HD11G help

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Construction and other equipment

Forum Description: everything else with orange (or yellow) paint

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=155968

Printed Date: 01 Feb 2026 at 3:22pm

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: HD11G help

Posted By: RonnieJones

Subject: HD11G help

Date Posted: 28 Nov 2018 at 9:04am

|

Hello everyone. I am wondering if you guys could help me out with this HD11G / 1502? So far this is the only numbers I can find on a plate that's riveted to the gauge panel on the left side. This is what I know about it. In 92 it went through a really big fire and has been sitting ever since. From what I can tell the plastic covers on the gauge face seem to be melted but ALL of the rubber lines/belts are in tact. So I don't think any of it was fire damaged expect the gauge faces and the name plates are a bit melted. It does have log forks and a Carco winch attached. There is a bucket nearby which I was told was for the crawler. This crawler came with the property we bought 2 years ago. I have been working a trail since we have been here to re-access the back of the property with a vehicle. So I am hoping this spring I can start working on this and see if it still runs. Problems I have never owned or have driven a crawler I need to move it safely from it's current location I know very little about heavy equipment. I am a auto mechanic but have little to no experience with this type of vehicle. When the rain breaks I plan on doing a video of the crawler so I can get as much information as possible. I refuse to buy books until I know for sure what I have and am dealing with. Resources seem to be very limited on this crawler. So any information, sites and books you guys could point me to would be a great deal of help and very much appreciated. Thanks, RonnieJones

|

Replies:

Posted By: jerbob

Date Posted: 28 Nov 2018 at 11:50am

|

Welcome to the forum Ronnie. That would be fun rescuing a classic tractor like that. Good luck. You couldn’t be in better hands the the folks on this forum. ------------- HD16DC, Bobcat 863 Turbo, Oliver 1855, John Deere 855, |

Posted By: DMiller

Date Posted: 28 Nov 2018 at 11:51am

|

On the right rear final drive housing below the fuel tank will be the stamped s/n. Will start off HD 11-. As to the fire what is burnt on the machine? Will need to pull floor pans to access the battery cable retainers, it IS a 24V Positive Ground system if the generator is still functional, been swapped to a alternator Could be a Negative ground. Will require serious batteries to get it to start. A photo of the machine will help as to nuances. To move will need to raise the blade arms, then verify out of gear, should have a parking brake lock for the right hand side brake(locks both rails as no differential just a spool). Technically this is a Loader not a Dozer. check fluids, oil, coolant if oil shows on trans or final and hydraulic. If has set LONG Time there is a access plate on the belly pan for engine oil drain, break that plug loose if has oil in it and bring close to out allow any water to drizzle out. Then the biggie, see if the engine will roll over by hand at all. These are starters, not ready to spin it back to life yet |

Posted By: DMiller

Date Posted: 28 Nov 2018 at 12:02pm

| There are quite a few Forum members in CA, most Prolific is ACMel, he has a Allis Museum up at Redwood Valley, operates Redwood Valley Gravel Products and may be a closest assist for you if in N CA. |

Posted By: Ray54

Date Posted: 28 Nov 2018 at 1:04pm

|

You are at a place to get information and help if you decide to get in all the way. This forum likes to be a cheerleader to anyone wanting to save old iron. But time as much as anything has not been on your side.Just a little bit of moisture and 25 years can stick a lot of stuff with rust. Anything can be fixed but at what amount of hours let alone the parts. My guess is Mel is in your part of the state at least. And has more direct experience than most so would be able to give better advice than most of us. Pictures in any form will help identify what you have. I cannot think you can put a battery in and spin it. If it was like that it would not have been left behind. But stranger things have happened. I would guess the hydraulics are front mounted and powered by the crank shaft. If you could get a bar or wrench in the drive and get some movement of the crank shaft that would be a big plus. If the engine is free fixing in place is a much greater possibility.

|

Posted By: DMiller

Date Posted: 28 Nov 2018 at 1:10pm

| If anything Mel may collect it up to at least try to preserve parts from it. |

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 3:26pm

-- Thanks I really appreciate it. I have been lurking for a while and have been trying to find other sources of information on this but this place seems to be the best for any information I need. Plus it seems to be the only place lol. --

I have to move this beast first to really access anything. It's been sitting so long that you can't see the bottom rollers. I had to clear away some brush just to get in it. The fire appears to me to have only damaged the electrical, seat, batteries are gone/missing, some paint torched off in the cab and the knobs for the levers.Best I can tell right now are all the hydraulics, radiator hoses, fuel lines and belts are not even melted. The cables for the winch look intact. There is also still fuel in the tank. I did pull the generator out that I was gonna use for something else but the Armature is cracked and bearings toasted. I bet it made all kind of noise when it was running. I will likely convert it to an alternator once I know it's going to run. Also I went out during a break in rain. I don't see any numbers at the moment back there. But I did take some photo's. My camera lens is a bit to long but hopefully it will shed some light on what I have. I'll post them in a bit.

Well the good Lord put us here two years ago and I don't believe he gave me a dead tractor. Although the case skidder is going to be a lost cause. Anyway me and my wife both believe it will run again and I am not afraid to work on anything. It will be slow and a whole bunch of learning as my diesel and hydraulic experience is limited A friend of mine use to fill old flat heads full of transmission fluid in the cylinders to free them up. Most of the time it freed them right up. Some ran great after the fluid burned out. I will make sure though everything is free before trying to start anything. From what I have found on this loader it would be perfect for what I need. It's on 43 very over grown acres, so it is definitely worth going all the way if I can, well working any way. Not sure about full restoration.

|

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 4:13pm

|

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 4:20pm

|

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 4:23pm

|

Posted By: DiyDave

Date Posted: 28 Nov 2018 at 6:09pm

Get some better pictures of the undercarriage, like the individual links, in the track chain, and the individual teeth on the rear sprockets. UC is the most expensive component, in a crawler, and often the limiting factor. With better pictures, those here can tell you what the wear there looks like. Before spending a nickel, on anything, I would also check to see that there's not a cracked block, and check all fluids. If something is empty, look around even more for the cause...

|

Posted By: Lazyts

Date Posted: 28 Nov 2018 at 7:11pm

| Cool find! LH track is on backwards... surprising how many crawlers have the tracks on backwards if you look! |

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 9:11pm

Depending on what the rain is doing tomorrow I'll try and get some close pics of the tracks. At least the parts I can see, if not it won't be until friday. The right rear sprocket has been welded on all the spokes. I am sure many things will need to be replaced. Every thing I have found on this property has been well used and needs some tlc. Mostly if it runs and can move on it's own I would be super happy. If I can find out what year it is would be a huge help for me to start sourcing parts for worst case scenario |

Posted By: RonnieJones

Date Posted: 28 Nov 2018 at 9:18pm

I would have never noticed lol doesn't surprise me at all though. The original owners seem to have done alot of odd ball things. Had great ideas but mostly just poorly executed.

|

Posted By: AC Mel

Date Posted: 28 Nov 2018 at 10:30pm

|

Ronnie, Looks like a good project...serial number indicates a 1957 year model. Every one that has chimed in so far has good advice. One thing we would want to caution you about...when you get closer..is being careful when you try to turn it over. Can't tell by the pictures..but I'm sure it would still have the original style Lanova engine. The fuel pump could seize up just like an engine...and of course by forcing the engine to turn over..not knowing if the fuel pump is stuck or not..you can do enough damage to the fuel pump to render the whole project almost useless. You're not there yet..we'll walk you through it. You won't be able to get to the front to turn it over because of the hydraulics . You can take the floor plates off and get to the driveshaft..between the clutch and transmission and use a bar in the ujoints or pipe wrench on the drive shaft...assuming you can engage the clutch and get the transmission into neutral...also maybe you have a torque converter...can't tell by the pictures either...I'm betting you don't. Your brain should be going into overload now....and there's plenty of more good info here to glean..so keep posting pictures

|

Posted By: RonnieJones

Date Posted: 29 Nov 2018 at 8:28am

|

Thanks AC Mel thats a really big help. The engine is the 6 cylinder naturally aspired. From what I have gathered it was what they called the buda engine? Not sure if thats the same thing you are talking about. I'll keep researching it. Is there a good source for operator manuals and service manuals? or is this just something I need to just wing it and see first hand how it works. Is the straight HD11 manuals good enough for the drive train stuff or does it have to be specific to the G series? I didn't think about the fuel pump being locked up. Maybe I should remove it before attempting to turn it over by hand. If it is in neutral which I think it is, is there anything else that would be damaged by turning the engine over? (by hand or starter) Like the Hydraulics or does that stuff run off the output side of the transmission? I don't remember seeing anything up front except the grill and radiator stuff, so when you mention hydraulics up front are you talking about the arms and cylinders for the bucket or is there more to it that I can't see yet? What about removing the glow plugs to relieve the compression? Just guessing by the dozen or so cans of empty ether I am going to assume all the glow plugs are bad. Any suggestions on how to get the wood rats out it lol Critter wise I am hoping no rattle snakes or skunks have called this home. I know my dog is real interested in something under it. I would be ok if chipmunks are living in it :) |

Posted By: DMiller

Date Posted: 29 Nov 2018 at 8:35am

|

No glow plugs on these Ronnie, and the hydraulic pump is splined to the front of the crankshaft buried under all that steel. Mel is correct, will have a PSB style Injection pump which should it be locked will fail in turning the engine over. No real way to get into it to validate. Lanova is a Buda Series engine. |

Posted By: gemdozer

Date Posted: 29 Nov 2018 at 9:53am

| The engine is BUDA 10000 desangaged the transmission and put the hydrolic lever in neutral fonction and removed the startor and try turning the flywel with a big screw driver |

Posted By: RonnieJones

Date Posted: 29 Nov 2018 at 1:39pm

|

Learning many things from you all thank you so much :) for the help. Finally found a operators manual specific to this model and they also have a service manual for a HD11. What I am concerned about is there a difference in service manuals (B,G..ect)? Are all HD11's mostly the same as far as the drive train goes? I am thinking all of them are the same and the letter just designates it's attachments/options. So for example the HD11 service manual I am looking at says "This manual covers SN#101-13366" I do realize there is some variations in the year/sn. I can get both for 100 bucks before shipping. The op manual is about 30. So way cheaper than the 200 I have seen other places. |

Posted By: AC Mel

Date Posted: 29 Nov 2018 at 2:38pm

| Ronnie I can help you with the manuals. When the wifi comes back on. Never done this on the phone .....maybe this won't even work. Wait on the manuals if you can |

Posted By: Ian Beale

Date Posted: 29 Nov 2018 at 3:01pm

|

If it has the Lanova combustion system the injectors are looking at you on the left hand side of the engine. If you don't know what an American Bosch PSB fuel pump looks like there ought to be an ID tag on the pump. These will also be on engine series later than the Lanova ones. The reason for being careful is that if the head is stuck and you try turning the engine it isn't good for the pump internals and parts are largely made of that stuff "unobtanium" While working on the engine of our AC 45 grader I had a borrow of a pretty comprehensive HD 11 manual that covered multiple models. I don't have the manual now, or any reference number. |

Posted By: RonnieJones

Date Posted: 29 Nov 2018 at 3:41pm

|

AC Mel I can wait on the manuals. I am in no hurry honestly. The WIFI thing I completely get. I am on satellite. Surprised this storm hasn't blocked my signal. Saturday it might happen though, we are supposed to get snow :( BTW what part of the state you in? I am 40 miles east of Redding in Montgomery Creek. If you don't mind me asking. Ian Beale I did look up PSB pump they remind me of the early style VW fuel injection system. The Germans had a fuel distributor that was so well machined it didn't need seals or gaskets. It worked the same as a ignition distributor except fuel of course. I don't know yet if this PSB fuel pump works kinda the same way. The few minutes I looked at them they don't look all that complicated but I have never taken one apart yet :) I am curious if this sprays all the cylinders at once or individually. I am trying to not get to technical because I am the type that wants to know how and why it works. If I know how and why then it's easy to fix, kinda

|

Posted By: Ian Beale

Date Posted: 29 Nov 2018 at 9:10pm

|

Injection is timed by the rotor in the head. A bit hard to do an early Corvette continuous spray in a diesel. Any diesel injection I've met is all fine tolerance no seals. My father told of a WW2 diesel fixer showing how just the body heat from holding a plunger in the hand expanded it enough to prevent entry to its cylinder. If you're going to take the head off there is a stud in the side of it that has to come out. More importantly there is a square section o-ring on the end of that stud that has to come out GENTLY as it is also made of unobtanium. For more on PSB pump try http://www.oldengine.org/members/diesel/Ambac/AmbacMenu1.htm" rel="nofollow - http://www.oldengine.org/members/diesel/Ambac/AmbacMenu1.htm

|

Posted By: NomoreJohnDeere

Date Posted: 29 Nov 2018 at 9:45pm

|

great link Ian ------------- HD3 |

Posted By: RonnieJones

Date Posted: 29 Nov 2018 at 11:31pm

Thanks Ian that is awesome.  I will finish reading in the morning but on page 19 has me a bit concerned. It says it's attached to the engine oil system. I am thinking after 25+ years of sitting, if it's really sat that long undisturbed it is probably dry. If it is dry, what do you think the chances are of it being rusted/stuck? Pretty high I would guess. What I have been told it's been sitting since 92. I don't plan on removing the head but I also don't want to destroy something that can be fixed if it is stuck. If head removal is the only way to get this off is it possible to just remove the oil line and squirt something in it to be sure. On the fuel side does diesel gum up like gasoline? I won't know if there is old fuel in the line still but there is fuel in the tank.

|

Posted By: Ian Beale

Date Posted: 30 Nov 2018 at 3:34am

As rare as these pumps are I wouldn't assume anything but I would check it. IIRC that stud on the side has to do with oil feed to the head (seems some later ones don't have that). And old diesel can smell pretty bad so I wouldn't overlook that either. So (IMO given the parts situation) you're looking at taking the pump off so you can gently feel whether it is seized or not. Which isn't the worst job you'll probably meet on this animal. A book will help. If needed I can scan the pages on that from our AC 45 manual - but that is for a supercharged one and there are differences. There is a little spring that lives in the pump timing shaft (or maybe this is only on the grader ones with supercharger drive?) What you do next to check needs input from someone who has been there - I haven't. It will help undoing the injector pipes from the pump if you have Allis special tool #??? to undo them. For this you get a picture of one , get a long socket of the right size (impacts are cheaper here in Oz) and get creative with a thin cut-off in an angle grinder. I posted on this here way back in bc. You can do it with a spanner - painfully. The low pressure fuel pipes use a patent rubber seal called a Sealastic. Minnpar had most of them when I was in need. Apparently you can cut rubbers for the ones without copper centres from appropriate sized neoprene tube. The copper centre ones weren't available and they (iirc) are used on the oil feed pipes so treat gently when you undo those. Also be aware that you are NOT going to be turning the engine to injection pump references before you take the pump off. But setting up to put it back when everything is freed up is not a pain if you follow the manual. My 2 cents worth for now |

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 8:33am

|

I am getting a service manual for this. Reading more up on these injection pumps I think it will definitely be worth removing. I see lots of potential problems looking at the diagrams. As far as rebuilding them I don't see anything scary. It actually looks rather simple to me. I am also comparing this to rebuilding automatic transmissions. I would be shocked if any of the rubber seals are still good. Usually but not always if you have a seal number it can be matched up. This brings me back to the hydraulic pump. Anything I should be concerned about here? Would it be worth removing as well and can it be removed once the radiator is out of the way. No way to get under it until it's moved, unless I do a whole lot of digging.

|

Posted By: CAL(KS)

Date Posted: 30 Nov 2018 at 9:47am

------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: JohnCO

Date Posted: 30 Nov 2018 at 11:07am

|

As long as there is oil in the hydraulic system, the chances of damaging the pump is small, although I guess it could have gotten water in it that could cause damage. Perhaps loosening a line at the pump and seeing what comes out would be wise. I wouldn't bother to drain the system unless the oil is really bad looking. Generally, diesel fuel doesn't go bad like gas does, unless it has biodiesel in it, which is unlikely as it has been so long ago. Again, water is the culprit to watch out for. Draining a bit of fuel from the bottom of the tank will show what the condition of the fuel is. Also rust in the tank can cause problems in the filters and even the pump if it gets to it somehow. I usually hook up a small fuel tank directly to the filters to avoid getting bad fuel in the system. Once running, dealing with cleaning out the fuel tank and all the other projects is a lot more satisfying when you know the machine runs! ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 2:24pm

Water is definitely and issue. I noticed today that the Hydraulic tank has on open hole. So I am sure it's full of water. I don't know if water could possibly make it's way down there but not going to take a chance. This is the most I have looked it over in the last 2 years. I also noticed that the main fuel lines are disconnected from the injection pump. I have lots of new pics to post on what I found today. It's going to be a few different post separating them.

|

Posted By: DMiller

Date Posted: 30 Nov 2018 at 3:01pm

| There is a drain beneath the hydraulic tank, is inside the access hole under the fender. |

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 4:03pm

| Thanks DMiller. I found an old coffee can stuffed in a corner and weaseled it in between the wing nuts for now. No way I am carrying gallons of fluid down the hill lol. It's wet slippery, muddy, cold and just waiting to warm up all over me. I would be one well oiled machine lol |

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 4:39pm

|

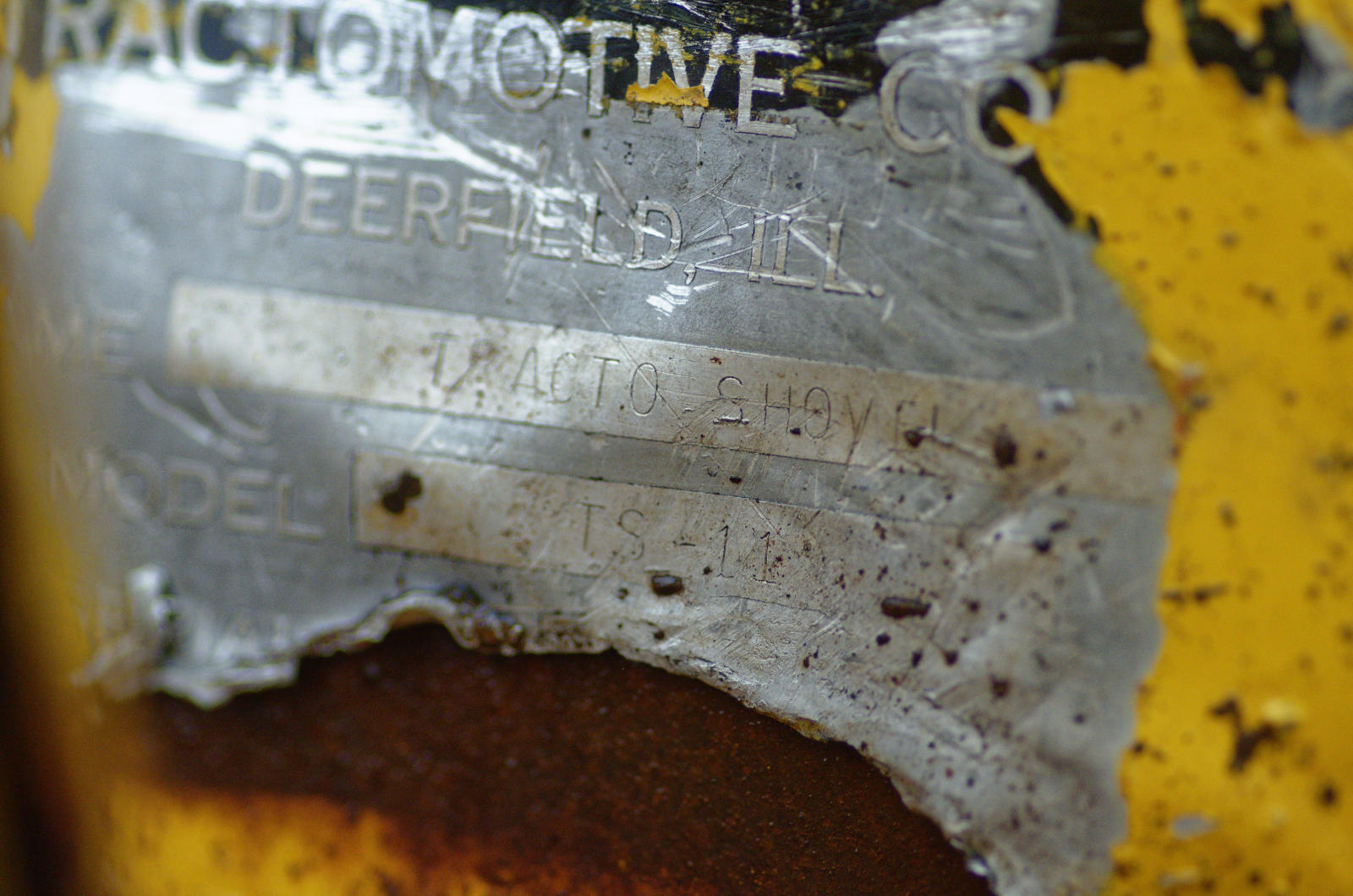

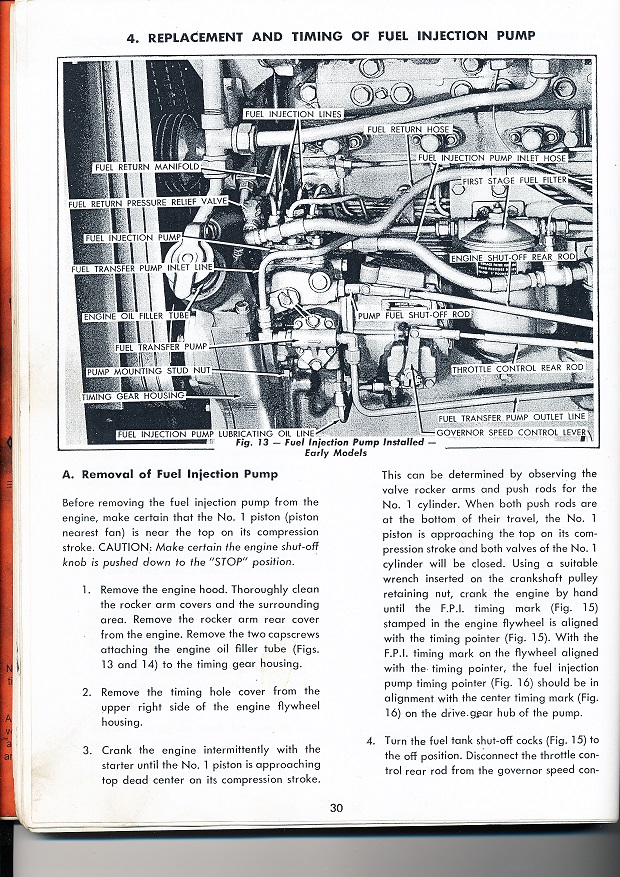

I guess I'll start with the Injection Pump. Some things I noticed was that both? fuel lines are disconnected. It looks like there is one at the filter, gonna say inlet. On the other end the return line if it has one, or is that something else? It also looks like the timing gear could possibly be behind the timing cover?  So here is the tag for the pump  I took a few different angles.  It appears to be a cover on the front/left also that rod looks like some sort of stabilizer that was broken.  I lightly pulled on the throttle and both of those linkages moved with no effort but I did not go all the way down. Just enough to see if they moved.  Just the injectors and remnants of the wood rats. This is it for the fuel injection. Why the fuel line is off I have no idea. The more I look at this I have a suspicion this was down before the fire. Next will be some miscellaneous photos. |

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 5:08pm

Here are few Misc things. I have no idea about the first one. It looks like its for part of the cooling system. It looked like it was attached to the water pump. The generator was in front of it. It hard for me to tell for sure whats up front from the sides. This is whats left of the wiring behind the instrument panel. I did not see a hour meter anywhere. Did they not have them in then? All I see are the four I took a photo of already.  I noticed this pipe is ether missing something or was cut. It looked like it's for PCV/ crank case ventilation. It runs across the valve cover.  After removing some more wood rat nest I was shocked to see the starter and more melted wire. I was looking at the bell housing to see if I could find any kind of numbers on it. All I seen was two plates. A large one on the right and a small on the left near the starter.  That's it for these will post under carriage next. Have to go do a few things first.

|

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 6:38pm

|

Alright this is the left side/entry. Both sides look pretty bad to me. So the tracks, if I have learned this correctly consist of plates which are bolted to the chain and ride on small rollers. Then the rear sprocket and the big wheel up front is the idler? So here is what I can tell. The chain on both sides are toasted. I doubt the pins are supposed to be half round. The rear top rollers are obviously damaged. The plates, many of them look broken. I don't know what they mean by rails but I think it's the bottom set of rollers and what they are attached to. I can only see whats above ground so have no idea what the bottom parts look like, probably bad. Ok so here are the pics of the left side.  - -  - -  - -  - -  - -  - -  - -  - I only took photos of the left plates specifically. I forget who it was mentioned the left side was on backwards. I wonder if they were trying to extend the life of the track. Thats it for the left side. Next will be Right side.

|

Posted By: RonnieJones

Date Posted: 30 Nov 2018 at 6:55pm

|

Ok here is the right side -  - -  ^ this one has all it's spokes welded - -  - -  - -  - -  - -  - -  - -  - -  - -  - - Ok thats it for now. Not going to upload any more today.

|

Posted By: Sugarmaker

Date Posted: 30 Nov 2018 at 7:21pm

|

Ronnie, I give you credit for getting the machine uncovered and taking the pictures. I dont have one of these, or any AC track machines (yet) But I do have a IH TD6 that I am still learning about, and as I look at your pictures of the under carriage and tracks I dont see to much good news. Track is very worn as you have stated. Yes anything can be rebuilt and or repaired. AC Mel would be the best guy I can think of to give you the best evaluation of your machine. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DMiller

Date Posted: 01 Dec 2018 at 5:36am

|

The fuel line filter to inj pump has been removed, for what purpose is unknown, quite possibly this had already seen a PSB failure, the burnt wiring almost to me indicates the machine was running the starter stayed engaged and smoked the electrical as no other real damage and is down where the local fire would not have gotten to it without scorching the entire machine, that also could be why they removed the fuel line, to try to shut the machine down. Being as was open this long has done no favors. Rails, rollers are toast, agreed but should it be worthy re=assembly with cat 6.906 rails and modifying the suspension trucks for cat rollers would remedy that. All that wood rat stuff/debris will need to come out before ANY start attempts are made. |

Posted By: RonnieJones

Date Posted: 01 Dec 2018 at 11:12am

I have a conspiracy theory for this :) I looked at some of those ether cans for a production date. I think they are from 87 and many are not burned. Aside from the belts and hoses not being burnt where is the batteries? no melted plastic or lead plates and cable ends are still intact. There is also some Milwakes best stashed in the corners of the cab un burned. I know the fire was close but as I continue to look closer at this I strongly agree with you. I think this was down before the fire and used the fire as an excuse to claim as a loss. Inside the cab the fuel tank looks burnt to me but nothing on the outside really stands out that says yep it's burnt. Now there is a 63 ish GMC think one ton that was definitely burnt and the case skidder. No doubts about these as it is very obvious. |

Posted By: RonnieJones

Date Posted: 01 Dec 2018 at 12:01pm

Thank you I have a lot to learn about this machine and AC in general. I have at most another months worth of work to access this part of the property with a vehicle. Right now it's only accessible by foot. So far I have cleared almost half a mile of brush with just a under powered chainsaw, weed eater, reciprocating saw, hand tree saw and pruners that I just broke about 2 weeks ago. Over the summer my neighbor came in with his small L35 Kubota backhoe and JohnDeere 750B dozer to help me put in a culvert so I could cross the creek with my truck. I still owe him a bunch of work for the day and a half he spent here. Basically I get to work on his equipment and learn about tractors. I help keep his atv,utv, cars, truck and anything else that has a engine running. He has the equipment and I have the time and most of the knowledge to keep his stuff running.

|

Posted By: DMiller

Date Posted: 01 Dec 2018 at 12:11pm

|

On the photo above the fuel filters to the inj pump the steel tube coming from the small block on the left side of the pump is the transfer pump feed to the secondary filter, the line missing came off that to the inj pump front fitting. Mel, you hanging thru all this? Would this be a parts machine for you at all? It needs a ton of stuff to make it anywhere near to viable again. Rails rollers, maybe sprocket rings, pump work, fuel lines, wiring, gauges and that just to get it to where can do the rest it needs. |

Posted By: Ian Beale

Date Posted: 01 Dec 2018 at 1:49pm

First one is the oil cooler. The pipe that you question being cut is the engine breather and would have had a rubber pipe joining it. Open tube, no pcv

|

Posted By: RonnieJones

Date Posted: 01 Dec 2018 at 4:33pm

Thanks Lets assume the pump is toasted as well. Has anyone attempted any kind of conversion that you know of? Ah you hurt my feelings

Are you discounting my redneck ingenuity already? Are you discounting my redneck ingenuity already? |

Posted By: RonnieJones

Date Posted: 01 Dec 2018 at 4:51pm

| Ian Beale I didn't notice it until I looked at the photos. That hose clamp on the injector line cant be good. I see the nut in the original photo is actually cut. If this is anything like they did with this house I am gonna be in for some crazy repair work. |

Posted By: Ian Beale

Date Posted: 01 Dec 2018 at 5:03pm

|

Maintenance by Joe Fiddler? If you mean the hose clamp in the second last one don't sweat. That is on the spillover line from the injectors and pump back to the tank. Another of those Sealastic fittings. In your photos of the pump that line comes from the fitting on the front of the head. It looks like you have the early valve setup there - which I've only read about. Later ones just have an elbow with a restrictor. I think the rest of the missing plumbing there feeds diesel back to the tank return. This might help on what went where around the pump. With that potentially stuck pump you're going to skip the alignment details below and set that up after the pump is out.  |

Posted By: AC Mel

Date Posted: 01 Dec 2018 at 9:56pm

|

Ok guys..up and running again. Went thru the PM channel to get Ronnies email to give him some info on Manuals I thought would be helpful...haven't got an answer back there yet..but I think it went through. So Dave... yes been following along...we concur with everything you have said..my brother and I both noticed the missing fuel line...and thought..."that's not good" whats that mean? red flag? So as a boy I remember a saying my father had (he was born in 1916...spent a lot of time on a horse...and yes the same guy in some of our posts with his new HD11 cable dozer in 1955) "BEEN RODE HARD AND PUT AWAY WET" well this would be applicable to this tractor. So that being said...since I have ''ORANGE" in my veins a Caterpillar couldn't have made it this far. So to answer one of Ronnies questions..the bracket for the hour meter can be seen in one the pictures (about 8 down on my page 2 to the right of nozzle 5 and 6...a standard place at the time. Yes the rails are extremely worn...sprockets very poor also...but...but..but.. if it was running..I could still get something out of it. On the top of the sprocket in one of the pictures you can see a gap in the pads on one side...leads me to say that it's possible that there is a broken rail link there...maybe maybe not. I'm only speaking from experience..."been there done that'' or "poor man has poor ways" Something else Ronnie could do would be to reach under the tracks and feel the pins and bushings...no need to try and even look under there..you can feel worn bushings..or track pins coming through bushings...I suspect that might be going on here. The intermediate pinion caps in the case have been welded around..which was very common until they upgraded the bolt size...doesn't look like it is a problem now. So that being said we think the track pads are better than the ones we have on an 11G in our collection for restoration. Ronnies tractor has the same affliction that a lot of crawler loaders acquire..some one always wants to ad grouser bars to there street pads to turn it into some monster dozer. So I have orange in my veins...I wouldn't give up yet..the dipstick..pull the dipstick...whats on it? oil? water? nothing? overfull?

|

Posted By: JohnCO

Date Posted: 02 Dec 2018 at 12:11am

|

Ronnie, just for our enjoyment, would you post pictures of the skidder and one ton? And thanks for all the pics you have posted, every entertaining! ------------- "If at first you don't succeed, get a bigger hammer" Allis Express participant |

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 6:28am

|

Ian yes for sure by Joe Fiddler. I have to give the guy credit though, we bought the house 20 years later after he rebuilt. Some of the ideas were great just poorly executed and of course some are like WHAT? That photo of the lines looks like I am missing more the just one but my oil filler is back by the starter. ---- ACMel It took me a bit to find that bracket in the photo. Maybe the meter is somewhere in there still. It sure was ran very hard. Looks like they just ran it until it couldn't take no more abuse. This may sound silly but it just dawned on me I haven't noticed a dipstick. Where should it be? I honestly have not looked at any of the fluids. I have left it the way I found it until now. Ok you lost me here "intermediate pinion caps in the case have been welded around" I did send you a email yesterday morning and a PM last night if you didn't get them I'll resend. I ordered the service manual, waiting to hear back on the parts manual and the Operators manual I haven't ordered. Holding off on the Operators until I get the service. When I let the critters out I'll go up and see what I can find. Hopefully the bear didn't come visit again if they did, I won't have time to go up today and I am also heading to town today.

|

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 6:42am

John right now this is all I have of the GMC. I haven't ran the VIN to see what year it really is, just going by the date on the plates. The inside of the cab is burnt out and in the photo I cropped for better view. You can see the wood for the dump bed is burnt and whats left of the rear tires. It also appears to have the two speed rear end. If I go up today I'll take a photo of the skidder. Most of the engine is missing and the rear axle is nowhere to be found. - -  - -  |

Posted By: DMiller

Date Posted: 02 Dec 2018 at 7:47am

| Late 60s early 70s GM ton and half(six lug) not quite a two ton truck. Cannot see if still has an engine in it, if 60s could have come with the old style V6 that was the Toroflow predecessor. back end got hot and cooked, cab looks decent enough for parts sales. Most likely a C5000 or 6000. |

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 8:10am

It does have the incomplete engine. V8 carb is missing among other things. Probably full of water as well. Not sure what engine would have been in this but my best guess would be 454. I'll take a look at those models you mention.

|

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 9:49am

|

Quick search shows no 454 option. It looks to be somewhere in the 60's according to the headlights. Someday I'll run the vin if it's still there. So I thought I would just add this for fun. The actual road is no longer accessible. Story is they built a dam that washed/broke out shortly after the fire. So I have found old culverts that I am reinstalling to access the back half of my property. The creek runs year around and the soft soil is a high danger for getting stuck especially heavy equipment. Which apparently happened once when some thieves tried to recover the AC. They ran over the owners water line hence getting caught stuck in the mud literally. - This obviously isn't precise but it's what I have been working on for the last two years  |

Posted By: AC Mel

Date Posted: 02 Dec 2018 at 9:53am

|

Ronnie, Got the PM..didn't get the regular email. I'm sure the hour meter was removed. The dip stick is between the fuel pump and the starter...and probably covered with the wood rats house yet..pretty low in the block...if original it will have a pretty big loop for a handle. The intermediate pinion cap is behind the sprocket spokes...say at the 10 or 11 o'clock position looking at the sprocket...the case around the cap has been welded and reinforced ... common for that vintage |

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 12:03pm

|

You are correct. Removed some sticks before pulling it out. Seems really watery/runny to me. Specially being its very cold and icy this morning. What weight oil do these use? I tried smelling it but my nose wouldn't stay put long enough to get a good whiff. I thought I may have caught a scent of fuel, can't say for sure though. I also didn't notice any water/oil separation and I pulled it twice. It's just a tad overfilled :/ -  -  |

Posted By: RonnieJones

Date Posted: 02 Dec 2018 at 1:18pm

|

I forgot to ask about the bushings. If you mean that stuff wrapped around a piece of steel that looks like a mouse chewed holes in, then yes they are there. Seriously though they are done as well. I wasn't about to stick my fingers on cold icy steel, yes call me a girly man if you will lol. If I got stuck to one no one is around to help remove my fingers lol. So I physically looked at them and not much left of the outside layer. I am assuming thats the bushing. The link will require better inspection but nothing noticeably broken. I did notice that the inside of the links are in better shape than the outside.

|

Posted By: Ian Beale

Date Posted: 02 Dec 2018 at 3:02pm

|

"That photo of the lines looks like I am missing more the just one but my oil filler is back by the starter." The filler is at the front on the grader engines. You won't have the piping above the fuel pump either as it is the oil return from the supercharger.

|

Posted By: michale34

Date Posted: 03 Dec 2018 at 9:01am

| We had a gmc 6000 one time about that year model we got with some other parts trucks and logging stuff. It had a v6 in it . It was the only complete truck we got out of that bunch but the guys wife we bought the stuff from couldnt ever get a title . So dad made a winch truck out of it with a tow bar mounted to the front. We got 2 tree farmer skidders and a old log loader . They went to wolf lake il to a salvage yard . |

Posted By: Ray54

Date Posted: 03 Dec 2018 at 11:18am

|

Just looked again and the Budweiser just jumped out on the hood of the truck. Which says to me it must have been a set up as a tractor to pull a beverage distribution semi. That may help guessing how the truck was specked out new. That body style was 67 or 68 until 72. |

Posted By: RonnieJones

Date Posted: 03 Dec 2018 at 12:31pm

|

lol never seen that and I have been looking at it for two years. Great catch. I did find the vin for it. One site says its 68-71 GMC truck with a V6. Engine was likely swapped for V8 but now I am also having my doubts. Next time I go up I'll look closer. Any thoughts on what the oil looks like? It can only be one of two things. Water or fuel. I am hoping fuel. Is it possible to siphon the fluid out through the filler? I have plenty of 5gal buckets with lids I could put it in. That would show any water.

|

Posted By: Garlic Pete

Date Posted: 03 Dec 2018 at 4:52pm

|

Within the last year, I spent some significant time, blind alleys and many mistakes doing exactly what you're getting ready to do with that PSB pump. Mine was on an 11000 engine, but concepts would be nearly identical. Mine had sat for at least thirty years with the fuel filters and supply lines removed, so I'm sure your experience will be similar to mine. I posted lots of detail here on an old thread. I think reading through that thread would be helpful, but when I looked, my linked, hosted pictures, which will be very helpful to you, have lost their links. If you'll give me a few days to a week, I'll edit those posts and relink the pictures. I think the thread might be very helpful. I would caution you not to attempt to rotate the engine until you free up the pump or remove it to be freed up. This is the voice of experience. My approach resulted in having to find three donor pumps for parts and required much more advice and help from this forum because of what I didn't know and because I rotated the engine before removing or freeing the pump. The thread is titled "An Auction for the Rest of Us" and you can find it through a search. I'll come back here and post a notice and a link to that thread once I've updated those photo links. Pete.

|

Posted By: Ian Beale

Date Posted: 03 Dec 2018 at 5:40pm

|

From the numbers on your pump in that first photo PSB6A 90EH 4363 From some notes I made when I had the HD 11 service manual 90EH says a 9 mm plunger - Allis also used 100EH with 10 mm That pump number says 516G engine above #95455 Or it mightn't Should be 4363A and it looks like your number has been over-stamped so maybe a pump change/recondition somewhere along the line. If the second digit was an 0 then it could have been 4083 which went with HD 11B, F, S The tag on the head gives the head part number. If it has an R in it the head was reconditioned

|

Posted By: RonnieJones

Date Posted: 03 Dec 2018 at 8:26pm

|

Garlic Pete I looked up that post you mentioned. Great info thank you very much. No hurry on the photo's the text is quit informative. I also book marked it. In fact if anyone is reading this it's here https://www.allischalmers.com/forum/an-auction-for-the-rest-of-us_topic144296_page2.html" rel="nofollow - https://www.allischalmers.com/forum/an-auction-for-the-rest-of-us_topic144296_page2.html Ian you mentioned something in that thread about the plunger being stuck in a up or down position. Up you thought it may block fuel from leaking off into the injectors and down, I gathered it may dump fuel to them. I haven't read the whole thread yet but is it possible the plunger is stuck down and fill the cylinders with fuel? If so this gives me wishful thoughts about the oil being way over filled. My service manual will be here this week and possibly the parts manual. Weather permitting I should be able to start taking this beast apart soon and see what I actually am dealing with, aside from all the obvious damage. My goal is just to move it under it's own power down the hill near the GMC, even better would be to get it to the house on a concrete slab. If it runs and the brakes work I'd be off to a really good start.

|

Posted By: RonnieJones

Date Posted: 03 Dec 2018 at 8:52pm

I tried manipulating the original photo to bring out the numbers better not 100% sure but it looks like a 0 under the 3. I might be able to get a different angle with a different lens if not I can for sure get a clear shot of the all the numbers when its removed.

|

Posted By: Ian Beale

Date Posted: 04 Dec 2018 at 2:39am

|

Gawd! That was a while ago. If the plunger is stuck at the top of its stroke it is past the spill port so diesel can't enter. If it is at the bottom it can. And might go further if the distributor slot is aligned with a port - but should only be to one injector. But as the engine isn't running there will be sfa fuel pressure and if that gets past the injector valvery you have a heap more problems. I'd guess the diesel tank would need to be full to even get fuel up that high. I'd reckon that if you got fuel in the oil sitting like that one has it would have come via leaks in the pump itself. There are two o-rings that seal the transfer pressure space below the head for instance - they aren't special if you need them. And the seal on the transfer pump shaft can leak. It is just a standard industrial seal. Another 2 cents worth

|

Posted By: RonnieJones

Date Posted: 04 Dec 2018 at 11:28am

| Sounds very positive to me. This gives me hope that the engine it self isn't destroyed |

Posted By: Ian Beale

Date Posted: 04 Dec 2018 at 3:19pm

| "Conjure up no more spirits than you can conjure down" |

Posted By: RonnieJones

Date Posted: 04 Dec 2018 at 7:16pm

| Yeah I know but I try to hope for the best. I have learned many things about this machine thanks to you guys. |

Posted By: Ian Beale

Date Posted: 04 Dec 2018 at 8:28pm

|

Ronnie I've just been looking at your pump photos on Page 2 and I hope I'm wrong for your sake. Go to the third one. The filter you can see is the primary. Diesel feed is from the tank, through it, then to the transfer pump and through the secondary to the injection pump. The hexagon at the back of the head section just in front of the rectangular cover of the top of the govenor section at the rear of the pump is the stud with the square section O-ring. Then just above it on the back of the head is a brown fuzzy area - which is where the fuel feed hose from the secondary filter is supposed to connect to the head. The other end of that hose should connect to the T-fitting from the front of the secondary filter which is just shows in the photo. So the head has been open to the weather since Joe Fiddler left it. Would it run like that? We first started the engine from our grader on an engine stand with a temporary tank. It did have the plumbing correct but the "reconditioned" injector pump was missing the bottom O-ring for the head so it had a massive diesel leak to the sump and less than design transfer pressure. It ran like that. So I guess the answer with yours would be "maybe" - but I doubt it would have made much power. What would have been fed to the pump as well as diesel if it did doesn't bear thinking about. IMO the pump is your first port of call. Today's 2 cents worth |

Posted By: RonnieJones

Date Posted: 04 Dec 2018 at 10:04pm

|

Here is a close view. Hopefully you are not looking at these on a phone lol I think I see what you are saying. The hole on the head should have something in it besides rust or mud. So they left the system open which doesn't surprise me one bit. Oh and I also seen a number on the head. Looks like there is a R stamped in it. - First the small one -  Still large but I had to make it smaller than I wanted to meet the 2mb requirement. -Hole I think you are talking about  |

Posted By: Ian Beale

Date Posted: 04 Dec 2018 at 11:48pm

|

Ronnie That is the hole. The detail of the first one was ok after I went and had a look at our grader and was reminded of where things went. IIRC that port feeds in below the head but that is where the plunger and the gear train that spins the distributor block are so water and /or dirt wouldn't be your friend. Assuming you can find that missing hose - I'm not sure what the hose material is called. It is reinforced and what we get has a blue fabric outer. The head number on one of our pumps is HD 4606AR, which should be an EH 100. (Correction to previous - 10 mm and 9 mm diameter plungers). The other one (that works) has a damaged plate. There is a little spring clip in the plunger area that (IIRC) holds the plunger tappet in the assembly. You need to be gentle taking the head off or it will get damaged. If you set about taking the injectors out the thread on the end under the dust cover is 22 mm, don't remember which thread number. A piece of our 3/4 water pipe was just right to make an adapter. I could use a slide hammer as they are out in the open (well relatively) on the grader. Someone else had to make a puller due to restricted room on the loaders - in an earlier post(s). I have a .pdf that lists many of the head numbers - from September 1976 so not much use to either of us. In case of the worst might be worth finding out if Hector Gemme (Spelling?) who posts here has anything - he had a wrecking yard up in Canada Later - those injector threads are 22 x 1.5 mm

|

Posted By: RonnieJones

Date Posted: 05 Dec 2018 at 9:55am

| Whats the difference in the pumps? Besides the plunger. Would a 100 work? A couple of quick searches leads me to believe the 100 is easier to obtain. I am thinking the 100 delivers more fuel. If they mount properly are they adjustable to some degree |

Posted By: Ian Beale

Date Posted: 05 Dec 2018 at 2:22pm

|

Ronnie Allis used both on HD 11's. The ADS516 (supercharged Buda) used 100EH. That "master workshop manual" I borrowed covered all HD 11's and has a list of pumps and the models that used them. It only had Allis numbers for the pump, didn't have actual head numbers. I have some sketchy notes as for a while it looked like we might have to run our grader without a supercharger. Seems the 90Eh ones are timed at 32 degrees and the 100EH ones at 28. Under the lid of the govenor section there are various things that look adjustable. I've never tried. There might be some indications of what does what in that listing I gave you - I haven't been there. A complete 100 pump would certainly bolt up. And probably a 100 head on a pump that had a 90. Some later heads didn't use that oil feed via the bolt and square washer and needed some sort of extra to work on oil-feed pumps - I don't have details. My listing of heads doesn't give alternatives for any numbers we've mentioned so probably not a problem here. I'd guess that a 100 pump at worst might run a bit rich. At least with a diesel if it were to run lean you'll only be down on power - you won't burn the engine. You can get a look inside your pump when it is on the engine by taking off the cover that has the shut-off in it - the one with 2 screws below the head. That will give you a look at the drive gear for the head and the general condition in there. There is a marked tooth on that gear you have to use for timing so you need to know where the pump drive was if you take the head off. And (IIRC) there is a loop in the oil return line from the bottom of the pump which might tell you if the last thing that went through was oil. So seems to me that your pump has to come off because of the risk of damage from turning the engine. And then you'll know where you stand with the pump. And once it is off you can explore the engine as to stuck or not etc. Also if it is an early model your starter might be a Dyer drive type. If it is burnt you can use an M40 IIRC. Close to all I can think of on this

|

Posted By: RonnieJones

Date Posted: 05 Dec 2018 at 4:30pm

|

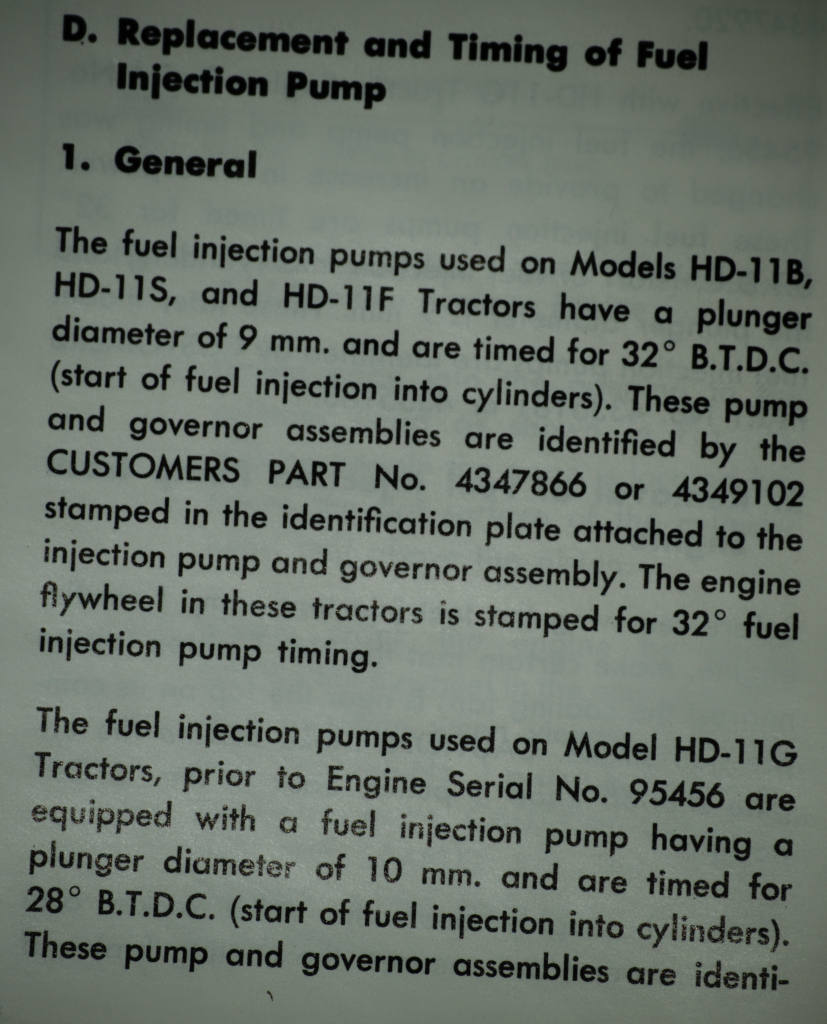

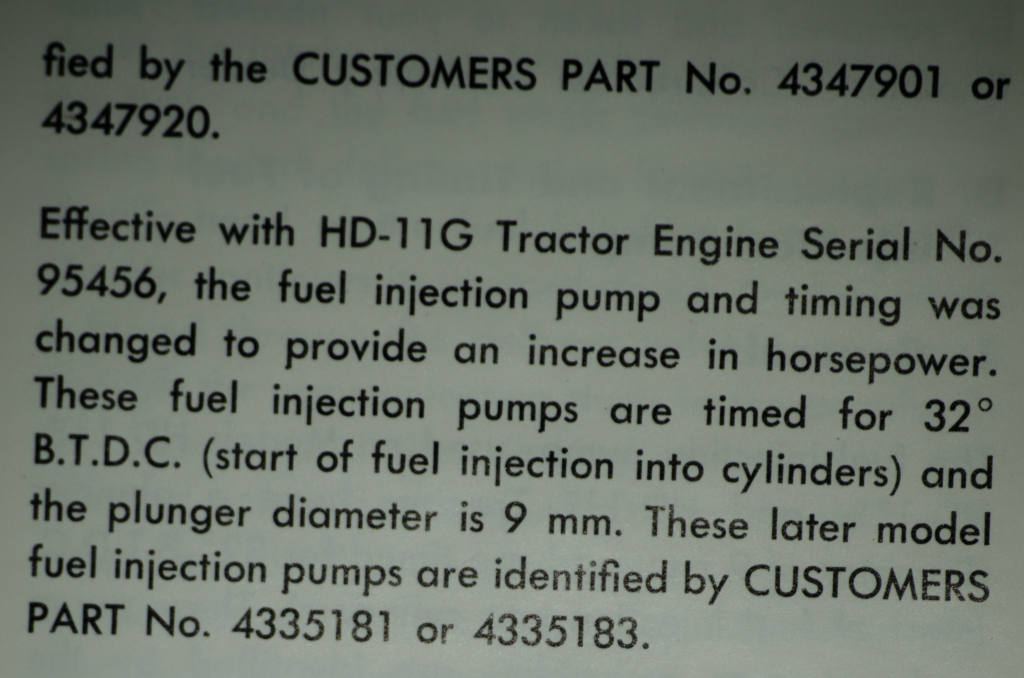

Ok came in for a quick break. I picked up my service manual. I'll post the actual contents of the pages later but from a short read they used 3 different pumps. The 90eh has two different timings 28 and 32 and the 100 has 28. Depending on engine serial number. So it appears any can be used but if I remember correctly the one with 32 was to increase the HP. According to the SM the engine tag is supposed to be near the starter hopefully it's still there. Publication date is June of 58. AC Mel I can't thank you enough for helping with the service manual :) Obviously further research is needed before I attempt to change or fix anything. Currently in the attic rewiring some shorted plugs, rather be working on the loader.

|

Posted By: RonnieJones

Date Posted: 05 Dec 2018 at 7:39pm

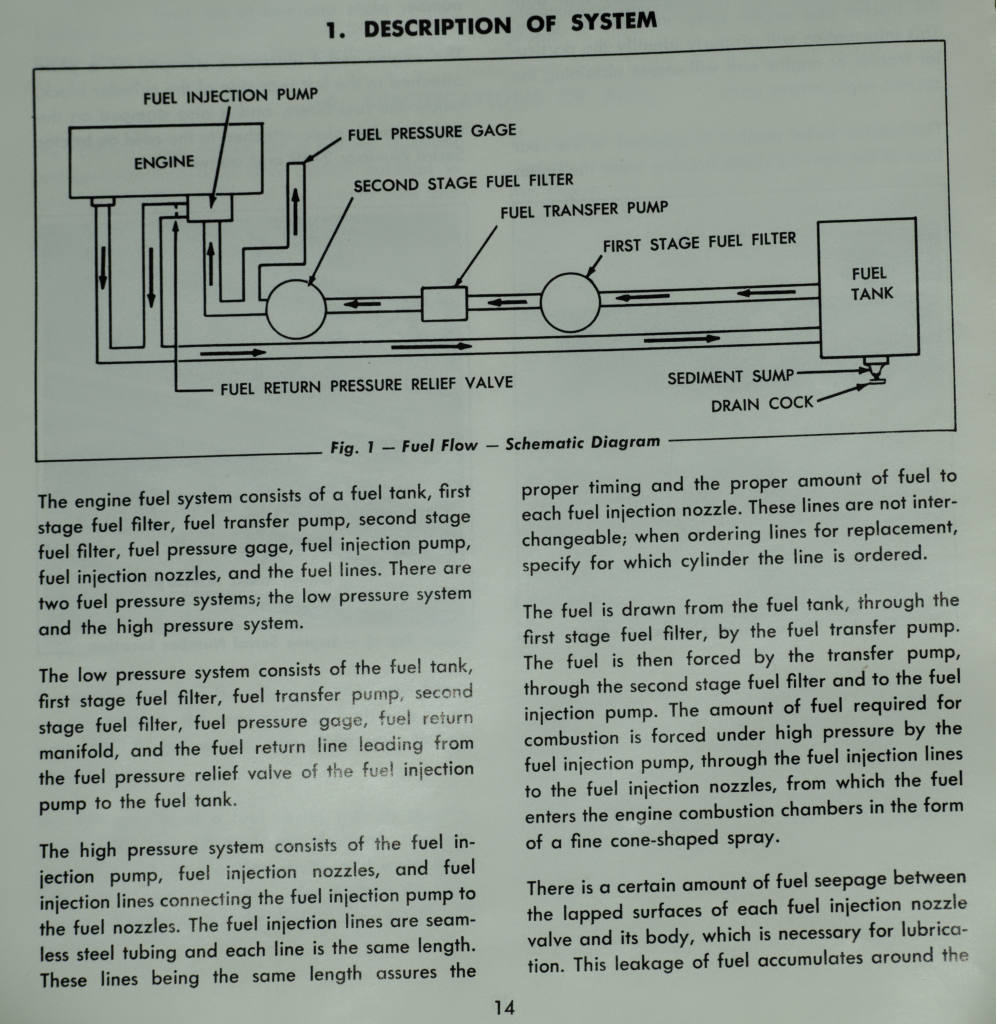

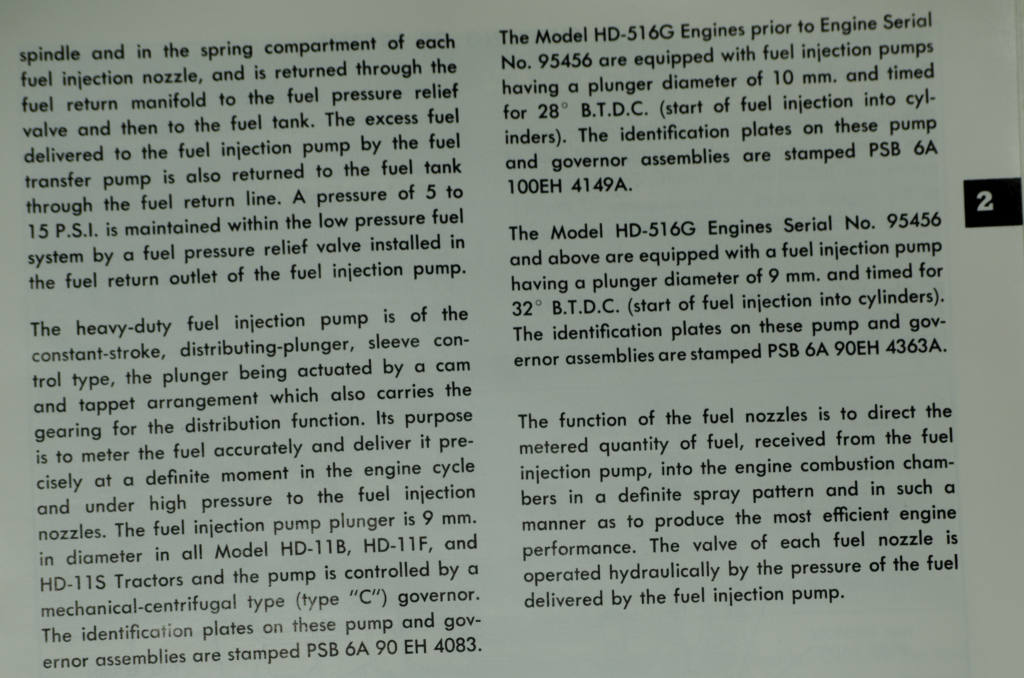

So here are 4 pages on the fuel injection. Hopefully this will help someone besides myself.    |

Posted By: Ian Beale

Date Posted: 06 Dec 2018 at 3:16am

|

Ronnie I'm guessing covered in there (but not stated) is the change from Budas with Lanova injection to direct injection with the 10000/11000 series engines. (Lanova ones have the injectors on the lhs of the engine and "energy cells" on the right). Just looking at that list it looks like early ones might have had 9 mm plungers at 28 degrees. The graders had 10 mm at the same timing. Which seems to make sense as they would have needed more fuel to keep up with the supercharger. IIRC the later direct injection ones got similar horsepower to the supercharged Budas without the blower, turbos even more. Seems some then used the blower drive pulley for the fan etc |

Posted By: RonnieJones

Date Posted: 06 Dec 2018 at 8:16am

|

Yeah I don't remember when they changed engine design. I do remember that they changed the piston. The newer one was more/deeper concave. I wonder if this allowed a bigger cam to get more Mixture into the cylinder, maybe they changed the duration of the valves. They had to of changed something else in order to compensate for a larger combustion chamber. I have to look but I don't think they increased the liters. It's still 8.5L. You can only do so much with 516 cubic in. and 8.5L before having to go bigger. I am curious on your grader what is the injector pop off pressure? This one says 2100psi new, used is 2k. Now I am really curious about the pumps as well. In the 10mm plunger did they keep the same stroke of the plunger or did they shorten it? In non forced induction systems I am thinking they would have to shorten it to keep the same mixture. Or is the amount fuel delivered controlled by the volume of the head? Seems to me the heart of a diesel is the injection pump, needs to be in a perfectly healthy condition. I realize this is getting into the very technical aspects and some of my questions may seem trivial but it really does help me understand how all this works together. I am not trying to reinvent the wheel just want to understand the how and why of the invented wheel. One last thing according to the re-stamped pump# on my engine it's the 9mm @ 32 degrees. It looks like the original number may have been for the 28 degree. Right now I can only assume the 9mm pumps are interchangeable with the only difference being the timing gear.

|

Posted By: Ian Beale

Date Posted: 06 Dec 2018 at 2:21pm

|

2100/2000 psi For what went on with stroke in the pump I guess you'd need an AMBAC parts book or two pumps to compare

|

Posted By: Steve allis dozer

Date Posted: 06 Dec 2018 at 7:09pm

|

All them cans of either would indicate that the pump is worn , once the American bosch pumps with single plunger get worn out they don't produce enough pressure while cranking over with the starter to open the injectors ! the either spins them over fast enough to open the injectors , when the pump is worn sometimes at low idle they will just stop as per not enough revs to keep the injector tips popping ! A fuel pump Dude over here thinks that an american bosch pump from an international can be fitted as you can still get parts for them (just have to make new injector lines )

|

Posted By: RonnieJones

Date Posted: 06 Dec 2018 at 8:53pm

Probably explains why they were excessively cranking it as someone suggested earlier, think it was DMiller. I honestly think that this is why it caught fire and did not really get touched by the big fire in 92. No starting system is designed for extended cranking. Modern cars have safety devices to keep you from catching your car on fire. I forget which car it was, when I worked for GM they recalled for this very issue. People were just holding the key until it caught fire. I can see it now one holding the starter button and the other loading it with ether until all the magic smoke was gone. The International pump sounds possible. Do you know what the pump number would be or what model it would be for? I was wondering if any of the modern pumps would work. If it mounted properly, provides the right pressure, same volume of fuel and can/is timed correctly, I suspect anything would work. I am still a bit new to diesels and almost ready for my test subject lol. The other issue is would you be able to find pluming capable of handling this type of pressure that won't leak under heavy vibration. I think it's entirely possible. Can't be any worse than putting a Ford engine in a GM. |

Posted By: RonnieJones

Date Posted: 06 Dec 2018 at 9:05pm

I did catch something today when I was reading this again http://www.oldengine.org/members/diesel/Ambac/AmbacManual23.htm" rel="nofollow - http://www.oldengine.org/members/diesel/Ambac/AmbacManual23.htm In the diagram it's called the control sleeve and somewhere in there it said something about it controlling the amount fuel, not pressure but the actual volume. So many questions and nothing to compare to :( You have a couple of old pumps you care to mic? lol This is kind of specific to design not sure if I can find specs this detailed.

|

Posted By: RonnieJones

Date Posted: 06 Dec 2018 at 9:16pm

|

Control sleeve chamber It would be interesting to know what the volume difference is between the 90 and 100 pumps. If it's possible to make this chamber equal Are the control sleeves just a different size Can the control sleeve be changed Anyone care to mic some dead pumps :)

|

Posted By: Ian Beale

Date Posted: 06 Dec 2018 at 9:42pm

|

Steve AD Likely an Ambac 100. The injection lines come off the head at an angle. I've heard of that possibility. But also that the parts situation is heading south. Also worth reading about them https://allischalmers.com/FORUM/ambac-100-pump_topic155274.html" rel="nofollow - https://allischalmers.com/FORUM/ambac-100-pump_topic155274.html If you can replace an AMBAC 100 with a Bosch A series inline then why not a PSB replacement for a possibility? I vaguely remember seeing something about some military 516's having Stanadyne pumps too - no details

|

Posted By: Ian Beale

Date Posted: 06 Dec 2018 at 9:47pm

Think you'll find that it is the position of the spill sleeve that counts and that it varies the spill cutoff depending on govenor control setting

|

Posted By: Lazyts

Date Posted: 07 Dec 2018 at 2:25pm

|

Later Allis engines in 8000 series tractors and N series combines used the American Bosch stuff too- not sure how they would fit. I think the old ones ran at engine speed and the Roosa Master runs 1/2 engine speed? That old crawler looks like a big project- bad injection pump, bad undercarriage and unknowns between... not impossible but I see alot of work ahead! If you want to move it, you will likely find the brake bands stuck to the drums in the rear end- just a heads up.. they can be loosened off pretty easy, but those tractors are really hard to move if they won't roll!

|

Posted By: Ian Beale

Date Posted: 07 Dec 2018 at 3:18pm

|

A bit more on pumps here. Check Injpumped's comment https://www.redpowermagazine.com/forums/topic/75288-american-bosch-rotary-injection-pump-swap/" rel="nofollow - https://www.redpowermagazine.com/forums/topic/75288-american-bosch-rotary-injection-pump-swap/ We got the engine going with what we had so this went no further

|

Posted By: SteveM C/IL

Date Posted: 07 Dec 2018 at 5:23pm

You can do the inline swap on a 8000 426 because the pump drive you need is on a 7000 426. Doubt there is a half speed drive for that old bird. |

Posted By: RonnieJones

Date Posted: 08 Dec 2018 at 8:40am

Unfortunately it is going to be alot of work. I wasn't expecting it to be easy and frankly a little disappointing in the shape it's in. The electrical stuff is easily fixable. On the other hand this makes me wonder how bad of shape the engine is in as well. It obviously wasn't well taken care of. I see some do repowers with a Detroit and I think Cummins. This might be a better option but hard to say at this point. I have been looking at the N5 fuel system and have been trying to find stuff on the Roosa Master. I haven't found much on either. For the same price of an old unreliable injection pump a more modern one may work but still diggin around on this. When we started this adventure going on 3 years now. This is why I stayed away from diesel pickup trucks. I knew injection pumps where pricey and the most likely to fail. We have 3 really big projects that we would like to do and this would help immensely to get those done. So I need do lot's of praying, research and finish up the honey do list on her palace. |

Posted By: NomoreJohnDeere

Date Posted: 08 Dec 2018 at 1:21pm

|

"three really big projects" you just answered your question this machine is a big project in itself, it will be one thing after another If you had another one like it up and going how good of a spare would this one be? If you had "messing around to do" then this one would be a possible project to mess around with. If it had undercarriage I wouldn't be so pessimistic ------------- HD3 |

Posted By: Ian Beale

Date Posted: 08 Dec 2018 at 2:08pm

|

Ronnie The AMBAC pumps run at engine speed. Also looking at the photo of your oil cooler shows oil pipe fittings from a very early engine. Later ones used different oil pipes or hose. Those fittings would indicate that the oil filter has bell and filter element above the base where with later ones it is below.

|

Posted By: RonnieJones

Date Posted: 08 Dec 2018 at 9:37pm

|

NomoreJohnDeere

Well considering the hard to find parts are what seems to go bad probably not much of a good donor from what I know about it at this point. I'll know more when I can get a vehicle to it. Ian Beale I went the other day to look for the engine tag. It's partially melted and none of the numbers are even close to readable, only somewhat legible was"lmers MFG" and USA. Pretty sure the filter does sit on top of the base. It's gonna take me a bit to source these parts. After the new year I'll start asking around. I do know there is some old machines up here. Who knows maybe I'll find a good barn find.

|

Posted By: Ian Beale

Date Posted: 08 Dec 2018 at 11:37pm

|

Ronnie "

Who knows maybe I'll find a good barn find." I think you'd be well ahead if that happened

|

jerbob wrote:

jerbob wrote: