D 15 won't back up

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=180913

Printed Date: 25 Aug 2025 at 5:32pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D 15 won't back up

Posted By: ACinSC

Subject: D 15 won't back up

Date Posted: 01 Jun 2021 at 12:16pm

| Been sitting in my shop several months . Tried to back it out and it won't move . Trans is full and it was fine when I parked it . When I take it out of reverse and let the clutch out it goes forward . Only have neutral with the power director in neutral . Guess the trans is hung up ? Any ideas ? THANKS !! |

Replies:

Posted By: steve(ill)

Date Posted: 01 Jun 2021 at 1:57pm

|

i have had that on a B before.. Shift forks or pins get WORN and let things flop around . your stuck in forward all the time.. Put it in Neutral and you have forward, put it in reverse and it locks up.. On the B, you remove the side cover and repair the pins / slides / shift fork slop.... D should be similar. ------------- Like them all, but love the "B"s. |

Posted By: ACinSC

Date Posted: 01 Jun 2021 at 2:26pm

| Thanks Steve . Guess I'll have a look . Hope the problem is easy to see and fix . Never been in a trans before . Thanks again ! |

Posted By: Leadoff

Date Posted: 01 Jun 2021 at 2:51pm

|

ACinSC I had similar shifting issues with my 1965 D15 II. Sometimes I could correct the alignment by carefully moving the shifter around, not forcing, or as noted above, going in thru the side plate (need to drain oil) to realign the shifting mechanism to "neutral position"- no gears engaged. My problem, I believe, was wear on the ball at the bottom of the shifter. Research reading on this forum showed this to be a common problem with some shifters/transmissions on some of the older AC models. Some guys solved the problem by building up the wear area on the ball. I solved my problem by purchasing a used D15 shifter, that had minimal wear on the shifter ball, and have had no issues since. A good AC friend, former Dealer/mechanic, told me that forcing the shifter into gear or not shifting properly, was a very bad thing to do with AC tractors, and would lead to gear wear and lockup problems. Now I am really careful when shifting gears There is a lot of good info on this topic in the forum archives Good luck getting going again ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 01 Jun 2021 at 3:04pm

| Thanks Robert . Just checked the archives and didn't see anything much . Maybe I didn't go far enough back . We actually have a spare trans but the side plate and shift linkage? are missing . I see Agco has a shifter pin listed . I'll have to pull the cover after I drain the trans and see what I can figure out . Thanks , again ! |

Posted By: Leadoff

Date Posted: 01 Jun 2021 at 3:25pm

|

ACinSC I just tried a search, use the advanced search feature, use "shifter problems" as the key words, and select "any date" in the "Find Posts" drop down menu for how far back you want to go. My computer snorted a bit, and after about a minute produced three pages of "shifter problems" threads. Lots of good reads/advice Also to clarify, (I might not have the correct terminology), I am calling the "shifter" the lever between your legs, with the rubber on the end, that the operator moves. As you know, on the D14/D15 it has an unusual bend to it before it enters the transmission housing. Good luck. I found it very frustrating to sort thru this problem, especially when it happened in a bad spot!!! ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 01 Jun 2021 at 3:49pm

| Good info Robert ! Guess it's kinda/sorta lucky that my tractor messed up trying to back out of my shop ? THANKS ! |

Posted By: ACinSC

Date Posted: 02 Jun 2021 at 3:20pm

| Have the shifter and side plate off . Took some pics that my fav son should post soon . THANKS !! |

Posted By: WeisAC2

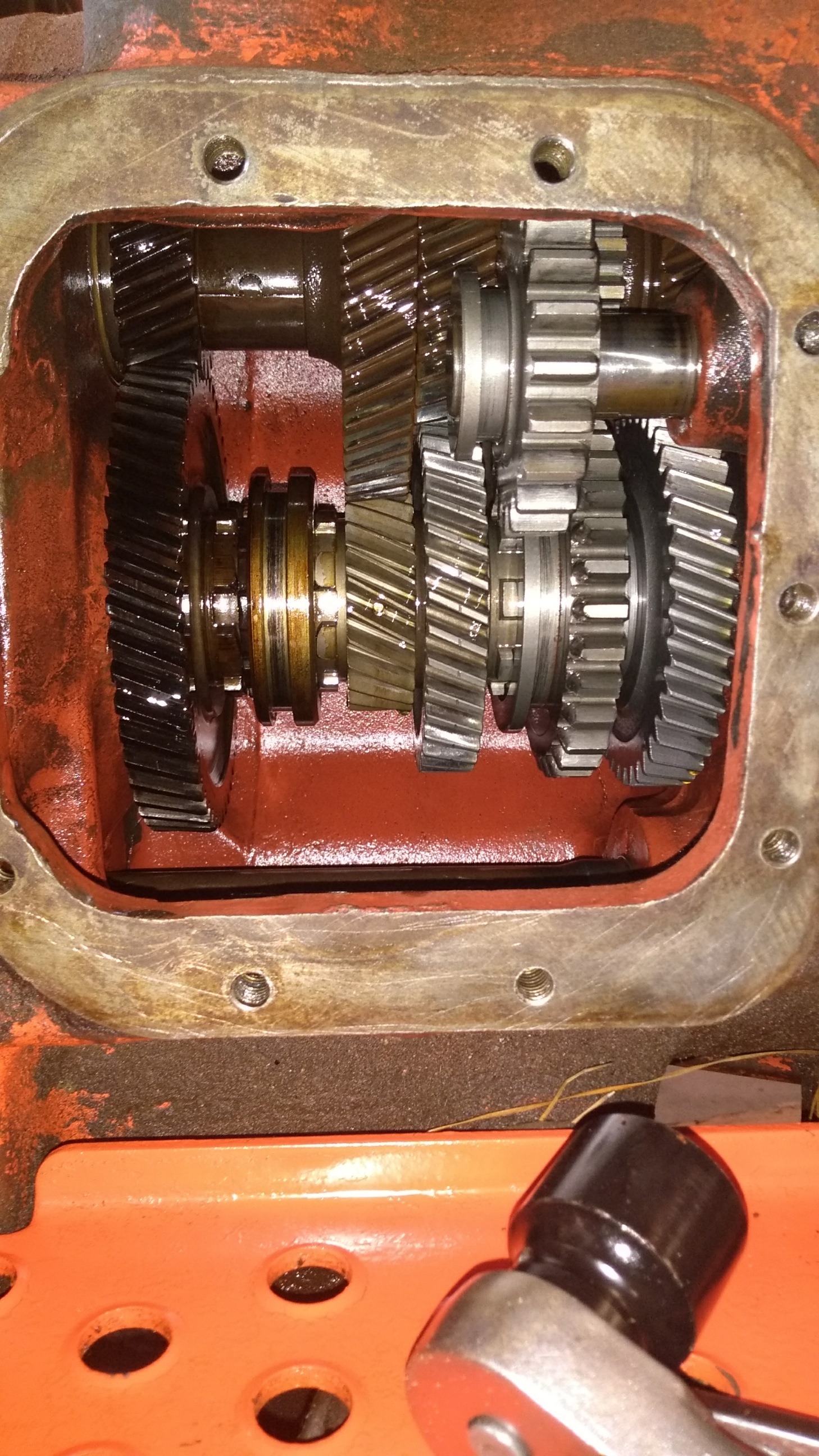

Date Posted: 02 Jun 2021 at 4:12pm

|

Posted By: Leadoff

Date Posted: 02 Jun 2021 at 5:52pm

|

ACinSC Great pics Getting the Tractor in Neutral Can you line up the Notches on the top of the shifting mechanism you just removed - so they form a perfect rectangle or row perpendicular to the centre line of the tractor. This Notch Row would be where the shifter ball sits, right in the middle. In Neutral, the Operator can move the shifter, perfectly right or left, and the shifter ball moves sideways in the Notch Row (and none of the Notches should move) The fork associated with each Notch assembly, should move a gear, or gears, forwards or backwards. One Notch at a time is displaced by the shifter ball, when the Operator selects a gear, and then deselects. You can see how critical it is to have the Shifter in the correct position, so it ONLY CONTACTS ONE NOTCH AT A TIME. Also try and determine if your shifter ball has much play as it moves thru the gears, how much contact it is making with the notches I played around with mine once I figured out how it functioned, placed the side plate back in the tractor (no oil yet) with the Notches/forks/gears in the Neutral position. Look down the shifter hole from the Operators position to ensure still in Neutral, and try rolling the tractor to ensure no gears are engaging. Then drop the shifter into its position and try shifting gears (without the tractor engine running). You should be able to tell if the shifting and gear engagement is working properly or not. Once you are happy with how it feels, you can tighten up the side plate, start the tractor, and go thru the gears again with power this time. Moving the tractor a foot or so is all that is needed. Then you can replace the transmission oil This is how I stick handled (Canadian hockey term) thru my "Shifter Problem" situation I do not have any other advice from my experience regarding the gears, wear on the forks etc. Hope this helps you with your project. ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 02 Jun 2021 at 6:09pm

| Thanks Robert ! Did you replace the pins ? My shifter ball has a small flat spot . Doesn't look bad to me , but what do I know ? I'll get back out there tomorrow . Thanks again !! |

Posted By: DrAllis

Date Posted: 02 Jun 2021 at 7:36pm

| The picture of the transmission gears shows that it is in SECOND gear and REVERSE gear at the same time. Your description isn't very clear " won't move" should have probably said " it kills the engine if I try to make it move". How in Sam Hill it broke sitting in the shed, I'll never understand. I've never had to rebuild any of the shifter mechanism on any D-14-15, so I don't understand how it got out of synch just sitting in the shed. |

Posted By: ACinSC

Date Posted: 02 Jun 2021 at 8:25pm

| Yeah Doc , it's dies when I try to back up . I don't know what happened either . Bad mo jo maybe . I'd very much like to fix it so it doesn't happen again . Thanks ! |

Posted By: DrAllis

Date Posted: 02 Jun 2021 at 8:40pm

| Well, at some time in past history, someone has had the shift cover off. The blue RTV is the dead give-away. |

Posted By: ACinSC

Date Posted: 02 Jun 2021 at 8:48pm

| Yeah I've seen that blue silicone elsewhere . Thanks again |

Posted By: Leadoff

Date Posted: 02 Jun 2021 at 8:52pm

|

ACinSC I did not replace the pins, only the shifter. The replacement shifter ball had more bulk than the old shifter, and that seemed to be enough to make the difference with keeping the ball tight/firm with the Notch. Also the Notches were well worn from many years of being rubbed by the shifter. Your ball looks good, but the flat spot might be an issue. I remember seeing specs quoted on the required size of the ball for a good snug fit. I was surprised how much a difference a slightly larger ball would make. In some of the examples quoted in the Forum, the guys who built up the size of the ball welded/ground smooth/dropped shifter into position/tried shifting/made minor corrections/repeated the exercise until they were comfortable with the fit You are in a good position to check your Shifter "snugness" as you shift thru the gears One other point I forgot to mention that was passed on to me by my old AC Dealer Mechanic friend......when shifting, place slight downward pressure on the shifter using the palm of your hand, as you move it to the desired gear position. Also, follow the shift pattern very carefully to ensure the best alignment with the ball and the desired Notch Good luck with your project ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: Leadoff

Date Posted: 02 Jun 2021 at 9:17pm

|

ACinSC Just reading the observations above re Second and Reverse Gear and tractor can't move etc............sounds very similar to my situation I concluded I needed a tighter fit between the shifter ball and the Notches and Clean up my shifting methods to try and follow the shift pattern properly ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: jaybmiller

Date Posted: 03 Jun 2021 at 5:47am

|

Ok, the 'cure' is to go buy a 'parts tractor' and just before you remove this and that, get it 'up and running, now you'll need another ... 'parts tractor' and just before you remove this and that, get it 'up and running, now you'll need another, now you'll need another... 'parts tractor' and just before you remove this and that, get it 'up and running, now you'll need another  THAT'S how to keep #1 running..... ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: ACinSC

Date Posted: 03 Jun 2021 at 10:45am

| Think what I need to do is put the side plate in place with a couple bolts . Then use the shifter or a screwdriver from the top to align the shifter notches and hopefully the trans into neutral ? Then test to make sure it's really in neutral ? THANKS so much Robert for your help . I have to order a gasket and may also get 2 pins . Agco seems to stock them and they're $14 each . Mine look ok to me , just worn enough to be shiny . THANKS for the help everyone ! |

Posted By: Leadoff

Date Posted: 03 Jun 2021 at 10:52am

|

ACinSC Good plan. Good luck ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 03 Jun 2021 at 12:32pm

| Oh well , that didn't work . Gonna pull the fender so I'll have more room to maybe see what's going on . THANKS ! |

Posted By: Leadoff

Date Posted: 03 Jun 2021 at 7:35pm

|

ACinSC Good idea, that is a tight area. Determine Correct Notches/Forks/Gear positions I was able to see which gear/gears moved forwards and backwards from the Neutral position for each Notch assembly. Once you have the fender removed, and are able to get a better view of the transmission area see if you can make that determination. It is a bit tricky as your view will be obstructed by the side plate, so a bit of trial and error as you inset the plate/forks and remove to figure out the applicable gears for each Notch assembly In simple terms, in the Neutral position, Notches forming a line from the top, no gear should be engaged with another gear, and the gears are held in position by the forks. As you move thru the shifting sequence, one Notch movement will move gears/gear into an engaged position, with the power gears It is a bit like solving a puzzle, but you know which gears are interconnected from the shifting pattern. If I recall, 1st and 4th share a Notch assembly, 3rd with 2nd, and Reverse is seperate in the middle. Knowing this will help you figure out the Notches/forks/gear pairings Hope this will help you with your project............Rob ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: Leadoff

Date Posted: 03 Jun 2021 at 10:23pm

|

ACinSC Found a couple of threads that might give you some additional info to help you sort out your transmission/shifting issue..... https://www.youtube.com/watch?v=k5uPi5HvYDU" rel="nofollow - Clutches and Gears in Tractors [Year-2] - YouTube https://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=ac&th=155810" rel="nofollow - D15 transmission question - Yesterday's Tractors (yesterdaystractors.com) The YouTube is very basic, and there are others on YT, but it provides the essentials of how a simple tractor transmission works. The D15 transmission thread is about gear jumping, and gear wear, but has a couple of pics of a transmission, and comments on work involved in repairs Hopefully you can determine if your transmission/gears/forks assembly is in the proper alignment, once you complete your inspections Good luck with your project ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: Leadoff

Date Posted: 03 Jun 2021 at 11:40pm

|

ACinSC I was reading this thread info over and figured we had not specifically checked off an important item.... Something that needs to be followed up.........Dr Allis comments above, re second gear and reverse gear engaged at same time.....that needs to be corrected Perhaps you have already, if not.......... When I compare your pic to the one in the Yesterday Tractor D15 thread (previous note) there are some differences in positions of the gears. I am assuming the D15 thread pic shows the transmission in Neutral (maybe not), but your pic gear alignment is not in Neutral (according to Dr Allis) Key message,,,,,,,,,,gears need to be in Neutral position before you re-install the side plate/forks which should also be in the Neutral position You can verify all gears are in the Neutral position by rocking the tractor by hand and/or cranking the engine (not starting) a bit When I performed my D15 adjustments/upgrades I had to move the gears a bit to ensure alignment with the forks as I was reinstalling the side plate Good luck with your inspection/re install ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 04 Jun 2021 at 6:59am

| More good info Robert . Maybe I can figure something out ? Sure not going to be an easy fix . I'm very thankful for your help . |

Posted By: steve(ill)

Date Posted: 04 Jun 2021 at 8:04am

|

You have to slide all the gears into neutral.. You have to put the side plate and forks in the neutral position. You wiggle the plate and try to align the forks as you slide it together. Yes, it takes some time and some wiggle... You have to have all gears in neutral before you start. When you THINK, you have it together, put in 1-2 bolts and snug them up.. try shifting. ------------- Like them all, but love the "B"s. |

Posted By: Leadoff

Date Posted: 04 Jun 2021 at 9:41am

|

steve(ill) Excellent description of the steps required ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 04 Jun 2021 at 10:08am

| THANKS Steve and Robert ! Anyone have a pic of the gears when the trans is in neutral , or a description ? I've pushed on the side plate notches a little , but they haven't moved . Are they hard to align by hand ? THANKS !! |

Posted By: steve(ill)

Date Posted: 04 Jun 2021 at 12:36pm

|

the side plate has 3 shafts that the forks mount to.. you can see a PLUG where the shaft goes thru each bushing.. I think there is a ball and spring DETENT at that position. PUSH on the end of each shaft, or bump with a hammer and you should see the shaft jump to the next detent positon... You may be able to see a NOTCH in one of the shafts where the detent sets when the shaft is moved.

you should be able to use your SHIFT KNOB position to see the forks are in neutral... then look at the forks and measure between them and position the GEARS back and forth ( put them in neutral) so they will align with the forks. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 04 Jun 2021 at 12:45pm

|

I dont have a D15 manual handy.. Here is a WD shift plate and forks.. you can see the SPRINGS and BALLS that are the detents.. Thats why the shafts appear to be "stuck".. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 04 Jun 2021 at 12:55pm

|

You might be able to jack up one tire an inch off the ground. Try to rotate the tire... If everything is in NEUTRAL, the tire will turn. ------------- Like them all, but love the "B"s. |

Posted By: ACinSC

Date Posted: 04 Jun 2021 at 1:11pm

| THANKS Steve , I have a Agco service manual but it's a reprint and some of the pics are blurry . Maybe with some help from you fellas I can get this thing back together . I'm pulling the right rear wheel now . Hopefully that we help me see what I need to do . THANKS again !! |

Posted By: ACinSC

Date Posted: 05 Jun 2021 at 12:33pm

| Have the rear tire off the floor . Only time it won't turn is when reverse gear ? is slid all the way forward . I assume it's in reverse and second gear ? I moved some gears around and now it turns pretty freely . Took a pic that my fav son will post soon . Hoping this is neutral ? THANKS !! Just realized I have the power director in neutral . |

Posted By: ACinSC

Date Posted: 05 Jun 2021 at 12:54pm

| I put the power director in high and the wheel still spins . Should've also said that the second gear from the front also spins . THANKS !! |

Posted By: Leadoff

Date Posted: 05 Jun 2021 at 1:21pm

|

ACinSC Sure sounds like you are making progress. The Power Director engaged in hi/lo is a good catch to determine is the gears in in the Neutral position, as you move the wheel and the gears. The pic will help some of the more knowledgeable in the Forum give you indication if all gears are in Neutral I remember a common expression at work over the years "self discovery is the best form of learning" and it sounds like you have a lot of that going right now!!! Good luck with your project ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 05 Jun 2021 at 2:04pm

| Thanks Robert ! Maybe I'm headed in the right direction . Still wonder why it hung up in the first place ? If I manage to get it up and running again I'll be very careful changing gears . Thanks |

Posted By: WeisAC2

Date Posted: 05 Jun 2021 at 2:19pm

|

Posted By: Leadoff

Date Posted: 05 Jun 2021 at 3:27pm

|

ACinSC I am sure you will be up and running again. I see your photographer has posted a great pic. Hopefully, a Forum expert can tell you if your gears are in Neutral or not. Aligning with the Forks as has been well presented above, and no gear movement when you turn the rear wheel are huge steps in the right direction, and are the limit of my knowledge As for how this happened in the first place..... as it has happened to me several times before I corrected the Shifter ball clearances with the Notch.... Possibility 1.........perhaps someone (no names please) banged the Shifter with their leg, as they were getting on/off the D15 before you discovered the problem. There is not a lot of room between the seat and the Shifter knob - I have had to wiggle my leg thru numerous times, mostly when dismounting, and that is not good because you could end up forcing the shifter in a undesirable manner. I know I have done that a few times. Usually, I leave the Shifter in Neutral, which provides a bit more room for your leg, but sometimes I forget, leave it in Reverse or 2nd and end up popping the Shifter forward Possibility 2........when I was a youngster is was lots of fun to climb on farm tractors (that were not running) and turn the steering wheel, turn on the lights, etc, AND MOVE THE SHIFTER THRU THE SHIFT PATTERN. My experience would suggest this in not good for a worn, 50+ year old tractor shifter/transmission. Now your tractor was in the garage with no loads on the gears etc, but if the shift pattern was not followed very carefully there could be a possibility of "sloppy shifting" leading to gear lockup I could easily see either of the above examples happening to my tractors, either by me or visitors, my son, or my grandchildren when they visit My old D15 II is a great tractor, but have learned to be really careful with the gear shifting, and there are no issues Good luck with your project ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 05 Jun 2021 at 7:03pm

|

Robert it's guys like you that make this site what it is. You're over 2,000 miles away and took the time to help me out . I've received help from many people on here over the years . Thanks again to you , Steve , Dr Allis and everyone else . Hope I haven't just jinxed myself. Should also say that I have nobody to blame but myself . |

Posted By: Leadoff

Date Posted: 05 Jun 2021 at 10:03pm

|

ACinSC Thanks ACinSC, just trying to help out. This Forum is so valuable to Allis Chalmers owners, especially when they are in need of information/guidance to get their equipment working again. I tried comparing the locations of your gears from your recent photo to the pic from the D15 Transmission article noted in an earlier post above. They gear locations look very similar with no significant differences. Not sure if the article pic has the gears in Neutral, but you would think it would be in Neutral before they opened it up. The online AGCO Parts Book, or any other good D15 parts book, shows the Forward gears and Reverse. This would help identify the gears that need to be loose to satisfy the Neutral position condition. A further check is to turn your rear wheel, and if none of them move, then you should be ok to proceed with the forks/side plate installation. steve(ill) provided an excellent description in an earlier post on how to install forks/side plate. Once you have completed his suggested procedure, including the final step - shifting you should be in good shape. Perhaps secure the Shifter at this stage as well As a final check, you could shift thru Neutral and all the gears, turning the rear wheel a bit after each shift, to see if the gears are engaging properly. The rear wheel should spin freely when the Shifter is in Neutral, and should not spin in any of the five gear positions If you get that far, and everything is looking good, get on the tractor, push in the clutch pedal, start the engine (idle), put the hand clutch/Power Director in hi or lo, gear shifter in Neutral, and SLOWLY /Gently let the clutch pedal out...........the rear wheel should not move If the rear wheel does not move in Neutral, then try each gear following the same procedure, and you should get the corresponding rotation for each gear. Once you have confirmed Neutral, and all gear positions are working, you can button up the remaining bolts on the side plate, return oil to the transmission, lower your wheel, and take D15 for a spin Good luck ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: steve(ill)

Date Posted: 05 Jun 2021 at 10:24pm

|

AC... i wish i could help more at this point, but i really can't "LOOK" at a set of gears and tell you what is engaged... The "DOGS" on the side of the gears are NORMALLY visible when you are in neutral... The gear to the LEFT of the page has the DOGS visible on both sides... The lower gears on the RIGHT side of the page, i dont see all the DOGS.. Wonder if that gear needs to slide a little, but i dont know for sure... maybe just the angle of the photo.............. again, if the tire turns, then you SHOULD be in neutral ( with PD engaged). Sometimes you got to install the plate a couple times to get it RIGHT.. Trying to shift it with 1-2 bolts installed is the final test.

------------- Like them all, but love the "B"s. |

Posted By: ACinSC

Date Posted: 06 Jun 2021 at 12:44pm

| Pulled the rear tire/wheel today . Took a good look at my service manual and it says to engage the reverse idler gear , then put pinion shaft reverse gear in neutral . Then put pinion shaft coupling in neutral and then reverse shift rod in gear . Very confusing . Gonna order a gasket Monday so I can put it on . If I ever get this side plate right I don't wanna remove it . Should say that I tried putting the side plate on with everything in neutral , at least I think it's in neutral and had no luck . THANKS ! |

Posted By: Leadoff

Date Posted: 07 Jun 2021 at 12:27am

|

ACinSC More searching and found D14 (very similar to D15 - side plate transmission access) info and found this very interesting thread which I think is very applicable to your situation https://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=ac&th=61173" rel="nofollow - D14 transmission locked - Yesterday's Tractors (yesterdaystractors.com) This guy probably had the same problem you encountered!!!! The section on Shifter Removal, last two at bottom of Thread, looks very promising, and it seems to line up directly with the information you quoted from your service manual regarding engaging Reverse Gear. The service manual is providing direction to reassemble the shifter mechanism and the YT article is directing how to open up the shifter assembly........how to open it up and how to close Both indicate that the key to opening or closing is TO HAVE THE SHIFTER IN REVERSE so you have minimal interference as you carefully remove or insert the sideplate/forks mechanism into/out of the transmission It is like the combination of a safe or lock.........put the shifter in reverse and the forks/sideplate can be removed with no interference, or the mechanism can be re-installed I know this is different than what we have have been trying to do (everything in Neutral) but I believe it is worth trying. The directions in your manual are essentially what happens when you use the Shifter to put the tractor into Reverse. All of those items mentioned move into position, when you move the Shifter into Reverse. The YT article calls for the same step before you open the sideplate/forks mechanism. Two different ways to essentially line things up so the sideplate/forks can be removed. So here is what you need to do.......... 1. move the gears etc as per your service manual, engage means move to a position where the gear turns when the rear wheel turns........neutral means it does not move when the rear wheel turns (there should be a diagram in your service manual showing the gears and their identification - if not go to the online AGCO parts manual for this info 2. Move the Reverse Gear Notch on the Sideplate/Forks assembly into the engaged position (simulating putting the tractor into Reverse Gear). This is the reference in your service manual "reverse shift rod in gear". The YT thread refers to using a screwdriver. after removing the shifter to do the same thing 3. Now the gears are lined up (step one) and the forks lined up (step two) and you should be able to insert the sideplate/forks into the transmission housing with minimal interference 4. The YT thread mentions "if you hold your mouth just right"....I think this means do it carefully and don't sneeze/cough 5. Hopefully this works and you can get the sideplate/forks assembly in place. 6. The directions noted in previous messages to perform integrity checks, shifting, manually turning the rear wheel to check each gear, then using the engine power to turn the rear wheel still apply To add confidence to this slightly different approach, here is a neat piece of info I found titled.....Installation Procedure of transmission Shift Tops". How to line up the gears/forks for WD45, D17, D19, 170, 175....all with top shift tops (D14/D15 on side) and similar shift pattern. The document is from Sandy Lake Implements. Perhaps they would have a similar document for D14/D15 https://cdnmedia.endeavorsuite.com/images/organizations/5b5d9e04-fbf3-45af-b85a-10b411f696fa/Bills%20Tidbits/Trans%20Shift%20Tops.pdf" rel="nofollow - Trans Shift Tops.pdf (endeavorsuite.com) The steps for the WD45/D17 are very similar to our example, with minor difference due to Reverse on side of shift pattern, not in middle like D14/D15 Hopefully this additional information will help you progress your installation Good luck ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 07 Jun 2021 at 6:05am

| Thanks again Robert ! Lots of good info . I did order parts from Brenda . I'll get back out there soon and see what I can do . |

Posted By: Leadoff

Date Posted: 07 Jun 2021 at 9:09am

|

ACinSC Here are a couple of additional info reads I found in the D14 searches. The YouTube vid shows the D14 transmission and commentary on work performed. The second thread has pics of a D14 transmission repair. You can see the D14 transmission looks very similar to the D15. https://www.youtube.com/watch?v=zlWYtN52jHE" rel="nofollow - Allis Chalmers D14 Transmission Gear Overhaul - YouTube http://www.bobstractorpartscorner.com/html/acd14transmission.html" rel="nofollow - Welcome to Bob's corner (bobstractorpartscorner.com) Hope this helps with your work Good luck ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 07 Jun 2021 at 9:33am

| THANKS Robert , think the D 14 trans is pretty much the same . I'm gonna check out all the videos and try again . Thanks !! |

Posted By: ACinSC

Date Posted: 21 Jun 2021 at 3:10pm

Been a couple weeks since I last posted . I see my attempt at pic posting didn't work . Today I put on my new gasket , knocked the side plate fork in reverse and put the plate on . Per my book I used a big screwdriver to put the shifter fork back in neutral . Wheel turns so I guess I'm good . Then I installed 2 new shifter pins ,the shifter and a new washer and lock ring . Shifter seems to work ok . Next I'll put the fender and loaded tire/wheel back on , add trans oil and see what happens . THANKS everyone for the help . Been a couple weeks since I last posted . I see my attempt at pic posting didn't work . Today I put on my new gasket , knocked the side plate fork in reverse and put the plate on . Per my book I used a big screwdriver to put the shifter fork back in neutral . Wheel turns so I guess I'm good . Then I installed 2 new shifter pins ,the shifter and a new washer and lock ring . Shifter seems to work ok . Next I'll put the fender and loaded tire/wheel back on , add trans oil and see what happens . THANKS everyone for the help .

|

Posted By: Leadoff

Date Posted: 21 Jun 2021 at 6:17pm

|

ACinSC Great news.......Congrats on your project. Looks like you are on your way. It is such a rewarding feeling to get your tractor back together. I got a couple of email notifications, (automatic by the Forum if you elect to receive email notification of additional posts after you have posted to a thread), one yesterday and one today, with an attached pic, which I could not open, showing you as the poster. I figured it was some sort of spam as the Forum did not seem to record the post?????!!! I have been using my D15 II the past week (first work with it since last fall) and had to remind myself to be careful shifting, and not rush or force the shifter into position Hope it works well for you. Happy shifting!!! ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 21 Jun 2021 at 6:38pm

| Yeah my picture didn't work . Sure hope I soon have my old D 15 up and running . Thanks again for all your help . I also plan to shift carefully . Still wonder what happened in the first place? If it hangs up again I'm going to pull the shifter and try to align things with my big screwdriver . |

Posted By: Leadoff

Date Posted: 21 Jun 2021 at 7:33pm

|

ACinSC That's the spirit. Now you are so much more knowledgeable of the whole shifting mechanism, having seen the internals, and worked with it. It really helped me to work thru my situation, and read the similar problems others had encountered. Self discovery is very satisfying!!! Good luck ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 21 Jun 2021 at 8:18pm

| Probably right , but I hope I don't need to get back in the trans . Thanks ! |

Posted By: ACinSC

Date Posted: 23 Jun 2021 at 1:05pm

| Happy to say that I backed my old D 15 out of the shop today . Even tooled around the yard a little . So far , so good .Fav son helped me put the loaded rear tire/wheel on yesterday and I hope he'll post a pic for me soon . THANKS for everyone's help !! |

Posted By: WeisAC2

Date Posted: 23 Jun 2021 at 3:19pm

|

Posted By: ACinSC

Date Posted: 23 Jun 2021 at 4:09pm

| There's a pic of my old D 15 in the yard . Hard to believe I bought it as a non runner over 3 years ago . I've fixed a lot of things on it but it still ain't pretty . Oh well , it does run pretty well . Mostly . Again THANKS for all the help ! |

Posted By: Leadoff

Date Posted: 23 Jun 2021 at 9:09pm

|

ACinSC Congratulations on your first travels post re-alignment of your trans/shifter parts. What a great looking D15 and kudos to you for bringing it back to life. I have much appreciation for people who take the time, energy, COST, and perseverance to restore items of whatever type and return them to useful service. Of course, if it happens to be an Allis Chalmers that is even better!! Best of luck with your project ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: ACinSC

Date Posted: 24 Jun 2021 at 6:53am

| Thanks Robert . I'm about ready to stir some dirt with this old tractor . |