 at 10:09am

| Not sure as this thread is kind of mixed up but I was asking about whether I can change out the steel lines that go to the oil filter and replace them with rubber as getting steel ones bent to fit with the correct flange sizes.Not to mention I broke the lines all to pieces when I pulled them out. |

Posted By: wayneIA

Date Posted: 25 Sep 2016 at 9:22pm

| Shouldn't be an issue using some hydraulic hose to replace the steel to the lube-finer, could probably just disconnect it though if you aren't going to use the crawler that much. All my equipment I have with the lube-finer has it disconnected and I just make sure to change the oil more often. My crawler doesn't have one on it so I'm not exactly sure how it is plumbed into the engine, but if like on the tractors and combines, you just disconnect the lines and plug the engine ports. You can just leave it mounted (for appearance) and unless someone gets really nosy, they'll never know it isn't hooked up. I've only seen the crawler lube-finer in pictures where it is mounted on the battery box, and I'm assuming that is how yours is. My crawler has just a smaller canister engine oil filter on it under the hood on the left rear side of the engine. |

Posted By: LeonR2013

Date Posted: 25 Sep 2016 at 9:53pm

| The large Luberfiner filter was replaced with a spin on filter #777B. Baldwins # is different I think but you can cross reference the # to any other filter maker. You would need the matching filter base and be convenient to put anywhere. |

Posted By: DMiller

Date Posted: 26 Sep 2016 at 6:48am

| Luberfiner filters are bypass filters only, they do not filter the entire lube oil flow. I took many of these off highway equipment years ago as oils and additives in oils became better where the need of them became less. My 7G has a canister oil filter, I will probably keep it until they no longer make them as it sits in a vulnerable location on the engine to the outside. To put a spin on would be handy but could end up losing the engine I am running. I have considered making and installing a remote location mount/canister replacement set up but that is time consuming and difficult at best to achieve proper function. |

Posted By: LeonR2013

Date Posted: 27 Sep 2016 at 2:43pm

| About the track adjusters, my 5 had two cinch bolts that kept the adjuster from moving. Rent, beg, or borrow a torch. That machine hasn't had the track adjusted in 20-30 years? So it needs some help and heat will do it. And it could take a bunch. Allis made a special wrench to adjust the tracks with. It was only about a foot long and was heavy enough to put any length cheater pipe on it. The head of it was curved so you could get a bigger movement out of the adjuster. When you get it apart drill holes in everything and put in grease zerks. You'll be glad you did every time you go to adjust the tracks. By the way you can probably get a adjuster wrench from several of the guys who deal in the 5's. |

Posted By: heron

Date Posted: 28 Sep 2016 at 9:14am

|

Yes, I'm pretty sure I have that wrench or my dad still has it in his garage someplace. My father said it had to be re-shimmed. Yes, torch should be my friend but now I'm trying to find a place to rent a torque wrench for the sprocket bolts if I get that far. I've got a mobile mechanic coming to take a look at it Thurs morning. Not sure if that will work out as my wife is on my case about dumping money into something that I don't and will not use.

|

Posted By: wayneIA

Date Posted: 29 Sep 2016 at 12:47am

| To torque the sprockets on my HD-5 I just calculated how many pounds I needed on the end of the wrench we built to come up with a torque value. May be hard to find a torque wrench that will work on it since you won't find many sockets deep enough to reach over the axle to the nut. If I remember correctly, and didn't mess my math up double checking, I had a 6' wrench and needed 250 pounds on it to make 1500 pounds of torque. |

Posted By: HudCo

Date Posted: 29 Sep 2016 at 9:39am

| was just reading and seen it said that the hydralics were over filled , could it have water in the bottom ? |

Posted By: Coke-in-MN

Date Posted: 29 Sep 2016 at 11:10am

|

rear sprocket torque , have a adjustable nut wrench (like large pipe wrench with smooth jaws) put that on and then 10 ft piece of 2" pipe over handle - figured 10' out from nut center - then my 180 pounds onto pipe = 1800 lb torque on nut . ------------- Life lesson: If you’re being chased by a lion, you’re on a horse, to the left of you is a giraffe and on the right is a unicorn, what do you do? You stop drinking and get off the carousel. |

dadsdozerhd5b wrote:

dadsdozerhd5b wrote: