Front Crankshaft Seal

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=156844

Printed Date: 13 Nov 2024 at 12:40am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Front Crankshaft Seal

Posted By: Allis Wd45

Subject: Front Crankshaft Seal

Date Posted: 01 Jan 2019 at 4:06am

|

The Front Crankshaft Seal and oil pan gasket are Leaking on my WD45. What all has to be taken off to replace the front main seal. How do you remove the old seal when you take the timing cover off? What all has to come out of the governor? How do you take it out and keep it in time? Can the seal be replaced with the timing cover on the tractor. I’ve read in other forums that you have to have the seal centered on the Crankshaft how do you do that? Also how do you remove the timing cover from the front engine support? Do you have to jack the engine up when you unbolt it from the support? Thanks for the help. I want an idea of what I need to look for before I tear into the engine. |

Replies:

Posted By: WF owner

Date Posted: 01 Jan 2019 at 4:48am

|

Do yourself a favor. Remove the engine and put it on a stand to do the replacement. It sounds like a lot more work, but it will be much easier in the end. Here's a link to a video that Don Bradley did. He is a very well respected AC mechanic that posts on here. It can be found in the Knowledge Base Section of the forum. I think the video will answer all your questions. https://www.youtube.com/watch?v=9LWCMvO_Dis&feature=youtu.be" rel="nofollow - https://www.youtube.com/watch?v=9LWCMvO_Dis&feature=youtu.be

|

Posted By: Allis Wd45

Date Posted: 01 Jan 2019 at 12:26pm

| Ok if it’s going I require the engine to be pulled I’m going to leave it a lone. I don’t want to get that far into it. |

Posted By: Sugarmaker

Date Posted: 01 Jan 2019 at 1:45pm

|

I understand about pulling the engine too. I did two of these per Dons instructions standing on my head. Both reduced the leaking in the front but I still have some rear seal issues. Its not easy to do in the tractor but not impossible. I spent time making sure the pan was straight when it went back on. Used the clips for the front seal. Didn't cut any seals, put a little sealant only where recommended, used the "F" shaped gaskets at the rear. Also made and used the pin guides to help position the pan on re assembly. Took me several days. Also made some plates to support and align the pan gaskets while the got set up. To do the front crank seal you need to take the radiator and sheet metal off. (That is almost as much work as pulling the engine.) You have to remove the hand crank assembly IIRC? Anyway with that off, and the crank pulley off. you can remove the front crank seal. A seal puller works good. You might consider a speedy sleeve on the crank to cover the spiral grooves which were for the old felt type seals. The new seal will probably be a rubber lip seal type. Guys jump in and correct me here, its been a few days since I put one in. Now that I think about it you may need to pull the front timing cover and then put the speedy sleeve on? That may be why one of mine is leaking? Bottom line is there is not a real quick and easy fix for these leaks. By the time you have all this stuff off the tractor and engine. I think you have about 4 bolts and some linkage to remove and the engine can come out and be rolled upside down and or much better access to the crank, to do this work in a better easier fashion. Sorry for being long winded. Maybe it helps? I have one that is going to leak a little till someone in the future tears it apart. I have a bunch of pictures if it would help you?    Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DrAllis

Date Posted: 01 Jan 2019 at 3:06pm

| When I know I'm going to do oil pan gaskets on one of those, I plan ahead. I place the arch gaskets inside a piston ring compressor for a few days to make them take shape. Have the ring compressor set small enough that the gasket ends just touch. Use fresh 3M brand #8001 yellow weather strip glue and attach the side gaskets to the engine and let dry. When pan installation time comes, clip the arch gaskets on the pan after lightly rubbing RTV on both sides of them. Lightly rub the same RTV all over the side gaskets and leave a daub at the 4 places each of the arch gaskets will touch. Use a speed handle to gently and slowly snug up all the pan bolts drawing them down evenly. I never get too tight on any pan bolt and let things cure overnite and them give all the bolts an extra tweak in the morning. Having the side gaskets already securely glued to the engine makes this job easy and leak free. |

Posted By: Allis Wd45

Date Posted: 01 Jan 2019 at 5:48pm

| Chris, would I have to buy the new seal retainer clips or can I reuse the old ones? It looks to me like there is something between the oil pan and bolts on the side rails. |

Posted By: Sugarmaker

Date Posted: 01 Jan 2019 at 6:54pm

|

Allis Wd45, I didnt have any used clips. So I had to get new ones. Maybe Don or Dr Allis could comment. I think If I had used ones and they looked good and not deformed that they should work as good as new ones. I mean these are only a aid to keeping the front gasket in place while you lift it in place. So that it doesn't get out of location. Not sure what you mean by something between the oil pan and bolts on the side rails.?? Oh I think I know what you mean there is a reinforcement piece/ strip on the pan. Lets see if I have a picture?  This stiffiner is welded to the oil pan.  Good idea to re-flaten any bolt hole area that has been over torqued and dimpled in towards the engine. Dr. Allis has a good method and I used similar techniques to adhere the side gaskets to the block first. Here is how I preformed the end gaskets.  This may be a little tough to see but I built a plate with same hole pattern as the pan this clamped the gasket to the block while the Indian head gasket material dried and held the gasket to the block. Also note the two guide pins to help align the pan during assembly.  Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 01 Jan 2019 at 8:50pm

| Chris, I will post a picture of the oil pan. I believe I am thinking of the reinforcements that are welded to the pan. Do you just use a soup can to form the end gasket size or how big is the can? |

Posted By: SteveM C/IL

Date Posted: 02 Jan 2019 at 8:57am

| ...round with ends touching....find your can (or that ring compressor |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 9:23am

| I use a Campbell's soup can (I also use the same cans for exhaust covers). I NEVER throw out one of those cans! |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 11:27am

| Ok Sounds good. I was looking at the reinforcements that are welded to the pan edges. |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 3:58pm

| The gasket at the end of the distributor housing next to the coil is also leaking. If I replace this gasket will anything fall out or fly across the shop? |

Posted By: Alvin M

Date Posted: 02 Jan 2019 at 4:11pm

| no |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 4:40pm

No, but before you remove anything, take the distributor cap off and mark where the rotor is pointing with a permanent marker. If you don't turn the engine over while you have it out, it will be very close on the timing when you reinstall the distributor. The best way would be to have it a TDC on the compression stroke when you take it apart. The rotor will be pointing to the #1 cylinder plug wire. It shouldn't be leaking very much because there should be very little oil in the governor.

|

Posted By: Sugarmaker

Date Posted: 02 Jan 2019 at 5:17pm

|

Allis Wd45, As mentioned nothing will fly out of the back end of the distributor housing. You don't even have to pull the distributor if you dont want to. Find a gasket in a piece of sheet material. Maybe some sealer on both sides and your good to go. Mine was very gunked up in there. The distributor gears need some amount of oil/lube. My can was a cherry pie filling can!  You going to do this project?? You going to do this project??Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 8:55pm

|

Sugarmaker, Yes! I am going to do the oil pan gasket. I think I will leave the front crank seal a lone for now though. Aaron |

Posted By: Sugarmaker

Date Posted: 02 Jan 2019 at 9:03pm

|

Arron, If it will help I have about 50 pictures during mine. Some pictures might help? Let me know. Many other folks on here that can help along the way too! Now that I think about it. Both WD's have threads on here, But it might take a while to find what you need!:) Good Luck. Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 9:24pm

| Make sure you have an AC Shop repair Manual (not IT) and go step by step |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 9:41pm

|

I don’t have a shop manual maybe I should buy an AC Shop manual. I got the pan bolts loose. But I can’t get the pan off. I don’t want to bend it or dent it. I think the gasket is just stuck to the engine. Aaron |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 9:54pm

| I think you can still buy original shop manuals through AGCO. You can buy a reproduction from JenSales. |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 9:59pm

|

Where is the best place to get the gasket at? I’ve been looking at Steiner’s gasket. But it looks like it’s black in color where the other ones are a light brown like cork. Also there are 4 end gasket pieces shouldn’t there just be 2? Aaron |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 10:04pm

| OK Tractor, DJ's Tractor or Tony's Tractor (all forum sponsors) all have good quality parts. |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 10:06pm

|

Ok, there are 2 shop manuals on Amazon. One says by AC and had 96 pages and is $22. Another one is by all states ag parts it has 196 pages and is $58.90. Which one is the better one? I assume the All states Ag one. |

Posted By: WF owner

Date Posted: 02 Jan 2019 at 10:10pm

|

Here are some other choices: https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2380057.m570.l1312.R1.TR10.TRC2.A0.H0.XAllis+Chalmers+.TRS2&_nkw=allis+chalmers+WD+service+manual&_sacat=0" rel="nofollow - https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2380057.m570.l1312.R1.TR10.TRC2.A0.H0.XAllis+Chalmers+.TRS2&_nkw=allis+chalmers+WD+service+manual&_sacat=0

|

Posted By: WF owner

Date Posted: 02 Jan 2019 at 10:12pm

| Make sure you don't order a CD (unless that is what you want). |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 10:22pm

|

Thanks. I definitely do not want a cd. Can’t take it out to the shop and look at it while I’m at the tractor. Thanks |

Posted By: Allis Wd45

Date Posted: 02 Jan 2019 at 10:41pm

| Well I got the pan loose, but it is hitting the front engine mount. Can I wiggle it around and get it out or do I have to remove the engine support. If I do where do you jack the engine up at? |

Posted By: Stan IL&TN

Date Posted: 02 Jan 2019 at 11:37pm

|

You can remove the support and no need to jack the engine up. The support may have thin shims so be sure to not lose them as these will need to go back in place after you are finished with the pan gasket. ------------- 1957 WD45 dad's first AC 1968 one-seventy 1956 F40 Ferguson |

Posted By: Allis Wd45

Date Posted: 03 Jan 2019 at 3:10am

| Ok after I posted that I went and looked at some past threads and seen someone comment the same. Thanks |

Posted By: Allis Wd45

Date Posted: 03 Jan 2019 at 3:11am

| Chris, Yes! If you have pictures that would be awesome. Thanks, Aaron |

Posted By: Sugarmaker

Date Posted: 03 Jan 2019 at 1:03pm

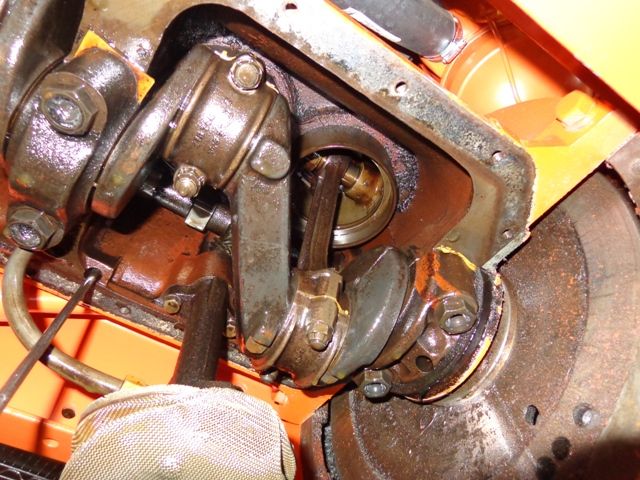

|

Aaron, Some shots of various things that might help. And yes that engine support need to come out. I just loaded up a bunch as I started the project. Hard to know what may or may not help you. No magic here.                 Some of these show the old sealing material and gasket in place when I first pulled the pan. Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Sugarmaker

Date Posted: 03 Jan 2019 at 1:12pm

|

Aaron, Pan clean up  Alignment pins    Trial fit          Hope this helps a little. As mentioned Don(MO) has a good video on this work. That is what i used as a guide too. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Sugarmaker

Date Posted: 03 Jan 2019 at 1:43pm

|

Aaron, Careful what you ask for!:) I found the pictures from the other tractor maybe these will help too? Guess I dont have any pictures of the rear main seal and "F" gaskets" under the rear main cap?? Maybe I was dreaming it?:) Total front end was off this tractor, including frame rails and pedestal too.   This is a good shot of the front crank seal too. I had put a Speedy sleeve on the crank prior to the timing cover going on. You have to make sure the timing cover is aligned with the crank too.     Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Don(MO)

Date Posted: 03 Jan 2019 at 1:52pm

|

Here's my video on pan/front and rear main seal replacement. hope it helps.Don http://www.youtube.com/watch?v=9LWCMvO_Dis&feature=youtu.be" rel="nofollow - http://www.youtube.com/watch?v=9LWCMvO_Dis&feature=youtu.be ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Allis Wd45

Date Posted: 03 Jan 2019 at 7:30pm

|

Sugarmaker, I ordered the gasket set through Napa today. I need to order the gasket retaining clips. I also picked up some Lion gasket Shellac. When you put the gasket on do you use the shellac on both sides or RTV. Also can the F gaskets be changes when the engine is in the tractor or do you have to pull the engine. Aaron |

Posted By: Sugarmaker

Date Posted: 03 Jan 2019 at 8:39pm

|

Well, I know I put them in both the tractors with out pulling the engine. Rear main cap has to come off. Watch for shims and their location. And then re-torque main cap after seal and gaskets. (I believe this is correct, just having a mental lapse, guess it could be because I am a year older today?:)) Dons rear seal replacement should show that. I may have to go look too, as I will have to do another one of these this spring. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 03 Jan 2019 at 9:52pm

|

Chris, Happy Birthday! By the way thanks for the pictures. The Napa gasket set shows 3 end pan seal pieces in the picture shouldn’t there be 4? 2 different sizes. Which does the wd45 use the wider one or the thinner one? Aaron |

Posted By: Allis Wd45

Date Posted: 03 Jan 2019 at 10:04pm

|

Chris, which agco front main seal is the correct part number? There are 2 in there part book one is 70229229 which says use before SN 289000 the other is 70226620 which says use after SN 289000. Which one is correct? I assume be serial number it means the tractor Serial number not the engine serial number. Thanks Aaron |

Posted By: Sugarmaker

Date Posted: 04 Jan 2019 at 8:57am

|

Yes I would assume tractor serial number too not engine. (Just a note if you work on enough of these you may find that the tractor has been repaired and have a different rear with different serial number). I don't remember if I even ordered the seal from AGCO? I may have just orderd a lip seal from my local bearing company, based on dimensions? Don(MO) Or Dr Allis may have the AGCO part number available. I am pretty sure some of the original seals from the factory were of a felt type and I am really not sure they are still available? Guess I am not able to help you much on this one without doing some digging!:) Aaron, You lost me on the NAPA gaskets and combo? I think you should have 6 pc fo rthe oil pan gasket change. 2 for the ends (following the round shape) 2 flat ones for the sides and then the 2 "F" gaskets. Its been a wilie and I did not get mine from NAPA. I got mine from Sandy Lake. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 04 Jan 2019 at 11:17am

|

I’ll wait till I get it apart and then get a number off the seal. The NAPA set has 2 side gaskets 3 end gaskets 2 f gaskets and the rear main seal. Aaron |

Posted By: Sugarmaker

Date Posted: 04 Jan 2019 at 12:15pm

|

Aaron, Sounds good on the gasket set from NAPA. I know you can call several of the suppliers on here and get the crank shaft seal. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 04 Jan 2019 at 8:39pm

|

Ok, I got the crank pulley off and I can’t see any numbers on the seal. It is a rubber lip seal. I assume that’s what I want to put back since they probably seal better than felt seals. Also, can I get it out with a screwdriver or should I buy a seal puller. Or remove the timing cover. Thanks for all your help Aaron |

Posted By: DrAllis

Date Posted: 04 Jan 2019 at 9:01pm

| 289000 is an engine serial number. They never made that many WD-series tractors in total, somewhere around 235,000 or so. There were always more engines made than tractors for gen-sets, merry-go-round engines, etc. |

Posted By: Allis Wd45

Date Posted: 04 Jan 2019 at 11:07pm

|

DrAllis, Thanks I got the seal out I used a paint can opener bent it straight put it inside the seal clamped a pair of vise grips onto it. Tapped them with a hammer it came right out. I dont see any numbers on the seal. But according to Steiner there seal part# ABC1996 is a rubber lip seal and will work before SN 269166 you just dont reuse the seal retainer. Which means it should work on my tractor since it didnt have a retainer. There don’t seem to be any grooves wore into the Crankshaft. Is it better to replace the seal with a rubber lip type or a felt? Aaron ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 05 Jan 2019 at 1:43am

|

I also noticed that the governor linkage going into the governor has some play in the bushing and looks to be leaking a little oil. How hard is it to replace the seal and bushing there. Do you have to remove the distributor to replace the bushing? I’m not sure 100% but it looks like the timing cover may be seeping a little also. Aaron ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Don(MO)

Date Posted: 05 Jan 2019 at 7:46am

If you are going to work on the bushings in the front cover the cover will need to come off first.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Sugarmaker

Date Posted: 05 Jan 2019 at 7:48am

|

Aaron, You are setting your self up for pulling this engine! I seen your thread on oil pressure too. The bushings for the cross shaft in the front cover can be changed but I think you may have to pull the cover. I did replace a set in one tractor. Good job getting the seal out. I didnt think you would find numbers. New seal will be a rubber lip type. Distributor can stay in place when you remove the front cover. Sounds like its leaking in all the right places too!:) Good time to do these projects! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: WF owner

Date Posted: 05 Jan 2019 at 9:19am

| I still say that pulling the engine is actually the easier way to fix the oil pan leaks. If you do pull it, you will be amazed how easy it is and how much easier it is to work on the engine. It's also easier to put just the engine into a clean heated place to work on it! |

Posted By: Don(MO)

Date Posted: 05 Jan 2019 at 9:25am

X2. I'd remove the engine too if you are going to stop all the oil leaks. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Ted J

Date Posted: 06 Jan 2019 at 5:27am

|

The more of these I read, the more I DON'T WANT to pull mine. Heck, it's a work tractor, not a show piece. MAYBE,,,,,,,some day. ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: Allis Wd45

Date Posted: 06 Jan 2019 at 1:50pm

|

TedJ mine is a work tractor and kind of a show tractor. We’ll see how it goes back together. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 06 Jan 2019 at 1:52pm

|

Another thing I’ve noticed is the tractor never has gotten the temp guage into the green area. Even when baling hay when it’s 90 degrees out. It normally runs at about 160 degrees. Is that ok or would it be better to put a 180 degree thermostat in? What issues could be created by putting in a hotter thermostat? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 07 Jan 2019 at 5:47pm

|

I don’t understand what you guys mean by centering the timing cover on the cankshaft. Are you centering the cover it’s self or the seal? Can you please clarify. Thanks ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Don(MO)

Date Posted: 07 Jan 2019 at 7:14pm

|

I talk about the front seal and cover in the video, if you watch it a lot of the questions will be answered. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Sugarmaker

Date Posted: 07 Jan 2019 at 7:40pm

|

Aaron, Yes the timing cover is installed loose then the crank seal hole in the cover needs to be centered around the crank shaft. Don uses a simple tube for this. I used a drill bit at three places. Then the cover is tightened down. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 08 Jan 2019 at 5:11pm

|

Ok thanks Chris. Don I didn’t remember seeing anything about that in your video I will watch it again thanks. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 08 Jan 2019 at 5:29pm

|

Don mentions that Allis sells or had a tool for this task too. Basically a close fitting I.D. /O.D tube to slip over the crank and into the cover prior to the seal being installed. I just don't know the dimensions of what the tube size needs to be. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Don(MO)

Date Posted: 08 Jan 2019 at 5:31pm

|

I start talking in the video about the front cover/seal around 28.00. hope it helps. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Don(MO)

Date Posted: 08 Jan 2019 at 5:40pm

Chris I don't remember the sizes ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Allis Wd45

Date Posted: 08 Jan 2019 at 8:18pm

|

Don, I watched the video, A 1-1/2” piece of pvc pipe fits the crank snug. But does the out side of the pipe have to fit the timing cover snug also? Thanks, Aaron ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Ranse

Date Posted: 08 Jan 2019 at 9:11pm

| Don used the 1 1/2 pvc to drive the seal in, not to line up the cover. That's what I assumed anyway. He used the other thing he made to line it up. It's obvious I've haven't installed one either. I understand lining the cover up with the crank. I just don't know why it's necessary. Are the holes in the cover bigger than the bolts? It looks like once all the bolts were in, everything should be lined up perfect. |

Posted By: Sugarmaker

Date Posted: 08 Jan 2019 at 10:12pm

|

Ranse, Don and others will answer better than me. But there are no dowels to align the cover with the engine block/crank and I think this little bit of extra effort may help keep this seal alive longer on the rotating crank? My guess without measuring is that the clearance in the holes in the cover allow the seal to be offset by as much as .030 inch off center from the crank. That's a guess. I will wait to see who provides a actual dimension? Maybe when/ if I ever get my WD45 engine back together I will try to measure the possible offset between the crank and timing cover in the area of the seal seat. I also think that the use of shims under main bearing caps on some WD series engines,was part of the reason to do the alignment of the cover/ seal to the adjustable center of the crank. Again just a guess on my part. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Ranse

Date Posted: 09 Jan 2019 at 6:07am

| I figured the holes had to be intentionally over sized. Now this my be a dumb question, but why couldn't you put the seal in the cover first? That way you use the seal itself to alien the cover. Just simply slip it on the shaft, install the bolts and tighten. I'm just trying to learn too, a WD or WD45 may be my next AC. |

Posted By: Don(MO)

Date Posted: 09 Jan 2019 at 8:18am

|

Chris is right about shimming on the mains will change the center line of the engine. The seal will not line the cover to the crankshaft because the spring in the seal is not strong enough to hold the weight of the cover up. If you had a let's say a D17 gas 226 engine cover off you'd find lining pins on the front of the engine because the engine doesn't use shims. It's just like the governor housing needs to have the gear back-lash set too, the older engines are not like a new engine, the older engines where built to be adjusted was they wear.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Sugarmaker

Date Posted: 09 Jan 2019 at 8:41pm

|

Hummm, I dont think I ever set the gear backlash on the governor housing? Something else to learn about! :) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Don(MO)

Date Posted: 11 Jan 2019 at 8:45am

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Allis Wd45

Date Posted: 11 Jan 2019 at 8:47pm

|

I also Noticed that the Timing Cover isnt perfectly lined up with the bottom of the engine block. Does this mean that the cover isnt aligned correctly? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Don(MO)

Date Posted: 12 Jan 2019 at 6:38am

No, but it needs to have the same alignment side to side of the block , the cover can be lower or higher than the block just needs to be the same misalignment on both sides of block. Most of the time it will be about the same alignment.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Ted J

Date Posted: 12 Jan 2019 at 10:44pm

|

Don, what are the specs on that PVC tool? Did you put it into a lathe to make? No wonder so many of these leak after guys have done a rebuild on them!! ------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: Allis Wd45

Date Posted: 12 Jan 2019 at 11:05pm

|

Don, I just thought it could have made some difference but makes sense since we’re looking for the seal to be square not the cover. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: IBWD MIke

Date Posted: 13 Jan 2019 at 8:48am

|

This may be a little overkill, the two I've done I used a dial indicator to locate the cover. |

Posted By: Sugarmaker

Date Posted: 13 Jan 2019 at 10:13am

Doesn't sound like over kill to me! Nice work! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dusty MI

Date Posted: 13 Jan 2019 at 11:10am

|

I need to do the front crank seal on my D-10 series III. Am I going to have the same problem with it? Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: Allis Wd45

Date Posted: 13 Jan 2019 at 2:21pm

|

Mike, Id rather have a little over kill than an oil leak. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 13 Jan 2019 at 2:23pm

|

Dusty, you shouldnt have to pull your timing cover as long as the main seal is the only thing leaking. If you do I believe the D series have lining dowels so you dont have to mess with getting the cover lined up. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 14 Jan 2019 at 11:51pm

|

So I got the pan back on tonight and managed to get the rear gasket off center. There is more coming out of the back on one side than the other maybe 1/4” difference. Did I screw up and going to have to take it back apart to re center it. If so I would probably need a new gasket set again. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 15 Jan 2019 at 10:36am

|

Good job getting the pan back on! That rear gasket is fairly wide so it might work and seal Ok as is? Probably only one way to find out. Or you could take a picture and let folks give opinions? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 15 Jan 2019 at 12:06pm

------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 15 Jan 2019 at 12:08pm

|

I did end up lowering the back of the pan because I couldn’t get the flywheel cover back into place with the pan up. I tried to get the gasket in a little further but it is in pretty much the same place. So it must be correct. The front I’m not sure of yet. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 16 Jan 2019 at 12:57pm

|

Sorry for the pictures being so big I post them all from my Iphone they look fine on there but are so big on a computer you cant read them. Why is that? ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Ted J

Date Posted: 17 Jan 2019 at 8:18am

------------- "Allis-Express" 19?? WC / 1941 C / 1952 CA / 1956 WD45 / 1957 WD45 / 1958 D-17 |

Posted By: Don(MO)

Date Posted: 17 Jan 2019 at 8:42am

|

So Ted if I decide make a short one will you film it for me? lol ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Fred in Pa

Date Posted: 17 Jan 2019 at 8:45am

|

Don ,That new PHONE u got ,U can do it yourself. LOL ------------- He who dies with the most toys is, nonetheless ,still dead. If all else fails ,Read all that is PRINTED. |

Posted By: Don(MO)

Date Posted: 17 Jan 2019 at 8:50am

Fred, I don't think I can hold this pain in the rear phone with one hand and to the work. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Kenny L.

Date Posted: 17 Jan 2019 at 2:34pm

In your camera setting you should be able to change the size of your pictures, I think that is right but don't know for 100% sure that is what my phone is like but I always put them on my decktop and resize them. HTH. Kenny L. |

Posted By: Kenny L.

Date Posted: 17 Jan 2019 at 2:46pm

|

Posted By: Kenny L.

Date Posted: 17 Jan 2019 at 2:48pm

| these are 600x400 your was 4???x???? |

Posted By: Sugarmaker

Date Posted: 17 Jan 2019 at 4:20pm

|

Well, Whats the verdict on the seal being out of place? Leave it or re-do it? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 18 Jan 2019 at 9:27am

|

Kenny, I don’t see a place where I can change the size when the photo is taken, but that makes sense maybe I will just have to resize them on the computer before posting. Chris, I had to drop the rear of the pan because I couldn’t get the flywheel cover back on I centered that gasket as best I could. I left the front alone because when I loosened the pan the sealer already seemed like it was cured, so we’ll see what happens. Now waiting on the thermostat bypass hose and fan belt from agco. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Don(MO)

Date Posted: 18 Jan 2019 at 10:01am

Maybe this will be a guide for the install next time you are there. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Allis Wd45

Date Posted: 18 Jan 2019 at 12:12pm

|

Don, for sure the picture you posted looks about where my rear gasket is. The front one is definitely not straight all the way around the bearing cap though. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Allis Wd45

Date Posted: 19 Jan 2019 at 1:48am

|

Well Chris, the dreaded answer to your question. Yes it is leaking oil from the front bearing gasket. Is there any chance that when I run the tractor and it gets up to temperature it’ll stop or is it just going to keep leaking. Besides that everything else seems to be holding oil. But I haven’t ran it yet. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 19 Jan 2019 at 1:02pm

|

Dang I was afraid of that too. Looked like a better than 50% chance it would hold to me. Guess I was wrong. I doubt your going to see any improvement to a no leak condition after running. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 19 Jan 2019 at 5:34pm

|

Chris, I guess I better just take it back apart again and retry since the radiator is still out. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Sugarmaker

Date Posted: 19 Jan 2019 at 7:17pm

|

I had some small leaks on mine too! I really think this is why Don and others suggest having the engine out and on a stand, upside down. Its just so much easier then fighting mean old MR gravity! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Allis Wd45

Date Posted: 20 Jan 2019 at 8:54pm

|

Chris, I agree. I loosened the front of the pan and dropped it down enough to get at the gasket. I didnt want to break the bond of the permatex on the edges because I was afraid of ripping the side gaskets. Anyway I pushed on the side that was sticking out and got it lined up with the other side except for the top where its tacked to the block. I know all this is a guessing game but do you think I should remove the pan and realign the gasket or would I need to get another gasket set? It looks like the side gaskets have already been compressed. ------------- WD45 IH Cub Cadet 149,1650,1250 #2 Cart, IH#2 Tiller |

Posted By: Don(MO)

Date Posted: 20 Jan 2019 at 9:43pm

|

I'm sorry it is still leaking after all the hard work you put into stopping the oil leaks, so you might be better off to just go ahead and pull the engine put her on a stand turn her pan side up and remove the new but now old pan gasket set and go ahead with replacement of the front crankshaft seal at the same time. You are not that far from pulling the engine (less that one hour from it) If you don't have a stand or engine host most parts stores will rent them. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: Sugarmaker

Date Posted: 21 Jan 2019 at 8:20am

|

Aaron, I will defer to Don's recommendations on this oil leak issue. He hasn't steered me wrong. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Allis Wd45 wrote:

Allis Wd45 wrote: