Allis 301

Printed From: Unofficial Allis

Category: Other Topics

Forum Name: Pulling Forum

Forum Description: Forum dedicated to Tractor and Garden Pulling

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=162130

Printed Date: 31 Jan 2026 at 11:32pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Allis 301

Posted By: Fullpull

Subject: Allis 301

Date Posted: 22 Jun 2019 at 10:37am

| Switched to the correct topic, Dr Allis did you have to use a gear reduction starter as it has a fairly high compression ratio and where would be a good place to get the right cam? |

Replies:

Posted By: Fullpull

Date Posted: 22 Jun 2019 at 1:10pm

| I had this posted in the farm equipment forum which was incorrect |

Posted By: bsallis180

Date Posted: 23 Jun 2019 at 2:24pm

|

I have been hunting for one also. With no luck but... a late seres 6080 starter works and I have not done it yet but a magnum starter off a 8.3 cummins if you rotate it counter clockwise one set of bolts it should work. But we have been running Lucas starters with no problems just get it gone over every two years. As far as a cam. Going to need to give Doc some more info on the motor and class to know what you need. |

Posted By: Fullpull

Date Posted: 24 Jun 2019 at 6:00pm

| This engine project is a Allis G 262. |

Posted By: DrAllis

Date Posted: 25 Jun 2019 at 7:13am

| A healthy factory stock OEM D-19 gas starter worked just fine for me, so I don't know why it wouldn't for you. You need a big battery, probably 880 CCA's and good sized battery cables that are clean. As far as the camshaft goes, you aren't going to "buy" one ready to go for an AC G-262 engine. You'll have to have yours reground to a different spec. That "grind spec" is determined by what RPM's you intend to run and to a degree the size of the carburetor and how much air the carb/manifold/cylinder head will flow. It's almost July 1st and the pulling season is usually over by Labor Day. Sounds to me like this will be a Winter project. |

Posted By: Fullpull

Date Posted: 25 Jun 2019 at 8:09pm

| Whats the best way to figure out the carb. /manifold cyl. head flow and yes this will be a winter project. |

Posted By: DrAllis

Date Posted: 25 Jun 2019 at 10:33pm

| The best way is to know your competition and the rules you will be expected to compete under. What RPM's will you be allowed?? What weight classes?? Does it have to remain stock OEM or can it be modified and to what degree?? It seems to me that all new pullers have grand ideas of wanting to be the champion and really have no idea how to get there and until you know what you are up against, you will surely be disappointed with the results. A G-262 with very high compression, a "175" cam grind and a 190XT Bendix carb with a larger venturi will make more than 100 HP at 24-2500 RPM. So, is that ENOUGH ?? Well, if you are running against a 560 Farmall with a 301 engine that has been made into 450 cubes and a huge aircraft updraft carb running 4500 RPM's, you will get your hind end kicked all over the place. |

Posted By: Fullpull

Date Posted: 25 Jun 2019 at 10:49pm

| I have been tractor pulling 12+ years so I have a little bit of an idea how it works. |

Posted By: DrAllis

Date Posted: 26 Jun 2019 at 6:03am

| OK. So what are your rules and what is your competition ?? |

Posted By: Fullpull

Date Posted: 26 Jun 2019 at 11:05pm

| All the stuff you mentioned is fine where I pull,except we can go to 3000 rpm this would be in the 4500lb class |

Posted By: Fullpull

Date Posted: 26 Jun 2019 at 11:12pm

| And yes 100+ hp should be alright. |

Posted By: Fullpull

Date Posted: 03 Jul 2019 at 7:38pm

| How much gap from top of piston to head on a G262 before there will be damage, would head studs be a good idea ? |

Posted By: DrAllis

Date Posted: 03 Jul 2019 at 8:18pm

| A distance of .350" including the head gasket would figure out to be 13.42 to 1 compression ratio and that is if the valves were flush with the head. Head studs would be fine but we never needed them, so do what you want. |

Posted By: Fullpull

Date Posted: 03 Jul 2019 at 9:31pm

| Thanks Dr Allis, would you have any recommendations where to get the cam work done? |

Posted By: DrAllis

Date Posted: 03 Jul 2019 at 11:04pm

| We used the AC 175 gas camshaft grind, which increased valve lift on both valves. Are there better cam grinds out there?? Probably. You will be limited to a degree by the high compression-ness of this engine with thin flat topped pistons, so cutting any valve reliefs into them would not be advised. Again, the RPM range you intend to operate it in has a lot to do with what cam grind works the best. Our engine always ran 3000 RPM or more and occasionally saw 4500 RPM. But, it was also capable of running pretty well at 2400 to 2500 RPM if the rules of the day dictated that. The size of the carb throat and intake manifolds ability to flow air/fuel mixture also plays into the cam lift/grind/timing. We used a 190 XT Bendix carb and later on went to the Deere 7700 combine carb. If you intend on using the Power Director clutch like an IH "TA", this would open the doors to possibly a different grind versus "let her lug to the end". Use of the Power Director clutch can be enhanced by changing internal gears under the fuel tank to make the speed change 20% instead of the D-19's terrible 35% change. Berry Cam from Lester Prairie, Minnesota is who I used 20+ yrs ago, but in the last yr I know of at least one cam grind they managed to screw up for a puller on this website. You have to decide how you intend to operate this engine and what rules (RPM) you have to contend with. Also, don't forget I had to use the thicker diesel head gasket to help get the compression distance that was needed. I'm thinking that gasket was .090" thick ?? I gotta get to bed. Tractor Pull tomorrow at 11 am. |

Posted By: Fullpull

Date Posted: 04 Jul 2019 at 9:09pm

| How did your A-C do at the tractor pull Dr Allis,I am thinking you must have a A-C tractor.What kind of tractor or tractors you have for pulling ? |

Posted By: DougG

Date Posted: 05 Jul 2019 at 10:08am

| Dr has some good stuff and is involved with some nice 180,s and 190,s , Id luv to hear some stories on the twin spinners ! |

Posted By: Fullpull

Date Posted: 05 Jul 2019 at 8:01pm

| Sounds like he runs nice tractors. |

Posted By: Fullpull

Date Posted: 07 Jul 2019 at 3:48pm

| Some one offered me a used soild copper head gasket from a G 262,would that be something I should use or should I get a new one ? |

Posted By: bsallis180

Date Posted: 07 Jul 2019 at 6:10pm

| I don’t see the need for the use of a copper head gasket and the use of fire rings less this build is going to be a turbo motor |

Posted By: Fullpull

Date Posted: 07 Jul 2019 at 6:41pm

| This will not be a turbo motor, with the compression being 13-14 to 1 a regular head gasket will be sufficient ? |

Posted By: tbran

Date Posted: 07 Jul 2019 at 11:56pm

|

My 2 cents, with that compression one is about what the diesel was - and you can search and find volumes here on the issues with D262 head/gasket/head bolt/sleeve stand out -need for studs and on and on. ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: Fullpull

Date Posted: 08 Jul 2019 at 7:21pm

| Ok,will do some searching. Thanks |

Posted By: bsallis180

Date Posted: 09 Jul 2019 at 5:29am

| I wouldn’t underestimate a good flat surface and the clamping force of a 9/16 bots on a naturally aspirated motor. |

Posted By: DrAllis

Date Posted: 09 Jul 2019 at 8:17am

| Every two revolutions of a diesel engine, there is a full compression squeeze of the air because it is an open hole thru the intake manifold. Makes no difference on the RPM or load. A gas engine is only at full compression pressure when the throttle plate in the carb is 100% open, so when not under any load, the compression pressure is very low. I told you we never used anything special and never had ANY trouble. Just a diesel head gasket (painted with copper coat)and OEM head bolts and retorqued after running down the track a couple of times when stone old. You go ahead and do whatever you want. |

Posted By: Fullpull

Date Posted: 14 Jul 2019 at 8:31pm

| I know it is along time when you had your G262 Dr Allis,but do you remember what kind of spark plugs you where using? |

Posted By: DrAllis

Date Posted: 14 Jul 2019 at 8:48pm

| AC Delco 42XL or 42XLS or 43XL or 43XLS. |

Posted By: Fullpull

Date Posted: 15 Oct 2019 at 10:31pm

| Dr Allis,we have started on the G262 project we installed 235 chevy pistons hoping we could use the used copper head but after some measuring we have .255" from top of piston to top of head gasket. What would the compression ratio be with that ,I am thinking I will need a thicker gasket . |

Posted By: DrAllis

Date Posted: 16 Oct 2019 at 2:17pm

| My math from a previous post said what the compression would be at .350" including the head gasket. Your current dimension would be a lot higher than 13.42 and that was with zero valve protrusion. |

Posted By: Fullpull

Date Posted: 16 Oct 2019 at 7:09pm

| Ok thanks Dr Allis,I will order a gasket to get to .350 |

Posted By: DrAllis

Date Posted: 17 Oct 2019 at 3:24pm

| The thicker you make the head gasket, the harder it will be to hold. Same as a 1/4" one-wire hydraulic hose versus a 1/2" one-wire hyd hose. The smaller hose will tolerate a lot more pressure before it fails. Cut your piston tops down. |

Posted By: Fullpull

Date Posted: 17 Oct 2019 at 6:41pm

| The gasket will be .155" does that seem workable ? |

Posted By: Fullpull

Date Posted: 25 Oct 2019 at 9:53pm

| Suggestions on where to get a Allis 175 gas cam grind done on a G262 ? |

Posted By: DrAllis

Date Posted: 26 Oct 2019 at 4:43pm

| 30 or more years ago, I sent a 175 cam to Berry Cam Lester Prairie, Minnesota for them to copy. I had them do probably a dozen regrinds for me over the years. I understand they are under different ownership now, and have heard maybe they aren't as dependable as they used to be. |

Posted By: Fullpull

Date Posted: 26 Oct 2019 at 6:36pm

| Thanks Dr Allis, I will see if I can find a shop with better review. |

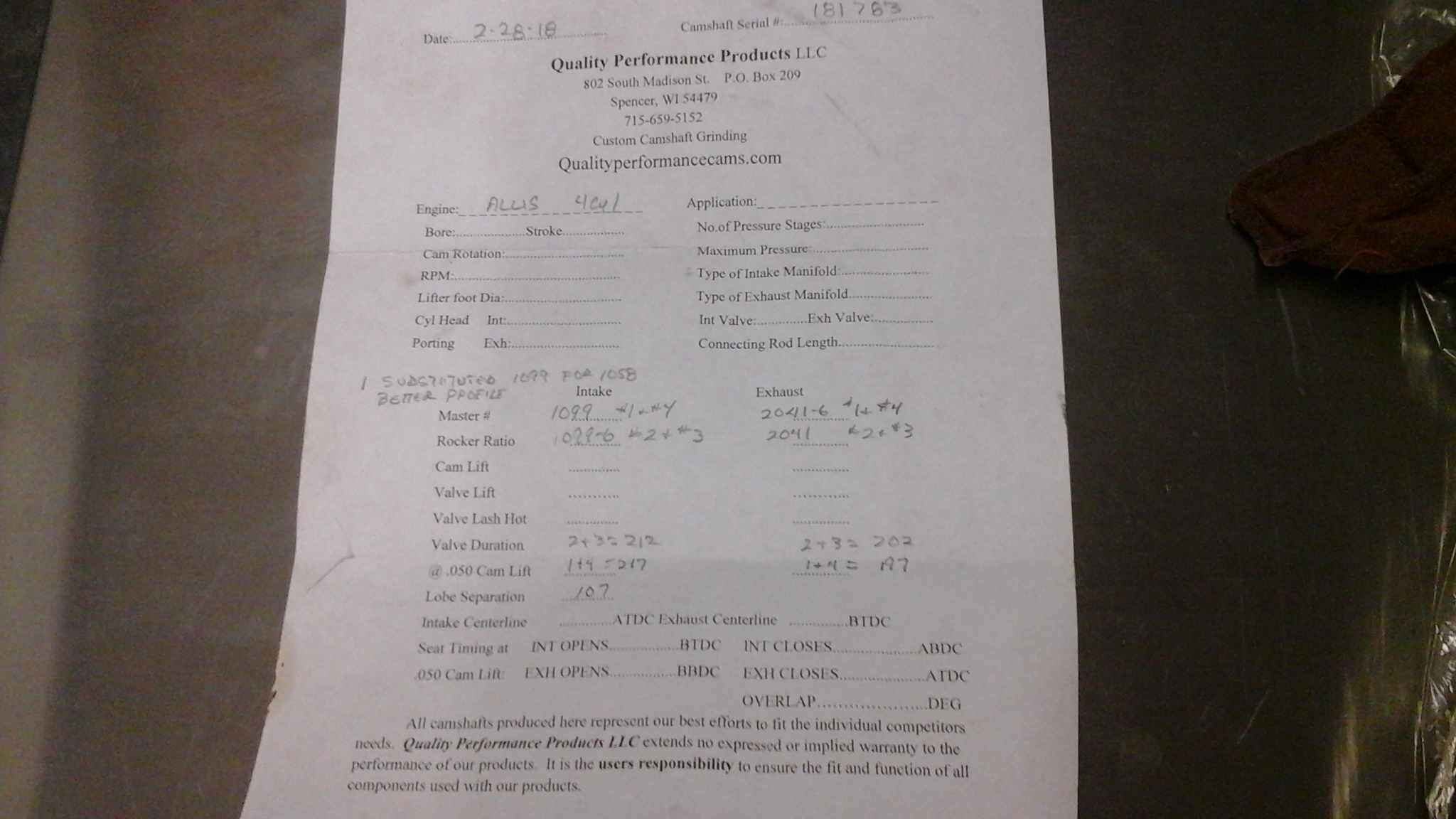

Posted By: Robacpuller

Date Posted: 27 Oct 2019 at 7:12pm

|

Quality performance products in Spencer Wi. ph. Number 715 659 5152. They did a 4 master grind on my D17 cam. Wi 50 does a lot with them. Give me a P.M. or ur cell number. I will give u a copy of my cam card. |

Posted By: Fullpull

Date Posted: 27 Oct 2019 at 8:50pm

| Thanks Robacpuller,do they have a good return on finished product time line? Do they do head work on AC G262 ? |

Posted By: Robacpuller

Date Posted: 27 Oct 2019 at 9:00pm

|

Call me at 608 228 4843. I can fill u in. |

Posted By: Robacpuller

Date Posted: 28 Oct 2019 at 8:44pm

I can't get my text to go through. I am posting it here.

|

Posted By: Fullpull

Date Posted: 10 Nov 2019 at 10:44am

| If I have a allis G262 stock bore flat top pistons, 0.195" from top of piston to top of head,0.175" head gasket, 3.75"bore head gasket what would the compression ratio be? |

Posted By: DrAllis

Date Posted: 10 Nov 2019 at 5:16pm

| 11.67 to 1 with no valve protrusion. |

Posted By: Fullpull

Date Posted: 10 Nov 2019 at 5:49pm

| Thanks DrAllis ,I am wondering with that setup how is it possible to start the engine with a snowmobile battery that has 320 CCA ? |

Posted By: DrAllis

Date Posted: 10 Nov 2019 at 7:06pm

| You won't. If that is all you can have for weight, you'll need a jump pack to get it started and disconnect it afterwards. You'll get tired of that after a couple of seasons and get a real battery in it. |

Posted By: Fullpull

Date Posted: 10 Nov 2019 at 7:48pm

| We had 700 CCA battery and a 320 CCA we would start it then remove the 700 CCA battery used the 320 battery for our ignition, I stalled it on a pull and restarted with just the 320 battery and that was with the setup with 11.67 to 1. |

Posted By: brad durst

Date Posted: 10 Nov 2019 at 7:54pm

| i have a good running gas 190 engine for sale. its complete 800$ the fan to the pressher plate |

Posted By: Fullpull

Date Posted: 10 Nov 2019 at 8:06pm

| Sorry not interested in the 190 engine. |

Posted By: Fullpull

Date Posted: 13 Nov 2019 at 7:34pm

| Was thinking someone would have an answer how it was possible to start the motor with 320 CCA battery with 11.67 to 1 compression,I am refreshing the motor now so if I did something incorrect before I would like to fix it. |

Posted By: steve fischer

Date Posted: 20 Nov 2019 at 10:38pm

| berry cam has two different grinds one is allis number 175 (very hot )the one you want is the model 175 gas grind |

Posted By: Fullpull

Date Posted: 21 Nov 2019 at 11:35pm

| Thanks for cam info. Mr Fischer |

Posted By: DrAllis

Date Posted: 27 Nov 2019 at 7:18am

| Why haven't you ran a cranking compression test on this engine??? You should have 240 psi or more, with the throttle wide open, all spark plugs removed and a battery charger on the battery to keep cranking speed fast and consistent. |

Posted By: Fullpull

Date Posted: 27 Nov 2019 at 7:50pm

| I have taken the engine apart and will be doing the stuff to it that you talked about and see what results I will get and yes I should done some more testing. |

Posted By: DrAllis

Date Posted: 28 Nov 2019 at 6:06am

| What exactly did you have your ignition timing set at and what octane of gas were you using ?? With 12 to 1 compression, it will require the timing to be LESS than the OEM timing of 25 degrees BTDC @ 2,000 RPM. More like 18 to 20 degrees BTDC and really should be done on a dyno of some type to achieve max power output. Octane rating needs to be 110 or better for best results. |

Posted By: tbran

Date Posted: 28 Nov 2019 at 10:55am

|

high compression engines are for high rpms - not 1800 rpm luggers. the peak cylinder pressure , unless controlled with octane and timing - as Doc sez on a dyno - will not be kind to internal components . ------------- When told "it's not the money,it's the principle", remember, it's always the money.. |

Posted By: Fullpull

Date Posted: 28 Nov 2019 at 9:09pm

| I was running 114 then 110 octane gas,do not have pto for dyno and running 3000 rpm maybe not a lugger. |

Posted By: DrAllis

Date Posted: 29 Nov 2019 at 6:06am

| And what was the timing set at ????? |

Posted By: Fullpull

Date Posted: 29 Nov 2019 at 6:12pm

| I do not remember Dr Allis. |

Posted By: SteveM C/IL

Date Posted: 06 Jan 2020 at 1:44pm

| We had a 261 Chevy (big brother to 235) and was notorious for cracking pistons when run above 3000 rpm. Don't know if 235 piston is stronger but you may be asking for trouble.Just saying.... |

Posted By: Fullpull

Date Posted: 06 Jan 2020 at 7:22pm

| The rpm will be 3000 max. We ran the other setup for 5-6 years at 3000 rpm and pistons look fine. |