PTO gearbox foreign bodies

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=201516

Printed Date: 24 Nov 2024 at 3:47am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: PTO gearbox foreign bodies

Posted By: MikeV

Subject: PTO gearbox foreign bodies

Date Posted: 27 May 2024 at 9:31am

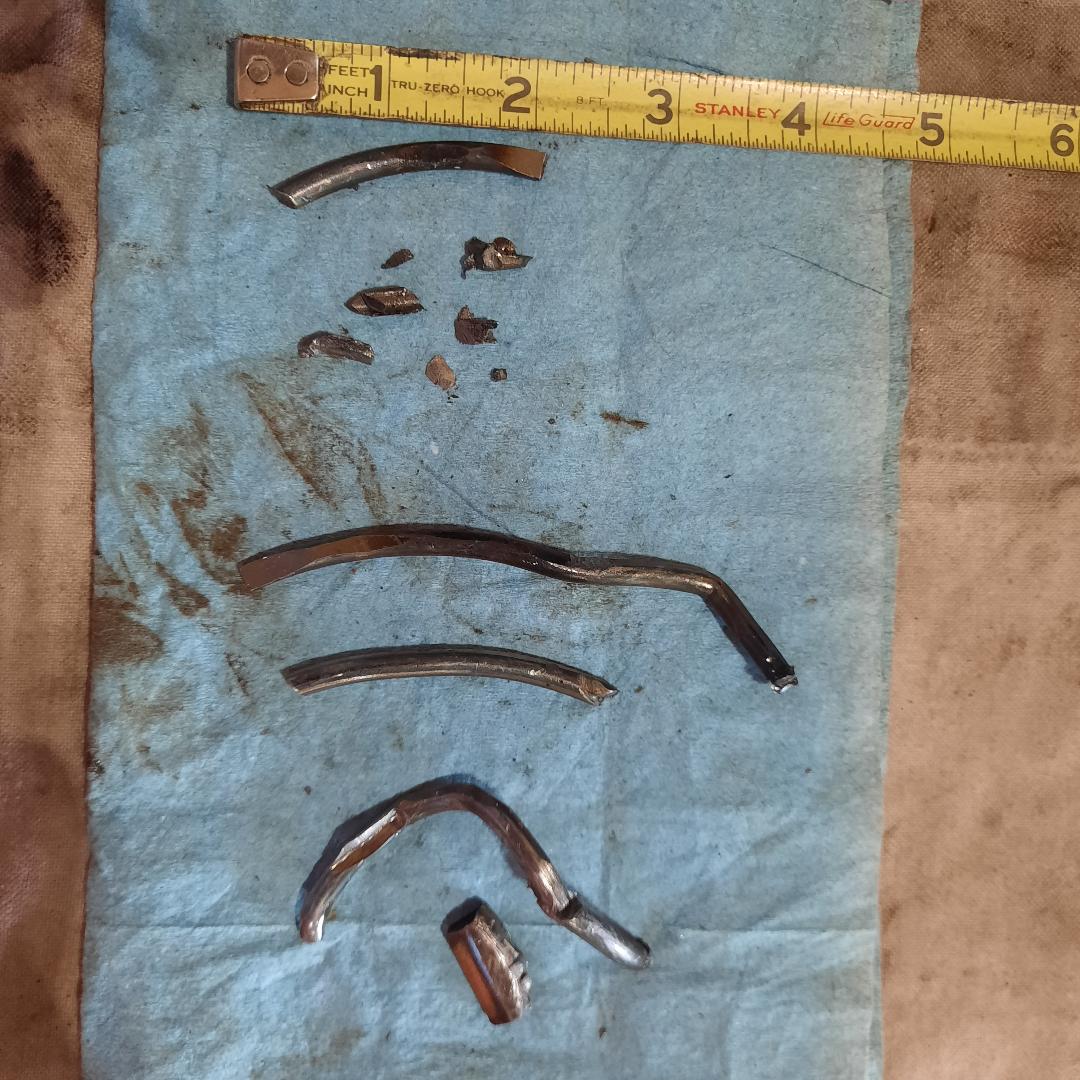

The complaint being that

the WD45 PTO made a ticking noise and wouldn't stay in gear prompted removal of

the gearbox for inspection. The pieces

in the attached photo are what was found in the bottom of the gearbox. The bottom piece is a gear tooth, unknown yet

which gear it came from. The remaining

pieces appear to be spring steel, two pieces of which have flattened ends; also

unknown where it came from. Gears are

certainly in need of replacement, but would be helpful to know what the foreign

body represents, as it seems likely to need replacement too. Any further information would be appreciated!

|

Replies:

Posted By: wjohn

Date Posted: 27 May 2024 at 11:06pm

|

Hand clutch snap ring? ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: IBWD MIke

Date Posted: 28 May 2024 at 5:54am

That's what it looks like top me also.

|

Posted By: DrAllis

Date Posted: 28 May 2024 at 10:03pm

| But, what's sad is, the snap ring came off. A good operator had to KNOW there was something wrong with the hand clutch because the hand clutch lever wouldn't have acted normally. Instead they continue to use the tractor with the snap ring floating around in there until it got ate by the PTO gear train. |

Posted By: DaveKamp

Date Posted: 28 May 2024 at 10:42pm

|

Basically, ANYTHING above, will find it's way to the PTO gearbox by virtue of gravity and oil flow. The PTO gearbox gears are unfortunate recipients of falling debris, and if that debris is hard, the PTO gears wind up taking damage. I have a WD that came to me with blown out PTO gears, from something coming down from above. When I reassemble it, I will be attempting to put in a scraper/catch screen/magnet to provide it with some chance of survival. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: MikeV

Date Posted: 30 May 2024 at 5:33pm

| Thanks, all good thoughts. Will try to look up on AGCO parts list to see what an intact snap ring looks like - I see now on the parts illustration that that's a likely explanation. Can I confirm it's missing by inspecting from above? |

Posted By: DrAllis

Date Posted: 30 May 2024 at 7:35pm

| Remove battery box and hand clutch cover. |

Posted By: MikeV

Date Posted: 10 Jun 2024 at 9:31am

|

While we haven't yet confirmed all those pieces to have been the intact snap ring, there seems little doubt. It also has yet to be confirmed that the broken gear tooth is from the intermediate gear, but some questions first. Will a new snap ring tolerate being manipulated over the shaft and be replaced while still on/in the tractor? If that's possible, can the idler gear be removed from the PTO gearbox (we do know it sustained enough damage to necessitate replacement) and then be able to use the tractor for the time being with an inop PTO? Lastly, where are new snap rings available?

|

Posted By: Mikez

Date Posted: 10 Jun 2024 at 2:28pm

| What’s the part number of snap ring |

Posted By: MikeV

Date Posted: 10 Jun 2024 at 5:12pm

| I don't know, the illustration I have doesn't include part #. In the picture, it is the rear-most piece depicted, about 3" diameter, same in WD and WD45. |

Posted By: Les Kerf

Date Posted: 11 Jun 2024 at 8:27am

Looking at the illustration on Page 53 of the shop manual it looks like it would be ok so long as the oil level is high enough for the intermediate gear to carry lube up to the hydraulic pump drive gear on the main shaft. I'm pretty sure it will be.

|

wjohn wrote:

wjohn wrote: