CA Brake Mystery - UPDATE #5

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=158517

Printed Date: 27 Nov 2024 at 3:23pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: CA Brake Mystery - UPDATE #5

Posted By: Dave(inMA)

Subject: CA Brake Mystery - UPDATE #5

Date Posted: 25 Feb 2019 at 4:01pm

|

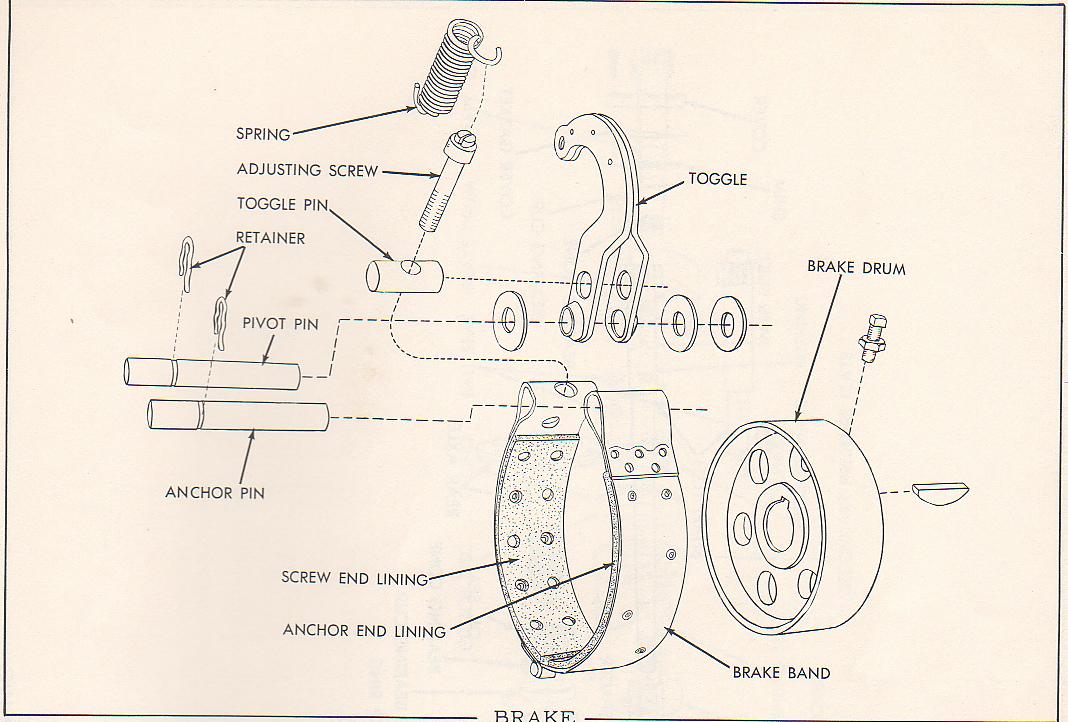

Update - see post dated 3-8-19. Update 3-6-19. See post dated today. Update 3-4-19. See post dated today about 7pm. Update 3-3-19. See post dated today. Here's an UPDATE on 2-26-19. I tested the brakes without the platform on the tractor. In 2nd gear, each brake would nearly stall the engine. I believe that this means that the platform is preventing the brakes from coming on fully. More when I know more. The brake bands in my CA were replaced a number of years ago. They are essentially still new. The adjusting screws are tightened to the point where the ends of the screws are hitting the bottom of the the openings in the brake bands and cannot be tightened further. When I apply the brakes, I'm getting almost no stopping power. Today I pulled the platform and disconnected one of the brake rods from the toggle/actuator. I jacked up the tractor final and applied the brake by hand by pushing on the toggle/actuator while turning the rear wheel. The wheel instantly stopped and I couldn't move it. I realize that I'm applying much less turning power than the engine, but this seems like a clue! I repeated the experiment with the other side but this time leaving the brake linkage connected and applying the brake using the pedal. Same result - the brake instantly locked up the wheel. I checked the brake drum surfaces - both are tarnished and show no indication of a brake band slipping on the drum. The question is: what could be causing the brakes to work with the platform removed but not when it's in place? Or is the test I did meaningless? Thanks for any advice on this. Dave

------------- WC, CA, D14, WD45 |

Replies:

Posted By: Jim.ME

Date Posted: 25 Feb 2019 at 4:42pm

| I've had to pull the linings out of my CA a couple times and clean/deglaze them. The were filled with rust and dust, no oil. Cleaned them with brake cleaner and a wire brush, then lightly scuffed them with a coarse emery cloth, then cleaned again before reinstalling. I cleaned the drums as well. Brakes were always fine after. Got to do it again before spring. |

Posted By: Dave(inMA)

Date Posted: 25 Feb 2019 at 4:58pm

|

Thanks, Jim. I may pull one of them and see what it looks like. But I'm still really puzzled about the test I described in my OP. ------------- WC, CA, D14, WD45 |

Posted By: Dakota Dave

Date Posted: 25 Feb 2019 at 5:08pm

| Put the platform back on and see if it stoping full movement of the brake lever. On dads C when we put it together th slots in the cover wouldn't let the levers engage far enough to actuact the brake. We cut the slots longer instead of finding out what we did. It has worked that way for 40 years. |

Posted By: Dave(inMA)

Date Posted: 25 Feb 2019 at 5:57pm

|

Very interesting, Dave. Glad to hear that I may not have lost my mind after all! I'm thinking that, before I put that goofy platform back on, I will reassemble enough to be able to drive the tractor and see if I really do have brakes w/o the platform. Thanks! Dave ------------- WC, CA, D14, WD45 |

Posted By: GregLawlerMinn

Date Posted: 26 Feb 2019 at 9:35am

|

Ditto on checking if the pan is interfering. Happened to me. ------------- What this country needs is more unemployed politicians-and lawyers. Currently have: 1 D14 and a D15S2. With new owners: 2Bs,9CAs,1WD,2 D12s,5D14s,3D15S2s, 2D17SIVs,D17D,1D19D;1 Unstyled WC |

Posted By: Dave(inMA)

Date Posted: 26 Feb 2019 at 12:48pm

|

Thanks, Greg. I've also thought of another possible cause. Both drums are scored - someone let the brake linings wear to the point that the rivets scored the drums. Perhaps the scoring has led to some wear of the drum surfaces, thus requiring the toggle to move further to apply braking power but the platform design doesn't allow the added travel? Comments welcome! ------------- WC, CA, D14, WD45 |

Posted By: Ted in NE-OH

Date Posted: 26 Feb 2019 at 1:19pm

|

Stopping the wheel with the tractor stationary and jacked up is one thing whereas stopping 2000 lbs of momentum is another. ------------- CA, WD, C, 3 Bs, 2 Gs, WC, I-400, 914 |

Posted By: Dave(inMA)

Date Posted: 26 Feb 2019 at 1:40pm

|

Totally agree, Ted. That's why I decided to run another today to see if the brakes would stall the engine with all 4 wheels on the shop floor. They would have done so if I let the clutch out fully. While not quite as good as testing on a slope with a loaded wagon on behind, this should be a lot more useful than the first test. Dave ------------- WC, CA, D14, WD45 |

Posted By: bradley6874

Date Posted: 26 Feb 2019 at 3:28pm

| Brake drums were so wore out from planting on our d17 that new shoes were almost out of adjustment as soon as installed replaced the drums adjustments were all the wAy out to keep from dragging might be time for drums on yours |

Posted By: Dave(inMA)

Date Posted: 26 Feb 2019 at 4:48pm

|

Worn drums makes a lot of sense - thanks. Though I've owned this CA for 10+ years, I don't know how it was used before I bought her. I know that I replaced the brake bands because the old ones were worn badly, so could have had a lot of wear and tear on the drums. so I am going to suck it up and replace them! Just ordered a drum for the left side. I've got a rhs drum on the shelf. It's used but you'd never know it....can't buy them new but this one was advertised on here years ago so I bought it thinking I might need it. My bride says that it's good to think ahead.....you never know when you'll need one.  Thanks for the help thus far. I'll post some updates as I get into this. I'm sure it's harder than it looks - nothing simple is ever easy! Dave

------------- WC, CA, D14, WD45 |

Posted By: Dave(inMA)

Date Posted: 03 Mar 2019 at 5:11pm

|

Got into the left side today. I now know why that brake wasn't working very well! Removed the tire, including the center, then pulled the final drive unit off. [Note to file - next time, drain the rear end before blocking access to the drain plug with dunnage! Ended up draining it through one of the lower final drive stud holes, thereby avoiding dumping oil all over the floor.] Here are a couple of pictures of what I found. Look closely at the drum, especially the 1/4" or so closest to the housing which is the part of the drum NOT worn by the brake band. Not only is the drum scored but the area scored by the brake band is worn down close to 1/8". The brake band is trash - the hinge was frozen and the lining was broken in a couple of places - more now that I wrestled it out of the housing!

The next step was to try to pull the drum. Hah! No good way to get a wrench in there to loosen the lock nut on the locking bolt. Decided to consult with Don(MO) who advised me to destroy the drum with a good sized bar and a BFH if I can't get the bolt loose. This will give me room to get at the lock nut and bolt. He warned me to be careful to not hit the final drive housing while destroying the drum. I will need to find both tools before proceeding! ------------- WC, CA, D14, WD45 |

Posted By: DennisA (IL)

Date Posted: 03 Mar 2019 at 5:35pm

|

Sorry I seen this so late. On my CA the drums were worn down . I take them to a fab shop where they spayed welded them and turned them true. Been working great ever since. ------------- Thanks & God Bless Dennis |

Posted By: Dave(inMA)

Date Posted: 03 Mar 2019 at 5:39pm

|

Nice idea, Dennis. Thanks. If only I could get at the *&%#$ lock nut to remove it! If you have a magic way to do that, please let me know!! ------------- WC, CA, D14, WD45 |

Posted By: steve(ill)

Date Posted: 03 Mar 2019 at 5:44pm

|

Is the CA different than the C and B ?? On the others, there is a 1 inch hole ON THE BOTTOM OF THE CASE, that you can use an extension and 8 point socket to get onto the retainer bolt / lock nut for the drum ?? ------------- Like them all, but love the "B"s. |

Posted By: Dave(inMA)

Date Posted: 03 Mar 2019 at 5:51pm

Steve - I think you are right! I'll check tomorrow (once we clear away the latest snow storm). That would be a happy result.  Now, why didn't I think of that?!!? Now, why didn't I think of that?!!?------------- WC, CA, D14, WD45 |

Posted By: jaybmiller

Date Posted: 03 Mar 2019 at 5:53pm

|

HMM.. thinking out loud here.. about the nut. I don't have my CA anymore to look but..humour me... Can you get some kind of wrench,or bar, or 'locking device' onto the nut, firmly ? Then rotate the pto or starter ,in gear , to spin the axle ? Obviously you gotta plug the plug wires , well the main coil one !!! My idea is to keep the nut solid or fixed, then turn the shaft.... think 'backwards'. I've done this trick on other stuff. Maybe someone will see if it's possible. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dave(inMA)

Date Posted: 03 Mar 2019 at 5:59pm

|

Jay, this bolt (and its locking nut) are perpendicular to the pinion shaft - and the final drive is off the tractor. But nice thinking outside the box! ------------- WC, CA, D14, WD45 |

Posted By: jaybmiller

Date Posted: 03 Mar 2019 at 7:13pm

|

OK....any pictures? Now I'm thinking HD mode.. can you get a socket onto the nut and bolt ? If so ,great... make this adapter.. socket is on 3" extension that has a sproket welded on. It turns on a long piece of 1by1 tubing. Chain couples that sprocket to another mounted the 'top end', It works as follow you put rachet on top sprocket, when you turn the rachet, the sproket turns the chain that turns the lower sprockt that turns the socket that turns the nut, and it falls off. HD guys us them to build the engines, seen that on TV ! If you put a piece of maget in the socket, the nut will stay in the socket. Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Grwhthunter

Date Posted: 03 Mar 2019 at 8:07pm

| Dave I just did one a couple weeks ago. Did use a socket and extension through the hole. Slow steady even pressure and it came out. I soaked it with penetrating oil first. Since it is impossible to remove the drum without damaging it even with the long puller(trust me I tried) I used a cutoff wheel and carefully cut it. Had to finagle it around as you don’t have a lot of room. DIDNT cut all the way through then spun it and cut almost through again opposite of first cut. I cut all the way through until there was a paper thickness left. Broke off outer drum as I went. Then used a chisel to break it off. Might not be the correct way but that’s how I did it without damaging anything else. Wasn’t as bad as I thought. I wish you luck on it. Ray |

Posted By: Dave(inMA)

Date Posted: 03 Mar 2019 at 9:03pm

|

Jay, I think you oughta make one and post pictures! Ray, I've been thinking about how I will convince that drum to move on the pinion shaft once I get the bolt out. I don't have any sort of puller that could reach all the way from the end of the shaft to the drum, so if the drum won't move with some leverage applied through the holes in the housing, I'll still have to destroy the drum to get it out. Don(MO) mentioned using a cutoff wheel, too. So that may be the way I go. We'll see! ------------- WC, CA, D14, WD45 |

Posted By: Gerald J.

Date Posted: 03 Mar 2019 at 9:08pm

|

Shop manual might help: http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf" rel="nofollow - http://geraldj.networkiowa.com/Trees/Allis-Chalmers-G-B-C-CA-Service.pdf Gerald J. |

Posted By: Grwhthunter

Date Posted: 04 Mar 2019 at 5:32am

ok so I got to work and I remembered that after I had cut some relief cuts I also had to drill some holes to get the air chisel started. Here are some pics of my carnage. I then used a 1 inch dowel rod 2 feet long to start to pound it out. I hope this helps you. Ray ok so I got to work and I remembered that after I had cut some relief cuts I also had to drill some holes to get the air chisel started. Here are some pics of my carnage. I then used a 1 inch dowel rod 2 feet long to start to pound it out. I hope this helps you. Ray

|

Posted By: jaybmiller

Date Posted: 04 Mar 2019 at 6:10am

|

gee Ray that's really,really sad it came out that way... even sadder is it sounds like MOST of them come out the same.... Can't a 'puller' be attached? If so I'm thinking of 2 half moons of 1/2" thick plate with 3 , 1/2" threaded holes to go 'behind'. then insert 6 allthreaded rods , then slide the 'pulling disc' on and add 2 washers and a nut to each rod. tighten the nuts 1-4-2-5-3-6 (like replacing a rim),evenly. The trick is the 2 halfmoons must fit agin the inner boss next to shaft, for max pulling pressure. Also having SIX rods keeps the pulley from deforming as it does with a 2 or 3 'jaw' puller Sure looks like a nasty job and ,sigh, there's the OTHER one to do afterwards. Can you use 'neverseize' on them during the install ? I do that with drive pulleys/ E-PTOs of riders cause there is ZERO clearance to get ANY kind of puller to get them off !! ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Dick L

Date Posted: 04 Mar 2019 at 6:19am

I have pressed the pinion shaft out of the drums with this setup on B's and C's. I have not pressed any pinions out of the CA's. I would think it would be the same as the C's on the inside.

|

Posted By: Grwhthunter

Date Posted: 04 Mar 2019 at 6:41am

| Jay I did try to use a long puller but was only a 3 rod. It didn’t even budge it only started cracking the drum where it was attached. The drum was I think a original from 1955. I read somewhere on here it wouldn’t come out that way. They said don’t use heat as it would ruin seals. I did use some heat with map gas and tried to soak it too. That’s when I broke it as was suggested on here from a previous post. Dick the ca is the same I just don’t have a press setup at work like that. Just a small one. I seen your setup on that other post I think and wished I had that. I did never-seize everything when I put it back together including those big pins. People think these brakes are hard to do and I agree. The ford 800 series with the heat collar seals are about the same pain if you ask me. The have to be drilled out and broken to be removed also when doing a complete brake and seal job. But that’s how the book and dealers tell you to do it. Ray |

Posted By: Dave(inMA)

Date Posted: 04 Mar 2019 at 6:52am

|

Thanks for all the suggestions, guys. This forum is indeed the best! Carnage would certainly be the right word for it, Ray! Thanks for your pm's and the photos. I expect that I'll end up with a similar result. I'll take some pictures. Jay, your idea sounds like it should work. It'd have to pull against the inboard end of the pinion shaft, though, and maintaining alignment might be tricky. BTW, the good news is that the drum is part of the clutch assembly on the rhs. I've had that out before....all I gotta do is remember how I did it, but I know the method was different from the lhs! Yup - I decided to start with this one cause it'd be easier, ya know....... Dick - thanks for the photo and suggestion. Yes - this is the same as the B or C on the lhs. Did you pull the bearing before starting erto press the shaft out, or did the bearing pop out as you pressed the shaft? Gerald, thanks. I read that section before starting on this project. Unfortunately it doesn't explain how to pull the drum! ------------- WC, CA, D14, WD45 |

Posted By: Sugarmaker

Date Posted: 04 Mar 2019 at 7:56am

|

Wow, This site brings out the best and worst in maintaining these old tractors! I am sure this will help many others avoid hours of frustration on projects like this. Havent attempted brakes yet on the WD45. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dick L

Date Posted: 04 Mar 2019 at 10:56am

| The tapered bearing just sets in the tapered cup. You tighten that bearing by removing shims behind the cover to let the cover push the bearing tighter in the cup.. |

Posted By: Dave(inMA)

Date Posted: 04 Mar 2019 at 5:55pm

I have won the battle! Old drum is off, new one on.  I created carnage as have others - broke off enough of the drum to give me access to drive it off with an air hammer. Discovered something that made the job a lot easier: the pinion shaft diameter between the drum and the end that engages the differential is smaller than the diameter where the drum sits. So, once it's driven off that section of the shaft, the drum is loose and can be removed with one finger. I haven't measured the old drum diameter to see how much material had been lost. Will do that tomorrow. Here are a couple of pictures. First, the old drum out of the housing:  And the new drum in place on the shaft. I used a piece of oak stake (1"x1") to drive it on:  Thanks to all of you who have contributed to this happy outcome! Dave ------------- WC, CA, D14, WD45 |

Posted By: Grwhthunter

Date Posted: 04 Mar 2019 at 6:33pm

|

Good job !! I’m glad you got it done. Yeah I forgot that part to about the tapered shaft. I was relieved when I hit that point too and it just slid off. Ray ------------- 1949 B 1949 WD 1950 WD 1953 WD45 1955 CA 1957 D17 1975 Gleaner K corn & soybean special 1959 D14 1970 160 assortment of snap coupler implements and my best friend my beautiful Wife Linda |

Posted By: DennisA (IL)

Date Posted: 04 Mar 2019 at 6:47pm

|

Wow, I must have been very fortunate. Both of mine came off with a fight but they came off in one piece. ------------- Thanks & God Bless Dennis |

Posted By: Dave(inMA)

Date Posted: 04 Mar 2019 at 7:45pm

|

Ray - thanks for sharing your methodology. Dennis, I think there's a chance that I could have gotten the drum off without the carnage. Had I known about the tapered shaft, I might have given it a try. But I was thinking that I would have to drive the drum all the way off - I was really surprised when it came loose once off its location on the shaft. The key, either way, is being able to drive the drum toward the rear end with the air hammer. In this case it's not a real loss as the drum was so badly damaged by the worn out brake band that was on the tractor when I bought it. We'll see how the next side goes! Dave ------------- WC, CA, D14, WD45 |

Posted By: DennisA (IL)

Date Posted: 04 Mar 2019 at 8:35pm

|

You might want to put on some anti-seize. You may need to remove it again sometime down the road ------------- Thanks & God Bless Dennis |

Posted By: Dave(inMA)

Date Posted: 06 Mar 2019 at 9:06pm

|

Took some measurements of the old drum. The original diameter was 6"; the wear is about 1/16" all around the drum. So the diameter under the brake band was 5.875". The 0.125" reduction in diameter equates to about a 0.4" reduction in the circumference of the drum. The only way to compensate for that was to tighten the brake band. It seems to me that offsetting the lost 0.4" would soak up a fair amount of the available adjustment. I'd be interested in other opinions! The left final drive housing and tire are back on the tractor. I'm waiting for new brake bands to arrive to see how much tighter the band is with the new drum. I'm set up to start working on the right side. Stay tuned! Dave

------------- WC, CA, D14, WD45 |

Posted By: Dick L

Date Posted: 07 Mar 2019 at 6:40am

|

I would have to see what was going on with my own eyes to understand what is/was going on. I have turned/sanded the drums until the grooves were gone and the brakes with new bands worked as well as the brakes work on this setup. They are never going to lock down like your car. It might be in the pin in the band end. When you put new bands on the tightening screw will seem to be to short until the bands take on the shape of the drum. They then will need tightening again. To get the band down thru the top they get straightened out quite a bit. Another reason I liked to change the brake bands thru the big hole with the final drive off. More room to work and you don't have to flatten the old rusty bands or the new bands. I wonder the condition of the toggle?

|

Posted By: Dave(inMA)

Date Posted: 07 Mar 2019 at 7:34am

|

Dick, the braking power on this tractor was almost non-existent. I couldn't hold the tractor on a slight grade. It's flat dangerous, especially here in New England. I think the lack of braking power is a combination of factors: the drum surface was scored noticeably, dating back to the bands that were on the tractor when I got it; worn drum surface; hinge in brake band frozen. The toggle seems to be fine - no slop on pivot pin nor the toggle pin. The brake band lining wasn't worn much, though it was cracked in a couple of spots - perhaps from being straightened to insert it? I like your idea of installing the band with the housing off the tractor. Wish I'd thought to do that! I could always pull it off again......the challenge is handling the tire which is loaded. Thanks for your questions and suggestions. I really appreciate having your experience on this project! Dave ------------- WC, CA, D14, WD45 |

Posted By: Steve in NJ

Date Posted: 07 Mar 2019 at 7:37am

|

Dave, Hope you antiseized the shaft and the drum before installing the drum just in case ya need to get back in there in the future. When I did my B, I antiseized everything that went together and or had threads on it! LOL! In my case, I don't have enough a$$ to get some of this stuff apart!  mailto:Steve@B&B" rel="nofollow - Steve@B&B ------------- 39'RC, 43'WC, 48'B, 49'G, 50'WF, 65 Big 10, 67'B-110, 75'716H, 2-620's, & a Motorhead wife |

Posted By: Dave(inMA)

Date Posted: 07 Mar 2019 at 9:28am

|

Steve, should have done so but I didn't. However, I'm expecting this drum to last for way longer than the modest wear and tear I'll put on it. So maybe I just created a problem for the next guy that owns this tractor?!!? I'll do better on the other side. Dave ------------- WC, CA, D14, WD45 |

Posted By: Dick L

Date Posted: 07 Mar 2019 at 5:00pm

|

If I remember right there might have been two lengths of the screws or different lengths of threads on the screws. I am so dang old and the memory is getting so bad. At one time I could have knew quite a it about this stuff. Or not! I have forgot so much lately it is hard to tell how much I might have known. |

Posted By: Dave(inMA)

Date Posted: 08 Mar 2019 at 1:30pm

I'm happy to report that the left hand side brake is done. The band slid right in, assisted by a length of wire I ran around the drum and attached to the pin bore at the end of the band. I didn't have to deform the band at all. Here's a shot of both ends of the band pinned to the housing and the toggle, respectively: Installing the retracting spring was lots of fun, but it got done. I haven't done final adjustment on the band yet - need to be able to drive the tractor for that. But with the adjusting screw set much looser I can barely turn the wheel, suggesting that braking power should be much improved. So, on to the right hand side! Contrary to my experience 10+ years ago, the drum slid right off the drive shaft so that the housing was easy to remove. And the clutch came off the pinion shaft with no work! I'm including a shot of the drum so you can see how scored it is. The replacement drum isn't perfect, but it's a ton better than this one!  Thank you to everyone who chimed in on this project. Everyone's experiences helped. Dick, I have no evidence as to whether there were two different adjusting screws, but the ones in my tractor are not threaded all the way to the head. I'm going to start a new thread on the clutch repair as this one is getting a little long - though it can't hold a candle to Chris's WD45 project thread!

------------- WC, CA, D14, WD45 |

Posted By: Dick L

Date Posted: 08 Mar 2019 at 4:58pm

| Fantastic! |

Posted By: Grwhthunter

Date Posted: 08 Mar 2019 at 7:24pm

|

That thing looks threaded !! Good job on getting the right side off. Glad it went easy for you. That spring is a real test to get on. I haven’t started my right side yet got a couple things that needed fixed pronto. Will be doing it in a couple days. I hope it comes off easier. Keep us updated when you do get it going and do final adjusting. Ray ------------- 1949 B 1949 WD 1950 WD 1953 WD45 1955 CA 1957 D17 1975 Gleaner K corn & soybean special 1959 D14 1970 160 assortment of snap coupler implements and my best friend my beautiful Wife Linda |

Posted By: Dave(inMA)

Date Posted: 08 Mar 2019 at 7:36pm

|

Yup, the drum took quite a beating at some point. I'll report back after I get the brakes adjusted. Thanks again, everyone. Dave ------------- WC, CA, D14, WD45 |

Posted By: Ted J

Date Posted: 09 Mar 2019 at 5:04pm

|

There HAS to be some kind of a trick to putting that spring on. When I do mine this summer, maybe I'll find one,,,,,,,,,,,,,,,unless someone else HAS a trick to it. I've got the brain cells spinning already thinking about it........ ANYBODY?? ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: pickup

Date Posted: 09 Mar 2019 at 7:06pm

| On my CA. I doubled the brake lining on brake bands. To take up the wear on the brake drum. |

Posted By: Dave(inMA)

Date Posted: 09 Mar 2019 at 9:21pm

|

Ted, i did the spring this way: inserted it through the toggle and hooked it over the the adjusting screw. Then I reached down inside the front of the brake housing with a long thin screwdriver and pushed the hook end out into the slot. Finally, I pried the hook the rest of the way through the slot. If there's a better way, I'd love to hear it! Dave ------------- WC, CA, D14, WD45 |

Posted By: Theriault

Date Posted: 03 Jul 2024 at 9:11am

| The issue is that the break lining is approximately 1/4 of an inch too long around the circumference of brake drum as new. It gets worst as the lining and drum worn-out. The excessive length reduces the usable life of liner and drum. When reachimg wear limit, the screw end of the band is touching the toggle, preventing the lining to clamp the drum. |

Posted By: PaulB

Date Posted: 03 Jul 2024 at 3:14pm

|

Over the years I've come across a few NOS B,C,CA brake reline kits that the lining was extra thick. I know I've never used them as the normal ones always worked just fine for any brake job I ever did. Now the question is: where are they stashed? ------------- If it was fun to pull in LOW gear, I could have a John Deere. Real pullers don't have speed limits. If you can't make it GO... make it SHINY |