Power director oil

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=203469

Printed Date: 02 Nov 2025 at 6:01am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Power director oil

Posted By: sdailey

Subject: Power director oil

Date Posted: 02 Oct 2024 at 12:46pm

|

On my D14 the oil from my power director section keeps equalizing level into my hydraulic pump section. This makes the hydraulic side level way over the full mark. What is the most likely culprit causing this? Also, what is the purpose of the oil transfer tube up high between these two sections? Thanks. |

Replies:

Posted By: DrAllis

Date Posted: 02 Oct 2024 at 12:51pm

| Sitting in the seat, the Power Director/PTO gear compartment dipstick is to the left side of the instrument panel. Proper oil level is right down on the very bottom of the dipstick. And you say that oil level goes down and the hydraulic compartment (dipstick under the gas tank on the right side) goes up ??? Never seen that before. If anything the hydraulic compartment oil level is higher than the Power Director compartment. |

Posted By: DSeries4

Date Posted: 03 Oct 2024 at 4:39pm

Happened to my D17 IV diesel a few years ago. Couldn't get a reading on the trans dipstick. Hydraulic dipstick was way above full. Replaced the transmission and PTO shaft seals and that fixed the problem. Best to replace the O ring on the PTO lever at the same time. Yes, you have to split the tractor...  ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: DrAllis

Date Posted: 03 Oct 2024 at 8:28pm

| D-14 not the same. |

Posted By: sdailey

Date Posted: 06 Oct 2024 at 11:31am

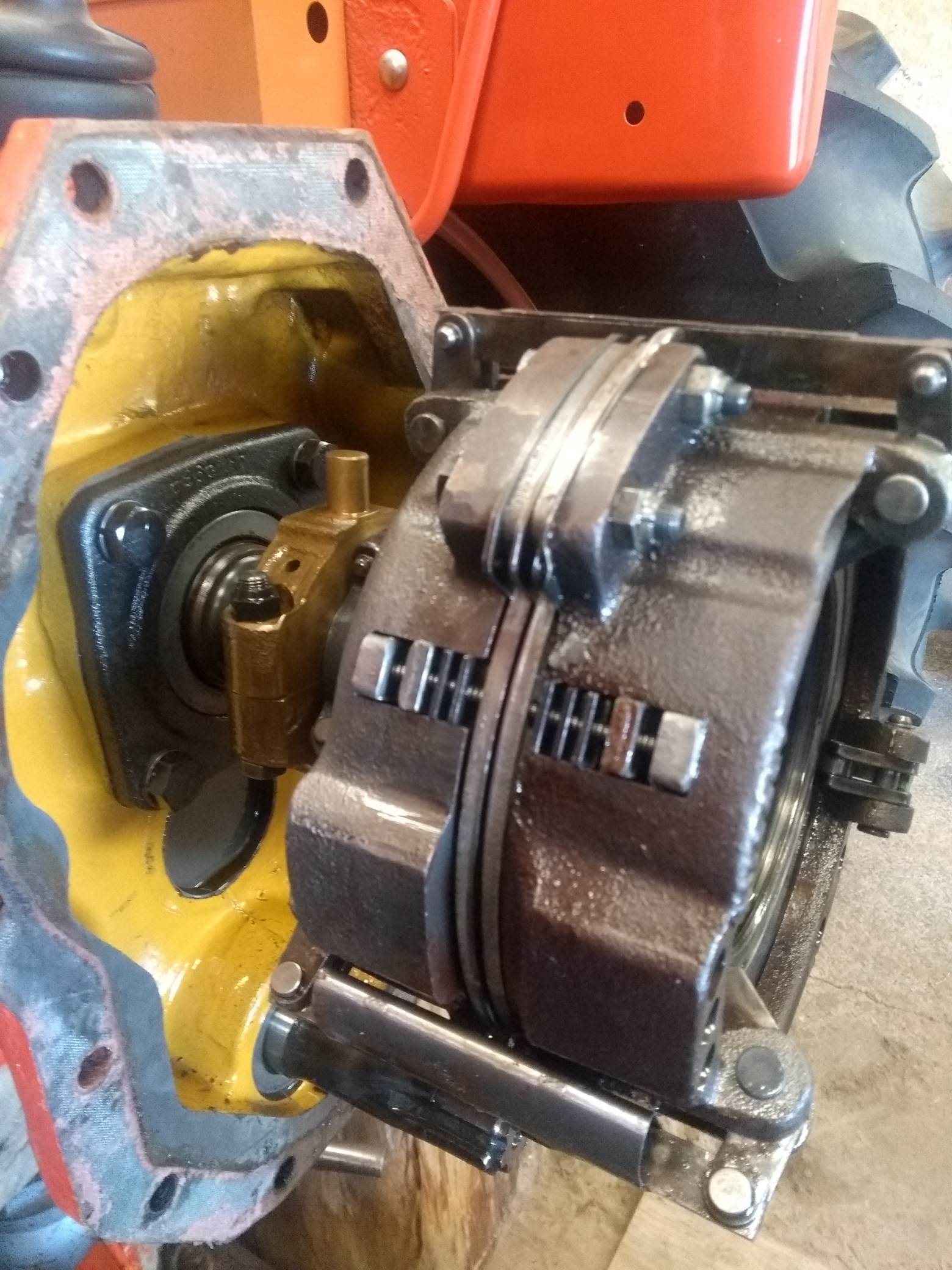

| Now that I’ve gotten the tractor split and am looking at the dipstick heights better I see that the level in the hydraulic side is way higher. They’re not equalizing like I thought. So how could the oil on the power director side get pumped to the hydraulic side? My only guess is the seals on the main shaft are bad between those two sections. |

Posted By: DSeries4

Date Posted: 06 Oct 2024 at 3:51pm

|

Power director and hydraulics is the same compartment. No separate dipstick for power director. If your transmission oil is very low and the hydraulic oil is very high, the seals between the transmission and torque tube are no good and need to be replaced. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: DrAllis

Date Posted: 06 Oct 2024 at 4:01pm

| D-14 and D-15 are like the D-17 series 1 and 2. A hydraulic compartment directly under the gas tank with a dipstick/breather on the right side behind the belt pulley hole. And the Power Director/PTO gears dipstick is to the rear left of the instrument panel with a hex head on it. Transmission/differential dipstick is next to the gearshift. |

Posted By: DrAllis

Date Posted: 06 Oct 2024 at 5:34pm

| Had this been my own tractor, there's no way I would have split it for this. If the oil is truly going from the Power Director area forward to the hydraulic sump area, that is a first for me. I've been fixing these for nearly 50 years, so maybe we now have seals wearing out 50 years later ?? Anyway, the dipstick vent to the Power Director clutch must be plugged, allowing pressure to build when the tractor is being used for extended periods of time. I don't know how it is used, but I am assuming this. Oil is carried up by the PTO gears and the oil is then augered thru the transfer tube to the inside of the Power Director clutch assembly. The oil seals (2) on the clutch shaft are in this area where the transfer tube is attached. I suppose if the vent to the Power Director compartment was plugged, the oil could slowly be pushed thru those clutch shaft seals when the compartment was warmed up and the tractor being used for hrs at a time. I have seen oil go the other way, but not this way. To replace those two seals is a very MAJOR project. The whole torque tube has to be separated from the engine and the rear end and stripped down to a bare empty housing. If it was mine, I would have dropped the hydraulic sump down and reached up in there with a pry bar and popped the frost plug loose to the intermediate gear bearing idler shaft and just let the oil run back and forth thru that bearing like a series 3 D-17 did. Carry the oil level high enough that the hydraulic dipstick is happy and not OVERFULL one bit. |

Posted By: sdailey

Date Posted: 06 Oct 2024 at 6:01pm

| Thanks a lot! That’s extremely helpful. I’m sure the vent isn’t plugged because that’s the first thing I checked. If it won’t hurt anything to pop that plug out I’ll do that. That’ll make the level way high in the power director side though won’t it? Which is worse? To let the power director side run high or leave the plug in and let the hydraulic side run high? |

Posted By: DrAllis

Date Posted: 06 Oct 2024 at 6:09pm

| A D-17 series 3 has the same hydraulic pump and sump. The Power Director clutch is centered on the clutch shaft center line. I would advise carrying the oil level (after sitting overnight on the level) to the proper height on the hydraulic dipstick (and no more) and don't worry about the Power Director oil level. Maybe start with the oil level just at the "add" mark on the hyd stick. You didn't say how this tractor is being used ?? Lots of steep hills ?? extended periods of running time ?? |

Posted By: HudCo

Date Posted: 06 Oct 2024 at 8:51pm

| dr i was going to change seals when i do my pto oring on my series 1 and all the gaskets should i make mine a common compartment but would that feed the hydralics with any fines from the trans |

Posted By: DrAllis

Date Posted: 06 Oct 2024 at 10:05pm

| I would not. This recommendation is a last ditch effort to keep a tractor running without MAJOR labor repairs in a pretty easy way. I still can't figure out how this tractor has oil from a lower level get into a higher compartment, but whatever. |

Posted By: DrAllis

Date Posted: 07 Oct 2024 at 6:01am

| This D-14 should have the PTO lever Oring replaced now while split. Also, clean the floor of the PD housing well and set in a magnet or two to keep the oil cleaner. |

Posted By: sdailey

Date Posted: 07 Oct 2024 at 12:50pm

| Its main use is during the summer to brush hog about 25 acres. It’s pretty much all hill. Some places are fairly steep. It does a lot of smaller jobs too but the brush hogging is the one where it gets extended run time at high RPM’s. |

Posted By: DrAllis

Date Posted: 07 Oct 2024 at 1:40pm

| Good luck with your fix. |

DrAllis wrote:

DrAllis wrote: