1951 WD

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=159746

Printed Date: 18 Dec 2025 at 9:23am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: 1951 WD

Posted By: wjohn

Subject: 1951 WD

Date Posted: 07 Apr 2019 at 11:48am

|

The seller just dropped this off today. Not exactly pretty, but it runs pretty well and everything functions minus the PTO that's missing the shear bolt. "Supposedly" the engine was rebuilt later on in its life. It's going to need a number of leaks fixed (including what looks to be the rear main seal) and hoses, a belt, etc. The drawbar bail has been welded on but looks fairly solid. Rims look good. It'll need a front tire soon, and it sounds like there might be some bearing noise or something back around the axles or final drives. Otherwise I'm hoping I can get out and disk with it soon and get some grass seeded with my JD drill.      ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Replies:

Posted By: darrel in ND

Date Posted: 07 Apr 2019 at 1:48pm

| Being mechanically sound usually trumps being pretty, and it sounds like it won't take much, and it'll be mechanically sound. Good snag! Darrel |

Posted By: garden_guy

Date Posted: 07 Apr 2019 at 3:20pm

|

Looks like a pretty good find! What's with the welding of the drawbar area?

|

Posted By: CTuckerNWIL

Date Posted: 07 Apr 2019 at 4:56pm

|

It wouldn't hurt a bit, to drop the final pans and clean out any sludge in there. Ya never know, it might have the original lube in it. Then while the pan is off, you can eyeball the final drive gears, and maybe pry around a bit to check for loose bearings. Straight gear WD's always did have more gear noise than the later model with constant mesh trannies. There is no "shear pin" in the PTO. Anything run off it, needs a slip clutch or a shear pin of it's own. The bolt that connects the PTO output shaft to the long shaft, is a case hardened shoulder bolt. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: trace

Date Posted: 07 Apr 2019 at 5:49pm

|

notice no flip up seat, when they start the flip up seat? love that on my 55. ------------- 1955 WD-45 WIDE FRONT W/ TRIP LOADER |

Posted By: Lonn

Date Posted: 07 Apr 2019 at 7:22pm

|

As far as I know the flip up seat was an after market item. ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: wjohn

Date Posted: 07 Apr 2019 at 10:14pm

I'm not sure. Someone must have broken that side of the bail at some point. It's not very clean looking but it seems to be solid, so I'll leave it for now. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 07 Apr 2019 at 10:17pm

Good point... It probably isn't designed as a shear bolt, but sometimes you get lucky and they do shear. I wouldn't be counting on it. I do plan to drop the final drive pans. This tractor is definitely noisier than the WD I grew up on, which was also a straight gearshift tractor. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 07 Apr 2019 at 10:22pm

Dad's '52 WD didn't have it either, so I guess I don't know what I'm missing! ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Alberta Phil

Date Posted: 07 Apr 2019 at 10:36pm

|

I've got two operating WDs here and one has a much noisier drive train than the other, but it's been that way for the last 20 years and hasn't gotten any worse! |

Posted By: WD45Diesel57

Date Posted: 08 Apr 2019 at 7:24am

|

i have three running WD's and they all are noisey in the gears, but yet all different tones of growl. I guess it depends on how hard they were used in there life with gear wear or run low on oil and got hot like my 49 WD it has a distinct howl in 2nd and 3rd, bearings were replaced when it happened but great grampa couldn't afford new gears. I don't even need to turn around to see what tractor is coming its not loud just a distinct sound! ------------- 1-B's, 2-C, 2-CA's,2-WF, 1-WC,1-G, 3-WD's, 2-WD45, 1-RC, 1-D17 Diesel, 1-D14, 2-D15,1-D17 row crop,1-D19 gas and All Crop 40,60,66,72,90 and 100 |

Posted By: Dusty MI

Date Posted: 08 Apr 2019 at 7:29am

X-2 ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: ac hunter

Date Posted: 08 Apr 2019 at 7:39am

| Dad's WD-45 had noise somewhere in the rear. Never knew what it was. Had it in the 1960's and still does. Never seemed to get any worse through the years. Maybe if it does get worse we'll figure out what causes it. |

Posted By: Sugarmaker

Date Posted: 08 Apr 2019 at 7:47am

|

wjohn, Man does that look like the ones I have brought home! It has indications that the engine may be a WD45. Looks like the oild filler cap is a WD45 type. Not sure but the head looks like the tall one. Has a WD45 decal on the rad shell. Power crater decal on the block?? Yea most have the welded bail. I have had to replace all three of my bails, I have one that's welded but looks pretty clean as a spare. Your tractor looks like it should function well for some discing work. Rims can be a big issue, so thats a plus if yours are good. Looks to have been mostly converted to 12 volt (alt) but still has the ballast resistor. My 45 had that too. Still cant figure why folks dont get the right coils when doing the conversions?? And yes some rear ends are very noisy. My wide front WD is very loud! I see you have a WD45 also, so you know the ins and outs of these already! Looks like a good tractor to add to the herd! Congratulations! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Bill Long

Date Posted: 08 Apr 2019 at 10:16am

|

I was surprised to see the WD-45 power crater decals and the 45 head. Looked at the shift lever and thought it may be a very late WD - they had the constant mesh transmission. Over all looks good for a tractor "pushing 70". Can't believe they are still operating. They made them good At Allis Chalmers. Good Luck! Bill Long

|

Posted By: Lonn

Date Posted: 08 Apr 2019 at 10:26am

|

Sideplate on engine means a WD or WC engine. Of course I bought a WD once but knew right away it had a WD45 crank in it by the way it snapped to attention. ------------- -- --- .... .- -- -- .- -.. / .-- .- ... / .- / -- ..- .-. -.. . .-. .. -. --. / -.-. .... .. .-.. -.. / .-. .- .--. .. ... - Wink I am a Russian Bot |

Posted By: Sugarmaker

Date Posted: 08 Apr 2019 at 3:51pm

|

Yep Lonn is right thats a WD block for sure! I completely missed that side plate. But as mentioned it may be a 45 engine lurking inside that block!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DougS

Date Posted: 08 Apr 2019 at 4:27pm

|

I saw the plate. I saw the Power Crater sticker on the side. Those stickers must have been a dime a dozen once upon a time. |

Posted By: wjohn

Date Posted: 08 Apr 2019 at 8:33pm

|

Dad's '52 has those same Power Crater stickers on it, too. I almost wonder if AC put them in with a "45" engine kit or if AC only offered WD-45 decal sets for service parts, and people wanted to use every last decal. I didn't include the engine SN for fear of picture overload in my thread, but here it is. Seems like it could be original and I was glad to see the PA suffix, although if the internals have all been swapped out that may be moot. I should stick something down the spark plug hole and see if I can measure what the stroke is.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 08 Apr 2019 at 8:35pm

|

I thought I remembered seeing something about the tall head being on some of the WDs - Dad's '52 also has the tall head. Looking in the parts book shows that engine SN 289000 on up had it which would mean it's probably original to this tractor, too. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 08 Apr 2019 at 8:36pm

I think the seller said he had to replace the governor at some point, which would explain why it's the newer housing and fill cap. Good catch. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 10 Apr 2019 at 10:15pm

|

I pulled a spark plug and measured the stroke at 4"... Just a plain old WD crank. The carb is a TSX 422 so at least that matches up correctly. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: TomMN

Date Posted: 10 Apr 2019 at 11:05pm

|

Your 1951 WD numbers fit in nicely on the WC, WF, and WD block chart I've been putting together. Block casting number: U 3019-31 Engine serial number: WD309752PA Tractor Number: WD101353 Here is a link to my chart: http://www.allis01.com/fossto/AC-WC-Engine-Data.html" rel="nofollow - http://www.allis01.com/fossto/AC-WC-Engine-Data.html

|

Posted By: Sugarmaker

Date Posted: 11 Apr 2019 at 10:58am

|

I dont know why I gravitate to these old rusty hulks too?:) I just know they have pretty good bones and they did a ton of work for their size in their day! Love to hear the governors open up, and they sound good! I need to get to the shop!:) We need more pictures and updates!

Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 22 Apr 2019 at 10:39pm

Nicely done - I didn't know anyone was tracking the engine numbers as well. I just about couldn't find the 1 in the -31 on my casting but it's there. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 22 Apr 2019 at 10:45pm

I had time to read through the first two pages of your WD-45 thread over lunch and have been too busy running around to finish the rest of it, but I'll keep reading when I get a few minutes. It looks like it should be a fun read. I agree they're the good ones to start with. I have a decent list of what this WD needs before I feel comfortable calling it totally field ready (radiator hoses, all fluids, carb kit, etc.). I need to put an order in and pick up the other stuff at TSC here soon, and get that front tire replaced. The weeds in my fields aren't getting any shorter. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: bhaynes

Date Posted: 23 Apr 2019 at 7:12am

|

Looks good! About how mine looked when I got mine from my grandfather. It is almost completely restored now and hopefully will be firing it up within the next week. The first time it has been started in almost 2 years! Looks like it has been converted to a 12v alternator and a distributor? |

Posted By: SGTJ

Date Posted: 23 Apr 2019 at 10:08am

|

When my dad gave me the WD, e said that a "WD-45 kit" was installed in it sometime in the 60s. Is that a thing / what's going on here with the engine ? ------------- WD , CA |

Posted By: bhaynes

Date Posted: 23 Apr 2019 at 10:21am

I don't want to misquote anything - but to my understanding, the WD-45 engine has bigger pistons. (by like .5in in radius I believe) and the biggest noticeable difference is the WD-45 engine doesn't have a removable push rod cover. It's a solid block. It seems to be common for a "WD" model to have a "WD-45" engine in it. Could be TOTALLY wrong and I am very new to this, but that was what I thought and heard at one point. ;-)

|

Posted By: Sugarmaker

Date Posted: 23 Apr 2019 at 11:45am

|

Trying not to highjaclk the thread: bhaynes has some of this correct. But you never really know about these old engines till you open them up. Very few are as they were from the factory. When my Dad and uncle put a 45 kit in the old WD's. it was moving from 4.00 dia inch stock pistons to oversize 4.125 dia pistons and sleeves. Most times the stroke remained as factory with a 4.00 stroke (factory for a WD) Now the WD45 had the same piston bore options but had 4.50 inch longer stroke. Different crank. It also had dished power crater piston compared tot he WD flat tops. So most of these parts are interchangeable and these engines have been confiqured many ways since they rolled out of the factory doors. A WD block (plate on the side) can be used to make a WD45 engine. And a WD45 block with no plate, was the replacement block at some point for all these. So it can be a mix and match of components to meet the owners needs. I think I have most of this right but feel free to add. Yes the head is taller on a typical factory WD45 also. Back to the current channel Wjohn has confirmed this nice tractor is a WD with some WD45 decals. I would drive it!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: CTuckerNWIL

Date Posted: 24 Apr 2019 at 8:24am

|

WD45 had the same diameter 4 inch piston as the WD. The difference was in the stroke of the crankshaft and the compression ratio with a shorter piston for the longer stroke. Oversized pistons don't make a "45 kit" . You would have to change the crankshaft and the pistons. You could also put a 45 crank in with WD pistons, and have a BIG jump in compression, that might make it hard turning over. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: wjohn

Date Posted: 30 Apr 2019 at 9:03pm

Yep, it's before the changeover to the distributor, so it would've originally had a magneto. I'm annoyed that someone hacked off that corner of the grille for the distributor but I see that all the time. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 30 Apr 2019 at 9:15pm

The only thing I would point out is that the tall head started sometime in '51 (engine serial number 289000) so there are plenty of WDs out there that had it from the factory. I just picked up a WD field cultivator from a forum member last weekend as well. I'm hoping it'll be perfect for knocking out some spring weeds while ignoring a few rocks in my fields.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 30 Apr 2019 at 10:04pm

|

Yea that grill corner hack job is very typical! Seen and repaired some of those too. Good looking cultivator! I have never seen on like that. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 25 May 2019 at 10:01pm

|

Well, it's been sitting since it was dropped off and I finally have space in the shop. It fired right up. I drained the engine oil, coolant, and gas. The gas tank has some sediment in it but I think it'll clean up okay. The air cleaner cup had purely water in it. I took the carb apart since it was leaking a little gas and it actually looked pretty good inside. The float seems to be okay but I could see some junk up in the needle seat, so hopefully that's all the problem was. The oil leak at the rear of the engine was mostly coming down the inspection cover. Took that off and the flywheel appears to be a little oily. I had not too high hopes that only the pan gasket was leaking but I'm pretty sure that the rear main seal is the main issue. It was leaking slowly when not running, and leaked a drop every 20 seconds or so when running. I'm not sure if I'll pull the engine to do the rear main seal now or wait until winter. There's a leak up toward the front of the engine somewhere too but not nearly as bad. Anyone know what this mystery wire could've been for (second photo)? It's just hanging off the governor shaft tube but looks like it was tied to something once upon a time.   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 26 May 2019 at 6:39am

|

wjohn, Typical oil leaks on these. I see the clips on the oil pan for the pan gasket end pieces. My guess on the wire was it hooked to a spring that attached to the carb lever? Looks like vertical governor lever has been tweeked to adjust the length between the end and the carb. Your doing good with it. Have fun with it! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 28 May 2019 at 8:44pm

Good thought. I bet it's for a missing surge spring. I seem to recall Dad's WD had a spring hooked down to the engine block coolant drain petcock, and there's nothing of the sort on my tractor. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 28 May 2019 at 8:58pm

|

The air cleaner didn't look so bad at first. I tried blowing compressed air through the top and wasn't getting much flow through it, and then I saw the mud dauber nest. There's a pile of other gunk up around that area where the intake tube of the air cleaner transitions into the space between the outer wall and the inner wall that holds the mesh. Not sure if that makes sense but on these air cleaners the air comes down between the walls and is then sucked up the middle through the mesh to the carb. Anyway, it's pretty tough to get to and it's nice and oily, so I finally figured out that I could shove a scrap piece of metal shipping banding in and work the crud loose. I never have found a good tool for screwing/unscrewing the needle valve seats in carbs. This old reciprocating saw blade works okay but could be a little stiffer.     ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 28 May 2019 at 9:13pm

|

wjohn, Your getting right into it! Awesome! Yes these air cleaners can have a bunch of gunk in them! Carb doesn't look to bad! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: SteveM C/IL

Date Posted: 29 May 2019 at 8:07pm

| When 45 came out,it had 1/2in more stroke than WD.Same bore.Took matching pistons with the wrist pin moved 1/4in. Rods would interchange but WDs were shim adjust and 45s were precision. |

Posted By: wjohn

Date Posted: 07 Jul 2019 at 10:04am

|

I put the carb and air cleaner back together last weekend. Now I'm draining fluids from the rear of the machine... The PTO/trans oil is pretty thin and definitely had water in it. I also got a quote on front tires and need to take those in to be replaced. On a potentially scarier note - anyone know what this part is in my pics below? It was lodged inside the cavity in the drain plug for the PTO housing. It's small, round, and sort of mushroom-shaped, like the broken off end of a good-sized nail. Looks like it's been pushed between a set of gears at some point on its journey... The end of some kind of pin, maybe?

------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 21 Jul 2019 at 8:19pm

|

Anyone have any thoughts on the mystery part? I got the right rear wheel off today. All the eccentrics came loose without much effort, but the left side ones are all rusted/painted solid. I broke off the bolt for the spinout stop and figured I'll have to soak/torch the eccentrics on that wheel someday. The fluid in the RH final drive wasn't as nasty as I expected. It definitely needed to be changed, but didn't seem to have much water or lumpy stuff in it. I made a couple of gaskets and got that side put back together. Then I moved on to the radiator/grille. Getting to those two larger bolts up under the frame was a pain until I found the perfect combination of extensions... And they still fought most of the way out. It also looks like the rusty thermostat housing was a problem waiting to happen, and there was no thermostat. All I'm seeing for replacement parts are the cast housings vs. this thin stamped steel housing that rusted through. I spent a few minutes beating on the steering shaft pins and got nowhere, and called it a night. From looking at other threads it looks like I'll have to get the drill out.    ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: mhankins

Date Posted: 22 Jul 2019 at 7:33am

|

I got 2 front tires for my WD45 from tireseasy.com. Free shipping,and the price was less than one locally.

|

Posted By: Sugarmaker

Date Posted: 22 Jul 2019 at 9:52am

|

wjohn, Well I see your right into this tractor. What are your plans? My plans took a bad turn when I found my engine was not good. Your doing a good job. When I attack the eccentrics: I take the wheel assembly off lay it on the ground and take out the 8 bolts holding the eccentric brackets to the wheel. Then gently tap out the center wheel with a 10 lb sledge and several big grunts!  The I take each eccentric and bolt it to something very solid and heat and work it till free. The I take each eccentric and bolt it to something very solid and heat and work it till free.Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 23 Jul 2019 at 9:57pm

Thanks for the tip - I actually got a quote for a pair of 5.50-16s from my local tire shop that was only $25 more than the cheapest tires on that site, and that included mounting and disposal of the old ones. I'm hoping they stay in business for a long time. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 Jul 2019 at 10:03pm

The main thing I want to do right now is replace the rear main seal that's leaking more than I'll accept. I've been studying your threads and Don's video! I'm almost to the end of your WD-45 thread, haha. I don't plan on doing anything cosmetic with this tractor anytime soon... I want it to not leak tons of fluid and be a solid worker for the next couple years. Everything I've read here on the eccentrics says lots of heat and/or soaking. They should be a good excuse to finally get a torch. I already bought an engine hoist for pulling the motor and I've been wanting one of those for awhile. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 24 Jul 2019 at 6:33am

|

wjohn, You have a good plan. Even after taking a lot of my tractor apart to fix things like oil leaks I still have a few that have not sealed. One is the left rear final drive. I saw some oil in the rim yesterday!:( I even had these axles machined smooth and bought undersized seals! Also the front crankshaft seal is weeping a little too. Reminds me of a old Harley, They tended to leak on the showroom floor!:) Having the right tools is safer and you will get the job done much eaiser. Looking forward to your progress! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 27 Jul 2019 at 7:40pm

|

Weeping I'm okay with on an old unrestored tractor like this one. Drip-drip-drip (like the rear main seal) not so much, but I'd be a little frustrated too if you had gone to all of that trouble and still had some weeping. I finally got the front pin for the steering u-joint drilled out. That's quite the ordeal. I picked up a Harbor Freight air hammer for $13 because I figured "what the heck" at that price. It didn't have enough oomph to punch the pin out without a lot of drilling first, though. Once I drilled out enough it was really handy, though. Maybe I should've grabbed the slightly larger model and had better luck with that. The u-joint is still stuck to the shaft after much turning and hammering, so I'm going to have to figure out how to drive it off of there. I may end up having to pull the frame rail. Fingers crossed, the rest of the engine removal process looks more downhill after I get that out of the way. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 27 Jul 2019 at 8:02pm

I think the original pins are slightly tapered. They can be a bugger. Almost everything I touched on mine had some issue that kept me in a headlock. It did not like being apart and is still adjusting to being back together. Parts are just starting to play nice! Taking the frame rail off will help with a lot of issues. Steering and engine removal and installation too. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: CTuckerNWIL

Date Posted: 28 Jul 2019 at 9:17am

|

I don't believe those pins are tapered. What I believe they did, was chamfer both sides of the U joint, and peen the pin to swell out into that chamfer. Basically making a rivet with a small head on each end. They can be a real bugger to get out. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Sugarmaker

Date Posted: 28 Jul 2019 at 5:31pm

|

CTucker, Your probably more correct. They were supposed to last the life of the tractor which was to be about 20 years, not 3 times that!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 07 Sep 2019 at 9:44pm

|

Small milestone: the steering shaft u joint is completely out. I removed the frame rail and the rear u-joint pin came out after some solid smacks. It's really helpful to be able to block it against the engine block so that you're transferring the entire force of the hammer blow solidly into it, instead of into all the slop of the shaft and supports. The support around the clutch is totally egged out. It's bad enough I'm not sure if I can oversize it and put a bushing in, but we'll see. The shaft also needs material added in several spots. I may leave that for a project in the distant future. For now I think I'm just going to rebuild the u-joint since I have it out and it clearly has no lube and lots of play. Hopefully now that I've knocked the pins loose once they'll come out easier the next time. Now onto the pin in the hand crank shaft. I know they're Sugarmaker's absolute favorite, and mine sure didn't want to budge at the end of the day today. I called it a night and made supper.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 08 Sep 2019 at 7:42am

|

wjohn, I like your documentation: pictures and descriptions! Yes getting something soild under any of these pinned joints is the key to knocking them out. The steering u-joint may be the toughest. taking the frame rail off seems like a pain, but will save you much frustration putting that joint back together. And you now have all those bolts loose in case you need to do this again. Add never seize to the bolt threads. On that crank pin it is way easier to work on them with the front grill off, which you have done. I like a floor jack between the back of the tires and a piece of solid steel coming up from the jack to support the shaft. Then you can get a real solid whack on the stubborn cross pins. After changing them 3 or 4 times, like I tend to do the come right out!  Are you pulling the engine to do the rear seal? Don and I will tell you thats really the best way to fix that leak. Pulling the engine probably not much more work than the u joint rebuild. By the way I had problems finding the new u joint (cross and bearing for these. Maybe they are more available now??? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: IBWD MIke

Date Posted: 08 Sep 2019 at 8:55am

|

Great idea pulling the frame rail! Wish I would have thought of that when I did the one on my narrow front. Getting ready to put (Char-Lynn) power steering on the wide front, will pull the rail. The joint I used in mine came from Napa, box has 861 on it as part no. Here's a qualifier; I had to do some filing on the yokes to get the clips in if I remember correctly.

|

Posted By: wjohn

Date Posted: 08 Sep 2019 at 9:06am

|

The parts book shows a cotter pin in the hole on the hand crank that I'm stuck on, but it definitely has a very rusty pin driven in it. I don't see any reason for it to be a solid pin (it's the one that sits against the back of the front pedestal casting when the hand crank is not being used and is pushed forward by the spring) so I'm planning on replacing it with a cotter pin if/when I get it knocked out. I'm worried that I'll have to take the front wheels off if I need to get access to drill it out. I am pulling the engine entirely just for the rear main seal. I'll take a look at the clutch and some other things while I'm in there, of course, but hopefully it just needs that seal and the oil pan gasket set. I did some searching on the forum and found NAPA part number NPJ P861 but I haven't checked measurements on it to make sure that's good info. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 08 Sep 2019 at 12:54pm

|

wjohn, That does sound like the right part from NAPA. Like Mike, I think I had to clean up some areas on the yokes to get the bearing caps retained properly. While you have it apart might as well do the seals in the torque tube, rebuild the hand clutch, and paint it! Just sayin!  Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 08 Sep 2019 at 1:28pm

|

Thanks for the confirmation on the part number, guys. Good to know about the clips. Chris, the hand clutch feels good but it might not be a bad idea for me to take a peek at it. Paint is definitely out of the question at this time. I don't have the time or the setup to do it for now. I just got the pin in the hand crank shaft out. I realized I had a 2.5' piece of 1 1/4" round stock in my shop that was there when I moved in, so I tried to figure out how to hold it and hit the end of it... Then realized it was heavy enough I could probably just use it like a battering ram, and sure enough the pin started moving. I think I'm ready to pull the engine off now. I don't have a stand so I'm either going to get creative or buy a cheap stand next week, haha. That sure would make doing the oil pan gasket job a lot easier as others have mentioned, so I may bite the bullet and buy one. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 08 Sep 2019 at 8:31pm

|

Success! Not a big deal to many of you veterans, but I'd never had to pull and engine out of an AC before. I think I'll have to remove the front wheels to get it back in because my hoist was up against the tires and wanted to pull the engine a good 5" forward to hang dead center the way I had it hooked up. I found a cracked rocker shaft pedestal so I'll need to source a used one somewhere. I'd rather not rob parts off my other tractors yet since I still think they all have hope. The front crank seal wasn't seated all the way, so the only thing I can think of is either it wasn't installed properly or someone was trying to keep it out of a well worn groove in the crankshaft. Disassembly will tell all. The clutch still has some life left. At least, there's a ways to go before it's hitting rivets. I'll check to see if there's a minimum thickness spec, but unless it's close to the bottom range of that then I'll plan on reusing it. Interestingly the pilot bearing had fallen out (I can only assume it tried to stay with the transmission input shaft during engine removal) and was missing the seal on one side of the bearing, so it didn't have long for the world. There was no lubricant left and it makes a nice loud rattle. Unfortunately I wasn't thinking and the "good" side of the bearing is showing in the pic with the clutch. That flywheel is a suprisingly heavy chunk of metal, too. Who would've thunk?    ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 09 Sep 2019 at 7:52am

|

wjohn, I believe I shortened one leg of the base of the engine hoist by the wheels and came in from the side of the tractor rather than the front. While your at Harbor freight getting the low cost engine stand, splurge and get the engine leveling unit too. You will thank me for both when your done! Your doing good! That front seal does look like its out more than normal? You will have that cover off so you can put in a new seal and check the crank grooves. I put a speedi sleeve and new seal and still have oil weeping a little. Geting the cover centered on the shaft is important. Just poking you on the paint thing! It takes a lot of time for that process. I bet someone on here has the good used pedestal that you need. Cant remember but I believe they are different from a WD to a 45? Keep hittin at it! Thanks for the pictures and the updates. Off to haul tractors to the local fair. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 09 Sep 2019 at 9:41pm

|

Are you talking about the same leveler I have hanging from the hoist in my last post? If so, yes, I wouldn't want to be without that. I was thinking if I had a different angle for one of the legs of the hoist I would've been able to slide in from the side, but shortening would be an option too. I'd prefer to not permanently alter the frame if possible. I was also wondering if I rotated the front wheels one way or another if that would let me sneak in as well... I may have to jack it up and play around with that just to see. I haven't looked at the parts book yet but I'm assuming the pedestal differs between short and tall heads. Centering the timing cover might be interesting but I think I can wrap up a piece of PVC pipe to the right thickness as I've seen somewhere on here before! Your seeping front crank seal is a bummer for sure. Odd that it happened with the speedi sleeve and everything, too. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 10 Sep 2019 at 7:37am

|

wjohn, Yes that is a great tool for this work! I used it on the torque tube and the final drives too. I looked at the front seal and don't see much oil so maybe it decided to seal up a little! I think the pedestals are formed metal on the short heads??? Cant remember? But I do believe they are different. This would be the time for a fresh clutch/ pressure plate, if your in need or in doubt. Hand clutch can be adjusted if the plates are good enough. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Steve in NJ

Date Posted: 10 Sep 2019 at 8:25am

|

If that were me, I'd give Rick a call or e-mail him and have him fix you up with a new clutch/PP setup. Can't beat his prices, and man, he does a nice job. You have the Tractor all apart, and you plan on using your attachment. Put a new clutch set up in it so you don't have to split the Tractor again down the road. Why do twice the work? JMHO. Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: wjohn

Date Posted: 11 Sep 2019 at 8:39pm

|

Measured the clutch today. The service manual says the lining on one side should be 1/8" thick and 5/32" thick on the other. This one is worn down not quite 1/32" on each side assuming it was the same thickness as what AC had specified. For better or worse that seems like it should be in good shape. If it goes out sometime in the future then maybe that's an excuse to paint and everything at that time, too. I would hope I have at least one of my other tractors here and running as a backup by then! Turns out the pilot bearing being open on one side is probably intentional. After looking through the service manual, it mentions engines prior to W310920 have a wick through the center of the crankshaft to bring oil to the pilot bearing. After that they quit using a pilot bearing until later on in WD-45 production when they must have realized they should have kept it and went to using a bearing, but sealed. It mentions that you should install it on tractors that didn't have it as it will increase clutch life and decrease the chance of leakage at the clutch housing seal, which makes sense. Anyhow, this engine is a little over 1000 serial numbers before the change, so I'll plug the oil wick hole and find a sealed bearing for it. I wonder if the rivet or pin head that I found when I drained the oil was from something in the hand clutch. I will be checking that out in a couple weeks when I get a chance to work on this again (getting a dumpster to clean up all the construction debris around my house for a couple weekends). Then I need to put in some parts orders. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 12 Sep 2019 at 8:33am

|

wjohn, Clutch will probably work for a long long time! We ran the heck out of these in the old days and I don't remember ever having a clutch go out on a WD series. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 28 Sep 2019 at 8:25pm

|

I snuck in a little bit of time with the WD again. I had snapped off one of the front pedestal mounting bolts, so I spent a long but successful time drilling it out. I wrestled with the engine on the hoist trying to get it on the stand I just bought but quit once I realized that I need two more bolts just 1" longer. Then I popped the cover off of the hand clutch, which has some light rust from what was probably condensation over the years. I've never dealt with a hand clutch before. The service manual says if grooves are still visible on the clutch linings then they're okay. I can still see grooves but I think what's left of the shims is just one big one so I'm off to watch Dennis' video on the hand clutch rebuild. EDIT: They're actually a lot of shims glued together. I'm probably okay. I have also decided that the head of the pin I found when I drained the transmission oil was probably from the hand clutch linkage. It must have been replaced at some point because I don't see any missing (and someone's been in it before since there was silicone under the access cover).  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 29 Sep 2019 at 12:28am

|

wjohn, A trick I learned on the engine mounting to the stand, which maybe your already doing? I took the pivoting head out of the stand and then worked with just it, on the back of the engine. When I got it fit and secured, then could just lift/ tilt the engine stand base to slide it on to the pivot portion. It was one of those Duh moments for me, but I have a lot of those! I have not had a WD clutch opened up recently. They are a 2 plate clutch vs a 3 plate in a WD45. Here is a picture of the 45 clutch I did last spring. This was before the rebuild I believe.  This was the worn plate, which was working when removed: ( Yes the grooves were about gone, and cleaning didn't improve them.)  Also what a new replacement hand clutch plate looks like. I think it was .100 thick? around $80.  Yours is a little bit rustier, but if the drive plates are Ok then it may be fine. Maybe snap open the hand clutch and take another picture of the plates of the hand clutch? Hard for me to see the drive plates in your picture? You have a lot of shims left so it has not been adjusted recently. Check for play in the brass collar. Now is the time to replace if its worn bad. They get worn on the inside as that gets moved back and fourth. It looks like your hand clutch area may not have had oil in it for some time? Was it full? One of mine failed due to lack of oil or years of wear? Actually broke the brass and rendered that hand clutch inoperable. The new brass collars are not a cheap date either. Around $200. While you have that frame fail off, is the time to service the oil seal on the hand clutch pivot rod if it needs it too. Your doing good checking it out as you go. I do know that Nic's old WD with a new brass collar and no clutch rebuild is still pulling strong against probably better fresher tractors. These clutches were pretty darn good units and worked for a long time! That video of Dennis' on the WD45 hand clutch rebuild is good! I watched it several times. How is the rear crank seal project coming along? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 29 Sep 2019 at 7:28pm

|

The only thing that kept me from mounting the stand and engine was that I need two more bolts 1" longer than what I have. I'll pick them up after work sometime next week. Then I'll pull the pan and crank seals. Pretty soon I'll need to actually order my list of parts that I keep adding to! I can't get a useable picture of the grooves of the clutch disks but I took a rough eyeball/caliper measurement of the thickness and got 3 mm which is just slightly over your 0.10" measurement. I'm sure mine would measure out close to that if I took them apart and actually got the calipers on both surfaces. Regardless, they seem to be plenty thick plus the fact that I can still peek at the grooves. Thanks for the tip on the brass collar. I checked and mine has some play in it but hopefully not so much that it might break anytime soon? It had oil in it, but it sat in a shed for several (maybe 10) years. $200 is enough to make me stop and think I can make it for quite awhile longer, and it looks like I don't have to split anything to replace it if I do get around to it later. Bad idea? The hand clutch shaft came out today as well as the seal. Not too bad of a job since I already have the RH frame rail off. I also took a peek at the front input shaft seal and decided it's definitely leaking... Plenty wet with oil. Hopefully I can pull that out from the front and drive in a new seal over the shaft? Although I also got to thinking the only other seal that would be easier to get to now is the one between the hydraulic oil chamber and the rest of the transmission that keeps the fluids from mixing... I think I should probably pull a few more things apart and replace those while I'm this far, unfortunately.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 29 Sep 2019 at 7:39pm

|

wjohn, If the brass collar does have much wear you will be good to go. So saving money can be a factor in these project! It can get out of hand and every thing can be replaced!:) One other thing some folks do is to run the same fluid in both compartments. Just have to check because one is at a different level. Cant remember which is higher?? Your moving right along! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 15 Apr 2020 at 9:38am

|

I was able to spend a couple more hours on this finally. Pulled the oil pan and didn't see anything obviously scary. I spent some time brushing up on Don's oil pan gasket installation instructions and making a list of parts I need to order. I'm planning on getting the Fel-Pro oil pan gasket kit. Pulled the timing cover up front and found some broken gear teeth. Those are probably from when the original governor fell apart. The camshaft gear seems to have borne the brunt of it and the crank drive gear just has minor damage. Should I be worried about that camshaft gear? The tractor sounded great when I tore it apart to fix the rear engine oil leak, but I'd hate for the rest of those two teeth to shear off at a random time in the future. I'm leaning towards finding a replacement unless the experienced folks on here have seen worse.   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Brian G. NY

Date Posted: 15 Apr 2020 at 8:47pm

|

The "tall" head was introduced in 1951 with Engine #WD289001. I think the distributer drive housing with the newer oil filler cap was also changed shortly after that but I don't know exactly when. My '51 WD has the old style oil filler but my brother's '52 (Ser. #WD116619) had the newer oil flller cap. When my Dad and I rebuilt his WD back in 1958 we put the 4-1/8" overbore kit in it. Lots of people called that the WD-45 kit but that's far from the truth......without that extra 1/2" of stroke, a WD is no match for a WD-45.

|

Posted By: Sugarmaker

Date Posted: 16 Apr 2020 at 10:39am

|

wjohn, Those gears may work broken for a long time??? I am not a good judge of that. I guess if I was going to continue to try and use them I would buff all the broken edges smooth. My only story on this is that the engine block that is now in my WD45 was in a WD I bought years ago and had two pistons froze up. I got the pistons out and the engine would only turn 360 degrees then stop. I did not try to force it. Asked a bunch of old Allis experts to no avail. Finally took off the timing cover and found two gear teeth from the governor gear stuck in the cam gear! Moral of the story would be to ry and find the broken teeth in the bottom of the cover. Second story was on my Dads WD I took the timing cover off and found a old set of chewed up governor weights laying in the bottom of the cover. You never know what happened to these tractors in their lives! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 16 Apr 2020 at 9:47pm

Thanks Sugarmaker. I looked at it again today and realized that two more teeth on the camshaft gear are completely sheared off about 180 degrees from the ones I took a picture of. I was concerned about those because that's the side of the camshaft gear teeth that drives the governor gear. That gear is narrower than the camshaft gear so the camshaft gear teeth are only engaging about 2/3 of their width with the governor gear... Approximately where my picture shows they sheared off, if that makes sense. Finding two teeth completely gone puts any doubts to bed now. I did not find any loose pieces so those must have been removed when the governor was replaced by a previous owner. Now I need to find a good used bolt-on style camshaft gear! ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: SteveM C/IL

Date Posted: 16 Apr 2020 at 10:17pm

| I would use a file and remove any high spots on crank gear. That cam gear needs to go. |

Posted By: Sugarmaker

Date Posted: 17 Apr 2020 at 8:48am

|

Yep sounds like you need to go shopping! Should be lots of good used ones out there. I will look and see what I may have in the vast warehouse!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 27 Apr 2020 at 8:37pm

|

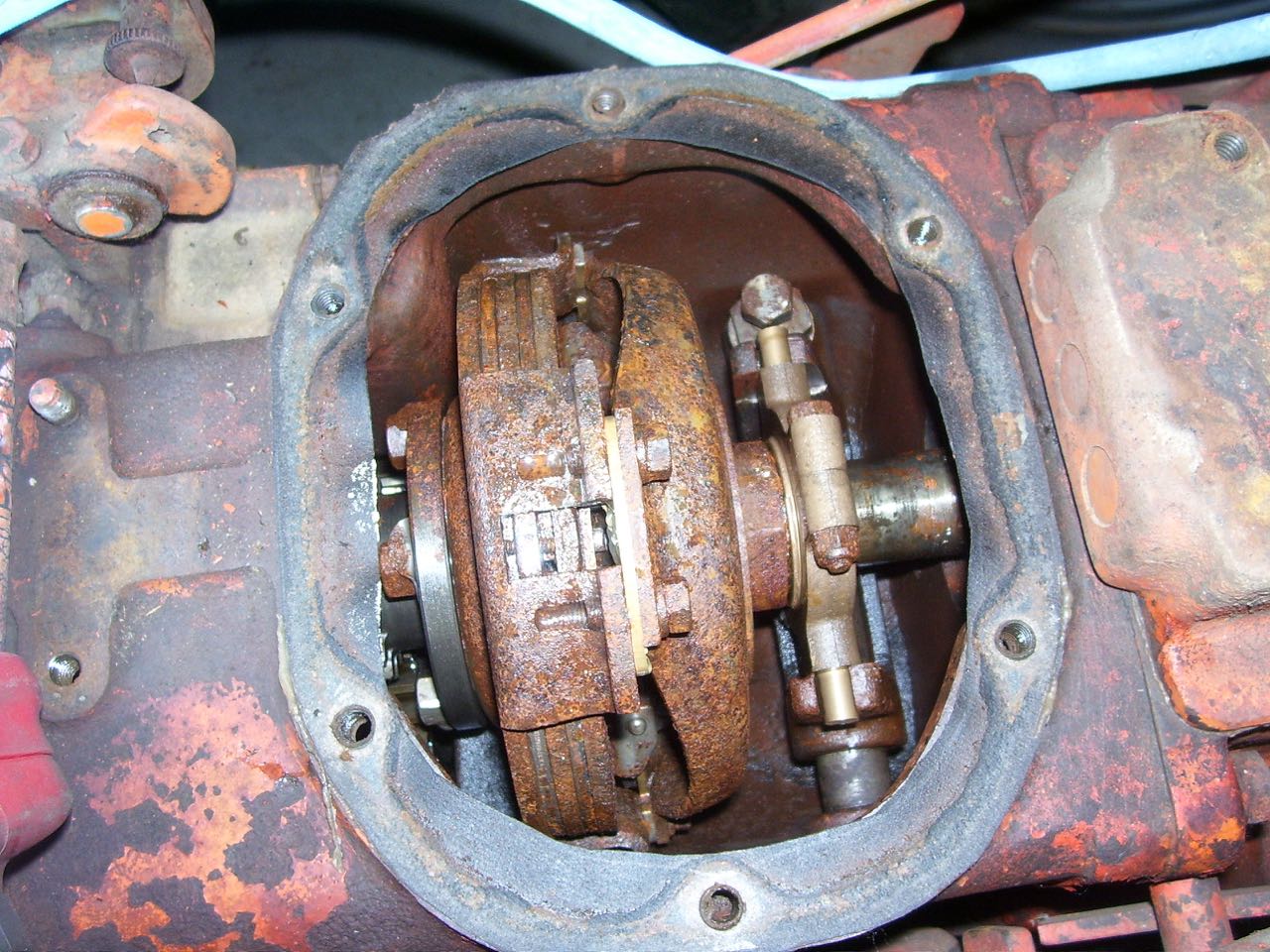

Huge thanks to Chris for finding a camshaft gear for me! For now I've been working on the stuff behind the engine, though. This crusty ball bearing at the transmission output shaft is getting replaced. A couple of the balls are pitted and it might have been some of the noise I was hearing in the drivetrain that I mentioned early on. Anything else I should be looking at while I'm in this far? I was not planning on getting into the transmission or differential unless the wise folks on here recommend checking for some specific things. All gears functioned.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 28 Apr 2020 at 7:43am

|

John, That bearing has a good crust on it for sure!:) Sounds like a good plan to look for any other issues. I have not had a transmission apart on one of the WD series tractors. So I am not going to be much help. Seals between the hand clutch area and the hydraulic area should be evaluated. If you have fluid mixing they probably need changed. Some folks just use the same fluid in both and monitor the levels. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 28 Apr 2020 at 10:04pm

|

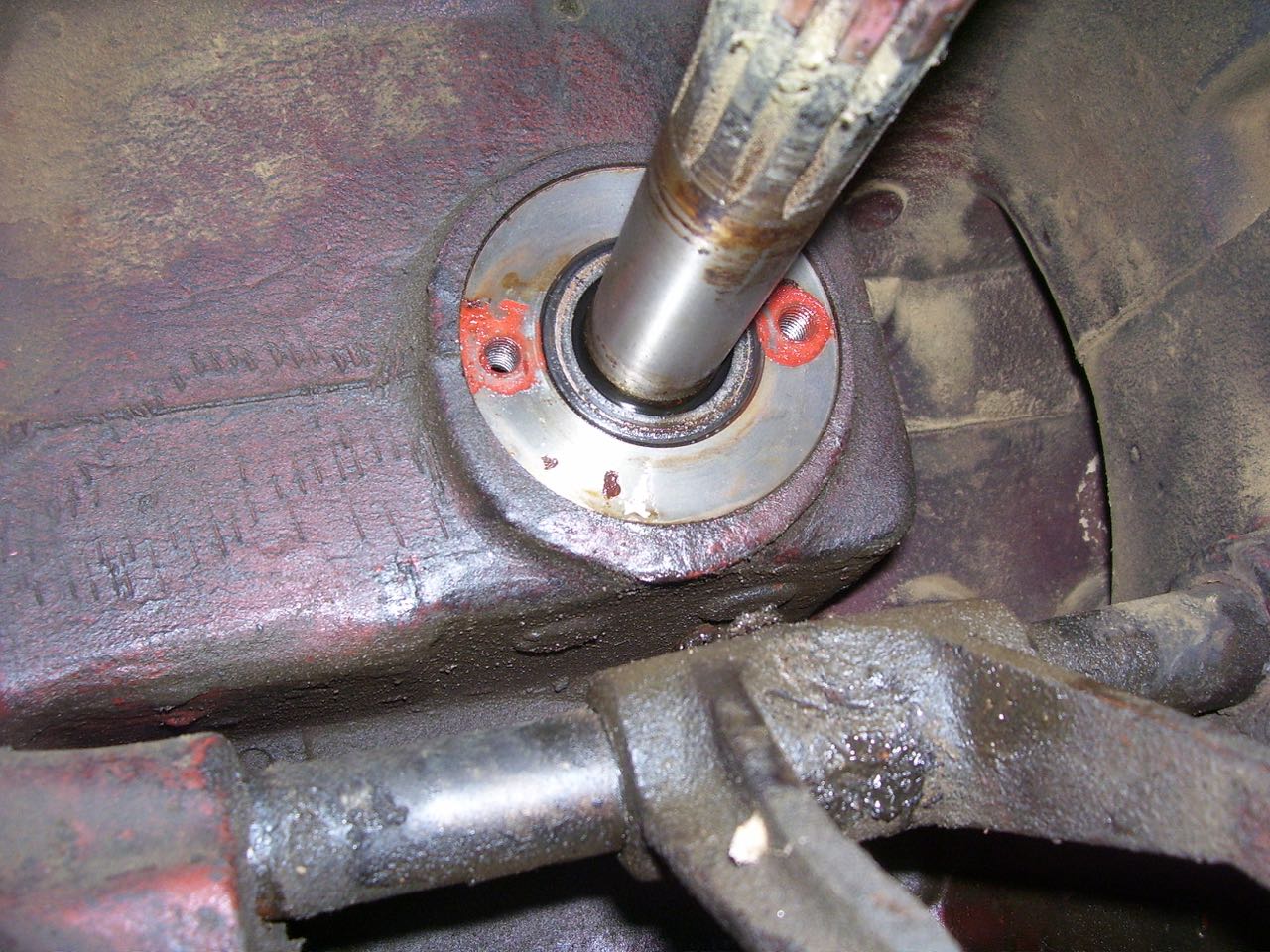

I didn't notice any mixing but I only ran the tractor for maybe an hour total after I bought it, and I figured I'd kick myself for not doing those seals now if they gave out a year from now and I had it all apart like this. I apparently forgot to drain the transmission when I drained all of the fluids. At least I noticed it before anything came out. Got the transmission output shaft knocked out so I can replace the ball bearing, and noticed that the roller bearing behind it was in sad shape as well. No numbers on it, but after some research it appears that a National J321640 should be the right size. The other shafts in the transmission spin nicely and the rear tapered roller bearing looks good, so they must have been low enough and submerged in oil while this thing sat and got rusty. I've never been anywhere near this far into a WD so it's still fun. The inside of the output shaft (where the outside of the roller bearing rides) is ugly, but not severely pitted. I'm comfortable polishing up the shaft in the trans (where the inside of the roller bearing rides) but I don't know about the output shaft. I personally wouldn't put it back in a car if I were rebuilding the trans... However I'm guessing I can't go buy a new shaft for my WD for $100. Do I clean it up as much as I can and reuse it?   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Lon(MN)

Date Posted: 29 Apr 2020 at 7:21am

| I have nice shafts and gears on the shelf if you decide to replace. |

Posted By: wjohn

Date Posted: 30 Apr 2020 at 12:53pm

|

Thank you Lon. If I can't get the inside of that shaft cleaned up acceptably I'll be looking for a new one. I had to take a sledge hammer and a block of wood to the engine clutch shaft in order to drive it out. It didn't want to move. All of the seals (engine clutch shaft, PTO, etc.) popped out yesterday with a little effort. The ones between the hydraulic and transmission compartments were about shot... Well, the rear one was completely shot, and the one on the hydraulic side was barely hanging on. I managed to over bend the snap ring on the PTO drive gear and it has funny measurements so I think I'll have to get that and a few other small odds and ends from my local AGCO dealer. In the meantime I should be able to get all the bearings and seals I need, and work on the engine a little more. Hopefully the only question on the engine is the camshaft bushings but who knows what I'll run into. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 30 Apr 2020 at 4:10pm

|

John, You are deeper than I have gone. I do have a parts WD tractor here but the tranny is still in it. Keep us up to date. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 01 May 2020 at 1:49pm

|

Not so great news on the camshaft bushings... Or even worse, the cam itself. The front bushing is visibly worn and measuring at 1.881" in about the worst spot (supposed to be 1.877" per the service manual). The journals on the cam look like garbage and measure from 1.868-1.871" (manual says 1.874-1.875"). AC calls for 0.002-0.004" bearing clearance and to replace if it exceeds 0.006". The manual also mentions "The 0.025" undersize bushings may be used if the shaft is worn 0.001-0.002"." Since I'm looking at 0.005" or so of wear and the cam journals would need additional cleaning up, safe to say this one is done for? Wonder if it was run low on oil or a bunch of junk got in the system. It also looks like someone filed or ground on the rear journal, maybe to try to chamfer it slightly for installation? Maybe I never should've looked at the cam and not known what was in here, haha. The engine did run well. Better go check the rest of the engine and make a list of what else I need to replace.    ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 01 May 2020 at 1:56pm

|

John, I think I may know where there is a cam that might fit that gear you have? Just sayin.... Not sure its any better than what you have? Would have to do some inspection. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 01 May 2020 at 3:33pm

Thanks Chris. If you're able to mic the journals that would probably tell you everything. No rush as who knows how many other parts I may need when this is all said and done! Main bearings visually look a little better and I'm trying to find my plastigage now. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 01 May 2020 at 7:08pm

|

The main bearings are done for, too. Here's a shot of the front... 0.0037" is the max allowed clearance per the manual, and I'm somewhere north of 0.006". This plastigage is good for 0.002-0.006 and it's still not even compressed to the 0.006 gauge width. I still need to pull the crank and measure diameters but it's looking like it'll need to be ground anyway. So much for sealing up the leaks and getting it back to work!  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 01 May 2020 at 9:21pm

|

John, I will bring it in from the vast warehouse and try to get some measurements on the old cam. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 02 May 2020 at 10:15pm

|

Pulled the head, pistons, and crankshaft today. The middle head bolt put up one heck of a fight. My 1200 ft.-lb. impact wouldn't budge it. It finally broke loose with a long cheater pipe on a breaker bar, and I have never seen so much powdery rust come out of a bolt hole in my life. I have yet to inspect the threads in the head. No nasty surprises upon visual inspection of the pistons and sleeves. They will likely get reused after a light honing and measurement check. The pistons say "Alcoa" and "1533" and some name that seems to end in "-ex" so I may do some digging to figure out what they are and what compression ratio. This was a gasoline engine from the factory and should have higher compression pistons but I suspect they've been replaced since 1951. They are still 4" vs 4 1/8" bore. The crank journals are all worn a good 0.020" or thereabouts. Since 0.040" undersize bearing sets are available I hope that they'll clean up fine... Now to find a decent machine shop here.   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 03 May 2020 at 7:53am

|

John, Your getting into it now! That needed taken apart. May want to consider getting a kit for it? By the time your done chasing parts the cost of the fresh kit will look pretty good. I was very happy with the kit I got from Sandy Lake Imp. Just a note about the crank turning. My shop recommended me to find another crank due to the old one needing to be turned to .040 under on the mains. He thought it was just to risky. The original crank needed a bunch of other work too. So I did find another crank that only had to be turned .020 under on the rods and mains. But it needed work on the flywheel end which was spray welded and machined to make it into a good crank, with some life remaining if it ever needs to be overhauled again? I have to go find that cam shaft!:) You will have a small fortune in the tractor but it will be a pleasure to use! Dont give up on the old girl! I am very happy with my WD45 being completed. I need to take it out for a ride and maybe wash it up a little too! WE have sunshine! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 03 May 2020 at 9:52am

|

Chris, Funny how this works... I bought what I thought was a decent running tractor, but you never really know until you get into it. Of course the oil pressure gauge had quit working who knows how many years ago so I wasn't able to verify that when buying. On the bright side hopefully I am catching things like the crankshaft/bearings before they were too far gone to be saved. Hopefully fixing this WD will still end up being cheaper and faster than trying to fix up my stuck WD-45. I have seen references to WD-45 cranks breaking when pushed to higher HP with different sleeve/piston kits, so I can see 0.040" undersize being of concern there. I could be wrong but I would think a WD should be okay if I have to go that far with it to clean the journals up. I will defer to the machine shop like you did. On the overhaul kits, it looks like the cheapest ones are still over $600 with a lot of the cost being the piston/rings/sleeves. I can get a complete gasket set for $100, and rod, main, and camshaft bearings look like they'll be about $200 altogether. Of course if these sleeves don't clean up in spec then I would have to go for a kit. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: CTuckerNWIL

Date Posted: 03 May 2020 at 10:30am

|

Where do you find .040 under bearings? They almost have to be NOS, since I couldn't find any listed anywhere, when I was working on my CA. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: wjohn

Date Posted: 03 May 2020 at 3:33pm

All State Ag has them. I don't see any for the 116/125 CI engine, though. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 04 May 2020 at 9:51pm

|

The sleeves are worn right around 0.009" at the top of ring travel. My scan of the service manual says to replace them if worn beyond 0.01X" with the X being some digit I can't make out due to scan quality, but that's probably close enough to tell me that they're fairly worn. The existing rings also have a ~0.090" gap. I don't think I'll even try ordering new rings. Guess it's time for a complete overhaul kit. I did get ahold of a shop today and they said expect about $180 to grind the crankshaft. I need to drop it off and see if/what they can clean it up to so I know what size bearings to order. I'm a little bummed that nobody makes a 4" bore WC/WD overhaul kit anymore. Hopefully my compression ratio won't drop too much with the 4 1/8" bore kit that is mostly designed for the 226 engine. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 07 May 2020 at 8:41am

|

The crank is with the machine shop now. He thought it looked pretty good all things considered and we're hopeful it'll clean up at .030". I spent yesterday taking the head apart. There was a noticeable amount of play in the valves, but the stems all measured within spec. The guides did not, however, and I noticed that some of them had been knurled (haven't seen that in a long time). They pressed out without too much trouble. I may have to finish getting my Sioux 645L valve resurfacer put back together and finally learn valve and seat grinding. One intake valve seat is maybe a tad low (manual says valve should not sit below flush with surface of head). Has anyone replaced seats in these before? Could I do it myself?   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: Sugarmaker

Date Posted: 07 May 2020 at 12:44pm

|

John, I dont have the skills, knowledge to do the head work. I have to rely on a good shop to do the right thing. Good luck on your rebuild and please keep us informed. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: wjohn

Date Posted: 22 May 2020 at 6:21pm

|

Still waiting on the machine shop to grind the crank. You were right, Chris! I've been hunting down the bearings and seals I need. The transmission input shaft roller bearing has been a doozy but I think I finally have it tracked down thanks to a local bearing supply company. I did have a question for the group - the input shaft ball bearing with the snap ring on it that I removed had a shield on the rear (trans side) and was open on the hand clutch side. It was a New Departure 47510-2A. I ordered an equivalent of a different brand, but they shipped the wrong part number and it is shielded on both sides. I am thinking about prying off one of the shields so that it will have plenty of transmission oil for the rest of its life. Maybe the AC engineers had some reason to shield the trans side? Does anyone know if that's the original style of bearing, with a metal shield on only the trans side? (Wondering in case someone else replaced it before me...)   ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: CTuckerNWIL

Date Posted: 23 May 2020 at 5:53am

|

I would guess, that bearing was sealed originally, because the transmission was supposed to be separate from the hydraulic fluid. If it were mine, I believe I would remove both shields , and run Universal Trans draulic fluid in both side. No need to separate fluids, and no need to prevent them from mixing. The only consideration would be the actual level of fluid being equal in each side. ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: DrAllis

Date Posted: 23 May 2020 at 6:59am

| The shield was to keep metal chips out of it due to people grinding gears. Leave it in there. |

Posted By: wjohn

Date Posted: 23 May 2020 at 9:08am

Thanks, that makes sense. I am planning on leaving the shield on the trans side, but what about on the hand clutch/PTO side? The bearing I pulled out did not have a shield on that side and that is the side that I think I should remove from the new bearing, since it is shielded on both sides. I am thinking that side needs to be open for lubrication, and not too much chance of PTO gear chips making it all the way up there... If I did ever grind PTO gears when engaging. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 May 2020 at 9:10am

On a WD/WD-45 the trans and hand clutch/PTO compartment use the same gear oil. The hydraulic pump compartment is farther up (in front of the hand clutch/PTO) and is separated from the hand clutch/PTO compartment by 2 seals. ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: wjohn

Date Posted: 23 May 2020 at 9:28am

|

Here's a picture of the new bearing. It's shielded on both sides (ZZ) vs. one side (Z), like the one I removed. Just trying to confirm that the bearing I removed is original, and should only have the shielding on the trans side (single Z). If so I will remove the seal on the PTO side. Heck, even if I left the seal on the bearing it might last for 20 years, but I'd rather put in whatever AC intended.  ------------- 1939 B, 1940 B, 1941 WC, 1951 WD, 1952 CA, 1956 WD-45 |

Posted By: DaveKamp

Date Posted: 23 May 2020 at 9:58am

|

If you talk with your local bearing suppliers about it, you'll probably find that there's not many production runs of single-shielded bearings outside of factory-spec (OEM) production. This is because, at the replacement level, the application may require just one shield (or no shields) and it'd require three different parts inventory to satisfy all three possibilities, so instead, for field-replacement-application, the counter guy will order both shields, and simply remove the one (or let you remove) the one(s) to suit your application. This reduces inventory and manufacturing process cost, while giving the ability to cover all applications in one production run. Doc's note about gear-chipping is the biggest concern I'd have... as Charlie said, running same fluid in both resolves mixed-spit situations, and for the uses we put these through nowdays, and the changes of lubrication technology, there's little practical advantage to doing otherwise. Having debris migrate from one side to the other really wouldn't be a serious issue, the pickup wouldn't be likely to ingest any... but a chip of case hardened steel in that bearing would lock and spin it in a heartbeat. I'd match the old arrangement just for that reason... and I'd probably epoxy a magnet to every drain plug when I put it back together. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

garden_guy wrote:

garden_guy wrote: