need to make a Hardened tool,,,,,

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Shops, Barns, Varmints, and Trucks

Forum Description: anything you want to talk about except politics

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=204582

Printed Date: 08 Oct 2025 at 7:01am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: need to make a Hardened tool,,,,,

Posted By: desertjoe

Subject: need to make a Hardened tool,,,,,

Date Posted: 15 Dec 2024 at 9:12pm

|

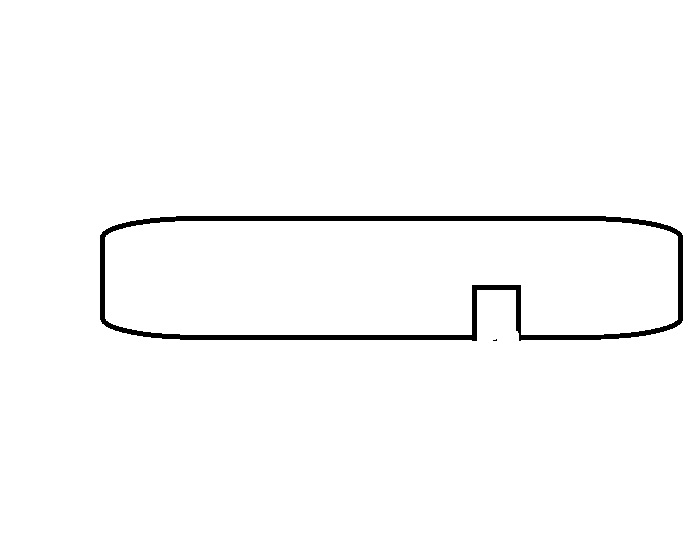

I have a need for a HARDENED open end tool, wrench. . to remove the fluid nozzle on one of my paint guns. At some point I used to have one that came with the gun. I quit loaning my paint equipment and that is what I believe happened to it. I contacted HF as they used to supply a tool for removal of the fluid nozzle but they do not do so any more,,!! How to HARDEN this tool,,?? The slot on the fluid nozzle is 1/8" wide and is kin to a 11/16" open end wrench. This "tool" will have to be hardened as the open end wrench I ground down the points just opened up when I tried to break the fluid nozzle loose,,,There are two machined surfaces right next to the slot for the wrench,,so one has to be very carefull to not ruin thse surfaces on the nozzle,,,?? Any ideas,,,??

|

Replies:

Posted By: KMAG

Date Posted: 15 Dec 2024 at 9:27pm

| Make it red hot and drop into warm used motor oil? I believe that part is an aluminum alloy or galvanized coated pot metal- not likely to take surface hardening well. |

Posted By: desertjoe

Date Posted: 15 Dec 2024 at 9:43pm

Yes,,KMAG, The fluid nozzle is most likely an aluminum alloy and I did NOT want to even try to heat the nozzle up as there is a gasket under it and O-rings in the fluid passage the nozzle screws into. I;m gonna try to machine an 11/16 box open wrench to fit in the slot in the nozzle, then heat it like you suggest,,,will it help the more times I do that,,,??

|

Posted By: steve(ill)

Date Posted: 15 Dec 2024 at 10:04pm

|

joe, if the wrench idea dont do it... you might try to BOIL the head in water to get it HOT... maybe it will stretch a little and then the wrench can remove it ??? ------------- Like them all, but love the "B"s. |

Posted By: desertjoe

Date Posted: 15 Dec 2024 at 10:13pm

|

That sounds like a great idea,,,Steve,,!! I'ma gonna rig up tomorrow to give that a whirl,,, Thanks,,

|

Posted By: KJCHRIS

Date Posted: 16 Dec 2024 at 12:08am

|

Sounds like you need to find someone with a set of "tappet wrenches" that were used on the flat head engines. IF you could locate 1 in 11/16" it might fit. I'm not near my shop this week or could check my Craftsman set's 11/16" for thickness. Snap-on Tools; # LTA2022, 5/8" x 11/16" is 5/32" thick, their std open end is 5/16" thick, according to online catalog. IF you grind down a wrench to fit slot, keep dipping it into oil or water to keep heat buildup low. ------------- AC 200, CAH, AC185D bareback, AC 180D bareback, D17 III, WF. D17 Blackbar grill, NF. D15 SFW. Case 1175 CAH, Bobcat 543B, |

Posted By: IBWD MIke

Date Posted: 16 Dec 2024 at 6:22am

| The first step in making a hardened wrench is having steel that is hardenable! Low grade steels like cold rolled aren't going to do it. If you were in a toolroom setting A-2 or O-1 would work. Then you would need to follow the procedure. For the hobbiest, if you had a piece of W-1 it could be water quenched. Cold rolled and other low grade steels can be 'case-hardened' but that is a rather involved process. |

Posted By: jaybmiller

Date Posted: 16 Dec 2024 at 6:45am

|

watched enough 'forged in fire' to wonder WHY guys 'cool with water'.... normally you get the metal orangy-yellowy in colour, then quickly into oil. Also if you don't get it right the 1st time, you stand a 99/44% chance of destroying it doing a 2nd heat treat. you might try grinding an open end wrench. 1st get the proper sized one, I suspect METRIC, since gun came from HF....... then use hand file to 'thin' it down, spalshing cool water on it often. The wrench IS already heat treated so if you reduce with grinder, you'll destroy the heat treat. I've done this with 7/16" wrenched to hold the 1/4-20 nuts on B&S starter electrical studs. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Thad in AR.

Date Posted: 16 Dec 2024 at 7:07am

|

A lot of router wrenches are 11/16” If it were me I’d go to work on a piece of leaf spring with an angle grinder. Don’t get it too hot. You could get that wrench hot and quench it as well. I’d remove all the chrome prior. Get it to non magnetic temp and quench in oil that heated to near 160 |

Posted By: desertjoe

Date Posted: 16 Dec 2024 at 7:21am

|

SAY,,,!!! I just thought of maybe what to use,,,how about a piece of a lawn mower blade,,?? They are fairly thin and most likely already hardened and wouldn't take much more careful grinding to get to correct thickness and shape,,,?? I'm liking Steve's idea of heating in water,,,,

|

Posted By: desertjoe

Date Posted: 16 Dec 2024 at 7:24am

You are correct and I have two of them,,,HMMmmm have to remember where they are,,,,,?

|

Posted By: steve(ill)

Date Posted: 16 Dec 2024 at 8:19am

|

one way to use mild steel / sheetmetal is to start with the piece about 3 inches wide..... cut your notch in it 11/16 wide and have the EARS 1 inch wide ( and sheet metal thickness) instead of the standard small Outer Diameter ears... you really dont care how WIDE the outside of the wrench is in this application.

some of those wrenches are actually a STRAP with a notch in the side as compared to a "normal wrench"..  ------------- Like them all, but love the "B"s. |

Posted By: Tbone95

Date Posted: 16 Dec 2024 at 10:28am

Quenching with water is a different cooling curve than oil, which is a different coiling curve than air. All are valid, just depends on what material you’re working with and what end result you’re after. We use nitrogen at about 6 BAR and circulated quite rapidly and can reach nearly 70 HRc depending on the material. If you screw up the first time, you fully anneal it before trying again and this never ruins it for us. If it doesn’t make spec the second time we junk it because there’s likely something wrong with the composition. The one sure way to ruin it is to wait too long between quenching and tempering. Much over 12 hours and we have to scrap it. |

Posted By: plummerscarin

Date Posted: 16 Dec 2024 at 12:07pm

| I made one for my Chicago Pneumatic angle sander thirty some years ago with stainless steel. Around eighth inch thick and ground the slot to fit. Never a problem. |

Posted By: desertjoe

Date Posted: 16 Dec 2024 at 1:32pm

|

Well,,,you guys ain't gonna believe this but as I was looking for a piece of 1/8" stainless and decided to try Steve's idea of heating the head of the paint gun in HOT water and after two trys,in Boiling HOT Water,,, 30 minutes later,,,,the dang nozzle broke free,,,!!! YEA,,!! Many THANKS fellows,,,!! I'm still gonna make a wrench with some hardened material,,,prolly SS,,, Thanks Again,,,!!!

|

Posted By: IBWD MIke

Date Posted: 17 Dec 2024 at 9:21am

| Jay, you water quench water hardening steel. Oil quench oil hardening steel. Same gig for air hard. Water hardening is a pretty old process and not terribly popular these days. An easy way to make a hard tool though. Heat it red and dunk in a bucket of water. |

Posted By: Tbone95

Date Posted: 17 Dec 2024 at 9:52am

Heat the steel with a molten salt bath, pull it out and submerge in brine! Ah what a pleasant environment!!   Managers wonder why the trolleys and wiring over the vats are such high maintenance items. Great to service also, because you don’t turn the heat off, too long and costly to get it back up to temperature. Is surprising how prevalent this process is still used. Managers wonder why the trolleys and wiring over the vats are such high maintenance items. Great to service also, because you don’t turn the heat off, too long and costly to get it back up to temperature. Is surprising how prevalent this process is still used.

|

Posted By: jaybmiller

Date Posted: 17 Dec 2024 at 11:51am

|

seems all the steel used on Forged in Fire is 'oil hardening steel' caus eeverytime gut does 'quench in water' , the hosts have near heart attacks( they ARE pros...) as the blade shatters ! ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Tbone95

Date Posted: 17 Dec 2024 at 1:12pm

Water/ brine cools the steel faster than oil, faster than THAT steel is meant to be cooled. Sure it’s very hard but then too brittle. Do you suppose they had that all figured out in the ancient times when swords were produced like this? |

Posted By: desertjoe

Date Posted: 17 Dec 2024 at 6:24pm

After trying and bending two make shift wrenches and not even budging the stuck nozzle,,I realized the "WEAK" points were at the juncture of the "EARS" on those make shift wrenches,,,,!!! Steve's idea is what Im going after using a section of a lawn mower blade with minimal grinding on the notch which will easily remove that XCFDT%$$#^ stubbern nozzle,,,,!!!!! |

Posted By: tadams(OH)

Date Posted: 18 Dec 2024 at 2:29pm

|

Pipe wrench |

Posted By: desertjoe

Date Posted: 18 Dec 2024 at 3:57pm

Pipe wrench,,,,?? PIPE WRENCH,,,!!!!!??? Holie Chit,,, Mr Adams,,,here we all are trying to finesse this " specially machined chunkof meta" off the spray gun and,,,,and,,,,AND you want us to destroy the nozzle in one fell swoop with a friggin pipe wrench,,,,my goodness,,,,!!!

|

Posted By: ORBill

Date Posted: 18 Dec 2024 at 5:00pm

|

DJ If Shameless was with us his one word solution would be........ TANNERITE!!! A pipe wrench is a finesse tool... |

Posted By: desertjoe

Date Posted: 18 Dec 2024 at 8:11pm

|

Yes,,,ole Shameless just did not have very much patience with stubborn things and even less with stubborn people,,,,  I sure miss that guy,,,,,

|

Posted By: DaveKamp

Date Posted: 19 Dec 2024 at 9:07pm

|

Lawnmower blades are NOT hardened EVER. They're high-quality steel, but in the realm of alloys, they are referred to as NON HARDENING. Here's why: Hardening is a state of crystalline structure. Making something hard, means removing the malleability. Malleability is what allows a mower blade to whack a rock, or a stump, and still remain in one piece. IF you were to 'harden' it, it would whack a few soft things and develop stress cracks... it would hit a few hard things and shatter off pieces... Then it would be off balance, and shatter... sending sharp pieces of metal out the sides of the deck at 217mph. A hardenable alloy is found in springs, SOME shafts (axle shafts), gears, etc., BUT... usually the hardening is very limited, frequently just enough to make an abrasion resistant surface for lip seals, more durability on splines, etc. IF the nozzle came off simply by applying a little thermal exercise, then the proper 'tool' for getting the nozzle free, is a little thermal exercise. The flex you saw in your prior wrench attempt, is elastic response to what amounts to a lever (the wrench handle) and a cam (the flats) turning the jaws into a spring. IF a wrench fits a nut really loose, it will do exactly this. If the wrench fits really tight, it won't be as likely, because there's not enough play to allow the 'cam' to rotate in the FIRST place. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: desertjoe

Date Posted: 19 Dec 2024 at 9:36pm

|

Hey Dave Kamp,, thanks for that info,,, actually it was not a simple application of a little thermal eexcercise,,,I had to get the water boiling really hard and took several attempts with the makeshift tools to get the nozzle broke loose,,,I was NOT gonna fess up that I had to use a big pair of vise grips to hold the ends of tool ears closed so they would not open up and after several attempts,,it finally broke loose,,,but I do not want to have to do that to break it loose on future uses,,,, I think I may have an old leaf spring that is 1 1/2" W by 3/8" ,,,would that be a qualified candidate,,,??

|

Posted By: desertjoe

Date Posted: 20 Dec 2024 at 8:00am

|

On second and maybe even 3rd thought,,since I have the lawn mower blade cleaned up,,,I'm gonna make a tool similar to Steve's suggestion with just the simple notch to grab the nozzle and more than enough "MEAT" on the ends to break the nozzle loose. I thought about tackling the real issue as to WHY the dang nozzle is so hard to remove and it must be the threads are not exactly kosher. This is one of the best spray guns I've ever used and has the Best spray pattern that rivals two of my Binks Guns and it being a gravity feed and HVLP is why I want to save it,,,,,

|

Posted By: jaybmiller

Date Posted: 20 Dec 2024 at 8:12am

|

as for 'why', my guess is it's cause you didn't properly clean it last time and leave the nozzle OFF. ANY amount of residue paint or cleaner in the threads becomes 'locktite' overnight. I HAD a $400 airbrush for years, always cleaned and kept it disassembled until next time.... loaned it out, came back 'clean and assembled'. it went into circular bin as NOTHING got it apart. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: desertjoe

Date Posted: 20 Dec 2024 at 1:58pm

|

Well,,,Jay,,We just got to fess up to a "Soft Heart" for our fellow man as far as loaning our treasured tools. After loaning one of my spray guns to my brother years ago,,,,,I made him take it back THREE times for recleaning. My Motto is,,,"IF I can tell what color paint you used with MY gun,,then it ain't CLEAN enough!! He never come back to ask to borry it,,,!!!

Suits me. Suits me. |

KMAG wrote:

KMAG wrote: