New to me WD45

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=203885

Printed Date: 02 Oct 2025 at 10:41am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: New to me WD45

Posted By: Agiesbrecht

Subject: New to me WD45

Date Posted: 28 Oct 2024 at 8:10pm

|

Hello everyone. I am new to the forum and this is my first Allis. I have had a couple Farmall B's and have had a lot of other things with engines that were a lot of fun. So, I purchased a 1955 WD45 from a friend. I have a few questions.

It comes with a front end loader as well. I have plans to build a 3 point hitch for it. Mostly this thing will be cultivating sweet corn in central Alberta Most everything works well on it, as long as the battery is charged, it fires up really, really well. Albeit it does turn over a little slow. How do I test if my generator or regulator are bad? If it isn't too much work to fix and too expensive then I plan to leave it 6 volts instead of converting it to 12 volts. Also, there is a small lever right behind the gear shift, what is that lever for?   |

Replies:

Posted By: Ed (Ont)

Date Posted: 28 Oct 2024 at 8:27pm

| Push on that lever and it disconnects your snap coupler hitch underneath. Look at the bell shaped thing that the drawbar pushes into. Take out the 2 side pins on the drawbar, push bar ahead a bit, push on that lever and drawbar falls on the ground. |

Posted By: Ed (Ont)

Date Posted: 28 Oct 2024 at 8:28pm

| So it disconnects your plow or cultivator or anything else you are pulling. Like a pintle hook on a truck. |

Posted By: Ed (Ont)

Date Posted: 28 Oct 2024 at 8:30pm

| Round knob just to right of steering support is the pto engage/disengage. |

Posted By: WF owner

Date Posted: 28 Oct 2024 at 9:53pm

|

Two of the most important things on a 6 volt system are adequate size battery cables (yours look pretty good from what I can see in the picture) and clean battery connections. An easy way to see if the generator is working is to use a multimeter before starting it to measure battery voltage, then start it and measure again. As you increase engine speed, voltage should increase slightly (not as much as with an alternator). The (push-pull) headlight switch also controls the charging rate and has three positions. Out all the way should be maximum charging. Middle position is lights on and in all the way is low charging. These switches do go bad with time. I like to replace the generator cutout with a (6 volt) voltage regulator and replace the original light switch with a regular push-pull switch.

|

Posted By: Ted J

Date Posted: 29 Oct 2024 at 2:03am

|

Are you talking the lever to the right of the gear shift? Has a bend in it about 90 degrees? If so, that is for putting the brake lock on. When you push the brake pedals down, you pull up on that lever and it locks the brakes in place. To disengage, just step on the brakes again and then push down on that lever to disconnect. HTHs ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: SteveM C/IL

Date Posted: 29 Oct 2024 at 7:06am

| That's a nice straight original 45 !! This forum can answer any questions you have. You will love that tractor! That ground cable looks big enough but the end connection looks looks poor. That won't help cranking. 6 volt systems are slower sounding than 12V even when all is good. |

Posted By: IBWD MIke

Date Posted: 29 Oct 2024 at 9:20am

|

Welcome to the forum! Like SteveM said, that's a good looking 45. Ted is correct on the brake lock lever. |

Posted By: Alberta Phil

Date Posted: 29 Oct 2024 at 10:17am

|

Welcome to the Forum! That's a pretty nice WD45. You will be able to find lots of help with most things on here. All my Allis tractors are original 6 volt systems, except my D17 which was always 12. I prefer the cables with molded on terminals. All my tractors work fine on the original 6 volt systems, but everything has be in good shape to avoid problems. |

Posted By: DSeries4

Date Posted: 29 Oct 2024 at 2:29pm

|

Good looking tractor. I would recommend getting an operator's manual. It will tell you everything you need to know. They can be found on e-bay pretty cheap. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: Agiesbrecht

Date Posted: 29 Oct 2024 at 11:50pm

|

Thank you all for your help. Last night I went out and figured out that the lever I was referring to was to unhitch the drawbar. But thank you all for answering. I do still need to figure out how to engage the side pulley. I am debating of running a hydraulic pump off of that to run the front end loader and add remotes. As for the 6 volt system, I haven't figured it out yet,but I do know I have some bad connections so I will look after those and check again to see if it is charging. Thanks again for all the answers. |

Posted By: Allis dave

Date Posted: 30 Oct 2024 at 5:43am

|

The pully slides in and out of the torque tube to engage. The is a tapered bolt with a square head and jam nut in the torque tube to hold the pully in position. Loosen the jam nut, loosen the square head bolt and slide in the pully. this will mesh the gears together. Then you'll have to tighten the bolt and jam nut. It's hard to explain but there are holes in the pully shaft that the bolt fits into when you tighten it.You'll have to "feel" the hole to tighten the bolt into it. there anr many holes in different positions. These change are far in the pully is for the gears to mesh correctly. Finding the correct hole and mesh will be difficult. I wouldn't mess wiht the pully unless you're actually going to use it. Also there's oil inside the torque tube, so if you go messing with it too much, the old gasket could start leaking.

|

Posted By: Alberta Phil

Date Posted: 30 Oct 2024 at 9:51am

|

I have a loader on mine and operate it off of the main pump that operates the lift arms. I installed a diverter valve on the side of the battery box and just move the lever to switch from the rear lift to the loader. It's worked great for years. Mine has an Allis loader. Where in Alberta are you? I'm just a few miles south of Tofield.

|

Posted By: AC720Man

Date Posted: 30 Oct 2024 at 6:57pm

|

My WD is still 6 volt and plan to keep it that way. First thing I did when I got it was to remove the small battery cables and replaced them with 2/0 welding cables with crimp connectors. Cleaned up all points of contact, especially the ground connection area. Now it spins over like a new tractor. A good battery is key also. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Agiesbrecht

Date Posted: 30 Oct 2024 at 7:12pm

|

Phil, I am not far away then. I am just north of Vegreville, close to Hairy Hill. I'd love to see some pictures of how you did the hydraulics. I did see something about this way of doing it somewhere but it came with the comment that it was quite slow. Do you find yours to be slow? Also, how is steering with the loader on it? |

Posted By: Agiesbrecht

Date Posted: 30 Oct 2024 at 7:13pm

| I might have to do that. The battery was new a couple years ago. So it's not an old battery. I'll clean up all the connections and see if that makes a difference. |

Posted By: steve(ill)

Date Posted: 30 Oct 2024 at 8:08pm

|

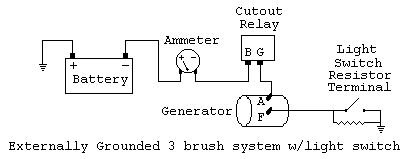

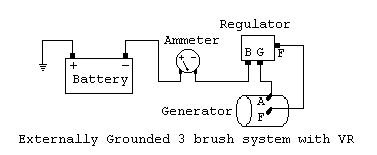

the battery cables look to be a good size, but the terminal CLAMP is not good... You need new ends, or maybe just replace the entire cable.. the GENERATOR will have a small BOX on top of it.. That is either a CUT OUT switch with 2 wires... or a VOLTAGE REGULATOR with 3 wires on it.. The CUTOUT needs the LIGHT SWITCH to help control the CURRENT charge ( lights on or off)... the VOLTAGE REGULATOR does it all by itself.... SEe what you have and we can tell you how it is wired. ( if the GENERATOR "F" terminal goes to the "BOX" then you have a VOLTAGE REGULATOR... on a CUTOUT , the "F" wire runs back to the light switch. as WF said, just measure the battery voltage with engine off... then again with engine ON to see that the battery jumps from 6.4 v to 7 + volt when you are running.

------------- Like them all, but love the "B"s. |

Posted By: Agiesbrecht

Date Posted: 30 Oct 2024 at 10:00pm

| I have a battery terminal replacement, it just needs to be put on. Hopefully, this winter it will get some love. |

Posted By: Alberta Phil

Date Posted: 30 Oct 2024 at 10:08pm

|

My loader is not slow. It was made for the WD/WD45 tractors and has the cylinders for the high pressure low volume pump. It lifts just as fast as the one on my D17 with the pump driven off the front of the crankshaft. Except the WD loader is hydraulic lift up and gravity down and has a trip bucket. It has the snow blade on now so that's not an issue. I have the factory service manuals for all the older Allis tractors, so if you need any info, let me know. Or send me a private message and come over and have a look!

|

Posted By: WF owner

Date Posted: 31 Oct 2024 at 6:23am

| Just so you know. the belt pulley stops when you push the (foot) clutch. It won't give you "live hydraulics". |

Posted By: Agiesbrecht

Date Posted: 01 Nov 2024 at 10:47am

| So, I have a 2 wire which means it would be a cutoff switch. Can I replace the light switch with a simple push pull switch from the local parts store? Does it need to be a 3 position? |

Posted By: WF owner

Date Posted: 01 Nov 2024 at 11:08am

|

The short answer is no. The original light switch has a part (I believe it's a resistor) that can vary the rate of charge the generator is putting out. If you put in a regular push/pull switch, it would not charge at all. If you hooked it direct, there would be nothing to stop the generator from overcharging the battery. Replacing the cutout with a voltage regulator solves that problem and isn't very expensive. It also saves the operator from having to remember to set the switch in the proper position. Click on this link to see what the original switch looks like: https://www.walmart.com/ip/RAParts-New-Light-Switch-Fits-Allis-Chalmers-WD45-Crawler-70208197/992391167?wmlspartner=wlpa&selectedSellerId=2113&adid=22222222227992391167_2113_14069003552_202077872&wl0=&wl1=g&wl2=c&wl3=42423897272&wl4=aud-1185573580265:pla-319455734609&wl5=9005005&wl6=&wl7=&wl8=&wl9=pla&wl10=117446690&wl11=online&wl12=992391167_2113&veh=sem&gad_source=1&gclid=CjwKCAjw-JG5BhBZEiwAt7JR6wdS5ZtTeVNbiCHDnsRiNkxljk_MGMh-OFgnT_OqvZgPkX5kd3VQWRoCqXEQAvD_BwE" rel="nofollow - RAParts New Light Switch Fits Allis Chalmers WD45 Crawler 70208197 - Walmart.com

|

Posted By: WF owner

Date Posted: 01 Nov 2024 at 11:12am

|

Here's a link to a 6 volt voltage regulator: https://www.ebay.com/itm/285892715068?chn=ps&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&mkscid=101&itemid=285892715068&targetid=2370186391901&device=c&mktype=pla&googleloc=9005005&poi=&campaignid=21772435673&mkgroupid=172165932430&rlsatarget=pla-2370186391901&abcId=10047345&merchantid=6477864&gad_source=1&gclid=CjwKCAjw-JG5BhBZEiwAt7JR637sLO2ZkuPfRaEe-F50XJAs1ygNm0XI-sYJTyEcyYGpxklvUjD7sBoCPdsQAvD_BwE" rel="nofollow - REGULATOR 6 VOLT FOR ALLIS CHALMERS D10 D12 D14 | eBay

|

Posted By: WF owner

Date Posted: 01 Nov 2024 at 11:19am

|

A common problem with the light switch is that it isn't properly grounded. The gauge and switch pod on a lot of the old AC tractors (including the WD45) simply slid onto tracks on the back of the battery box. As they aged, rust developed in the tracks and the whole pod lost a good ground or lost the ground completely. When that happened, the switch was not grounded and could not control the charge rate. If your tractor isn't charging, that's the first place I would look. If the tractor has set for very long, often you can't move the switch at all, which would be a good time to change to a voltage regulator and regular light switch. I think you would be happier with a voltage regulator.

|

Posted By: steve(ill)

Date Posted: 01 Nov 2024 at 2:03pm

|

The CUT OUT is just an ON - OFF switch that closes when the engine starts to let the generator charge the battery.. The swith OPENS when the generator stops turning / engine off..... You have no REGULATOR for the system.. So they put a 3 OHM resistor on thel ight switch.. When the lights are OFF, the "F" wire of the generator goes thru the resistor to GROUND and the generator puts out about 3 amps... When you turn on the LIGHTS, you bypass the resistor and the "F" wire goes straight to GROUND and you get about 8 amp charge.... You "COULD" just buy a 3 ohm resistor (BIG) and connect the "F" wire to it and ground it and that would work... If you buy a VOLTAGE REGULATOR, it has a CURRENT REGULATOR inside.. it will have 3 terminals "F" , "G" ( generator ammature), and "B" for charge... This eliminates the LIGHT SWITCH and you can then use a TOGGLE switch for the lights..

------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 01 Nov 2024 at 2:06pm

this will be on the back of your original light switch... you can use it, or buy seperate if you want to eliminate the light switch and keep the CUTOUT.  ------------- Like them all, but love the "B"s. |

Posted By: Les Kerf

Date Posted: 01 Nov 2024 at 6:08pm

Correct. Not 'true' live hydraulics, but it is about the next best thing to it. My late Father-in-law removed the belt pulley on his WD and attached a hydraulic pump directly to the belt drive, it ran the loader quite nicely. I loved that hand clutch! I still have his tractor but the engine is stuck. It is on my long list of projects.

|

Posted By: Agiesbrecht

Date Posted: 04 Nov 2024 at 1:10pm

| Well, thank you all for the information. It has been most helpful! |

WF owner wrote:

WF owner wrote: