Allis Chalmers 5040 Clutch

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=207933

Printed Date: 05 Feb 2026 at 12:35am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Allis Chalmers 5040 Clutch

Posted By: lkennett

Subject: Allis Chalmers 5040 Clutch

Date Posted: 25 Aug 2025 at 2:40pm

|

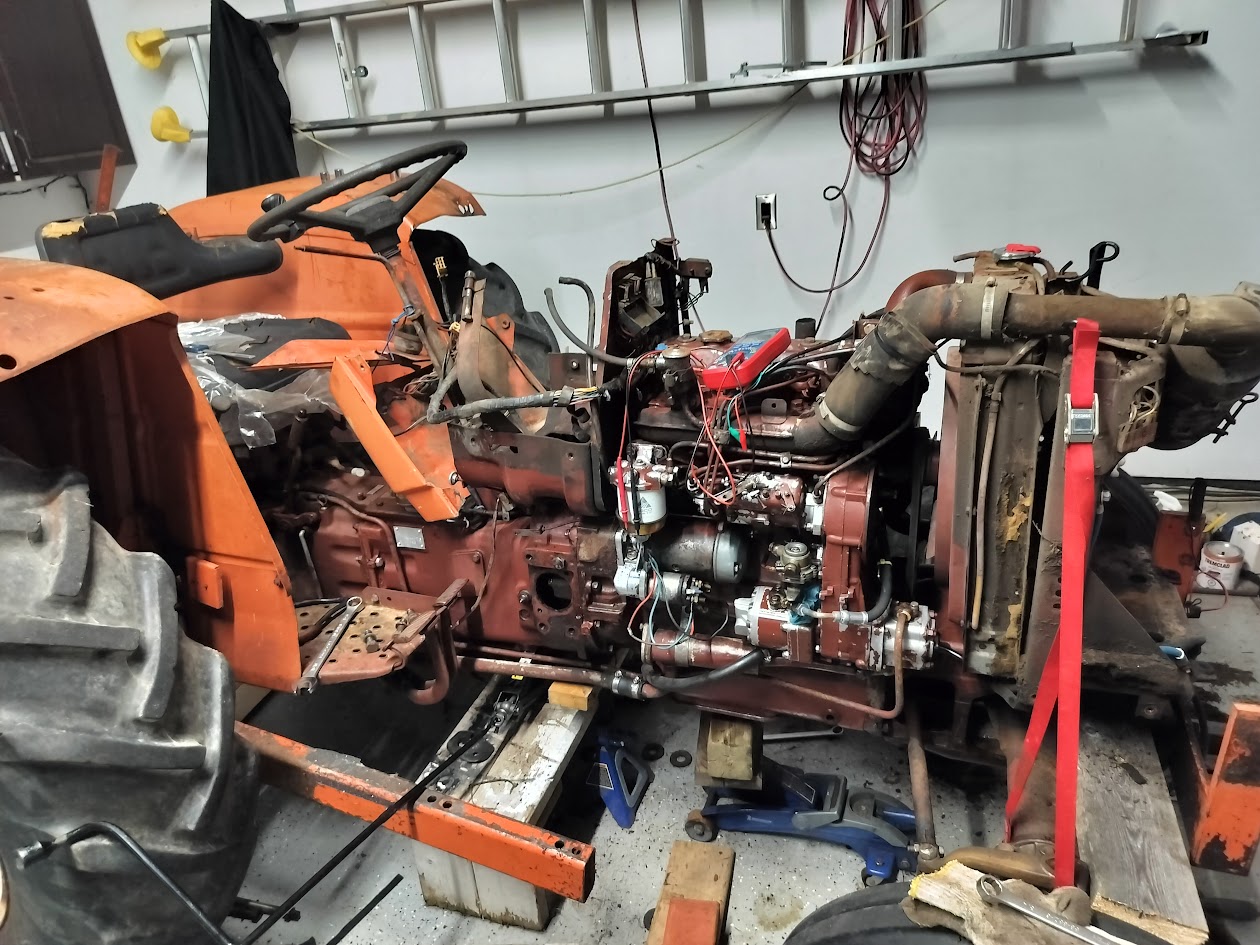

Hi guys, I have a new to me 1976 5040. 6 speed with the dual clutch. The clutch has been slipping badly (known problem when I picked it up) I have the inspection plate removed after taking the loader frame off. Anything in high range is completely useless. When I take the inspection plate off the first thing I notice is alot of grease. Second thing is the clutch fingers are touching the throw out bearing (I think there should be a gap). Does anybody have access to the clutch specs. How to adjust? Basically pages from the service manual. I am about a day from splitting the tractor, I only have the fuel linkage and a hydraulic line to disconnect and I can start. I expect once I get it apart it probably needs a whole clutch kit and flywheel machined but I would like to verify if I knew the tolerances.   |

Replies:

Posted By: AC720Man

Date Posted: 25 Aug 2025 at 8:07pm

|

Not familiar with those but My guess is someone over greased the throwout bearing? Assuming that’s what the grease zirk is for. Hopefully Gary Burnett will see the thread, he knows these tractors well. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: lkennett

Date Posted: 25 Aug 2025 at 9:17pm

|

I have never had a tractor with a greaseable throw out bearing. Nice feature but don't over do it I would think. My dad just had to have the throw out bearing done for the second time on his Case 685. $$$ to have a shop involved. He wishes it was greaseable!. Lots of mysteries with this 5040. Unknown hours. The previous owner said it was a loader tractor used in the hay field. He is an older guy that seems to buy and sell alot of equipment. He was using the loader and noticed the transmission was overflowing with fluid. The seal on the loader pump let go (I posted previously) and was dumping into the trans. I said is it possible a bunch of fluid got dumped into the clutch area? It just feels like nothing is there. I can pop the clutch in 3rd low and the tractor just starts to walk forward. High range 4th it wont even move unless i am downhill. No smells, no smoking. I only have to disconnect the main hydraulic return line and I can have it split tomorrow or the next day. It would be nice if I took this apart and it just needed a clutch disc and not the whole kit. I am in Canada, probably looking at $1500 for the parts at least. Lawrence  |

Posted By: lkennett

Date Posted: 26 Aug 2025 at 9:02pm

|

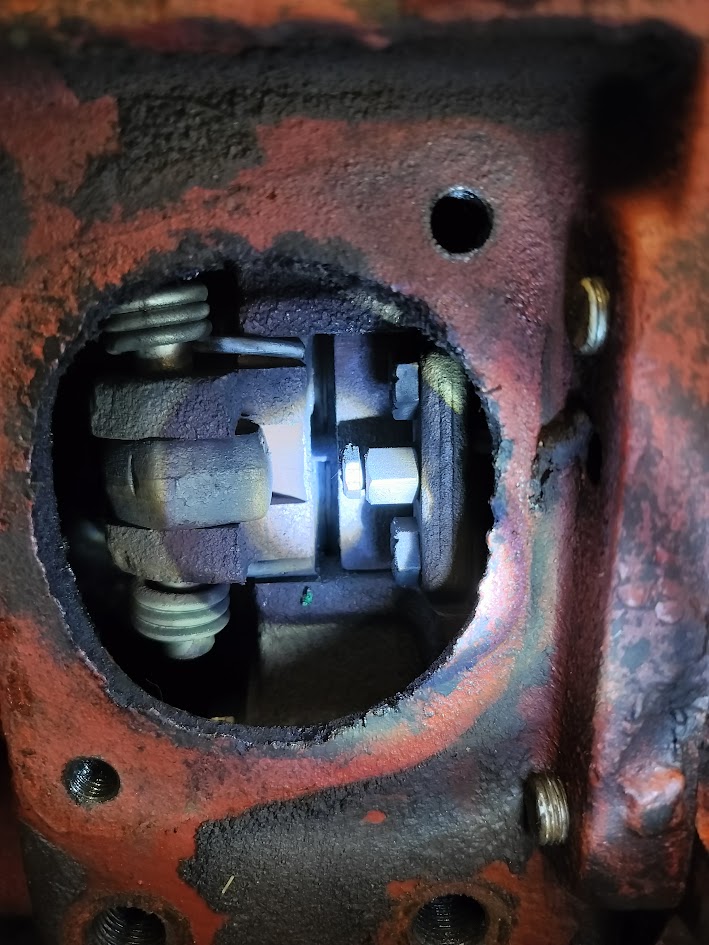

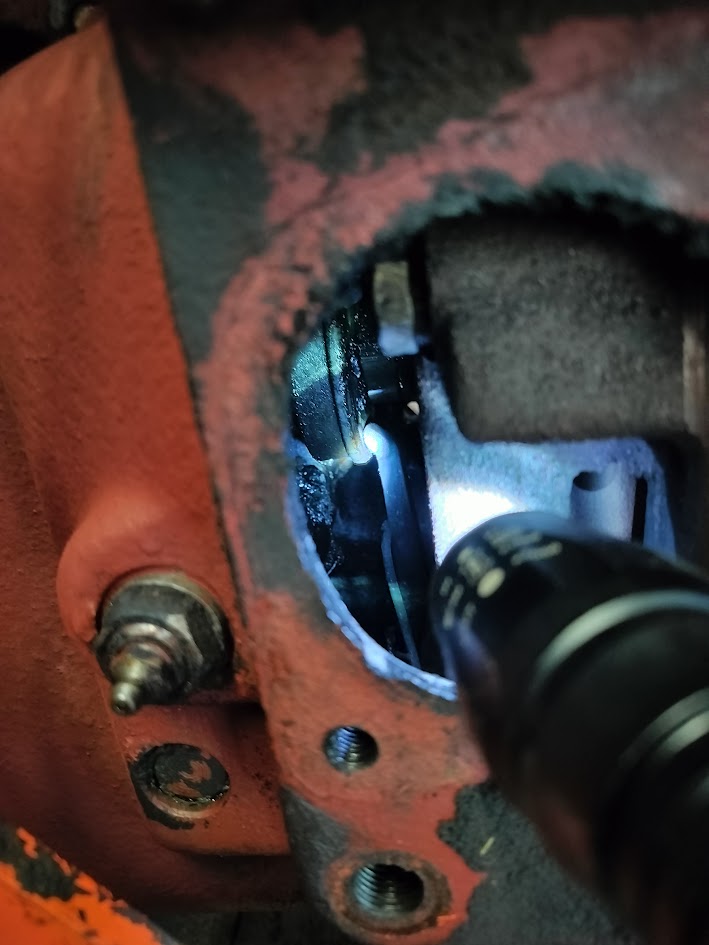

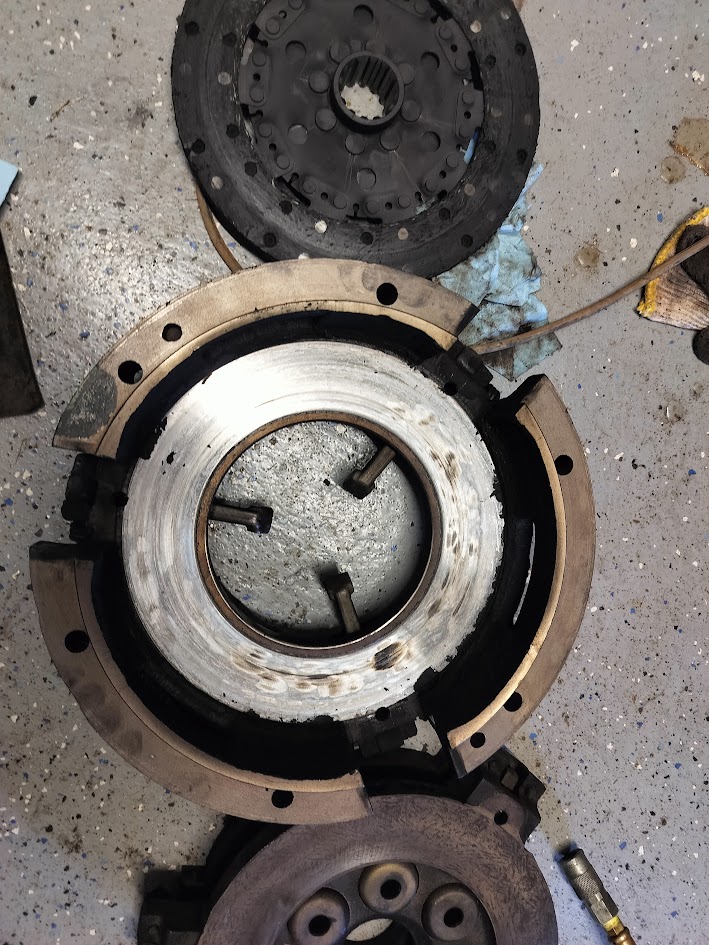

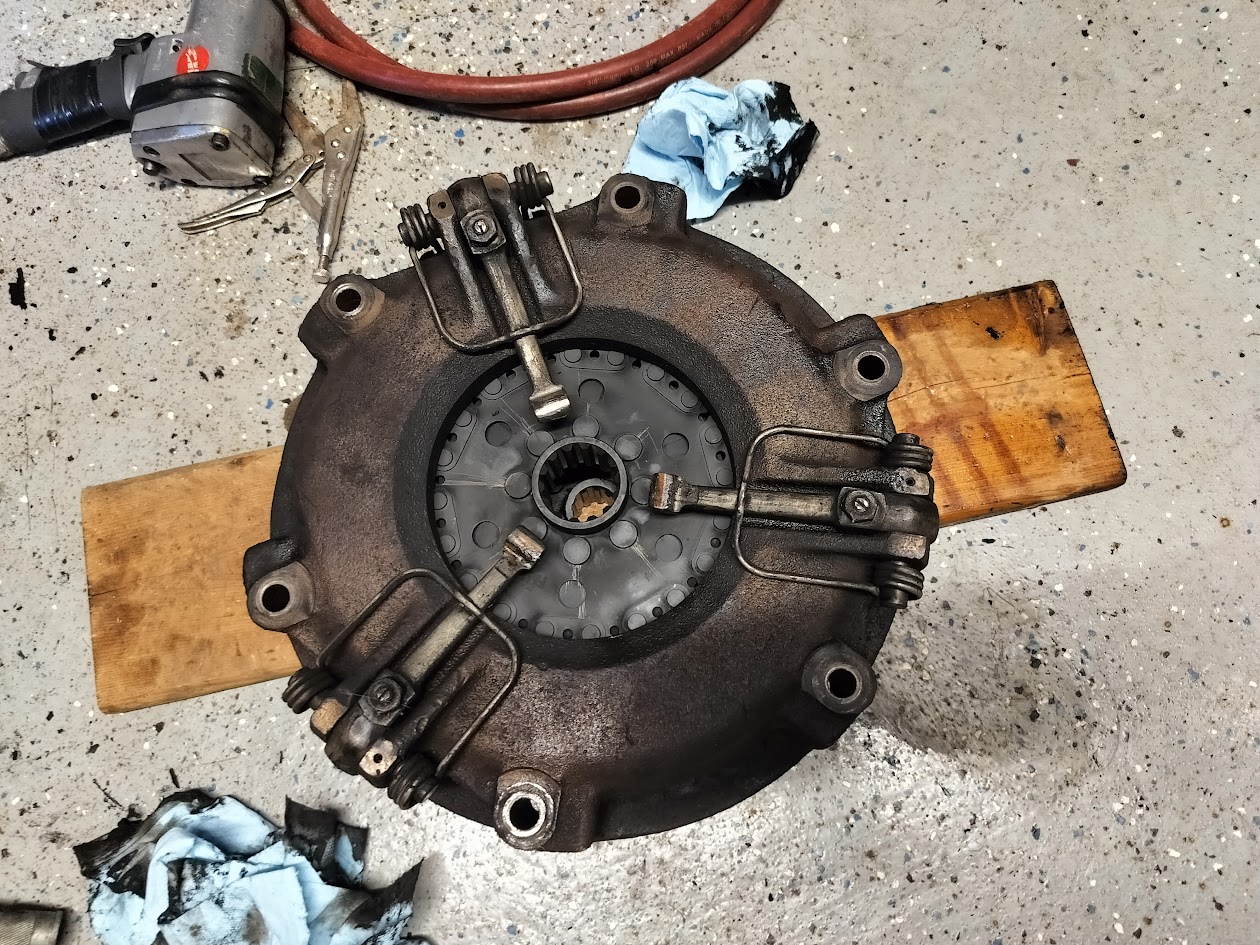

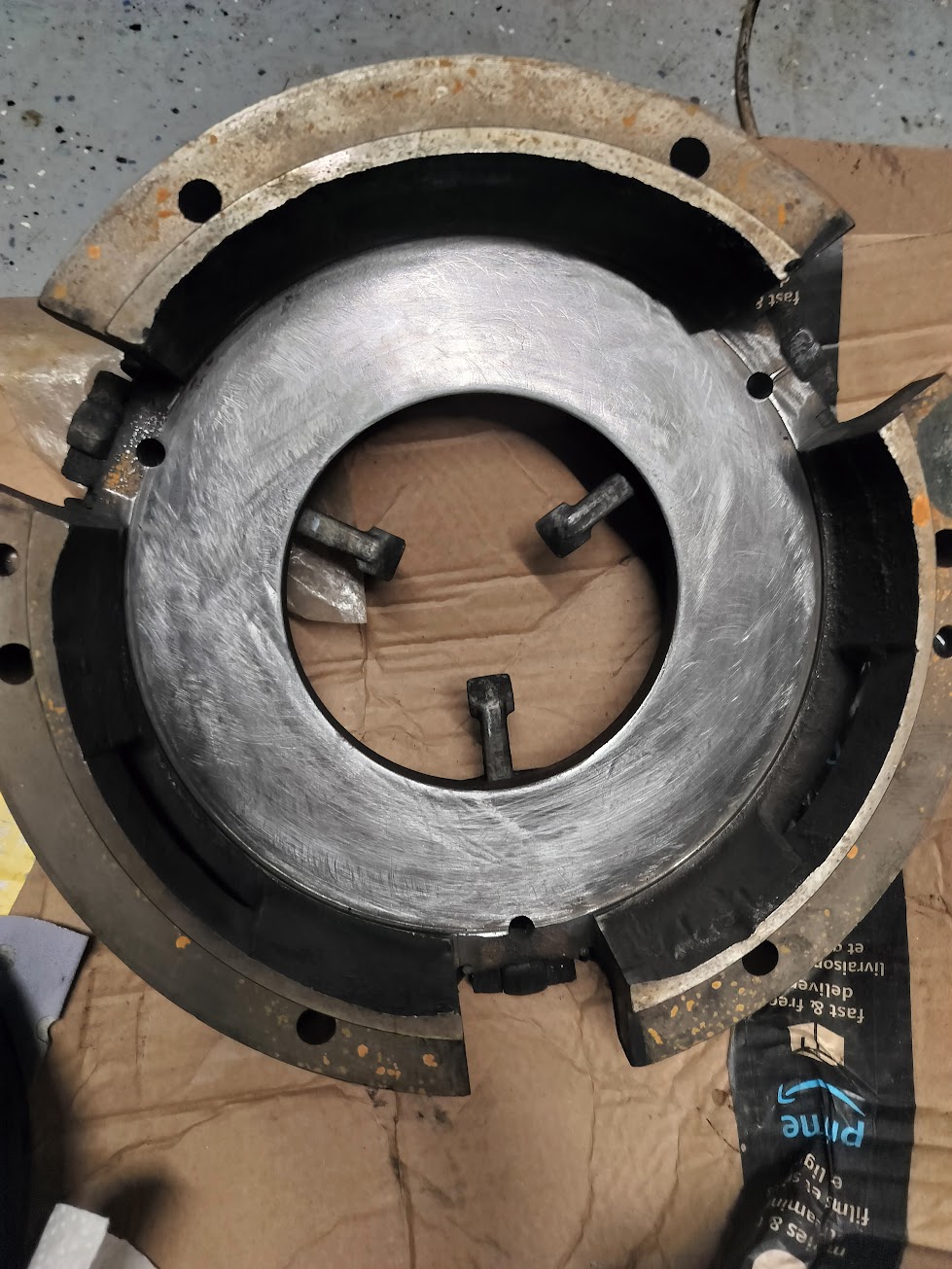

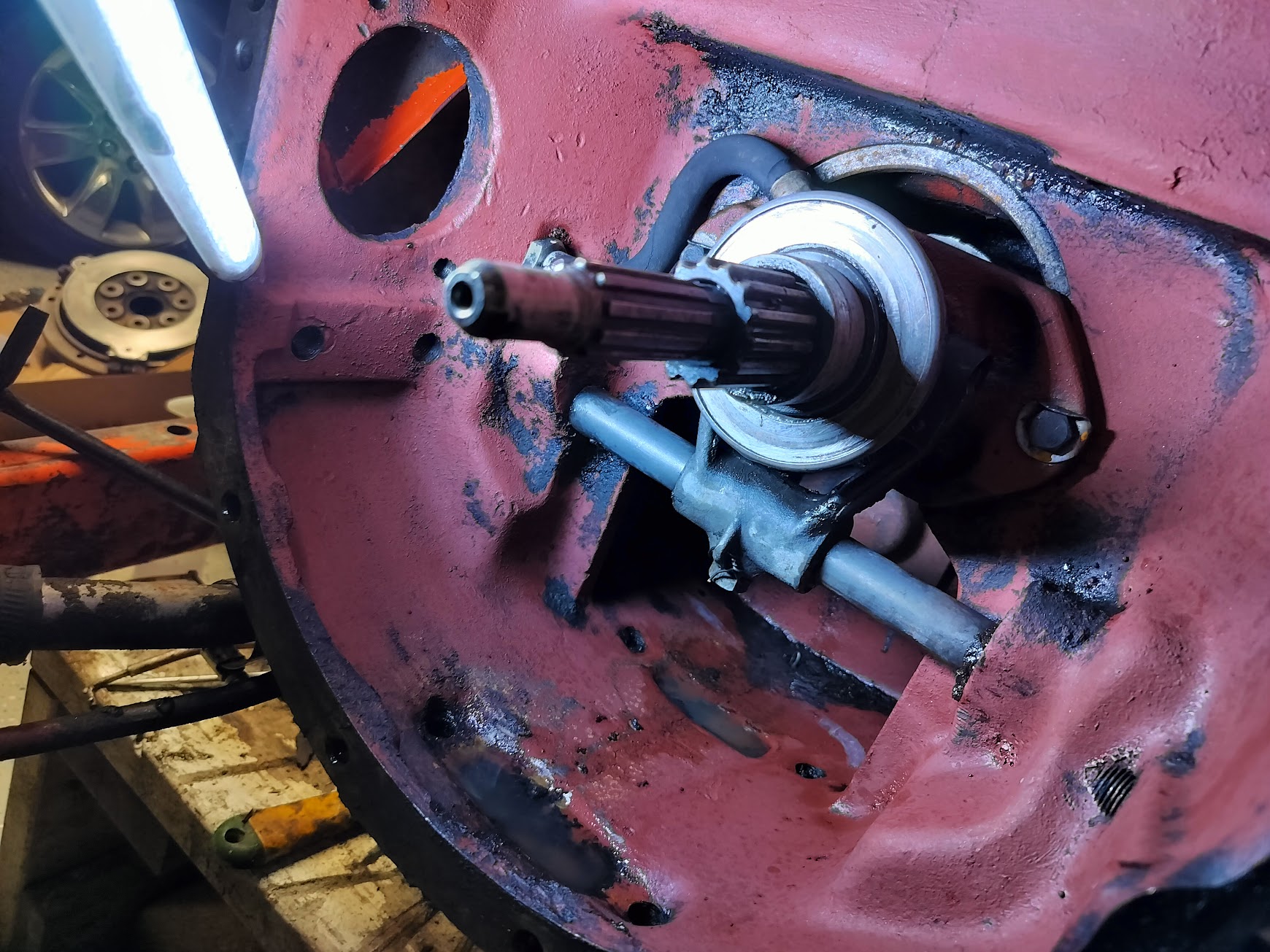

Split the tractor tonight. Not dusty but greasy! seems like alot of oil. I had a half can of brake clean but I will run to town tomorrow and get a couple more cans. Just so much to clean up. The driven clutch is toast. PTO clutch looks fine. Throw out bearing and Pilot bearing also look fine. I am not sure about the rest of it. If anybody has specs it would be appreciated. Trying to figure out next steps. Here are some pics.        |

Posted By: DougG

Date Posted: 27 Aug 2025 at 6:33pm

| Wow- it is toasted,, Everything can be redone- gotta find the source of the contamiante,, might as well put a new rear main seal , and every seal thats in there |

Posted By: Gary Burnett

Date Posted: 28 Aug 2025 at 1:58am

| If it was mine I'd get an all new already set up clutch pack and with new PTO disc,plus new release bearings.Redid my Oliver 1365 4WD a few years ago,same basic set up used all new parts.Putting old parts against news ones in those units doesn't work out well most times. |

Posted By: lkennett

Date Posted: 28 Aug 2025 at 5:01pm

|

Behind the flywheel is dry, transmission side has seen some oil. Gonna work on cleaning it up tonight. Got some products to degrease. I knew going into this it needed a clutch. I was expecting worse actually. The flywheel is not bad, neither is the pressure plate. Nothing to catch a finger nail on. no ridge on the edges. I am on the fence about spending the money or just throwing a PTO and Trans clutch at it. The PTO clutch is actually in really good shape. The tractor is very easy to split. not saying I want to do this again in a year. I had mentioned the seller told me the transmission had been overfilled and was throwing fluid out the vent. It was overfilled due to the loader. Not sure if this pressurized the transmission and it could have blown oil out the input shaft seal. The countershaft has a gasket. We suspect it to be high hours and who knows how many hours since the build up inside the bell housing has been cleaned. Ill send some more picture after its been cleaned up.

|

Posted By: Les Kerf

Date Posted: 28 Aug 2025 at 6:39pm

I would be much more concerned about preventing the leakage from happening again; therefore I would probably do the bare minimum of only replacing the transmission clutch in case of a repeat leak. I have never so much as touched an Allis 5040 but I have done similar two-stage clutches on other brands. The main thing as far as adjustment is to keep everything even all the way around, and I do mean EVEN. Use a feeler gauge. It would be nice to have the specs but if you study the linkage it is not all that difficult to make them work correctly. I gave up trying to use a clutch alignment tool on these, I have better luck just eyeballing it. It's just like centering a front sight in a rear peep sight. Best wishes

|

Posted By: lkennett

Date Posted: 28 Aug 2025 at 7:34pm

|

Just came in from the garage. Got 90% of it cleaned up, with a tooth brush and some castrol super clean. Same on the pressure plate. degreased and then i hit the surfaces by hand with some 220. I am looking for ridges that would tell me I would have reduced clamping. I am not seeing that. I think I am going to have to grab that service manual to check what the tolerances are, I assume this has been machined before. hopefully tolerances are provided in the manual. Also, see below a picture of the PTO pressure plate vs the Trans plate. The trans / driven plate is closer to the transmission. PTO is still in pretty good shape. The last picture is the vat of gunk that came out of this housing. Might be normal for a 50 year old machine?      |

Posted By: lkennett

Date Posted: 28 Aug 2025 at 7:36pm

Pto Plate Vs Trans plate

|

lkennett wrote:

lkennett wrote: