Model B steering

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=28225

Printed Date: 17 Nov 2024 at 11:06am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Model B steering

Posted By: Scott in MA

Subject: Model B steering

Date Posted: 30 Mar 2011 at 12:43pm

|

Hi all

What can cause very hard steering (with no loader or implements) on a Model B. It's been like this since I bought it. Maybe this is normal - I don't know. The steering box oil level is normal. I assume that the steering shouldn't be this hard on such a light tractor. It has car tires if that matters. Should I be relying on brake steering instead? Thanks for the help.

|

Replies:

Posted By: wfmurray

Date Posted: 30 Mar 2011 at 12:53pm

| The shaft that turns the wheel proably needs greese . |

Posted By: Scott in MA

Date Posted: 30 Mar 2011 at 1:08pm

|

I already greased that but the zerk is the push-in type (as opposed to threaded) and it keeps popping out when I get enough pressure with my grease gun. What can hold that in? The green loctite intended for flanges? That's all I can think of. There's just a bushing in the steering box, right? If I'm correct, that would rule out a bad bearing.

With the exception of the troublesome steering shaft zerk, I've already greased every zerk between the steering wheel and front wheels.

|

Posted By: Bee

Date Posted: 30 Mar 2011 at 2:36pm

|

Pop the steering arm off that bolts to the steering box, then you can see if the box rotates freely. May help to isolate your problem.

------------- Bob, North Carolina 1949 B |

Posted By: Dick L

Date Posted: 30 Mar 2011 at 2:47pm

| Very hard to tell where a problem is when you have more than one moving part hooked together. You need to remove the drag link and see how easy the front spindles move and then turn the steering wheel to check there. You could have bad bearings in the steering box on the bottom of the lead screw. The cross shaft could have became rusted in the outer bushing. the pawl could have made a wider area in the lead screw and someone tightened the adjusting screw on the right side plate and the pawl not have enough room to move beyond wide area. One or both of the spindles could be tight for some reason. If a bushing wore out and a piece broke off and wedged its self down into the bushing. So many things can happen to an old tractor. This is one of those type problems that most generally needs to be taken apart and looked at to find where the problem is. |

Posted By: wbecker

Date Posted: 30 Mar 2011 at 2:55pm

|

The B should steer very easy.

Do as Bee said, take the arm off the steering gearbox, or the drag link off the arm.

Then turn the steering wheel. If it is still hard (should be very easy with 1 finger), see if the adjusment on the steering box is over tightened, the screw should be just snugged, then back off 1/4 turn or so and tighten the jam nut. If it is still hard then the bearings on the worm shaft are very bad, (this is not a common problem).

If the steering wheel turns easy with the arm or drg link off, then you have a problem with the spinels in the front end bushings.

Hope that helps.

Bill B ------------- Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152 |

Posted By: rickwsomd

Date Posted: 30 Mar 2011 at 4:06pm

|

I know it probably is not your direct problem, but I find that if the air in the front tires get a little low on my B, it gets harder to steer. Rick W. ------------- Rick W.(So.MD) |

Posted By: wbecker

Date Posted: 30 Mar 2011 at 6:24pm

|

Rick has a good point, tire pressure will make a difference, and big tires will also.

The steering gear on the B is the weakest item on the tractor in my opinion. You should never turn the weels while the tractor is not moving, this saves a lot of wear on the sector shaft and the worm gear. ------------- Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152 |

Posted By: Dick L

Date Posted: 30 Mar 2011 at 8:28pm

I have taken several apart that this bearing in the botton was rusted to the point it was almost gone. Tok both hands to turn the steering wheel.

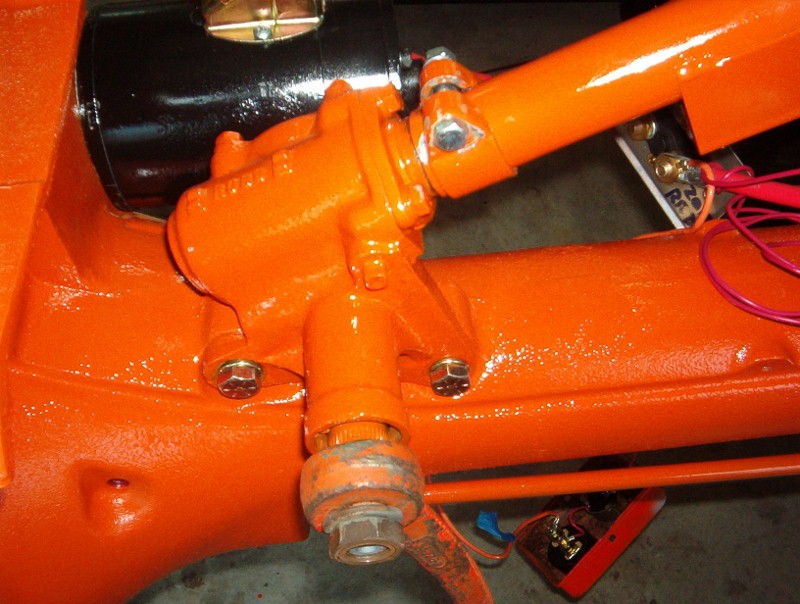

This cross shaft was rusted in the places shown and even though the pawl was in good shape the steering was very hard to turn. The bottom bearing race was rusted real bad and fell apart when removed from this Ross B steering box. The cross shaft was also hard to remove becaues of the rust in the bushing area. rain water can run down the shaft on these and enter the steering box thru the top bearing.

|

Posted By: Chris/CT

Date Posted: 30 Mar 2011 at 8:34pm

| Does a "CA" Steering box fit in a "B"?? I'll answer my own question, no. |

Posted By: GlenninPA

Date Posted: 30 Mar 2011 at 8:48pm

|

Things get extra bad, once the seals go, and grease get's pumped in instead of filling with oil. The bushings are lubricated by a little hole in the casting that let's oil down in between the two bushings on the shaft. Once the grease goes in, that little hole gets plugged up, and it practically invites the rust to take over. You can see where this has happened on the first shaft photo Dick displays above. I have tore apart several of the Ross boxes that were froze up. All of them had bad seals, had been greased, and ended up rusting fast in the shaft area of the bushing. All the ball bearings were rusted as well, and the races were pitted beyond repair. Believe it or not, grease drys out and makes a powdery dirt that is a real pain to clean out. A glass bead cabinet does the best job.

Some had a wore out "button" on the arm, I got replacement from Tracy Martin on this site. The arm is pretty hard steel, needed carbide tools to drill out and ream the spot to weld in the new piece. That wore piece made for a lot of play.

|

Posted By: Dick L

Date Posted: 30 Mar 2011 at 8:48pm

| It all depends on how you define the word (FIT). It will bolt into place but to work in the right steering wheel direction it would need the C or CA wide front. The narrow one would work but to look like a B you would need the wide front. The sterring box arm Would be up rather than down to turn the front wheels the correct direction. The CA Ross has two pawls on the cross shaft rather than the one on the B. A much better design for lasting. |

Posted By: Chalmersbob

Date Posted: 30 Mar 2011 at 8:49pm

|

Is your B a "wishbone" front or an adjustable front axle.

I have a B with the adjustable front axle that steered really hard. I found the both tie rod ends were rusted fast. Once I got them freed up, it steers very easy. Bob

|

Posted By: Scott in MA

Date Posted: 30 Mar 2011 at 9:18pm

|

Thanks for all the quick info. Once my shoulder heals from surgery I'm going to try the Bill B. approach involving the steering tension adjustment. I found the bolt head with my hand on top of the steering box. Looks like the tool box has to go first for me to access it. Bob, I have the wishbone front. I'm hoping the fact that the previous long-term owner kept the B in a shed while it was under his care kept water out of the box. |

Posted By: Dick L

Date Posted: 30 Mar 2011 at 9:43pm

| You should be able to get to the adjustment screw by removing the starter. All tank supports/tool boxs have a hole that will let you put a socket on the lock nut. If someone replaced the tank support with an after market one all bets are off. |

Posted By: mudduck46b

Date Posted: 30 Mar 2011 at 11:55pm

| had same prob. a few years back and had to jack front up ,lower or loosen wheel assembly and found there were shims for proper spacing . also gave me opportunity to clean gears . dont do this alone and block your eqiupt. sucure .but as grandpa ALLWAYS SAYS check the easy stuff first !! hope this helps |

Posted By: wbecker

Date Posted: 31 Mar 2011 at 2:25pm

|

Glenn,

I restored a John Deere M and found it has a very simmilar Ross steering gear, the big difference is they have a removable/replacable "Pin" in the sector shaft. It just slides in, can't fall out due to contact with the worm gear.

What I have been doing whith the B Ross is I heat the pin area while keeping the shaft cool with wet rags, this takes out some of the hardness so it can be drilled with cobalt drill. Then I get a new "Pin" from John Deere PN AM1515T, and slide it in.

The john Deere "Pin" is $66, not cheap but is very hard. I'd like to have the info for the "Pins" you buy, and price. Are they hardened?

Thanks, Bill B ------------- Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152 |

Posted By: GlenninPA

Date Posted: 31 Mar 2011 at 2:46pm

|

Bill,

Tracy Martin (TN) on this site makes and sells the hardened pins for the Ross gears. Contact him via PM and he can give you the specifics. I was pleased with his work.

Glenn

|

Posted By: mudduck46b

Date Posted: 31 Mar 2011 at 2:59pm

|

Posted By: mudduck46b

Date Posted: 31 Mar 2011 at 3:14pm

| here is the b iam working on I took light off and I need to fix the seat but it seems pretty complete I am starting a garden this spring and looking for a small plow save $ on food this year maybe? |

Posted By: Dick L

Date Posted: 31 Mar 2011 at 3:22pm

| I hate to burst your bubble but that there B ina picture am a C. |

Posted By: David Gibson (OH)

Date Posted: 31 Mar 2011 at 4:31pm

|

That's not a B, it's a C. ------------- David Gibson http://www.darkecountysteam.com" rel="nofollow - http://www.darkecountysteam.com 1956 WD45 |

Posted By: mudduck46b

Date Posted: 31 Mar 2011 at 5:41pm

| well this is good to know dad always said b but things he said were iffy at the end ,but maybe he confused the old deere b he actually cried when he sold it . dous my ''C'' seem to be a 46 and how can I tell? and whats the differnce between b & c |

Posted By: David Gibson (OH)

Date Posted: 31 Mar 2011 at 5:59pm

|

The B is a one row tractor and a C is a two row tractor. The serial number should be stamped on the torque tube by the shifter. It should start with a C (If the tractor was a B it would start with a B) There is a database on this site that will tell you the year by the serial number. On a side note I actually find the C's easier to get on than a B. ------------- David Gibson http://www.darkecountysteam.com" rel="nofollow - http://www.darkecountysteam.com 1956 WD45 |

Posted By: Dick L

Date Posted: 31 Mar 2011 at 6:58pm

Quick easy way to tell is to look at the drawbard. The C has the wider drawbar.

|

Posted By: Scott in MA

Date Posted: 02 Apr 2011 at 8:31am

|

PART II I think the steering shaft is my problem. Can anyone tell me how to remove the shaft that the steering wheel attaches to. Will I lose steering box oil all over the floor. I followed the wise advice here. Removed the arm from the box. Steering wheel still hard to turn. I removed the starter and adjusted the steering box screw all the way. Barely a difference. When I go to grease the steering shaft the pressure causes the (push in, not threaded) zerk to pop out. I'm guessing there is a whole lot of crud stopping the grease from dispersing, so instead the weakest link - the zerk - pops out. I'm thinking some sandpaper, wire brush, and a bunch of fresh grease might do the trick. Any suggestions, advice, warnings, instructions? Thanks thus far, gentlemen. |

Posted By: Dick L

Date Posted: 02 Apr 2011 at 9:54am

|

No worry about oil on the floor if you put a tarp down or a big pan.

Your not going to get the shaft out without removing the fuel tank, tank support/tool box. The back steering box cover will have to be removed, the steering arm will have to be removed, the cross shaft will have to be removed, the steering wheel will have to be removed, the steering shaft tube should be removed, then the four cap screws will have to be removed, the top bearing retainer will have to be removed and then you can pull the shaft out.

Myself I would get the steering wheel out of the way then remove the steering box assembly in one piece then disassemble it on the bench.

|

Posted By: Bee

Date Posted: 02 Apr 2011 at 10:11am

Shaft resides in the steering tube which is a press fit with a clamp. Like Dick l states you will have to remove the gas tank, Steering wheel (don't lose the half round key), the tool box, unbolt the clamp near the steering wheel to downtube so you can remove the tool box. The tube is bolted on with a clamp and once removed you can wiggle it off. Now you have access to the shaft. The tube is bolted on with a clamp and once removed you can wiggle it off. Now you have access to the shaft. ------------- Bob, North Carolina 1949 B |