Allis Chalmers 7060 Timing

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=201222

Printed Date: 23 Nov 2024 at 11:45pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Allis Chalmers 7060 Timing

Posted By: AllisOwner7060

Subject: Allis Chalmers 7060 Timing

Date Posted: 07 May 2024 at 8:04am

|

Hello, I had my injection pump rebuilt on my 7060 because it was sitting for 7 years. I have fuel TO the pump but i’m not getting any smoke out of the exhaust when i try to start it. I believe the shop timed the pump to 10 BTDC, I believe the harmonic balancer is set to 18BTDC though when the marks in the pump are lined up. Does this mean the timing is 18 BTDC or 10. I’m not real excited to pull the injectors to have them tested but i can if needed. I pulled the return line off the injectors and i only had fuel come out of #2 and #4 when i pulled it off. |

Replies:

Posted By: SteveM C/IL

Date Posted: 07 May 2024 at 10:29am

| So you lined up timing marks before pulling pump right? And then never rotated engine? And what was the balancer on then?. Bottom line,if marks line up and it shows 18 deg that's what it is. I'm not there so I don't know if you're on #1 or #6 TDC. |

Posted By: rw

Date Posted: 07 May 2024 at 11:39am

|

As long as it sat you may be thinking right on nozzles. if you want a better chance of getting the most out of the rest of the life of the engine it would be a good idea to see the spray pattern so you get good combustion. Poor spray pattern can cause uneven temps in the cylinder possibly leading to holes burned in pistons or other kinds of maladies. I have done my nozzles a few times and replaced the spray tips once. Be sure transmission range shifter is in park. To get it running so you can maybe see what you have, try opening the fuel lines a couple turns of the nuts at the nozzles and crank the engine to be sure you have fuel getting all the way to the nozzles, then close some of them as some one cranks starter and it will probably start. Be sure range shifter is in park. A lot of times the air in those long injection lines just compresses so the lines never fills to a solid stream of fuel therefore doesn't reach the nozzle. That will cause the no smoke while cranking. Usually you will at least get smoke while cranking if you bleed those lines.

Hopefully you have a fully charged, prime condition battery set, perfect cables and heathy starter. |

Posted By: AllisOwner7060

Date Posted: 07 May 2024 at 12:50pm

I removed the gear after i marked teeth where they were, I forgot to make sure the line was lined up in the pump before i removed it so i think the timing is all messed up, im probably going to have to pull the valve cover to make sure i have it on the right stroke. My best bet is i’m 180 out but that doesn’t explain why i get no smoke when cranking |

Posted By: AllisOwner7060

Date Posted: 07 May 2024 at 12:52pm

I’m going to go buy a battery specifically for this purpose because I know exactly how it’s going to go haha. The last time I played with it in september, I had fuel up to 2 injectors but none of the others, I have the fuel turned on, primed up to the pump, crank a little, pump some more, crank a little, pump some more. I also bled the pump with the screw on the bottom and had no air come out. |

Posted By: Les Kerf

Date Posted: 07 May 2024 at 3:35pm

I am not familiar with that particular engine but can you pull an injector and blow air into the cylinder? If you are 180 out one of the valves will be open and you can hear the air coming out. If it is on the compression stroke then no air should come out of either the intake or the exhaust. Just an idea, I have done this on gasoline engines.

If it is 180 out I don't think you will get much smoke because it isn't on compression when it injects

|

Posted By: SteveM C/IL

Date Posted: 07 May 2024 at 5:12pm

| I would rather pull valve cover than injector. Might be just as easy to change it 180 deg and see what happens. Definately leave lines cracked at injectors till you have diesel leaking out. Tighten the first wet one and see if it stares firing. Why do so many people jerk pumps off without setting timing first? |

Posted By: injpumpEd

Date Posted: 08 May 2024 at 7:46am

|

Any shop that did the pump without doing the injectors is asking for problems. If the fuel was gummy and rusty inside the pump, it is in the injectors as well. They need removed, disassembled and reset just like the pump was. You'll be lucky if you haven't seized the pump head. The injector needles do get stuck and won't open. You can't just have them tested either, they need to come apart to be cleaned properly. New tips may even be needed. While injectors are out, you can then find #1 compression stroke by plugging #1 inj hole, turn engine over clockwise (viewed from front) until plug pops out. You are now coming up on compression stroke, so at 18* Before TDC is where you need the pump marks to line up with each other. Good luck! ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: AllisOwner7060

Date Posted: 08 May 2024 at 7:30pm

|

Thanks for the ideas everybody, a mechanic buddy of ours was out working on something else and he took a look at the tractor for, we tried pulling the #1 injector and it would not budge even with 2 bars and some lube she would not come so we opted for the valve cover. I had it 180• out and the pump wasn’t timed right either. Injectored, when we pulled the pump and sent it to be rebuilt, they never asked us about the injectors, i was going to pull them to have them tested but with as much trouble as we were having just trying to get one of them out, I don’t even want to imagine what the rest of them is like. Hopefully i didn’t seize the pump head because then i’d be out 1400$ on that pump rebuild. I pulled the return line off the injectors and only 2 of them had old fuel come out, #3 and #5. the rest were dry. Would I be able to take a squirt can with diesel fuel and put it in the tops to see if fuel would go down inside or is that not how they work |

Posted By: SteveM C/IL

Date Posted: 09 May 2024 at 8:02am

| I don't think that's how they work. Never heard of loose return line for fuel bleeding. Always loosen pressure line. |

Posted By: AllisOwner7060

Date Posted: 09 May 2024 at 9:36am

| When I say i had old fuel come out of the returns, i mean when pulled the return lines off to pull the injectors i had old fuel come out of the 2 that were mentioned |

Posted By: tbran

Date Posted: 09 May 2024 at 10:05am

|

As stated before, the top of the injectors - assuming they are AC and not Bosch - the AC has the drip line on top - are is exit point for the leakage of the fuel that is necessary to lube the moving parts of the injector - on some AC injectors there is a fiber 'filter' that can act as a plug if really contaminated. The drip line exits to the tank along with the case drain of the fuel pump. IF your pump had stuck plungers due to varnish etc, bad fuel the injectors could be stuck - If not and you have a fuel restricion issue no amount of rebuilding will fix the issue. It is very common for us to receive calls "we just had this rebuilt and it will still not run" - We usually use a separate fuel supply source to eliminate the tractors as a fuel source. Even if it is 180 out of time - every AC tractor I have seen WILL smoke - and smoke bad - and will run if hit with a shot of ether but runs horribly . IF the pump plungers were not stuck or the pump full of crud, the injectors probably will not be either - you need to talk to the rebuilder. Also Pull the Fuel filter - unclip it - and see if there is a roll pin for location - if there is - pull it out flush out behind it and throw the roll pin away - there was a service bulletin decades ago about this. After this replace filter - loosen the line going into the center of the pump and pump the hand primer - you should get no air but all clean fuel blowing out at each stroke. Just things from past experience. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: Acdiesel

Date Posted: 09 May 2024 at 11:15am

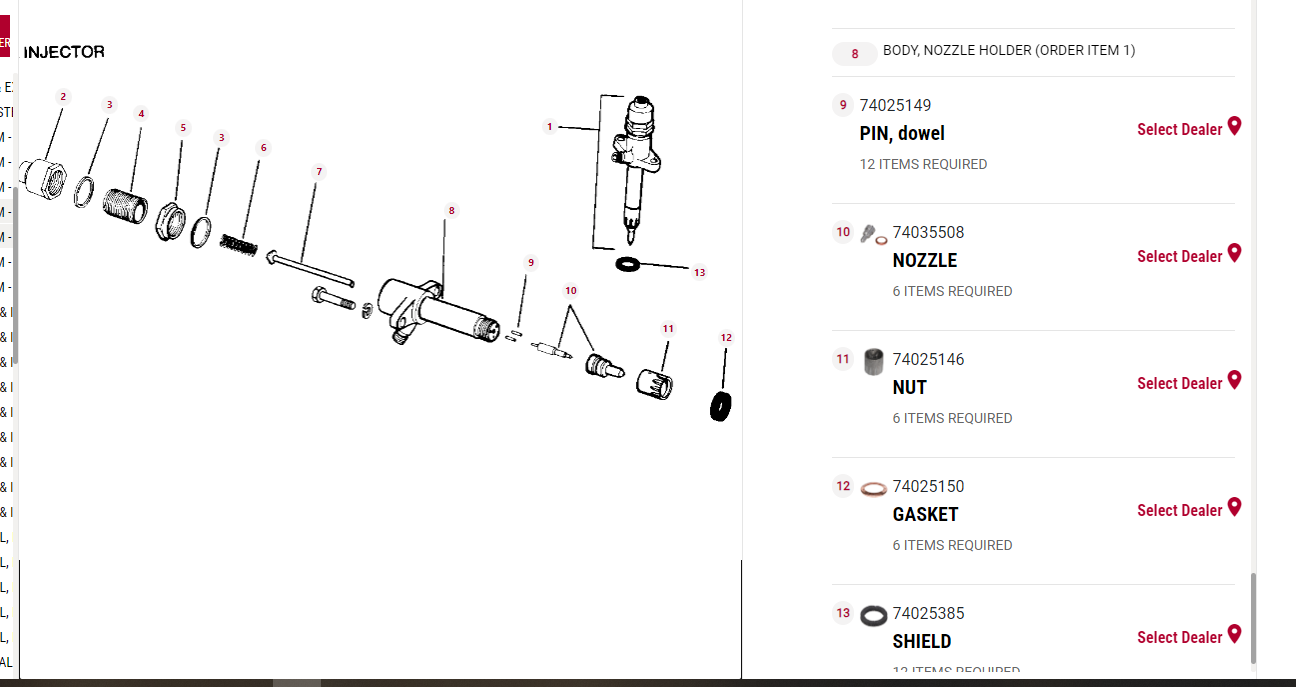

As injpumpEd stated. What Happens from the old varnished fuel is on #10 in the picture is the Pintle will get siezed in the nozzle and fuel can't be delievered out the tip of the nozzle assy. So if everything down stream of the pump is blocked and that fuel has no where to go it can hydraulic lock the injector pump head. You are not able to pour fuel in the injector and see if it goes down. gettting the injectors out can be a chore if they been in the head for a long time. soaking and having the correct tools to pry on the injector with out damageing it key. I have been able to use two fully threaded bolts with a nut, one in each ear of the injector, put the bolt through the top of hole put the nut on the bottom (under the ear) and thread the bolt throught the nut with two wrenches, tighten each bolt equally and making a puller to extract the injector. you will need a small plate so not to mess up the threaded retaining holes in the head. Dan Dan ------------- D19 diesel,D17 diesel SER.3 D14 NF,D14 WF, D15 SER.II wf D15 SER.2 DIESEL,D15 ser.II nf D12 SER.I, D10 Ser.II 2-720'S Gmc,caterpillar I'm a pharmacist (farm assist) with a PHD (post hole digger) |

Posted By: SteveM C/IL

Date Posted: 09 May 2024 at 1:21pm

| Dan. In your scenario could you just use a longer (all thread) screwed into clamp bolt holes with the nut under the injector and not deal with a push plate? |

Posted By: Les Kerf

Date Posted: 09 May 2024 at 1:44pm

Thank you, that is excellent information; is this because even though the fuel is injected at the wrong time, it is still floating around in the cylinder and gets ignited upon the next compression stroke?

|

Posted By: Amos

Date Posted: 09 May 2024 at 8:42pm

| Is there any reason why a slide hammer that has a nut that threads onto the top of the injector would not work to pull them out? I've done this many many times on other engines, just not on any of the 426 cu in allis chalmers ones |

Posted By: injpumpEd

Date Posted: 10 May 2024 at 7:38am

|

The slide hammer works great on engines with the inlet on top, like Ambac/Bosch injectors in an AC. Using the slide hammer on the AC holders usually ruins the body. Sometimes you have to ruin parts of the injector to get them out without pulling the head. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: Acdiesel

Date Posted: 10 May 2024 at 10:45am

yes, that would work as well, I was cheap and just used what i had in my bolt bin at the time. ------------- D19 diesel,D17 diesel SER.3 D14 NF,D14 WF, D15 SER.II wf D15 SER.2 DIESEL,D15 ser.II nf D12 SER.I, D10 Ser.II 2-720'S Gmc,caterpillar I'm a pharmacist (farm assist) with a PHD (post hole digger) |

Posted By: Amos

Date Posted: 10 May 2024 at 12:56pm

| Thanks Ed, I had a memory lapse there on the older style allis chalmers injectors...got slide hammer on the brain too mucj |

Posted By: AllisOwner7060

Date Posted: 12 May 2024 at 7:05am

| Small update, i cracked the lines at the injectors and verified i had fuel up to them, I put the lines back on and tried cranking the tractor. I had pretty good smoke and it sounded like it tried to fire but the one battery and junk cables was not enough to get it going. I’ll have to go buy 2 good batteries and better cables to see if it wants to really fire off |

Posted By: Michael V (NM)

Date Posted: 12 May 2024 at 11:03am

|

if ya gonna get new cables with new batteries,, I'll suggest to get the batteries with threaded post, group 31 ,, I think,... check your grounds also, from the battery box to the tractor transmission case this is what I done on my 7060,, works good. had the parts store jus put the new ends on the old cables

|

Posted By: GM Guy

Date Posted: 22 Jun 2024 at 2:10am

x2 on this. Threaded stud is vastly superior to post. I buy bulk cable and ends and make my own cables, I wont even stock a post type end. ------------- Gleaner: the properly engineered and built combine. If you need parts for your Gleaner, we are parting out A's through L2's, so we may be able to help. |

SteveM C/IL wrote:

SteveM C/IL wrote: