All Crop 66 Separator Belt

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=207811

Printed Date: 05 Feb 2026 at 9:23am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: All Crop 66 Separator Belt

Posted By: olelakefarm

Subject: All Crop 66 Separator Belt

Date Posted: 15 Aug 2025 at 2:06pm

|

Hello group, just joined. I have an all crop 66 that has a bad separator belt, and I found on another post here what size the belt should be, but we cannot get it to stay on once we put it under load. My first question is should there be a twist in the belt between the Separator drive sheave and the tailings conveyor sheave. The belt we have is 5/8" wide, should it have been 1/2"? Any help would be appreciated. BTW, the WD tractor pulling the combine is my Grandpa's he bought new in 1950 and the combine is one a neighbor had that I bought, which was used to combine my families grain when I was a kid. I am still trying to use it as much as possible.

|

Replies:

Posted By: dkattau

Date Posted: 15 Aug 2025 at 2:46pm

|

Posted By: dkattau

Date Posted: 15 Aug 2025 at 2:50pm

| It’s a B240 belt. 5/8 x 243 inch. |

Posted By: orangereborn

Date Posted: 17 Aug 2025 at 3:45pm

|

Posted By: CrestonM

Date Posted: 17 Aug 2025 at 9:29pm

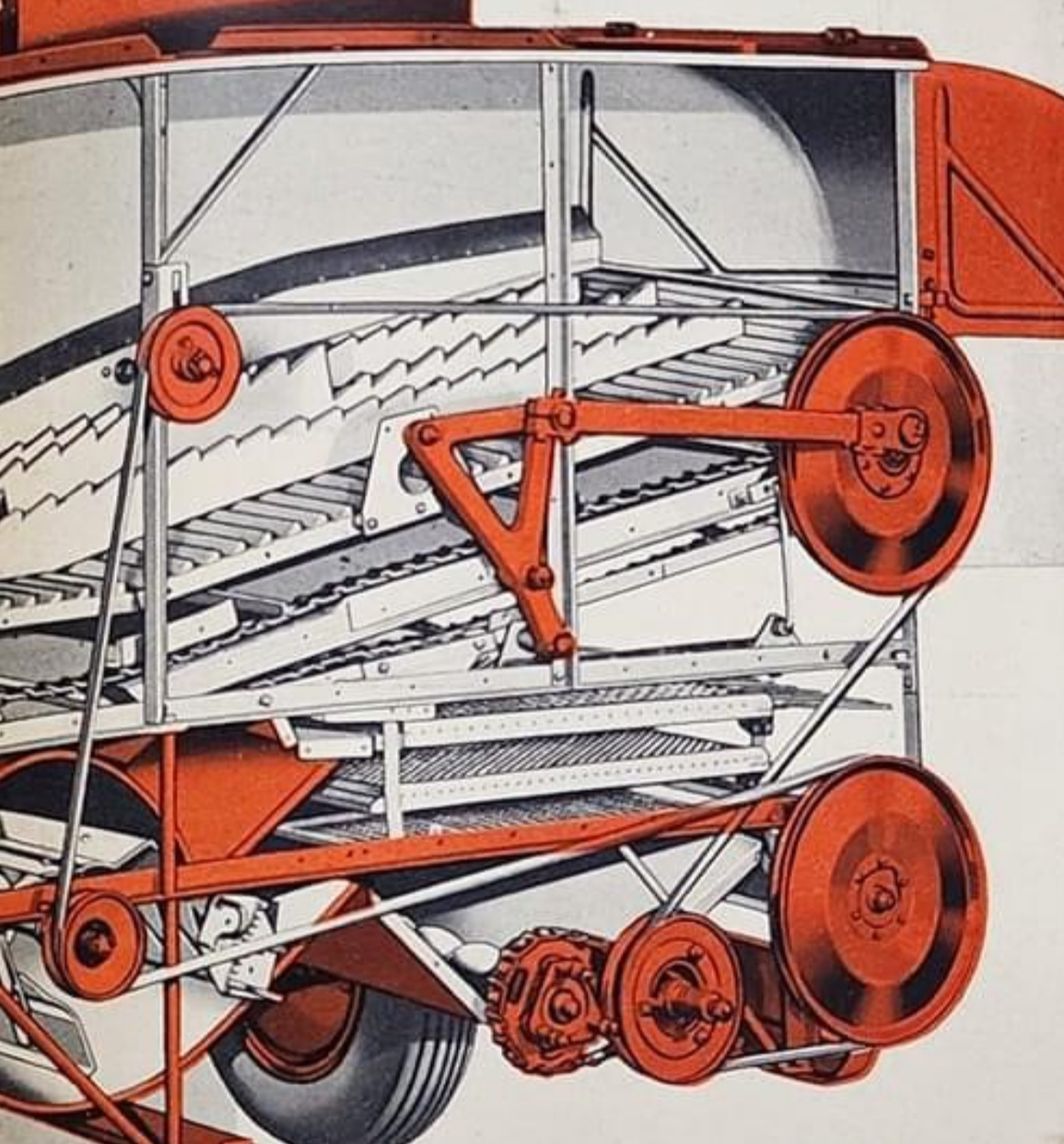

| Dale, which combine is that diagram for? The colors look Allis but the diagrams don’t match any I’ve seen. |

Posted By: SteveM C/IL

Date Posted: 17 Aug 2025 at 9:42pm

| Appears the twist is between sep drive and fan |

Posted By: Mikez

Date Posted: 17 Aug 2025 at 10:50pm

|

Welcome to the forum. I’m pretty sure we have nos belt available.

|

Posted By: DanielW

Date Posted: 18 Aug 2025 at 7:09am

|

As others noted, it's a standard B-section belt - any Napa or industrial supply can order one. And the 66 does have a twist in it. It's also important to get the twist the correct way, or it'll keep walking off (see the diagram posted by dkatttau above, and note how the belt span between the fan and cross-auger is in front of the span from the slip-clutch to the shaker drive). If it still keeps coming off, some other things to keep in mind: - The two largest sheaves/pulleys are rather thin and chintzical - easily bent. If either of them is slightly bent/bowed, it won't keep the belt tracked and it will keep popping off. It's easy enough to bend them back because they're so thin and flimsy. And if you want an upgrade, buy a B-section sheave the same diameter with a weld-in hub from TSC: The ones from TSC (or anywhere else, for that matter) are much more rigid/stiff than the original Allis ones. - On the 60 and 66, the large span between the tensioner and shaker drive can be a problem (and a rather poor design). A home-brewed flat tensioner/idler at the mid-span helps calm the belt down and stops it bouncing around and wanting to walk off. I've added idlers there to both my 66's. - If it's been stored for a long time with tension on the belt, the twist may have become semi-permanent on the belt, and may be causing issue as it tries to go around the sheaves and un-twist as needed. You may need a new belt, but can hopefully just keep working the old belt to get it more pliable.

|

Posted By: orangereborn

Date Posted: 18 Aug 2025 at 2:11pm

| Dan has you on the right course...By the time the "72" came out around 1966 there were a lot of concepts floating around. We actually used a "J" bolt on the top span first but leary about belt damage. But none because it never let the whip get into it's mode...Later we replaced it with a flat pulley and I think using the same bracket as the adjuster pulley. Used significant down pressure to the end of the adj slot. Belt had a little more pulley contact also. The pulley was a AC but don't recall which one. I don't know Dans experience but for us that ended the problem. Tried to get them on all combines we set our eyes on. We convinced AC to put out a yellow service bulletin. As for the big "Gate" pulley it was understood it's design was "intentional" so that it would bend the pulley and not the shaft when it hit the gate post...Don't know, but the theory had merit...Dale |

Posted By: SteveM C/IL

Date Posted: 19 Aug 2025 at 1:09am

| Dad bent his on the barn wall..... |