Allis 80 T or R Sickle Mower

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=36476

Printed Date: 15 Sep 2025 at 12:53am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Allis 80 T or R Sickle Mower

Posted By: jfrey

Subject: Allis 80 T or R Sickle Mower

Date Posted: 31 Aug 2011 at 10:39am

|

Hey everyone, I just purchased an 80 R or T not sure which but I broke one of the connecting arms under the twin drive. Does anyone know of a salvage dealer that could come up with a replacement? The local dealer I called said the part is no longer available. Thanks in advance for the help. Joe

|

Replies:

Posted By: Dusty MI

Date Posted: 31 Aug 2011 at 10:49am

|

It would help if we knew where you are located. Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Tracy Martin TN

Date Posted: 31 Aug 2011 at 11:11am

|

The 80 R is a Snap Coupler attaching mower. The 80T is a trailer type mower. Someone parting some out can probably help you out. Tracy Martin ------------- No greater gift than healthy grandkids! |

Posted By: jfrey

Date Posted: 31 Aug 2011 at 1:10pm

|

I'm located in Nebraska to answer the post on location. Thanks Mr. Martin on the clarification, someone previous to my ownership re-engineered the mower so it mounts as a three point model. I think its an 80R though based on photographs I’ve seen on the internet. I am regretting buying it as I'm a believer in keeping things original. Unfortunately, I needed a mower to cover some seeded buckwheat and I made a hasty purchase. I’m not sure if I’m having an unusual large amount of issue with the mower or if I have a lemon. But out of curiosity I have this on my JD 730 and run it at PTO speed, am I pouring too much RPM into it? Between a belt (previous one wasn’t the proper belt), shearing a pto pin, losing a knife (routine maintenance I know), and now busting one of the arms that moves the sickle I’m beginning to think I may have taken a ride on this purchase. Any advice from the veteran Allis supporters? |

Posted By: KGood

Date Posted: 31 Aug 2011 at 2:34pm

| I wouldn't think it's normal for a connecting rod to break unless it was hammering from a bad bearings in the rod or the reel drive tower. I have a #7 pull type and after new bearings in the con. rods wich are pricy and aircraft grade and getting a tower to quit leaking oil I like it. With help from guys on here on setting it also. It should be pretty quiet when opperating if not you've got some slop in the drive somewere and it will end up breaking. |

Posted By: Tracy Martin TN

Date Posted: 31 Aug 2011 at 2:36pm

| The 80 and 82 series mowers if maintained are trouble free as they come. If you broke the knifehead, more than likely this will help. Your sicklehead has a post that bolts to it, it runs in the twin wheels crossbar. If excessive slop they will break sicklehead. If your mower is dull and choking, you will notice a louder slapping noise at this joint with excessive play. Sounds like you have several conditions that need attention. Eliminating them will increase the service of your mower. HTH Tracy Martin |

Posted By: jfrey

Date Posted: 31 Aug 2011 at 4:33pm

| So the road ahead seems a little long, does anyone know where I could buy another connecting rod so I can start to diagnos these other concerns? |

Posted By: Dusty MI

Date Posted: 31 Aug 2011 at 4:49pm

|

I've never run a twin wheel drive A.C. mower, it's my under standing it is a very good mower. I had a 7' semi mounted IHC mower. I ran it with a IHC C, full throttle 3rd gear, 4th was road gear. So I would say no you are not running it too fast. Good luck on getting it working right. Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: NNYACAL

Date Posted: 31 Aug 2011 at 5:10pm

|

I also just bought a 80r mower aand it had a broken bearing support that drives one of the twin balance wheel, called sandy lake and they aare having a new one shipped fron Kansas city parts depot tomorrow direct to me. were very knowledgeable and a lot of help sure hope parts come fast cause the grass is growing wicked.

NNYACAL ------------- G,IB,B,C,CA,RC,WC,WF,WD,WD45,D14,D17SERIES 1,2,4 |

Posted By: CTuckerNWIL

Date Posted: 31 Aug 2011 at 5:32pm

|

The only sickle mower I have ever run is my old JD I rigged up on the 45. I have never ran it at PTO speed. I think it would shake apart. I have mowed thick grass at half throttle in second gear and it works fine. I have mowed weeds off in the pasture at a little over an idle in 3rd gear.

------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Chalmersbob

Date Posted: 31 Aug 2011 at 10:33pm

| Dem old JD's shake everything apart |

Posted By: Chalmersbob

Date Posted: 31 Aug 2011 at 10:35pm

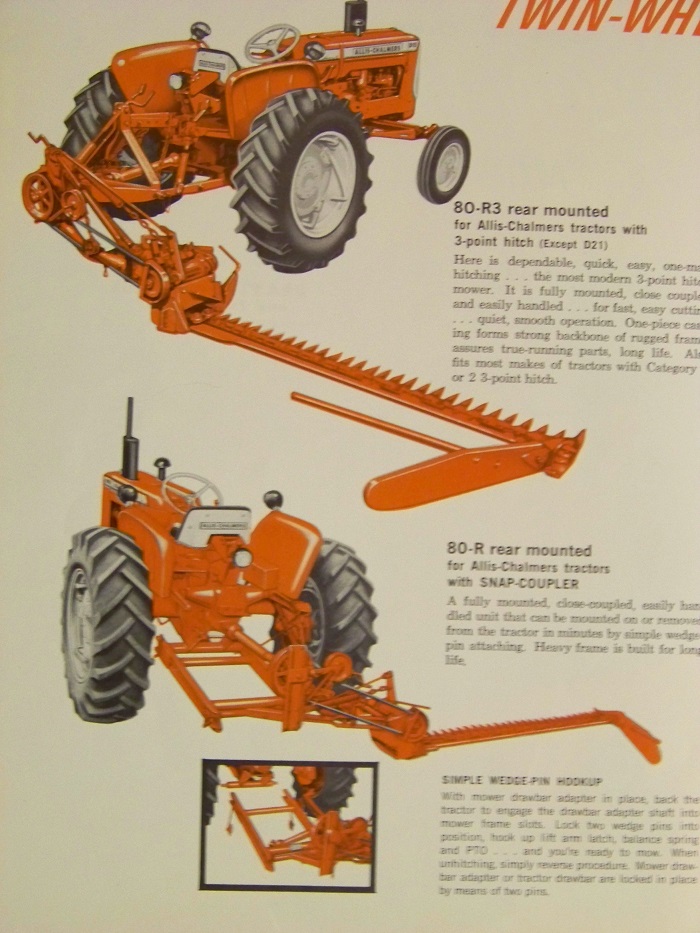

| They also made a 80R3 that was a 3 point. Bob |

Posted By: ranger93

Date Posted: 30 May 2013 at 7:12am

| i just found this post and i have a ac sickle mower as well, not sure how to hook it up and where i can find a bet for it. it was given to me about a year ago. where do i find the numbers on the unit so i can get better help from everyone on here |

Posted By: Gatz in NE

Date Posted: 30 May 2013 at 7:21am

|

you can view the AGCO parts book as a "guest" http://www.agcopartsbooks.com/PartsBooksN/login.aspx?region=NorthAmerica (hopefully) here's the 80 series mower parts list & diagrams. http://www.agcopartsbooks.com/PartsBooksN/Viewer/Default.aspx? just click on the model # you're interested in, and on the next page, click on one of the headings at the left side to choose what to view. |

Posted By: john(MI)

Date Posted: 30 May 2013 at 10:18am

|

pictures posted on here will help with identifying mower type. To me the easiest to identify are the 80T and 82T. The axle on the 82T is angled, the 80T is not. for more help in narrowing it down: T = trailer type. has tires. S = side mount. mounts in front of rear wheels. R = mounts to rear of tractor. I think its R3 for a 3 point mount? ------------- D14, D17, 5020, 612H, CASE 446 |

Posted By: orangereborn

Date Posted: 30 May 2013 at 11:53am

|

Look like this if this works....Maybe someone can help if it does not. http://www.allischalmers.com/forum/forum_posts.asp?TID=55804&title=a-c-82t-sickle-mower" rel="nofollow - http://www.allischalmers.com/forum/forum_posts.asp?TID=55804&title=a-c-82t-sickle-mower I have parts mowers. Thanks....Dale Orangereborn 964 192nd Ave New Richmond, WI 54017 715-247-3079 715-781-2055 mailto:Orangereborn@hotmail.com" rel="nofollow - |

Posted By: RMD

Date Posted: 30 May 2013 at 1:42pm

| I have a No. 7 mower and have aquired some spare parts over the years. I think I might have a connecting rod that fits an 80 that doesn't fit my No 7. I have the parts books, so if you know the part number that you need I can look up which style it is and whether or not it is what I have. I won't give it away ( I've paid dearly for what I've collected), but would sell for market value. |

Posted By: Ray

Date Posted: 30 May 2013 at 6:09pm

|

I would have the connecting rod along with many other parts for the Allis mowers. Sickle heads,bushings,sectilons,bars,guards,caps,lift cable,belts,ect. 785-353-2392 Thankss |

Posted By: Flint23

Date Posted: 03 Jun 2013 at 1:20am

does it look like one of these?

------------- been there done that, not doing it again... |

Posted By: ranger93

Date Posted: 03 Jun 2013 at 9:26pm

| having a tough time loading photos of mine but yes my mower looks like that bottom picture |

Posted By: Flint23

Date Posted: 06 Jun 2013 at 9:39pm

|

OK. you have the 80-R. They made two different styles of the connecting rods and crossbars, prior to serial no. R-6101 the connecting rod didn't have a bearing cap with grease zerk on it. The serial no. is on the top of right frame above the front tube. HTH. ------------- been there done that, not doing it again... |

Posted By: Flint23

Date Posted: 06 Jun 2013 at 9:40pm

|

P.S. not sure if bearing are the same in both or not. ------------- been there done that, not doing it again... |

Posted By: walterfd

Date Posted: 30 Jun 2015 at 4:56pm

|

Your comment about the knifehead piqued my interest as I have broken one on my 80t. I pulled this out of a fence row and the knifehead was broken. It hadn't been used in a number of years. I replaced it along with the sections, some of the guards, the tires, a drive pulley spring and the drive belt. I still missing both of the original caps on the twin wheels where the crossbar / bearing sits. I made two of these 3-bolt bearing covers out of tin but I'd like to find two originals. Until then, I keep using it with my homemade ones.... After lots of wire wheel rust removal, cleanup, grease and oil it was running very smoothly and quietly. It was cutting very nicely in 3ft tall grass/red clover mix. Then bang! the new knifehead broke. Both knifeheads were broken at the first rivet, closest to the twin wheels crossbar. The "post" where the knifehead connects to the twin wheel crossbar is actually a large bushing with serrations on the bottom to match the serrations on the knifehead, a large bolt goes down from the top, through the "post/bushing" and screws into the knifehead. While the "post/bushing" floats up and down easily in the twin wheels crossbar, I wouldn't call it slop. It seems to me that the twin wheels crossbar travels up and down some while being pushed in and out. It would appear that anything done (such as a large washer on top) to secure the twin wheels crossbar to prevent the up and down movement (slop?) would also keep the "post/bushing" from turning inside of the twin wheels crossbar. You could be correct and have highlighted a cause for my issue as well the original poster here, so I'll take a closer look at this point when putting it back together. I actually suspected that the problem was with the most inside section hitting the inside rock guard (most likely the upper part) instead of sliding through it smoothly. In both cases there was damage on one or both of these first section/guard components. The was thinking it must be an issue with the first hold-down bracket or the wear-plate. I appreciate all the great help on this site any additional suggestions will be welcomed. Doug. |

Posted By: AaronSEIA

Date Posted: 30 Jun 2015 at 5:30pm

|

If you look at pictures, the original hold downs on the first 2 were special and "square" much more than the replacement high arch ones are. I think that helps keep the sickle bar from flopping around fore/aft too much. Book says to adjust the clamp bolt on the drive bushing so a soft hammer blow can move the cross arm. At least that's how I read it. AaronSEIA |

Posted By: DennisA (IL)

Date Posted: 30 Jun 2015 at 10:58pm

The #7 mower was the snap-coupler mower. For the 80R mower you had to take the hitch off and mount a bracket where the hitch bail would mount. ------------- Thanks & God Bless Dennis |

Tracy Martin TN wrote:

Tracy Martin TN wrote: