wiring

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=177450

Printed Date: 18 Dec 2025 at 5:51am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: wiring

Posted By: hunter321

Subject: wiring

Date Posted: 11 Jan 2021 at 12:03pm

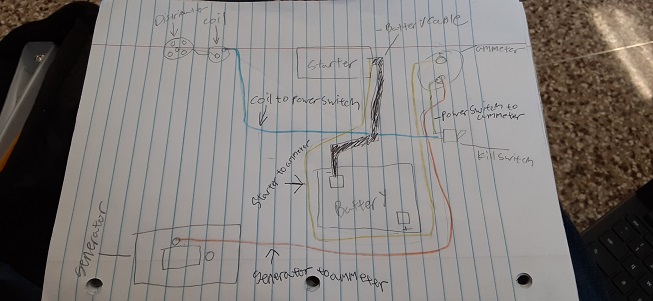

I am rewiring my ac wd45 and was wondering if this is the correct diagram |

Replies:

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 1:10pm

|

that drawing was taken from the Allis B-C service manual.. I dont know about the WD45, but may be "close"... does your tractor have a Magneto ? ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 11 Jan 2021 at 2:01pm

|

Yes I believe it has a magneto |

Posted By: hunter321

Date Posted: 11 Jan 2021 at 2:44pm

| Also does anyone know if I can get 6 volt led sealed beam lights for my wd45 |

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 4:05pm

|

hunter, you need to figure out what you want to have in the end. If you are restoring and want it original, then the 6v might be the way to go... If you use the tractor and want it more common with other vehicles, you might want to switch to a 12 volt battery. Your magnito does not use the battery, so ignition is no problem.. Your starter does not care if the battery is 6 or 12 volts and it does not care if it is positive or negative ground. Quite a few people have changed to a more common 12 volt battery and negative ground ( like your car or truck) when they are rewiring... If you do that, then head lights and other accessories are easier to come by. The above diagram is basically right for a WD 45.. but i think you have a dash with light / switch, other that the B and C did not have. Good time now to decide now what voltage / ground you want to have in the future. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 4:07pm

|

The charging system is also a concern. If your generator is in good shape it will put out just enough to keep a 12 v battery charged. You would eliminate the light switch resistor and install a voltage regulator... Another idea is to install a small automotive alternator with an internal regulator and simplify the wiring.... all depends on what you want in the end. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 11 Jan 2021 at 6:34pm

|

I wired the tractor tonight and it still won't start it hasn't started in at least 14 years. It had a oil change wiring is brand new new battery but no spark. I am restoring it and am keeping it 6 volt positive ground |

Posted By: hunter321

Date Posted: 11 Jan 2021 at 6:35pm

| I am a 14 year old and have no idea what I am doing. I just look up what I need to know |

Posted By: jaybmiller

Date Posted: 11 Jan 2021 at 7:31pm

|

re: 6 volt led sealed beam lights yes, you can take a 12 volt sealed LED unit, providing it has BOTH red and black wires ( power to LED). You'll need to buy a 'voltage booster' module ( $5+-) good for the amps of the LED unit. ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 7:56pm

|

hunter, if you have a magnito it will have 4 wires on the cap that go to the individual spark plugs.. The magnito has no BATTERY POWER. It is a rotor and coil inside the housing that generates it own spark.. A DISTRIBUTOR ignition system has a black cap with 5 wires.. the one in the CENTER comes from an external coil that is powered from the battery... just like an old truck. Assuming you have a MAGNETO with 4 plug wires only, you do NOT need any other wires or battery to get the spark.. All the battery does is crank the motor over... If you remove the black plastic magneto cap you will see a point inside that opens and closes and makes the spark JUMP... There might be corrosion on the point faces. spread them 1 /16 inch and drag some fine sand paper across the contacts several times.. See if that works.. If not, you might had additional problems with the condenser or internal coil. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 7:57pm

|

the drawing show ONE WIRE going to the magnito from a KILL SWITCH.. Just to be safe, take that wire OFF THE TERMINAL to make sure it is not GROUNDED ( = no spark)

a magneto looks like this (below)... will have 4 spark plug wires. a distributor cap looks like this ( below) ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 11 Jan 2021 at 8:14pm

|

hunter, dont take the mag off the tractor because right now you dont know how to retime it during install......... just watch this movie and maybe get an idea of how things work. https://www.youtube.com/watch?v=2fmnP700qXc" rel="nofollow - https://www.youtube.com/watch?v=2fmnP700qXc ------------- Like them all, but love the "B"s. |

Posted By: DrAllis

Date Posted: 11 Jan 2021 at 8:46pm

| A WD-45 with a magneto ??? |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 6:19am

| It definitely has a distributor. I have friends who have ac wd45 and can help with the work you guy mentioned before. Thanks |

Posted By: Steve in NJ

Date Posted: 12 Jan 2021 at 7:01am

|

Sitting that long, it probably just needs some Brakekleen on a rag run through the points. It'll probably fire right up! Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: WF owner

Date Posted: 12 Jan 2021 at 7:20am

... and it probably has a better quality condenser than you can buy today !

|

Posted By: hunter321

Date Posted: 12 Jan 2021 at 8:33am

| ill try that |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 11:15am

| if i have everything wired ecpet the light switch would it matter |

Posted By: steve(ill)

Date Posted: 12 Jan 2021 at 11:44am

|

all you need is a hot wire going to the COIL from the battery ( negative if that is your HOT).... then a wire from the coil (+) to the distributor point..... those two wires will give your distributor point power... if it starts and you want to stop, just pull the little wire off the battery. ( or on - off switch). you dont need the light switch, generator, etc. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 11:52am

This is what I have wired right now

|

Posted By: steve(ill)

Date Posted: 12 Jan 2021 at 12:01pm

yea, that looks pretty good.. While you were posting, i took the ORIGINAL drawing at the top of the page, put the coil and distributor in, and highlighted the HOT wire ( negative), from the battery, to the starter, to the amp meter, to the on- off switch, to the coil to the distributor......... i think that is what you have shown..  ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 12 Jan 2021 at 12:05pm

|

you dont need the light switch or the generators wires, or head light wires to make it run... all you need is the HOT red wires i have shown from the battery - starter - amp - switch - coil - distributor .... then the POINT has to open and close and have good contact faces.

like mentioned earlier... if you dont know if the amp meter and ingition switch are good.. you can run a wire from the battery negative terminal straight to the coil... and the coil wire to the distributor... it should have power with those two wires. ... you can also use a test light or meter to see if you have 6 v at the coil terminal. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 12:12pm

| The switch is new I am getting a new ammeter and me and my dad are going to see if I have power to the coil or not |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 12:14pm

| Once I get it started I am going to add in the light switch |

Posted By: hunter321

Date Posted: 12 Jan 2021 at 4:42pm

| Could the sparkplug wires and the wire from the distributor to the coil be bad |

Posted By: DrAllis

Date Posted: 12 Jan 2021 at 5:03pm

| Sure, they could be, but until you know you have power or not to the coil and thru the points, that is just a guess. |

Posted By: hunter321

Date Posted: 01 Feb 2021 at 10:55am

|

I have power the coil and every thing but when I checked if I had spark I still dont

|

Posted By: hunter321

Date Posted: 01 Feb 2021 at 11:36am

| What do I try next |

Posted By: Sugarmaker

Date Posted: 01 Feb 2021 at 12:59pm

|

No spark? Might try cleaning points and or check/set point gap. Need these things too which I assume you checked: Fuel? Check for flow through the carb. Compression? Check each cylinder for pressure on compression stroke. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: ac45dave

Date Posted: 01 Feb 2021 at 1:04pm

|

Make sure the distributor is grounded.If not grounded,then clean the mounting surfaces were the dist mounts into the engine.

------------- 54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors |

Posted By: hunter321

Date Posted: 01 Feb 2021 at 1:31pm

| I dont think I have power coming from the coil |

Posted By: hunter321

Date Posted: 01 Feb 2021 at 5:39pm

| How do I know if the coil is bad |

Posted By: Jim.ME

Date Posted: 01 Feb 2021 at 7:37pm

| The two small terminals on the coil are the primary side terminals, the high voltage wire is called the secondary. With the key on and the points open (they must be open) you should have power at the two small terminals on the coil. If you only have power on the switch side (- terminal), try unhooking the primary wire going to the distributor and checking the terminals again. If you have power on both terminals with the wire to the distributor unhooked, the coil is most likely ok. If the terminals both had power look for that primary wire, the condenser wire, or the straps on the points being grounded out. If the points aren't opening it could be a problem as well. What are you using to test for power? Voltmeter, 6 volt test light, or something else? |

Posted By: hunter321

Date Posted: 02 Feb 2021 at 8:30am

| I have a normal test light |

Posted By: Jim.ME

Date Posted: 02 Feb 2021 at 10:40am

| Your test light will work to make those tests. Let us know what you find. |

Posted By: hunter321

Date Posted: 02 Feb 2021 at 6:48pm

|

I don't have power from the secondary wire from the coil |

Posted By: Jim.ME

Date Posted: 03 Feb 2021 at 7:05am

|

The opening and closing

of the points collapses the field inside the coil, producing the secondary high

voltage for the spark. There are some tests that can be done with a test light at the secondary terminal but are not as commonly done. Did you have power at both primary (small)

terminals when tested as I posted? What were the results at each test

location I asked about? Here is a link to an IH/Farmall FOS (Fundamentals Of Service) manual, on the Farmall Cub website, that I think will help you understand the coil and ignition system better. Understanding how things work will make the test results more meaningful to you. The theory and components are common to both IH and AC (and about anything with a point type distributor ignition). It details several tests you can make besides the ones you have been given so far. http://farmallcub.com/rudi_cub/www.cleancomputes.com/Cub/Blue%20Ribbon%20Service%20Manuals/FOS-20%20Chapter%206-Ignition%20Circuits/FOS-20%20Chapter%206-Ignition%20Circuits.htm" rel="nofollow - http://farmallcub.com/rudi_cub/www.cleancomputes.com/Cub/Blue%20Ribbon%20Service%20Manuals/FOS-20%20Chapter%206-Ignition%20Circuits/FOS-20%20Chapter%206-Ignition%20Circuits.htm |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 8:19am

| I have power to the other 2 terminals |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 8:36am

|

hunter, you have run the basic tests.. You have 12 volts INTO the coil and 12 volts OUT of the coil. If the point is corroded and not closing, you would still have voltage at the coil terminals... Your next step is to clean the point contacts and then touch them together with a screw driver or wire and see if you get a spark... or loose the 12 volts on the coil wire to the point......... "NORMALLY" what happens at this point is the guy would replace the point and the condenser and see if that fixes the problem.. If not, then buy a new coil... It is hard to pinpoint exactly what the problem is at this point.. You have done all the testing. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 9:06am

| Should I have 6 volts because it is a 6 volt system |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 9:09am

|

YES.... my bad........ If you have 6 volts into the coil, and 6 volts out of the coil to the POINT, then that is good... and the point is OPEN... try to short out the point ( clean contact facts) and CLOSE the point to see if you loose the 6 volt on the small wire TO the point. ............. again, there is no way to say 100% exactly what is wrong.. Your close. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 9:10am

|

Now that you say it is 6 volts, that makes me question the coil... It may be VERY OLD ? Still need to check the point for clean first. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 9:15am

|

The tractor has not started in at least 14 years It just wont start |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 9:18am

|

Me and my dad think it is the coil or the distributor or the Sparkplug wires |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 10:56am

| So I should get a new coil |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 12:52pm

|

If you replace the coil, the point and the condenser, you should be in good shape... If you want to try the coil only, that is a good first step, but drag some fine sand paper or etc thru the point faces to make sure there is no CORROSION on the faces.. Setting for 14 years is almost 100% guarantee of some contamination on the faces. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 12:53pm

|

If you get a new coil, make sure you tell them it is a 6 volt SYSTEM... Dont use a 12v coil. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 12:59pm

I was going to order this

|

Posted By: Mdguy

Date Posted: 03 Feb 2021 at 1:18pm

|

I’d try Napa if there’s 1 close to you. I know they’ll at least look It up for you if it’s not in their computer and usually they have 1 on the shelf. At least the Napa stores around here are like that. On another note I think it’s great you and your dad are working on this together. May seem like a small thing to you now but this is something you’ll remember the rest of your life. Don’t get frustrated at it not working it’s usually something simple. Good advice on here so far. Check/clean or replace points and condenser and/or change coil. Once you know that’s all good if still not firing work way up to plugs and wires. My 2 cents worth |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 1:24pm

| Ok |

Posted By: Jim.ME

Date Posted: 03 Feb 2021 at 1:44pm

|

I would not order a coil yet. To me you have not proved the points are working. If the points aren't working it won't make a spark with a new coil either. With lead on your test light lead grounded and the probe on the coil primary terminal for the wire going to the distributor, crank the engine over. If the points are working, your test light will blink as the points open and close. Are the contact surfaces of the points clean, smooth, and shiny? Or are they dark (maybe kind of bluish colored), rough, and uneven surfaces? If I was going to get a 6 volt coil I would go to NAPA or other parts store and get a 6 volt coil. Your picture doesn't tell anyone exactly what the coil is to properly confirm your choice. Giving the brand and part number and the written description would. It may be 6 volt. The writing on it looks like it was intended for use on a 12 volt system using an external resistor, which was often done with 6 volt coils when vehicles were changing for 6 to 12 volts. Not trying to give you a hard time. its just that sometimes little things can make a difference. The more, and better, info you provide when working through things on a forum, where people can not see what you are looking at helps. You are the eyes for the group. You are doing good, keep at it. There is an International Harvester FOS (Fundamentals Of Service) manual on ignition systems that might help you. It explains a good bit about how the parts of the ignition system work. Their ignition systems are very much like the ACs so the tests and checks will help you. Here is a link to it. http://farmallcub.com/rudi_cub/www.cleancomputes.com/Cub/Blue%20Ribbon%20Service%20Manuals/FOS-20%20Chapter%206-Ignition%20Circuits/index.html" rel="nofollow - http://farmallcub.com/rudi_cub/www.cleancomputes.com/Cub/Blue%20Ribbon%20Service%20Manuals/FOS-20%20Chapter%206-Ignition%20Circuits/index.html |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 2:14pm

|

so I should clean the points and see if they are opening correctly https://www.herschelparts.com/aspx/prodDetail.aspx?id=17221" rel="nofollow - https://www.herschelparts.com/aspx/prodDetail.aspx?id=17221 I was trying to find a cheaper coil |

Posted By: Jim.ME

Date Posted: 03 Feb 2021 at 3:57pm

|

Yes, you should try cleaning the points and see if they are working properly as the guys have been telling you. The points must be working before you determine you need a coil. The last manual I gave you a link to explains how the points make the coil work to give a spark. Please read through it, so you understand how a distributor ignition system works. The points must be working properly or even a new coil will not work. You may find you need to replace the points, not the coil. Cheaper is not always the best way to go. You will likely get by with that coil, if you need one. For points and condenser, I recommend Standard brand's "Blue Streak" grade or NAPA Echlin ones. For other ignition parts I use Standard or Echlin. When you have a problem check the books first, gather advise, diagnose and troubleshoot next, buy parts when you know what parts are bad. People have thrown a lot of money in parts at problems, only to find a broken wire or empty gas tank is all it was. JMHO

|

Posted By: hunter321

Date Posted: 03 Feb 2021 at 4:34pm

| Ok |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 6:13pm

| I cleaned the points and they are working but the tractor still won't start |

Posted By: Jim.ME

Date Posted: 03 Feb 2021 at 6:43pm

|

Ok, remember I can not see what you did or what you are seeing. Can you explain what you mean by "the points are working"? Did you check using the flashing test light method to see that they are making and breaking as the engine is cranked over? Fill us in, you are our eyes on this. Put a plug wire in the coil tower and hook a plug to it. Ground the plug to the engine block and crank the engine over. Do you see a spark at the plug electrodes as the engine is cranking? If you remove the plug, slide the plug boot back and expose the clip that slides on the plug, you should be able to hold that clip about 1/4" from the block and the spark should be bluish white and jump that gap. If it does your coil is ok. Be careful if the insulation on the plug site is bad you could get a shock. Best to hold it with insulated handle pliers, if you have them. Let us know how this goes. |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 7:21pm

| I cleaned the points and there is a spark when the engine turns over but is not creating the compression needed to start the tractor |

Posted By: Jim.ME

Date Posted: 03 Feb 2021 at 7:47pm

|

Ok, sounds like you don't need a coil, you agree? Compression is made by the mechanical the action of the pistons and valves. Do you have, or can you borrow, a compression test gauge? It is best to actually check compression with a gauge, not guess. A gauge can tell you if there is one of more bad cylinders. After setting 14 years rings or valves could be stuck. There are is a way to get an indication of the problem possibly being rings or valves. So can you get a gauge and do you know how to do a compression test. Do you know why it was parked 14 years ago? |

Posted By: steve(ill)

Date Posted: 03 Feb 2021 at 8:18pm

|

you might put a couple ounces of AFT in each cylinder and let it set a couple days... then see if you have more compression... Rings could be stuck from setting. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 03 Feb 2021 at 9:23pm

| My grandpa said a seal went bad |

Posted By: Jim.ME

Date Posted: 04 Feb 2021 at 5:04am

|

Does your Grandpa remember which seal? steve(ill) has a step you will want to try, but I would do the first compression test without putting anything in the cylinders. After that test is done then 3 or 4 squirts of ATF or Marvel Mystery Oil in each cylinder before a retest. The ATF or other oil will add some sealing action and may raise the compression. If the compression in a cylinder doesn't change with the oil, it can be an indication of a valve stuck open. When you do the compression test, have all the spark plugs out, throttle wide open, battery fully charged and keep the charger on it. You want the engine to turn at the same speed and the same number of times as you test each cylinder. Write the results down for later review.

|

Posted By: WF owner

Date Posted: 04 Feb 2021 at 6:33am

|

As Steve said, try some ATF in the cylinders to loosen things up. A compression gauge would tell you a lot. When you turn it over with a crank, does it seem that each turn takes equal force? if you have spark, you might want to try a couple different things. You might want to try giving it a shot of starting fluid to see if it tries to start. Have you checked to make sure you are getting good gas flow to the carburetor ? Another alternative is towing it to start it. (Also check to see if it is building oil pressure when it is turning over.)

|

Posted By: hunter321

Date Posted: 04 Feb 2021 at 11:20am

|

I didn't see a spark but I forgot to use the insulated pliers and got shocked |

Posted By: hunter321

Date Posted: 04 Feb 2021 at 12:05pm

| He said the final drive seal |

Posted By: Jim.ME

Date Posted: 04 Feb 2021 at 3:03pm

|

I think we have all gotten "bit" at least once, it just part of the territory. Bet you remember pliers or something to give you more insulation next time. At some point you should do the check and look at the spark to check its quality, but for now it tells you what is there works. I think you will find it easier and get more understanding of the systems if you focus on one thing at a time. Check out the compression next. Once you get that checked out, then work on the fuel. The final seal can come later, it won't affect the engine starting/running.

|

Posted By: Stan IL&TN

Date Posted: 04 Feb 2021 at 8:45pm

|

If you don't have a compression tester available you can squirt a little gas in each cylinder then install the plugs and try to start it. If it runs for a couple of seconds then you have enough compression for it to run and then I would look at the carburetor next. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: hunter321

Date Posted: 09 Feb 2021 at 11:38am

| I got the carburator cleaned 2 weeks ago. I still have to test the compression but could the gass line be clogged |

Posted By: Jim.ME

Date Posted: 09 Feb 2021 at 12:40pm

| Yes, it is possible for a gas line to be plugged. A quick check is to take a quart jar or such to catch gas in, and remove the drain plug from the bottom of the carburetor bowl and see how much gas you catch in the jar in two minutes. You should get at least a pint. If it doesn't flow that much in a steady stream you will need to drain the tank and start checking for a blockage. It may be plugged right in the sediment bowl housing above the tank shutoff valve. You have to remove the sediment bowl housing to check and clean it correctly. I have fixed a number that were plugged in that location. Blowing back through the gas line can open it up for as while ( the air can also blow the sediment bowl gasket out), but if the tank is dirty in will plug again. |

Posted By: hunter321

Date Posted: 09 Feb 2021 at 12:51pm

| I cleaned out the gas tank but not the sediment bowl. I also I kno wI dont have much gas right now |

Posted By: Jim.ME

Date Posted: 09 Feb 2021 at 1:18pm

|

You need to have at least enough gas in it to cover the outlet in the tank. Just as it sets, do you have gas in the sediment bowl and, if you pull the drain plug out of the carb bowl does it have gas in it? If it has that much gas in it I think it would at least fire if all other things are right. When you cleaned the carb, did you have a kit to put in it or did you just take it apart, blow it out, and reassemble with the old parts? Did you check the float setting? I won't say any or all of those things will keep it from starting but they may be a factor in the problems.

|

Posted By: hunter321

Date Posted: 09 Feb 2021 at 1:24pm

| I replaced the carb gasket and used a wire brush to clean the rest of it and rasembled it with the old parts |

Posted By: hunter321

Date Posted: 10 Feb 2021 at 10:04am

|

this is what I have done so far https://docs.google.com/document/d/1UFrPqZJGU3uhSaHj19A6XjEK9KKMHNtJbAfLofFBzV8/edit?pli=1" rel="nofollow - https://docs.google.com/document/d/1UFrPqZJGU3uhSaHj19A6XjEK9KKMHNtJbAfLofFBzV8/edit?pli=1

|

Posted By: Jim.ME

Date Posted: 10 Feb 2021 at 10:25am

|

Hi Hunter, Your Google documents is not an open to see document. Any one trying to look at it will have request access to see it.

|

Posted By: hunter321

Date Posted: 10 Feb 2021 at 10:36am

| https://docs.google.com/document/d/1UFrPqZJGU3uhSaHj19A6XjEK9KKMHNtJbAfLofFBzV8/edit?usp=sharing" rel="nofollow - https://docs.google.com/document/d/1UFrPqZJGU3uhSaHj19A6XjEK9KKMHNtJbAfLofFBzV8/edit?usp=sharing |

Posted By: WF owner

Date Posted: 10 Feb 2021 at 11:58am

|

Someday, you will look back at that and be happy that you documented everything. Good luck !!!

|

Posted By: Mdguy

Date Posted: 10 Feb 2021 at 4:07pm

| Just am wondering from reading what you have done to your tractor you said that you replaced the spark plugs. Is your tractor in time still. As particular as you were about rewriting the lights I can’t imagine you pulled off all the plug wires and then tried to guess where they went. But I have seen this happen before and the plugs are firing out of order. |

Posted By: hunter321

Date Posted: 11 Feb 2021 at 7:30am

| I looked up the spark plug wire order |

Posted By: Jim.ME

Date Posted: 11 Feb 2021 at 9:58am

|

#1 may not match where a book shows it in a picture. Are you sure the spark at #1 plug matches when #1 cylinder is on compression. I have pulled #1 plug and ground it near its hole (You may get a shock if you try to hold the plug). Hold a finger tightly over the plug hole and have someone crank the tractor over. You should see the spark at the plug the same time it pushes your finger off the hole, if the timing is close. You need the wires in the right firing order, going around the cap in the same direction as the rotor travels. Have you checked compression yet?

|

Posted By: hunter321

Date Posted: 11 Feb 2021 at 10:35am

|

I have not testeded it yet it has been to cold to work on it |

Posted By: hunter321

Date Posted: 11 Feb 2021 at 10:41am

| the wires where still attached to the distributor cap when I started |

Posted By: hunter321

Date Posted: 23 Feb 2021 at 7:36pm

| I did what you said I cleaned the gas line and put gas in the places where you said to it turned over a little faster but still won't start |

Posted By: Jim.ME

Date Posted: 24 Feb 2021 at 7:20am

|

I suggest you do the compression test, and record the results, so you know where compression stands. There might be a stuck valve, or other issue, from setting. Then while the plugs are out, line them up, wires connected, near the cylinders they go in and crank it over to see if the spark at the plugs match the puff of compression out of each hole. Be methodical, completely check one thing and verify it is right or wrong, before moving to something else.

|

Posted By: WF owner

Date Posted: 24 Feb 2021 at 7:52am

|

Let's try the basic things first. When you turn it over with a hand crank, does it turn very easy or is there resistance every half turn. If it turns quite hard, you should have enough compression for it to start. You say you have spark and fuel to the carburetor. That, to me, means there could mean: A. timing is way off. B. fuel is not going through the carburetor. Has anyone removed all the spark plug wires or turned the distributer since it last ran? The first thing I would check is to make sure the distributer turns consistently when turning it over. A few years ago (ok a lot of years ago), I had a roll pin shear off that held the gear on the bottom of the distributer. There was enough friction to make the distributer turn, but it hesitated occasionally. It took me hours to find it. If it turns good and there is any chance that the timing may have been changed, make sure it is timed right (or close to it). Rather than go through it step-by-step, here is a link that explains it better than I could. http://dueyschutter.freeservers.com/photo4.html" rel="nofollow - Allis Chalmers Page 2 (freeservers.com) Once you make sure the timing is right, try it again. If it still doesn't start, remove the hose to the air filter and leave it off until you get it running. Running it a few minutes without an air cleaner won't hurt it. If it doesn't start, try giving it a shot of starting fluid. If it starts and stops, you will know your problem is in the carburetor. Good luck !

|

Posted By: hunter321

Date Posted: 24 Feb 2021 at 10:23am

| I have not removed all of the spark plug wire since I got it because I didnt want to forget where they went. I dont think anyone has turned the distributer since it ran last. I do know that when the pionts open they make spark. my dad thinks the rings might be stuck |

Posted By: hunter321

Date Posted: 24 Feb 2021 at 11:47am

| I also don't have a compression tester |

Posted By: WF owner

Date Posted: 24 Feb 2021 at 8:22pm

|

Have you tried turning it over with a hand crank? Does it turn over the same with the spark plugs in or out ? I would be very surprised if stuck rings is your problem. Stuck valves is a possibility, but I doubt it would be the rings.

|

Posted By: Jim.ME

Date Posted: 26 Feb 2021 at 6:58am

|

Hunter, I understand you don't have a compression tester, so try this. Make sure your tractor is in neutral. If you remove all 4 sparkplugs, then one at a time hold your finger tight over a spark plug hole and crank the engine over using the pull rod, with the ignition switch off. Each cylinder should blow your finger away. Squirting 2 or 3 pumps of oil, from a pump oil can, in each cylinder then trying the test again. The oil will help seal the rings and compression usually will increase a bit. If one doesn't your push finger away, that cylinder isn't making compression and that might be because of a stuck valve. If you have a cylinder like that, you have to remove the valve cover to check to see if the valves, not just the rocker arms, are all moving. A possibility on getting a compression tester to use is to ask at parts stores. Some, like O'Reilly and AutoZone have rental/loaner tool programs. The parts store you use might also if you ask. Then you could do a real compression test at little or no cost to use the tester. Is your engine turning over at a good speed when you crank it with the starter? Haow does it seem to be turning over compared to another tractor? |

Posted By: hunter321

Date Posted: 26 Feb 2021 at 8:30am

| It turns over slow compared to our oliver tractor |

Posted By: WF owner

Date Posted: 26 Feb 2021 at 4:26pm

| Where do you live? If you are close to someone on this forum, they may be willing to give you a hand. |

Posted By: hunter321

Date Posted: 07 Mar 2021 at 2:59pm

| We put atf in the spark plug hole and it turned over a lot faster but when we put the spark plugs back in it still turned over very slow |

Posted By: Jim.ME

Date Posted: 07 Mar 2021 at 3:16pm

| You need a multimeter with a DC voltmeter scale that will read 20 volts and down. Check to see what the voltage is when measured across the battery terminals when the switch is off. Then measure it again while the engine is cranking. Test at the starter solenoid to ground as well, both setting and cranking. The difference in the readings will give an idea of the battery, battery cable, and starter conditions. Make the checks and post the results. Turning a lot slower when the plugs are in, could be a sign of a bad cable or connection, weak battery, weak starter or some level of all those things. |

Posted By: hunter321

Date Posted: 07 Mar 2021 at 3:50pm

| The battery is brand new and the battery cables are brand new to |

Posted By: Jim.ME

Date Posted: 07 Mar 2021 at 4:13pm

| They may be new, but sometimes you do all the tests to have a base to work from. In this case the battery and cable checks should give good results. Having those good results on record will make the results of the voltage check when the starter is cranking the engine over (with the plugs in) more meaningful of the starter condition. Also a check is most generally worthwhile as even new parts have been found to be bad at times. You can also check the voltage at the starter while cranking with the plugs out. If the starter cranking makes the voltage drop way down from when it wasn't cranking, it is a possible sign of a bad starter. Good mechanics/technicians use diagnostic tests to try to figure out what is wrong, instead of just replacing parts willy-nilly. |

Posted By: steve(ill)

Date Posted: 07 Mar 2021 at 4:23pm

|

hunter, i think you said you have a 6 volt battery. 6 volt systems naturally turn slower than 12 volt systems.. Also the 6 volt system normally has BIGGER diameter battery cables than the 12 volt... Half the voltage, twice the AMPS to get the same power out of the motor. You have to be real particular with the cables, clamps, ground, etc when using 6 volts.. As long as it is turning over fast enough to start, that is fine... With 6 volts it will not spin over like your dads truck. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 12 Mar 2021 at 9:58am

|

Me and my dad are going to try to pull start the tractor to see if the starter is the reason it is dragging when it try's to start |

Posted By: hunter321

Date Posted: 12 Mar 2021 at 10:29am

| if it does start when we pull start it does that mean the starter needs to be rebuilt? |

Posted By: steve(ill)

Date Posted: 12 Mar 2021 at 12:17pm

|

could be a weak starter, or a bad terminal at some point... if not that, you can rebuild the starter, or use a 12 volt battery on the tractor. ------------- Like them all, but love the "B"s. |

Posted By: hunter321

Date Posted: 30 Mar 2021 at 11:15am

| I know that all the contact points are clean and all the connections are tight once i cleaned everything I tried starting starting it. it turned over faster but still didnt start. me and my dad are waiting to try and pull the tractor until the roads dry up |

Posted By: hunter321

Date Posted: 06 Apr 2021 at 8:24am

| we pulled the tractor the firs time and nothing happedend so we stopped for the night we cleaned a few things and messsed with stuff and tried it again the next day it sortof started but would die when the truck stopped moveing. why is this. there is fuel |

Posted By: steve(ill)

Date Posted: 06 Apr 2021 at 9:25am

|

you need FUEL, SPARK and at the RIGHT TIME..... If you know you have FUEL, then you need to check for GOOD SPARK... If you have that, then your timing is off..... Only 3 things. ------------- Like them all, but love the "B"s. |

Steve in NJ wrote:

Steve in NJ wrote: