2900 engine questions

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=168593

Printed Date: 07 Nov 2025 at 2:08pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 2900 engine questions

Posted By: WF owner

Subject: 2900 engine questions

Date Posted: 25 Feb 2020 at 9:14am

|

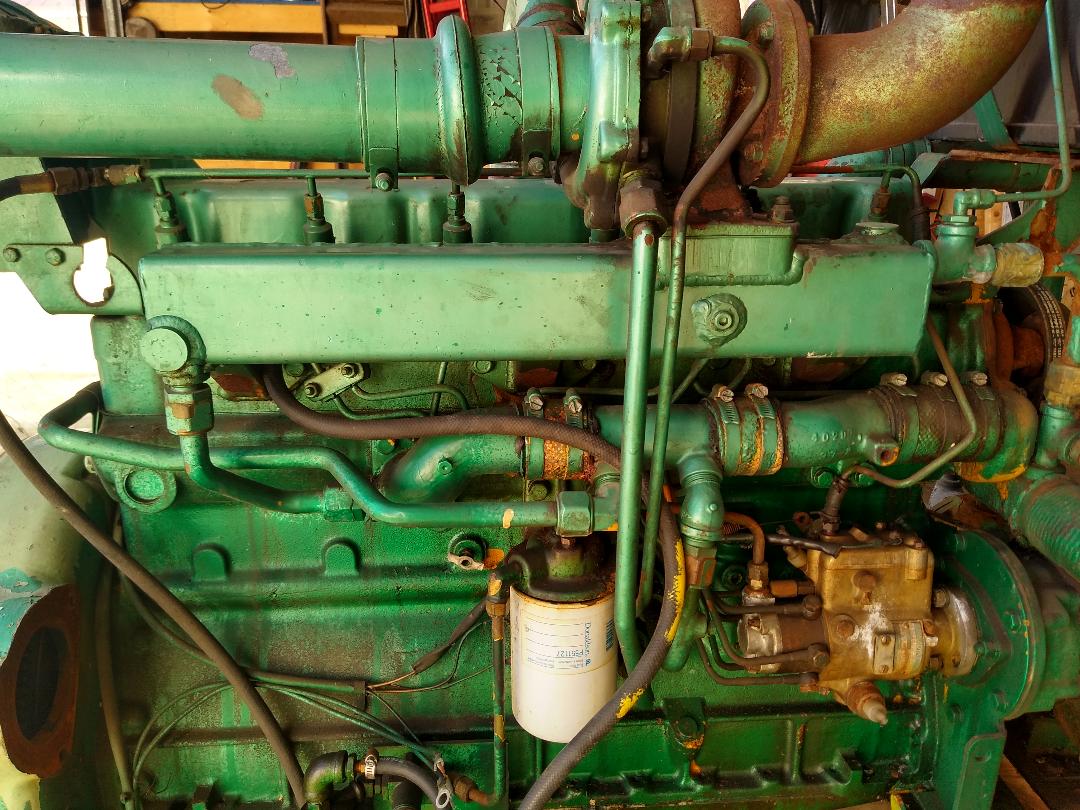

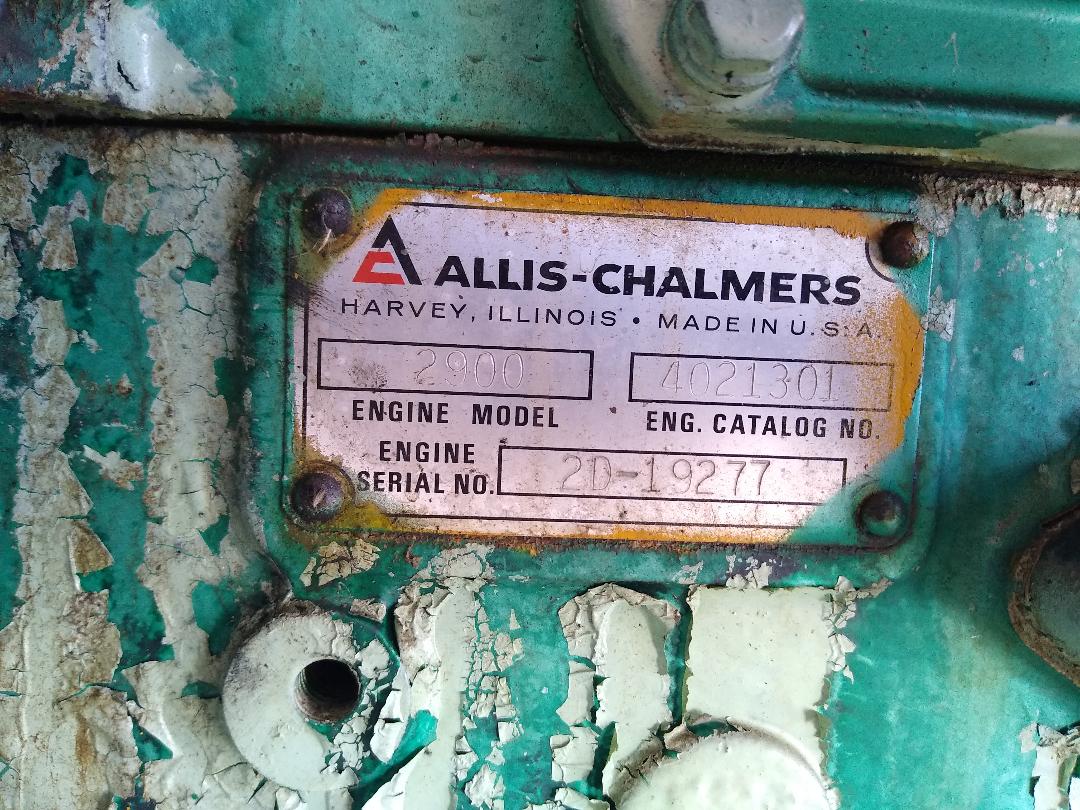

I just bought this 2900 engine. The guy told me it was on a generator inside a (college) building. He said the meter showed less than 100 hours. I am planning on putting it in a 180 that was my Dad's. I have a few questions: I have never seen an exhaust manifold like the one on this engine. It appears (to me) that it may have been to, either, preheat the coolant or to cool the exhaust. My assumption is that it would have to be changed to use in a tractor? It appears that the engine has a lift pump (second picture). Would it be beneficial to leave the lift pump on it when installing it in the tractor? Will the injection pump work in a tractor or will it need to be changed. In the last picture, it appears that this engine has provisions for a hydraulic pump. Do you think I will still have to change the front cover? I expect to have to change the flywheel (and use the tractor housing) and oil pan. What else will I need to change to adapt this engine to a tractor?     |

Replies:

Posted By: DougG

Date Posted: 25 Feb 2020 at 9:31am

| It will work but gonna take some original 180 Allis parts to get it in there, very interesting as it has a water cooled exhaust manifold as to your questions-1 the exhaust manifold appears to be water cooled and will need an original 180 manifold-2, shouldn't need the lift pump 3 like Ed said the injector pump is prolly stopped at 1850 rpm,s , 4 looks like a hydraulic pump will bolt on the place it should go and the front plate looks as it will bolt in the frame rails too, , - - I AM VERY INTERESTED IN THE BELLHOUSING AND ENGINE FLYWHEEL BOLTED TO THE REAR OF THE ENGINE IF IT BECOMES FOR SALE ! |

Posted By: injpumpEd

Date Posted: 25 Feb 2020 at 9:49am

|

Use the tractor injection pump, that engine has a speed droop governor designed to operate at 1800 full load, 1850 no load, for generator application. Lots of different parts inside that pump compared to the tractor pump. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: DrAllis

Date Posted: 25 Feb 2020 at 10:05am

| Appears to be a basic 190XT engine from 1964 thru 1969 ish ?? Has the Thompson turbo on it. |

Posted By: WF owner

Date Posted: 25 Feb 2020 at 10:13am

You know way more about it than I do Doc ! Have you ever seen an exhaust manifold like that? Do you think that front cover might work for the hydraulic pump? I have zero experience doing something like this. What else am I going to need to do? Does the info on the engine plate tell you anything?

|

Posted By: DrAllis

Date Posted: 25 Feb 2020 at 12:16pm

| I've seen other water cooled exhaust manifolds, just not on an A-C engine. The engine tag has the newest AC logo, so that happened in about late 1966 or later. The serial number is 19,000+ so that to me might indicate 1968 or 69 ?? Front cover looks OK, but you'll have to see if the drive from your old engine lines up wit what's there. I'll bet the turbo has a real tight exhaust housing on it for running 1800 RPM's instead of 2400 RPM's. No lift pump wanted or needed. |

Posted By: concretepumper

Date Posted: 25 Feb 2020 at 5:15pm

| I have retrofitted a few stationary 3500 gen sets into tractors, I haven't done a 2900, but the best way to do it correctly and have it look as original as possible is to pull the tractor motor, strip the gen set to bear long block, and switch everything over from the tractor motor, front plate, front cover, rear plate, ECT... This way you can reseal the motor and with the gen motor stripped down you can then paint it back to orange. I would check the oil pan to make sure it is baffled, all the 3500 motors I have done have not had baffles due to being stationary units. |

Posted By: lowell66dart

Date Posted: 25 Feb 2020 at 7:33pm

|

If you decide to go ahead with this project I have a AC parts catalog for the 2800 & 2900 Mark 1 & 2 engines that could help some. PM me if you need it. ------------- AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear. |

Posted By: MACK

Date Posted: 25 Feb 2020 at 9:36pm

| Exhaust manifold looks like a marine manifold. MACk |

Posted By: WF owner

Date Posted: 26 Feb 2020 at 5:34am

| Thank you for all the replies ! I'm sure I will be looking for more input as I get into this project. First thing on my list is to get it running. I really appreciate all the help !!!!! |

Posted By: tbran

Date Posted: 27 Feb 2020 at 11:10am

|

the water cooled exhaust was to keep the heat down in an enclosed area - transmitting the heat to be dispersed where ever the radiator was located - which would be away from the generator unit. I would be tempted to run it as is for a while monitoring it closely - open the water openings and leave them open - do not run through radiator on a 180 or it will overheat. Looks like you have the correct front cover,,, will need the rear plate off the 180. If you want to keep the budget light - I again would say the fuel pump if not gummed up would work - not perfect - but backing out the high idle screw a tad as the 180 had a rated load of 2000 rpms. Have to cut a hole in the hood. Check the oil pan - if it is the same depth use it, The 180-185 cooling system has a lower fan location. The shroud will have to be relocated upward about 4". These power units also had a lower hp setting than tractors/combines - but the 2900 will be above the 180 slightly. As Ed said the rpm 's will probably be 1850 ? , Also have to run a wire to the key switch for run/kill. Finally in thoughts the electrical systems are usually 24V - check that out as well - if so might have to replace all 24v items with 12v stuff. Should have a sweet running , unique rig. (do not remove the cooler if you change to 180 style cooling system w/o learning about the lube plug in the back of the block when you remove that line that wraps around the back) ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: WF owner

Date Posted: 27 Feb 2020 at 4:49pm

I appreciate all the info, but you completely lost on the statement above.

|

Posted By: DrAllis

Date Posted: 27 Feb 2020 at 6:08pm

| The engine oil cooler on the right side, above the injection pump. DO NOT remove it, or you will have to dig into the rear of the engine block deeper to remove an oil passage block. In short, you remove the engine oil cooler, you will ruin the engine in a few minutes of run time due to lack of oil pressure to the main and rod bearings. |

Posted By: WF owner

Date Posted: 27 Feb 2020 at 7:12pm

I will probably be asking you guys more questions when it warms up enough to work on it !

|

Posted By: Kevin210

Date Posted: 02 Mar 2020 at 5:07pm

|

Just my 2 cents worth.From the looks of that engine before you go to all the time and trouble to make it work which it should with some work I would at the very least take the head off and take a peek. Now reason being,I drove to Nebraska from Indiana to buy a running engine for my 210 that was an irrigation motor,couldn't read hour meter so had/have no idea how many hours are on it.Got it mounted and running and found 2 injectors squirting fuel out of injector ports and had a lot of blow by and also a fuel leak on throttle shaft.So I decided to put new rings and rod bearings in it ok,when the head came off I found a piston with a pencil sized hole in it and a burnt spot and another cylinder sleeve was bad also. It would be a whole lot easier to peek now verses later,just sayin. Kevin. |

Posted By: WF owner

Date Posted: 02 Mar 2020 at 6:37pm

|

It has finally warmed up a little. My first order of business is to put the starter on it and get it to turn over, then maybe hook up some fuel and try to start it.

|

Posted By: ACjack

Date Posted: 03 Mar 2020 at 9:04am

|

A water cooled exhaust manifold on a D2900 is a first for me. In all the time I worked at the Harvey engine plant I had never seen one. by the way you're missing the clamp that goes on the oil feed and oil return line on the turbo. It's mounted about the midway point of the two lines.

|

Posted By: WF owner

Date Posted: 03 Mar 2020 at 12:33pm

| I accomplished step #1 today. I put a starter on it and got it to turn over (with booster cables to another tractor). Next step is to get it running. |

Posted By: tbran

Date Posted: 03 Mar 2020 at 10:49pm

|

the more I look at this - this looks like a full blown marine /boat engine. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: MACK

Date Posted: 04 Mar 2020 at 6:50am

| I agree with tbran, a marine engine. MACK |

Posted By: lowell66dart

Date Posted: 04 Mar 2020 at 6:51am

|

Would that be a plus? ------------- AC 6080 (8030,7060,200,175,D-17HC, 6040,160,6140 all gone) Farmall 1066 & 656 Hi-Clear (for sale), White 2-62 High Clearance, JD 4255 Hi Clear. |

Posted By: ACjack

Date Posted: 04 Mar 2020 at 9:05am

|

Marine/boat engine or Generator set engine? Based on my experience working at the engine plant in the 70's my money is on it being from a generator set. I only had the opportunity to inspect and ship very few marine engines and they were for Gray Marine and painted gray. There are electrics mounted down by the oil pan and I don't think that is a permissible location to mount electrical. The oil pan appears to be very shallow which would be acceptable on a stationary engine such as a gen set. Engines used in non stationary applications had deeper pans that also included baffling for which the engine was going to be used. Another tipoff is what RPM is on the injection pump plate. Only engines for use in gen sets were built with pumps set for 1800rpms. The greenish paint color is very similar to the color that Onan (generator MFG) uses.

|

Posted By: WF owner

Date Posted: 04 Mar 2020 at 9:11am

|

All I know about it is what the seller told me. He claimed the engine was mounted on an indoor generator (from the color, I assume Onan) at a college. He claims the generator went bad and they replaced the whole unit. With Doc's estimate that it is a late 60's engine, I 'm sure age was part of the reason for replacing. I assumed that it had a remote, outside, radiator with an electric fan. I've seen commercial generators hooked up like that in several commercial applications. After Doc told me that it was a water cooled exhaust manifold, I assumed it was to cool the exhaust to hold down temperatures inside the building. It seems like it would get unbearably hot inside a building without something to moderate the exhaust temperature.

The seller said he was hired by a contractor to remove it. He said he looked into having the generator repaired and it would cost more than it was worth, so he scrapped the generator part and salvaged the engine. That's all I know about it. I can't imagine that he had any reason to lie about it. I have never heard of Allis Chalmers engines being used in a marine application, but that doesn't mean they weren't. |

Posted By: DrAllis

Date Posted: 04 Mar 2020 at 9:42am

| I'll bet the tag on the injection pump says "1800" on it somewhere. |

Posted By: SteveM C/IL

Date Posted: 04 Mar 2020 at 9:47am

| Sure looks like a heat exchanger where you would otherwise use a radiator. Common in boats and "inside" applications. |

Posted By: WF owner

Date Posted: 04 Mar 2020 at 10:06am

I will look when I get a minute. What I did notice is it has an electric fuel shutoff and there is a spring holding the throttle in one position. I will post some pictures when I get time to fool with it.

|

Posted By: injpumpEd

Date Posted: 04 Mar 2020 at 10:43am

|

The dead giveaway to me for it being a genset pump, is the knob to externally adjust the droop, right in front of the fuel inlet. USA runs 60HZ which takes 1800 rpm, Canada and Europe I think are on 50HZ so they would run 1500 rpm. ------------- 210 "too hot to farm" puller, part of the "insane pumpkin posse". Owner of Guenther Heritage Diesel, specializing in fuel injection systems on heritage era tractors. stock rebuilds to all out pullers! |

Posted By: ACjack

Date Posted: 04 Mar 2020 at 3:23pm

The gen sets that were sent north of the border (To John G Steel) were 60HZ 1800 rpm. Other gen sets that where shipped out of the country were both 50HZ and 60HZ. It all depended on what the customer ordered.

|

Posted By: tbran

Date Posted: 04 Mar 2020 at 3:43pm

|

YOU ARE CORRECT on gen set -droop screw is really unique as well - I had to blow it up to see it - I have some pumps off gen sets w/o the external adj droop - and yes now that you mention it , it was probably an out side radiator - no need to doubt what was told you as to the origin . Doesn't really matter except as to the uniqueness of the water cooled manifold and the lack of fan or radiator. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: theropod

Date Posted: 04 Mar 2020 at 5:36pm

|

Cogeneration could have been used wherein the exhaust heated water/coolant was used to keep something/anything warm. That engine could heat a lot of water when it was pushing electrons. ------------- Put the bunny back in the box! 1938 B, 1977 Yanmar YM2200 No private messages: use email: theropod AT yahoo DOT com |

Posted By: levipatch

Date Posted: 04 Mar 2020 at 5:56pm

|

Hey WF just a reminder , Before you start it , get a fix on where the throttle position is , because when it starts ,its going to governed speed NOW! whether you want it to or not. ------------- Billy..Big cam 300, bcam 400,,941 CAT.,,Deere excavator..900 row crop.. 66 D 17 diesel IV... 985 Pratt and Whitney..4360 Pratt and Whitney... gitten tired ! |

Posted By: WF owner

Date Posted: 04 Mar 2020 at 8:31pm

Good point ! Thank you !!!!!

|

DrAllis wrote:

DrAllis wrote: