D15 3 Point?

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=154856

Printed Date: 09 Jan 2026 at 7:21am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: D15 3 Point?

Posted By: modirt

Subject: D15 3 Point?

Date Posted: 16 Oct 2018 at 4:14pm

|

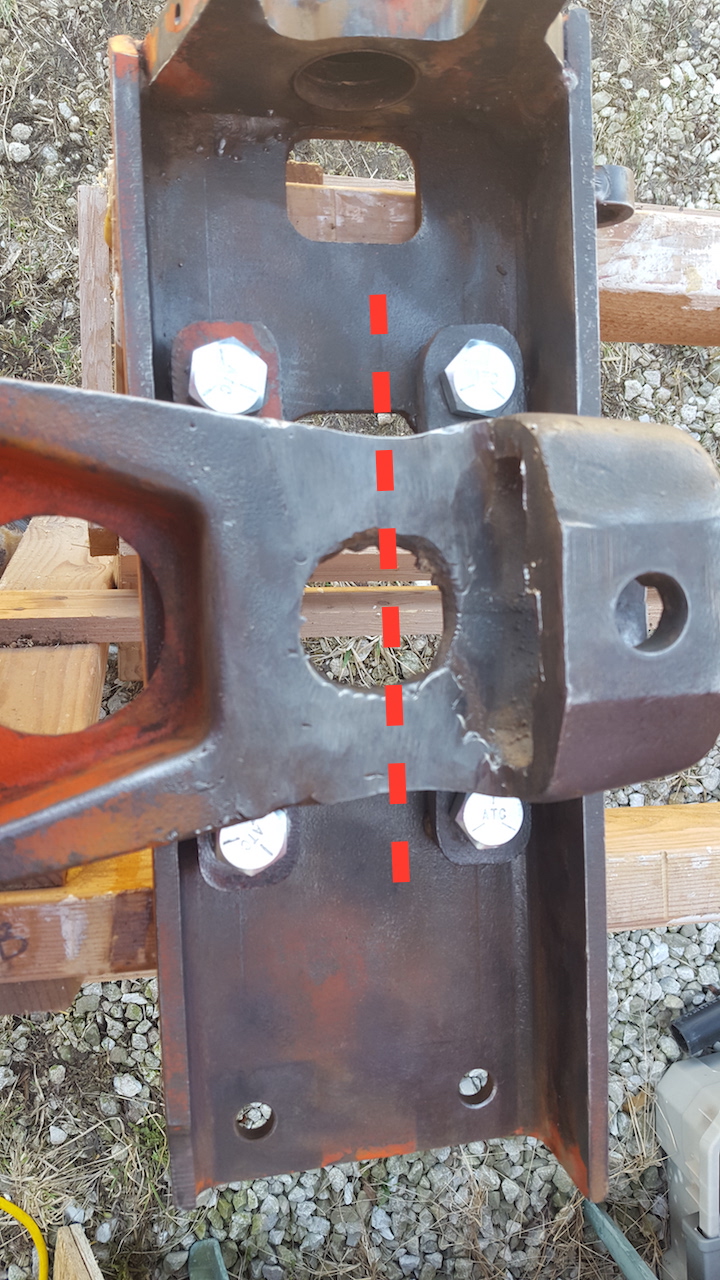

The saga continues. Two concurrent threads on this D15, but will ask this here as yet another stand alone thread related to this topic. So it can be found by others. Was in the process of installing the replacement stud needed to keep the factory 3 point in place, and for some reason, my eye caught a crack in the draw hitch assembly casting. I had checked to see if the bolts were tight, but hadn't crawled under that far, so I had entirely missed these before. Turns out not one but two of these mounting flanges were broken off, and clearly have been for some time. As I found the tractor, it seems there was really only 1 bolt out of 4 that was still intact and working. Good thing they parked it when they did.   Worse, not only are the bolt flanges broken off, but the casting has been broken at least once and welded back. (see red arrow) Bottom line is I'm rapidly coming to the conclusion that the factor 3 point is not nearly as robust as the snap coupler was. Since this is intended to be a user, not a show piece, I'm interested in the stouter option. Fragile.....some might say flimsy.....is not on my color wheel. Looks to me like when it left West Allis, it left with way more engine and tractor than hitch assembly to match. I know there is an option to covert the SC version to a 3 point, but has anyone gone the other way and grafted the factory 3 point arms onto a snap coupler hitch? If I understand correctly, the snap coupler is setup to use either the drawbar or lift arms but not both at the same time? Forgive me (please set me straight) if this is not right. I want to use both at the same time, so if it could be done, finding a way to graft the factor 3 point lift arms onto a snap coupler would offer the best of both worlds. If all else fails, I can go on the hunt and find a replacement casting for the factory 3 point, but knowing it failed once, and knowing I'd like to put some strain on it, I'm a bit reluctant to put something back I'm going to have to baby.

|

Replies:

Posted By: DSeries4

Date Posted: 16 Oct 2018 at 8:33pm

|

Sorry to find out the hard way that the factory 3 point hitch set up was not really up to the task. The rest of the tractor is strong as anything, except for this set up. As you eluded to, yes the snap coupler is much more durable. Fortunately, everything will bolt on your tractor with no problems. However, there are a lot of parts you need to accumulate. If you can find a complete tractor being scrapped out, that would be your best bet to get everything you need for your tractor. ------------- '49 G, '54 WD45, '55 CA, '56 WD45D, '57 WD45, '58 D14, '59 D14, '60 D14, '63 D15D, '66 D15II, '66 D21II, '67 D17IV, '67 D17IVD, '67 190XTD, '73 620, '76 185, '77 175, '84 8030, '85 6080 |

Posted By: PaulB

Date Posted: 17 Oct 2018 at 3:11am

| The failure you see it what is typical of what happens on all of the 3pt hitches on the D15 as well as the D10/12 tractors. The cure is to replace the lift arms and everything under the tractor with the Snap-Coupler parts. It is unfortunate that the Allis engineers did not re-design the D15 series II in the same way that the D17 seriesIV was. That may have lead to the carryover of only changing the sheet metal on the D15 to make the 160 instead of turning to an import to fill that HP need. It is a real shame that what most are using the 3pt for the most nowadays is what does the most harm to them. A 3pt brush-hog or blade is like a wrecking ball on those 3pt hitches. A homemade 3pt will only be a mismash of poorly designed parts. How do you plan on using both the 3pt and drawbar at the same time? |

Posted By: jaybmiller

Date Posted: 17 Oct 2018 at 6:01am

|

Yeesh, that's a real thin(cheap on metal) casting !! No wonder it broke apart,sigh. Couple of options I can think f 1) Make a replacement for the busted part from 1/4 or 3/8 angle iron. I'd probably spend a morning making it,3/4 time spent on a wooden model , then an hour cutting/welding up the steel one. Since it's a common failure, maybe it's a viable part to mfr and sell especially with CNC/LASERs being in shops these days. I did the wood model for a copy of the 'top link' mount and got 3 made. 2) All my D-14s are Snap Coupler, so I've mounted SC to 3PT adapters to stone rake and 5' rototiller. For 'drawbar' uses I made a Snap Coupler 'carryall' with a 2" receiver in the middle. Allows me to quickly add a ball sleeve or blank when required. Ball for hauling utlity trailers, blank for pinning wagons and disc. For me SC is a LOT easier to hookup than 3pt. just a couple options for you to ponder Jay ------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Butch(OH)

Date Posted: 17 Oct 2018 at 6:13am

|

As they said, common problems with that set up. Mine D-15II is factory 3 point also but prior owner added several braces that solved the issues with the mountings. I use the 3 point a good bit and it hasn't given any problems,,, yet. |

Posted By: DougS

Date Posted: 17 Oct 2018 at 6:17am

|

The best of both worlds might be to convert it to snap coupler and buy an aftermarket 3-point that uses the snap coupler. Those types usually use the existing traction booster. The only problem is that soon enough you are throwing some real money at it. |

Posted By: modirt

Date Posted: 17 Oct 2018 at 7:10am

Can you share photos of this setup? Big weakness of the factory 3 point seems to be it only uses the 3 bolts and a stud to take all the pulling forces in sheer, and weight hanging on the drawbar and 3 point in tension. Not unlike what might happen if you mount a loader on a tractor and only bolt it to the torque tube......gets a whole lot stronger and you will do less damage if the loader mounting frame also runs back and bolts to the back axle. So the goal of this conversion is to continue using the existing 3 point lift arms for Cat 1 implements, but find a way to mount them onto a drawbar assembly frame that is either a snap coupler hitch, or one that functions like it, in that it uses the same forward connecting points as the snap coupler, PLUS the 4 holes in the back castings. Using all those multiple connecting points. Forward holes help with the pulling loads in sheer (converts them to sheer PLUS tension or compression) and then the existing rear mounts only have to hold the weight of the assembly up, same as the snap coupler hitch does. Should actually be easier than converting a snap coupler to a cat 1 three point, as I already have the lift arms, and center link.

|

Posted By: modirt

Date Posted: 17 Oct 2018 at 7:27am

Can you share photos of your D14 conversions? This sounds like what I'm after. Except I want to graft my existing 3 point setup onto the snap coupler, bypassing the need for the SC to 3 point adapter.

|

Posted By: modirt

Date Posted: 17 Oct 2018 at 7:32am

|

For those wondering where I'm heading, a reminder.....I've got a 7' NH haybine, hay rake, NH 315 square baler (might be iffy on the baler), plus a whole slew of Cat 1 3 point implements available to me. In theory, the D15 is more than enough tractor to pull all of them, but not with a gimpy hitch that just about any of those can tear up. |

Posted By: Gary Burnett

Date Posted: 17 Oct 2018 at 7:42am

I'll bet you also check to make sure the hitch bolts stay tight.Just about every tractor I buy the bolts that hold the hitch in place some are loose.The 185 I have now just about every bolt needed to be tightened or replaced.No maintenance equals problems.

|

Posted By: BrianC

Date Posted: 17 Oct 2018 at 9:11am

|

I have questions. In the previous thread about needing a stud, the last two pictures you posted show the stud in the casting. There is a recess/spot face around this area. Do the 4 tabs on this broken draw bar support mate to those recesses? My confusion is, how would the 3pt torsion beam fitting (looks flat to me in the parts book) mate to these spot faces- they use spacers? It is a sandwich of parts, torsion beam fitting, then draw bar support, held on by the 3 bolts and one stud? I think you mentioned the pic was of a D14 (with the spot face I mention), is the D15, different, perhaps all milled flat or proud pads? I addition, just curious, are the two forward holes in the differential housing, and the two aft holes in the rock shaft lift housing, this draw bar part bridges them together? And, does the actual draw bar pin to that small hole at 12 o'clock? Do they break because the bolts get loose? Is it the loads when using the 3pt that break this, or the loads from using the draw bar. What if the part were cast steel or fabricated, instead of cast iron. What if you just tossed this part, didn't use the draw bar. The 3pt hitch torsion beam frame will still bolt up, shouldn't it? The bell for the snap coupler, isn't there a mounting area for that further up (fwd), could a draw bar be made to pull from there? just speculating, and without a clear picture of the existing design. Curious to know how they fixed the D17. But this does look like a highly stressed area. Yeah check into what Butch mentioned. Pics of the whole thing would be nice. |

Posted By: Butch(OH)

Date Posted: 17 Oct 2018 at 9:30am

The entire loading of the bottom 3 point arms is controlled via 4 closely spaced bolts on the mount under the rear end. Any side loads or twisting motions on the hitch greatly stresses those 4 bolts because of the close spacing. They work loose and if not attended to all the time one by one they fall out and that stresses what is left even more. The design is flawed, period. My'15 is out at the farm. I will take a few pics next time I am there. The "fix" isnt pretty, but it is functional.

|

Posted By: Leadoff

Date Posted: 17 Oct 2018 at 2:58pm

|

MoDirt My experience from many years ago.......our D15II drawbar / TPH support casting broke similar to yours when the tractor was hauling very large loads of very heavy manure in a New Holland 510 Spreader. The failure occurred when one of the tractor rear wheels went down into a roadway depression causing increased downwards loading on the drawbar - bang!!! As most manure spreaders are designed back then(early 70's) there was lots of vertical load on the spreader hitch to the tractor, and it was too much for the D15 design, especially impact loads. Our low cost, simple solution, was to install two steel bars, holes drilled at each end, from the bottom hole on the Three Point Hitch Top Link Mount just above the PTO, to the rear horizontal bolts on the cast mounting in your pictures. In your pics this would be the bolts that connect the steel plate drawbar bail to the casting that failed. The connection needs to be snug with no play. We removed the PTO shield as it was not needed. The new steel support bars need to be bent outwards to allow access to the PTO. The new design, and a new cast iron support from the dealer, lasted for many years including many more loads of manure and rough rides. The drawbar had a permanent curve downwards from years of heavy loads and work, but that cast iron support never failed again. I do not have any pics for you, but I would be happy to discuss by phone or email. The design we installed changes the vertical loading conditions for vertical drawbar loads on the cast iron support. The drawbar and supports changes from a cantilever to a supported cantilever where most or all of the vertical load transfers up through the new steel bars to the TPH Top Link connection. The cast iron support is now pushed up into the tractor frame (instead of pulled down)which is more robust for the assembly. The solution loading condition now is similar to the tractor TPH arms and how loads are transferred to the tractor frame (vertical and horizontal). The design does not change loading conditions for horizontal/pulling/pushing loads on the drawbar. As other forum members have noted, the D15/D14 design appears ok for normal pulling loads. The cost is the two steel bars, longer bolts for the steel bail connection to allow for the steel bars width, and you can probably reuse the old steel bail bolts in the top connection to the TPH Top Link mount. We gave up use of the PTO Guard Shield and the bottom hole in the TPH Top Link Mount but that was not an issue. Hope this helps. Let me know if you need more info...... ------------- 1963 D17D Series III. 1965 D15 Series II. 1965 D17 Series IV. 1975 185. 1978 716H. 1979 716H. 1965 780 Harvester/1R&DC. 1957 Model 73 SC 4 Furrow Plow |

Posted By: DrAllis

Date Posted: 17 Oct 2018 at 3:53pm

| The snap-coupler drawbar bail hangs from those same four bolts/studs, so I don't think the design of the mounting hardware is necessarily too flawed. The 3 point bracket that is broken may be too thin and not heat treated enough, which could make the hardware loosen up and then troubles down the road. If you ever look at a D-17 S4 you will find all the components are essentially the heft of the 190XT, a 95 HP rated tractor. |

Posted By: jaybmiller

Date Posted: 17 Oct 2018 at 3:55pm

|

------------- 3 D-14s,A-C forklift, B-112 Kubota BX23S lil' TOOT( The Other Orange Tractor) Never burn your bridges, unless you can walk on water |

Posted By: Alvin M

Date Posted: 17 Oct 2018 at 3:57pm

| I had some made out of steel years ago. sold out. any good machine shop can make one |

Posted By: Butch(OH)

Date Posted: 18 Oct 2018 at 6:11am

It isn't flawed for a snap coupler  , as you well know the snap coupler is not only a pull point but also a pivot thus it and the mounting bolts are subjected to only a small amount of side pull or twisting forces. However when that same mounting is used for a 3 point there is no pivoting. If you have a blade on 3 point tractor and hook a root or rock with the corner ALL of the twisting generated by the implement it transferred to the tractor through those 4 bolts, same deal when you have a brushhog on it turn sharp and hit the brake to turn. As evidenced by the fact that virtually all of them are buggered up either the bracket, mounting studs or both, it is a poor design that could have easily been made much better with a few braces to spread the load out. , as you well know the snap coupler is not only a pull point but also a pivot thus it and the mounting bolts are subjected to only a small amount of side pull or twisting forces. However when that same mounting is used for a 3 point there is no pivoting. If you have a blade on 3 point tractor and hook a root or rock with the corner ALL of the twisting generated by the implement it transferred to the tractor through those 4 bolts, same deal when you have a brushhog on it turn sharp and hit the brake to turn. As evidenced by the fact that virtually all of them are buggered up either the bracket, mounting studs or both, it is a poor design that could have easily been made much better with a few braces to spread the load out. |

Posted By: Ray

Date Posted: 18 Oct 2018 at 8:30pm

|

I think the D-15 series 2 with three point hitch Is the finest tractor every made. They are a small tractor and should be used that way. No they will not do the work of a 100 HP tractor. How long will a 1/2 ton pickup (any brand) last pulling a grain cart with 1000bu, of corn out of these muddy fields. Do not give up on that three point. I have a factory three point for a D-15 for sale. Also could go back to original snap coupler. Thanks 785-353-2392 |

Posted By: JoeO(CMO)

Date Posted: 18 Oct 2018 at 8:35pm

|

Tanks have been broken also! ------------- |

Posted By: Steve Zidlicky

Date Posted: 18 Oct 2018 at 9:49pm

| get a good part from Ray and bolt it down good and tight. check it when you change the engine oil each time to make sure it stays tight. no need to reinvent the wheel |

Posted By: modirt

Date Posted: 19 Oct 2018 at 2:05pm

You could be right about that, but despite nearly 3 months effort and throwing a bunch of money at it, I can't seem to get her working long enough to find out. To date, I've only managed a couple recreational laps around the parking lot. Also frustrating, as there are some things needing done around here that she would really come in handy for, yet I can't seem to get her on the ground doing it. Simple stuff like moving hay equipment left parked outside into the barn. As far as I know, the only 3 point part I need to get her put together to get her working is that busted casting. The rest looks to be good. If I could get my hands on a good casting, one that is not mangled and welded up, I'd be willing to put her back together as a factory 3 point so I can begin using her. That is the quick and easy way to get her here to find out. That is assuming in that mode she is capable of handling those light Cat 1 implements like a 60" garden tiller, 6 foot disk, etc. Basically duties of a souped up garden tractor. Only farm work is that 7' Haybine, hay rake, etc. One way or another, she has to be able to handle at least those, or else I need to be looking into the SC conversion, or for something else that can. |

Posted By: Steve Zidlicky

Date Posted: 19 Oct 2018 at 2:31pm

| something to ponder over for you. the series 2 factory 3 point is light years better to use than even the factory snap coupler conversion. I have used both a lot. I fixed one for someone years ago and like a fool quaranteed it to hold. It held together and I am not looking for a job. yours has been already stressed other than where it is now broke since it was only holding by two bolts. a repair would be taking a chance unless you could get it magnafluxed for other cracks and if none are found maybe fix it. If you cannot do better, I have a repaired one on a parts tractor. I did not do the repair, it isnt pretty, but looks like an old repair so should be ok. |

Posted By: modirt

Date Posted: 22 Oct 2018 at 8:26am

|

OK, here is where we stand as of today. Have heard from folks on the forum that the factory 3 point is good and I should find a casting and put it back together and use it. Have heard from others on the forum, and others not on the forum, that the snap coupler version, while perhaps not as user friendly, is far and away stronger. To relay the sentiment expressed by several, if you were going to really use the tractor and put a load on it, the snap coupler hitch would still be there when the tractor had had enough and stopped pulling. The factory 3 point, under equal strain, might get left behind. So usable, but flimsy by comparison. Put another way, you don't see many snap coupler hitches torn up from use. Worn down, but not busted. Not so with the factory 3 points. But either way is better than no way, which is what I have now. So as of today, I'm looking for either the 3 point casting, or a snap coupler replacement. First one I can find is how we will put it back together. As is, tractor is not good for any use. So if anyone has either from a parts tractor, please send me a PM. PS: Not sure what happened to Ray. Called and got no answer. Left a PM and got no answer. |

Posted By: modirt

Date Posted: 23 Oct 2018 at 7:16am

|

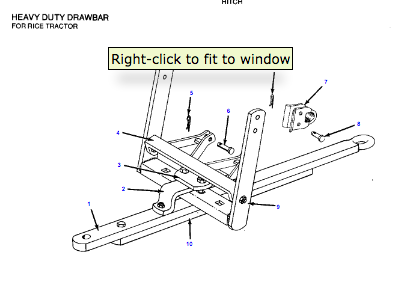

BTW, while perusing the Agcopartsbook diagrams for D15 hitches so

as to get a feel for how things were setup and what parts are needed for

each option, I discover there were four different drawbar options for

this tractor. They were....... 1. Snap coupler 2. Base tractor (I think series 1) 3. Rice Tractor ("heavy duty".....I like the sound of that) 4. Adjustable drawbar for factory 3 point (what i have) My

lack of experience with the Snap Coupler setups makes all this hard for

me to visualize how it is supposed to work with Cat 1 - 3 point

implements. Whatever the case, goal remains to get a sturdy option that allows use of the drawbar or Cat 1 - 3 point implements with no changes needed. Back up to one or the other and off you go. Or at least that is how it has worked with every other tractor I've ever used and that is several dozen of them over the years.

|

Posted By: Steve Zidlicky

Date Posted: 23 Oct 2018 at 9:13am

| This is a little long and critical but it seems as if you have a real lack of understanding the situation starting with the carb and moving foreward. I feel you are really trying to do the right thing and ask questions concerning things you do not know about. So many people have tried to help you with good intentions and maybe it has overloaded the process. so you have that urge to get this tractor running asap. what did you use before it came along? slow down and fix it back right with the original part. If you keep the bolts tight holding the casting to the tractor you will probably never have an issue. notice how yours was loose and appears to have been a long time. that is what causes breakage when the part is shocked. leave it factory 3 point and the tractor will be worth more later on. due to your admitted lack of knowledge of snap coupler design and usage and you have non snap coupler 3 point implements fix what you have. if you think you have to have a snap coupler setup consider this: unless you have snap coupler implements you will have to use an aftermarket 3 point assembly that attaches to the drawbar. another 3-4 hundred. Kind of stupid to remove the factory lift arms and other parts you already have and downgrade to the aftermarket stuff wouldn't you think? If you keep the factory lift part and just use the snap coupler bottom end it will be mickey mouse and hurt the value of your tractor that you have been throwing a lot of money at for various reasons. if you do not leave the drawbar plate loose where the drawbar bolts down to the drawbar bail, the traction booster will not work as it is activated when the draft is pulled at the bell whereas the factory 3 point draft linkeage is attached to the assembly you currently have off. so do you want your drawbar loose and sliding around foreward and back or tightened up like it is supposed to be? the only other option for everything to work as it should is to go with snap coupler implements then you are getting stuff that only works on snap coupler tractors plus the availability and cost is not practical. if you went with that direction you can also buy a factory 3 point conversion for using any standard implement ( a good conversion 3-4 hundred dollars) if complete and you have to remove the drawbar assembly to use it. Have done that and it gets old. and....you have the expense of buying all the parts to convert to snap coupler. |

Posted By: BrianC

Date Posted: 23 Oct 2018 at 3:25pm

|

When we say keep it good and tight, I say uhh? How many ft-pounds torque is good and tight and right, here? What did Allis-Chalmers say in service manual. In fact since this is a trouble spot, did they ever issue a TSB, technical service bulletin? Did Fiat issue anything for the 615 industrial? I would keep it original factory 3-pt. You have the search on for a replacement casting. Maybe slow down on this drawbar issue and shift to other issues. However, I would want to know right now that the (4) 3/4-10 holes in the bottom of tractor are OK. What scares me about these old tractors is the 3-pt control valve. If that is bad, now what. Aside from being ready to fall off tractor, did the 3pt hitch work correctly hydraulically? |

Posted By: modirt

Date Posted: 23 Oct 2018 at 7:49pm

|

During the limited time I've had the tractor running, we did test the factory 3 point. It went up and down fine, and I also got to test out the one way hydraulic cylinder and it went in and out too. Still think that is the oddest setup on a tractor I've seen to date, as the same control lever on the steering wheel controls both the 3 point lift arms AND the hydraulic remote cylinder. I think back to an 8' boom pole I built in a high school shop class that used both the 3 point lift arms to raise and lower it, and a hydraulic cylinder in place of the three point top link to tilt it up and down. That would have been an interesting situation with both working off the same lever.

|

Posted By: DrAllis

Date Posted: 23 Oct 2018 at 7:55pm

| Your tractor has the standard hydraulic system. If you want to operate a 2-way cylinder or multiple cylinders, you add-on the optional spool valve/valves. This OEM optional valve isn't available anymore, so you'd have to locate a used one or create your own system with a new valve. |

Posted By: modirt

Date Posted: 23 Oct 2018 at 8:02pm

|

As for the factory 3 point, I'd be perfectly happy to put a good factory 3 point casting back on if I had one, but I don't, and I've been told by some folks that short of buying an entire 3 point setup off a parts tractor, a lot of parts I don't need, finding just the casting is going to be tough. At least a good undamaged casting that I can trust. On the other hand, there are lots of snap coupler parts available, not to mention the snap coupler setup is far and away more robust and can handle a lot more work. Or so I've been told......again, I have no experience with these little guys so I'm listening what everyone who does have experience has to say. |

Posted By: modirt

Date Posted: 23 Oct 2018 at 8:06pm

|

I understand the one way cylinders. Both the 3 point and remote are working that way. What I find unusual is both are controlled by the same lever. Push the control lever up and the 3 point arms go up, and the cylinder extends. The one with the least resistance goes first, then the other. Only tractor I've ever been around that did that. |

Posted By: Steve Zidlicky

Date Posted: 23 Oct 2018 at 8:49pm

| the reason they are both controlled by the same lever is because the internal 3 point lift cylinder and the remote line are hooked together so whichever has the heaviest pressure load on it is the last to work. it is all about equal or unequal pressure. If you will look left and behind the seat you see the remote coupler and it has two steel lines that go to the hydraulic pump. one of those lines is the high pressure and the other returns oil to pump. under the block that those two lines hook to is where the hose goes from the block to the lift cylinder. you cannot see this hose unless the block is removed as the hose is all internal. that whole setup is why and where the fluid goes both directions with only one lever. hope this helps |

Posted By: DanWi

Date Posted: 23 Oct 2018 at 9:42pm

| Just a suggestion take it to a good welder that knows what he is doing and have it fixed maybe you could find a way to reinforce it even. Use it with care knowing that is the weak spot and continue looking for a good replacement, at least that would get you going for now. |

Posted By: Tracy Martin TN

Date Posted: 23 Oct 2018 at 10:41pm

|

A good machine shop could reproduce that part for you. Wouldn't be cheap, but would last. JMHO, Tracy ------------- No greater gift than healthy grandkids! |

Posted By: modirt

Date Posted: 25 Oct 2018 at 11:25am

Ray, I'm still in the hunt for a good drawbar/3 point support casting. I've called the above number a few times and nobody answers. Check your PM for my phone number so you can call me when its convenient for you. Thanks! Or if anyone else has a good one, feel free to PM me with contact info and details. This one........  |

Posted By: Don(MO)

Date Posted: 26 Oct 2018 at 12:49pm

|

Try calling Austin Farms Salvage at 660-679-4080, they are in South West Mo. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: modirt

Date Posted: 26 Oct 2018 at 1:08pm

|

Called Austin's already.....nope. Called Hilltop Salvage in Lamar......recording sounded like they had gone out of business. Called Cooks in Clinton......nope. Sandy Lake Brenda......nope. OK Tractor.......nope (and no off the shelf replacement either) Currently watching ebay and trying to reach Ray. For those of you who have had a machine shop make you a replacement, how was that done and what does it look like? Pictures? |

Posted By: modirt

Date Posted: 26 Oct 2018 at 1:12pm

|

BTW, what is the best guess as to how many factory 3 point D15's were made to begin with? However many that was, less all those with busted castings, less all those already parted out or potential parts tractors hidden away behind barns or stashed away in barns, may be all that are left to work with. They may be few and far between by now. |

Posted By: Don(MO)

Date Posted: 26 Oct 2018 at 1:41pm

|

Might try searching for "tractor salvage yards in Missouri" tractor salvage yards in Kansas and them try searching state by state, might find one out there. Good luck. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: modirt

Date Posted: 28 Oct 2018 at 6:58am

|

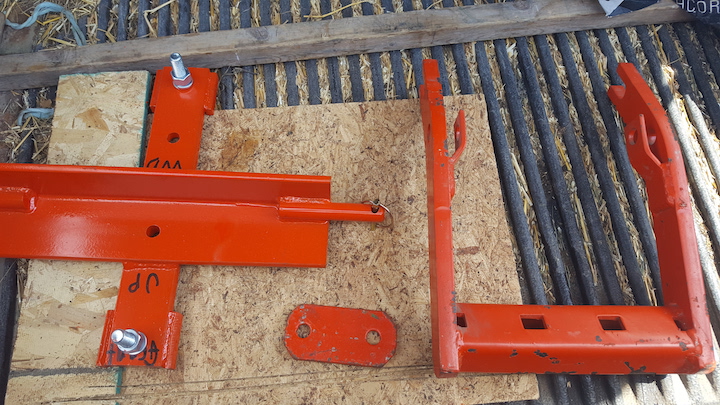

A forum member has sent me these photos of what appears to be an adaption of a SC hitch onto a factory 3 point tractor. Not sure if it is an aftermarket factory make, or someone made this at home. Does anyone recognize it? Although it is not shown, I"m told it also has the ability to accept a drawbar, in which case, it would seem to be what I'm looking for. A hell for stout hitch replacement that fits Cat 1 3 point implements, plus has a drawbar and can be used interchangeably without modification or need to swap options. In the hell for stout category, this has it. Utilizes the SC forward attachment points, including bell. Instead of the cast bracket that has failed, it uses the typical SC drawbar support brackets and 4 holes, including cap screws and stud, plus it has the support arms that go all the way up to snag the top link plate plate fastner holes, and replaces the plate with it's own holes. All the same geometry as the original. This one would take all the stress the tractor could dish out. As a bonus, it seems to take most of the stress off the existing bolt holes. Only downside I can see is the traction boost feature would be lost, but that wouldn't matter to me anyway. Thoughts? PS: (Still no leads on a replacement casting, other than to weld the one I have).     |

Posted By: DrAllis

Date Posted: 28 Oct 2018 at 7:10am

|

That is an after-marketer's attempt to put a 3-point hitch on a D-series tractor. What you haven't figured out yet is this.....that frame hangs and PULLS from the same 4 studs/bolts as yours does. That fact that it is plugged into the snap-coupler bell is deceiving. The pulling eye has ZERO tension on the snap-couplers hook and even if it did have tension on it, the coil spring can still yield when yanked on. So, in the end....the same four connection points are doing all the work. I still maintain your (and every other ones) hardware was NOT torqued TIGHT and kept tight. Maybe the broken bracket is weak, but when all 4 studs/bolts aren't working together, they will work loose. |

Posted By: Jim.ME

Date Posted: 28 Oct 2018 at 4:38pm

| To your question of how a machine shop made a replacement and what it looked like. I have not had one of these made so can not show you photos, but I have had steel replacement parts for different cast parts made over the years, many more complicated than this part. Clean your broken one up good, take it in hand, along with the center to center and the diagonal measurements of the four mounting holes in the housing, and go talk with the shop. There are generally different ways to do things depending on the tooling and materials they have available and they will explain to you how they can do it with their equipment. If they are a "real" shop they won't need, or likely want, you to tell them how you think they should do it. When done it will look very close to the original, but with all 4 mount tabs. And, no it won't be cheap but none of the options, like converting to a snap coupler and building a 3 point to work in conjunction with that, you are kicking around here will be either. You can always check out two or 3 shops if you want to shop it around. JMHO |

Posted By: TimNearFortWorth

Date Posted: 29 Oct 2018 at 12:42pm

|

Doc, hard to tell but look at the last two pictures. This unit does pull directly from the SC eye, and the frame system "floats" by being supported by the heavy bar stock frame. The frame is supported by the drawbar hangers, which the aftermarket frame bolts to, plus the frame of the unit hangs off the rear lift housing at the milled flat for the seat mounting. Having two factory 3-pt. D15II units and knowing most have had the lower bracket mounting plate causing damage from being run loose, I have kept this old conversion in-case I needed it when I get around to restoring one of those 3-pt. units as I also use my tractors. That hitch adaptor is on a S1 that I bought for parts years ago. The idea was for MoDirt to post these so Jim D. or someone could possibly ID the brand, or even find one for him if any are still out there. We may just have this one copied at a friends shop so the 3-pt. units can be adapted by adding the SC bell and hanger brackets along with this adaptor. Two things I would do if I use this on one of my 3-pt. units; make a bracket for mounting with two bolts up front like the factory top link and just add strap back to the main frame behind the seat, easy enough to do. Make the drawbar where it extends back for use, or add a section that can be bolted on to extend the DB rearward for light use. These little tractors are just that, little tractors and I consider the D15 3-pt. to be no heavier than the little 8/9N Fords. Would still like to know if anyone recognizes the brand of this adaptor . . . .

|

Posted By: Pat the Plumber CIL

Date Posted: 29 Oct 2018 at 12:58pm

|

Modirt , have you tried Bill Deppe , Deppe salvage. He posts on here and he may have one or know where to find one . Somewhere in Iowa ------------- You only need to know 3 things to be a plumber;Crap rolls down hill,Hot is on the left and Don't bite your fingernails 1964 D-17 SIV 3 Pt.WF,1964 D-15 Ser II 3pt.WF ,1960 D-17 SI NF,1956 WD 45 WF. |

Posted By: modirt

Date Posted: 29 Oct 2018 at 1:28pm

|

Didn't know about Bill.....and don't have his contact info. If he finds this, I hope he will PM me. |

Posted By: JoeO(CMO)

Date Posted: 29 Oct 2018 at 7:20pm

|

I think that 3 point could be one that alot of after markets were pushing. I recall farm magazines, used tractor parts sales, Wards, Sears, Central Tractor Parts in IA, and more. I recall but can't swear to it. A neighbor had one on his IH M, maybe a little different the came from Danuser I believe,, but that was 60+ years so I'm a little foggy on it but he was sold on anything Danuser sold. Look in old Farm Magazines from the '50s. It was like anybody with a welder were pushing them. M+W Yetter Coulter ------------- |

Posted By: modirt

Date Posted: 11 Nov 2018 at 10:12am

|

It occurs to me I failed to update this with a progress report. Have considered a lot of advice......from advocates of the snap coupler conversion to advocates of the factory 3 point.......and for now, have decided to stick with the factory 3 point setup. Will get her back up and running that way, then evaluate how it is looking. After visiting with an AC enthusiast who claims to own somewhere around 250 AC tractors, including several D15's, including a couple D15 restoration projects of his own, his belief was a guy could look for over a year for a pristine replacement casting and not find one. Would probably have to buy a parts tractor to find one. One 3 point assembly, with casting, was made available, but carried a 4 figure price tag. So, a local machine shop has the casting and it will be repair welded, then re-installed. The welders who run the shop, and AC guys who know the shop tell me if they weld it, it should hold. In addition to the casting, they will also be doing some surgery on the drawbar itself, along with side sway turnbuckle chains, which are frozen up.....and one was broken off. Then, we have also had to remove the front traction boost assembly, as the rubber seal mounted on the traction boost lever pin....the seal that holds in all the hydraulic pump oil.....started hemorraging oil after we removed the casting. Probably dried out after sitting for all that time. If the new seal holds, all that is needed is to re-install the 3 point casting assembly and she should be done and ready to run. Will post a photo of the welded up, finished product. |

Posted By: Don(MO)

Date Posted: 15 Nov 2018 at 9:49am

|

Here's a three point. http://www.allischalmers.com/forum/this-guy-has-some-d14-15-things_topic155579.html" rel="nofollow - http://www.allischalmers.com/forum/this-guy-has-some-d14-15-things_topic155579.html ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: modirt

Date Posted: 15 Nov 2018 at 7:17pm

I also saw that in the classifieds, but in the photo provided, I'm not seeing the broken casting, which is the only part I need. As near as I can tell, I already have everything else shown in the photo. Close........but no cigar!!!  |

Posted By: Don(MO)

Date Posted: 15 Nov 2018 at 7:40pm

|

Did you try calling him to see if he has more parts? here's the call back number (717) 422-0267. ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: SteveM C/IL

Date Posted: 15 Nov 2018 at 8:48pm

|

Jack of all,master of none...I believe I could fab up a bracket to replace that broken one.May look alot different but would work. Best thing you can do on reassembly is locktite studs in casting and use nuts on the ends.Might even locktite them.

|

Posted By: JoeO(CMO)

Date Posted: 16 Nov 2018 at 8:17pm

|

Modirt, of the numerous D15's I've had, the first one was damaged like yours, broken DB bracket, studs in transmission and lift housing had been damaged to a point they were welded inside of the housings. All as a result of misuse!How are the mountings in the bottom of the housings?Are you interested in selling? ------------- |

Posted By: modirt

Date Posted: 17 Nov 2018 at 9:00am

That seems to be the general consensus from informed D15 users. And it may be as much neglect and ignorance as to the importance of keeping things tight down there as it is misuse or abuse. Sources tell me if the bolts are kept tight, the hitch as designed is adequate and durable for light duty use.....but if allowed to work loose, the assembly may self destruct and do a lot of collateral damage in the process. Ergo the importance of checking those bolts and keeping things TIGHT! As for the housing holes......I'm not certain what condition they are in. Even though the casting flanges were broken off, the bolts holding up the broken pieces were still holding tight. The only bolt that was loose was the one inserted into the transmission where a stud should have been. It was loose (and dripping oil), but that flange was still intact. The stud that went back in that hole went in tight. If really bad, what options are there other than helicoils or swapping out for a pristine casting off a parts tractor? What is to become of this little jewel once she is back together and running is uncertain. I'm not interested in collections or such......when I started this rehab, tractor was intended to be a user. If it winds up with a gimpy hitch that is unable to do anything other than look pretty and do only very light work, it would be of no use to me.

|

Posted By: Stan R

Date Posted: 17 Nov 2018 at 9:34am

| We had a D15 (not sure what series) and beat the crap out of it and never had problems with the 3 point factory system. Hauled manure (high speed thru the fields loaded...), pulled and jerked frozen logs out of the woods, etc. Maybe lucky? Whatever... |

Posted By: modirt

Date Posted: 17 Nov 2018 at 9:52am

You are not the first person who has offered similar stories. They also claim heavy use with no issues. And just as many others mention failed and broken castings. It's almost as if we are not talking about the same machine. The common thread among all stories is the bolts holding the casting up. Loose bolts = damage. Keep the bolts tight and the hitch can handle it. Or so I'm told. I'm still not convinced it is anywhere near as strong as a snap coupler hitch, but with drawbar or 3 point available with no swapping out of parts, it is a whole lot more handy.

|

Posted By: modirt

Date Posted: 13 Mar 2019 at 4:13pm

|

Is anyone familiar with this 3 point conversion from Cross Manufacturing in MO? Can the draw bar and 3 point be used either or without swapping out or changing anything? Requires conversion back to a snap coupler setup, but I can find the parts to do that.  |

Posted By: Don(MO)

Date Posted: 14 Mar 2019 at 8:23am

|

Just call Tony (503)-767-3660 he will fix you up. he will drop ship it to you. TonysTractors.com Tony Carbaugh Enterprises LLC, 12781 Marion Rd SE, Turner OR 97392, USA Here's the link to Tony's three point hitches. http://www.tonystractors.com/ac3ph.htm" rel="nofollow - |

Posted By: john(MI)

Date Posted: 14 Mar 2019 at 2:43pm

|

I had a Saginaw Tractor Parts 3 point on my D14. They no longer make them. It is labeled to fit the 14, 15 and 17. I got a piece of hardened thread rod. Using break cleaner and a die, i cleaned out all four holes. I put four studs in with locktite. I mounted the three point using double nuts. It did not come lose or break. ------------- D14, D17, 5020, 612H, CASE 446 |

Posted By: modirt

Date Posted: 04 Apr 2019 at 5:53pm

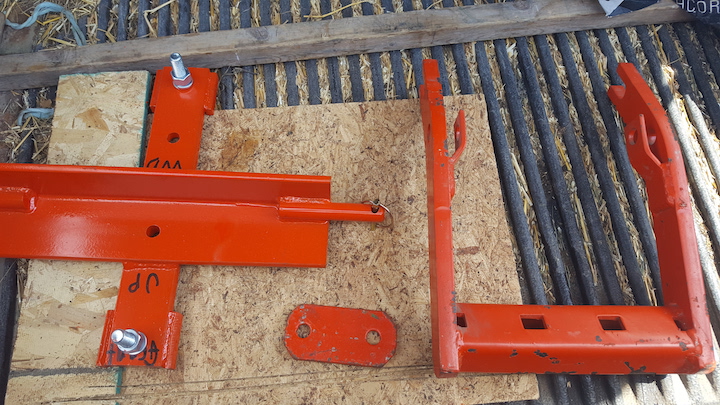

Update........things have been quiet here, but been a lot of churning behind the scenes. It has taken me a while to get there, but advice given by Doug above is where I'm going. For starters, direction I'm headed got lined out at the Boonville swap meet, when forum member AJ showed up with this aftermarket 3 point hitch for a SC tractor:  Would have bought it but it was already sold. But that confirmed it was the direction I wanted to go. So went back to the welding shop......bracket had not been touched, so picked it all up and brought it home. Found a new welder to look at it.....but he wanted it cleaned up first. This is what I found once all the crap was removed.....  At some point in time, bracket has been snapped in half......front and back, and was welded back. Best guess is when weld was completed, the feet were not left entirely flush with each other......so when it was bolted back together, at least two of them were put under strain, so it only took one more good jolt to snap the legs off em.  So knowing it had already been snapped in half once, welded and snapped again, this one was not going back......and after 6 months of looking and not finding a replacement.....and having the Cross aftermarket hitch available, that is the direction I went. So we started the conversion back to a SC tractor. Got all the factory 3 point stuff stripped off.....and started scrounging SC pieces off parts tractors and got those cleaned up.    To be continued........ |

Posted By: modirt

Date Posted: 04 Apr 2019 at 6:51pm

|

So once you abandon the factory 3 point, and go back to the SC attachment points, yet still want to have a functional 3 point and drawbar on the tractor at the same time.....here are some of the options I found. First is to view the factory 3 point itself..........  Missing the drawbar, but you get the idea. A light weight Cat 1 hitch. BTW, only four bolts hold the entire thing on......bolts are spaced 4" front to back and 7 1/4" side to side. Any weight on the drawbar has an incredible amount of leverage on the bolts. Then I found this hitch......which I'm guessing is from Worksaver.......and offered by a few parts vendors.....OK Tractor, YT tractor, to name a few..... https://www.yesterdaystractors.com/Allis-Chalmers-D15_3-Point-Conversion-Kit_HK306.html It grafts to the SC bell and 3 point arms........  Much more robust, but at $1,200 +, also expensive.....and has to be made to order. This 3 point adaption was seen on a D15 on the classifieds......described as a "ginger" tractor. This one seems to be using the factory 3 point system, except it has been modified to include the vertical straps that go over the housing above the PTO to support vertical weight......and also looks to me like it has D17 or some other Cat II lift arms (also described as lugs), yet uses the factory 3 point lift links. It has an aftermarket drawbar. No clue where it came from, however. It may be entirely custom & homemade....and no clue what is hanging down below holding it all up. Factory bracket and torsion bar or ????? But looks to be a lot more robust than what the factory came up with. If I could have bought one of those I probably would have.  Lastly comes the one from Cross Manufacturing......and one found on numerous aftermarket parts sites.......  Drawbar is shown for affect, but not included in the conversion kit. Since I already have the 3 point arms and lift links, I didn't need those. I just needed the cross piece that mounts to the drawbar (unpainted piece in the photo)....plus the drawbar support bracket / yoke / assembly. The conversion kit also includes a sway bar assembly that eliminates the need for sway chains or arms. It slides over the drawbar support and clips into place. Shop already had that. So with most of the SC parts found, what I needed to complete the ensemble was the cross piece and drawbar hanger, and Cross would sell them to use by the piece.....grand total of $175.....actually less than I was quoted to weld up the bracket.  We found a WD drawbar that fits and the 3 point lift arms fit just fine. Lastly I needed the support brackets and opted to go for new replacements as all the old ones I could find were worn pretty bad.... |

Posted By: modirt

Date Posted: 04 Apr 2019 at 6:53pm

|

These were the replacement L brackets from Heitman Tractor.....  Once I get these painted up.....tractor should go back together in a hurry. |

Posted By: modirt

Date Posted: 04 Apr 2019 at 7:01pm

|

BTW, I think we have the drawbar issue worked out, but if not, I'd be tempted to go this route...... https://www.yesterdaystractors.com/Allis-Chalmers-D15_Drawbar-Yoke-Assembly_232074.html Interesting that the drawbar parts number it is shown to replace on the D15 is NOT the standard SC drawbar. It is the drawbar for the HD SC hitch for the rice tractor.....this one.....have seen at least one price quote for drawbar alone of around $230.....or some such thing. Same one is used for the D14, D15 and D17 kits. That should do it!  I have looked and studied and cannot for the life of me see where those two vertical hanger support straps would attach to. On my D15, there isn't anything there. Does anyone have this HD rice hitch or has anyone ever seen one? |

Posted By: lentsch

Date Posted: 04 Apr 2019 at 7:43pm

|

I had problems with my D15 with factory 3 point as well. Local welding shop built me a new bracket (as others did) but I still had problems with the bolts coming loose. Finally the threads were about shot from the bouncing of a 300 hundred gallon sprayer so I drilled them out and used metric bolts which were only slightly bigger than the original bolts. I also built a bracket using the 3 bolts around the PTO shaft extending down to the drawbar frame and welded and bolted it-really a simple fix but hard to explain. May post pictures later if anybody is interested. This repair was made well over 20 years ago and has never given me problems again despite still pulling that sprayer and a lot of other things. ------------- WD,D15,190XT,7000,8010x2,7060,8070 |

Posted By: modirt

Date Posted: 05 Apr 2019 at 6:45am

I would be interested in the pictures. Both brackets.......one under the tractor being harder to get good clear pictures of. It seems many....if not most all.....of the home solution repairs includes vertical straps to support the weight of the drawbar. The HD SC drawbar for the rice tractor included them....  When you realize the bolts running fore and aft are only 4 inches apart, that is a lot of leverage force working on the casting. Mine broke the first time in a "thin" spot as it looped under the torsion bar. But as for those vertical straps, there isn't a good, solid place to bolt them to......so most seem to have integrated it into the top link plate........some going so far as to replace the top link plate with one they made. Almost all the solutions I posted photos of that had these vertical straps did it that way.

|

Posted By: modirt

Date Posted: 05 Apr 2019 at 6:46am

|

Also curious to know if the bolts working loose and drawbar support failures is an issue with SC tractors as well.....or just confined to the factory 3 points? |

Posted By: DrAllis

Date Posted: 05 Apr 2019 at 7:26am

| Can't say I've ever seen those four bolts work loose on a snap-coupler drawbar. They were BOLTS, not studs with nuts. |

Posted By: Marlyn nwia

Date Posted: 05 Apr 2019 at 10:51am

|

after all the discussion regarding the weakness of the factory 3pt on a D15 II; should I dare to mount a recently purchased 360 lb. four wheeled hay rake? I will be raking very rough terrain, water ways, road ditches etc.

|

Posted By: DrAllis

Date Posted: 05 Apr 2019 at 12:03pm

| If you do, I'd make sure the nuts/bolts are all TIGHT !!!! |

Posted By: JoeO(C-MO)

Date Posted: 06 Apr 2019 at 9:30am

|

------------- D10 III, D15 II 3 pt, D15 II SC, 170 Gas w/shuttle, 175 Diesel UI ROPS, 185 w ROPS. AC 653 w/6 way blade, ROPS AC 615 Ind. WD45 running/Parts. |

Posted By: lentsch

Date Posted: 06 Apr 2019 at 8:08pm

|

Will try to get picture of my fix tomorrow-Thanks for your patience. ------------- WD,D15,190XT,7000,8010x2,7060,8070 |

Posted By: lentsch

Date Posted: 07 Apr 2019 at 6:54pm

------------- WD,D15,190XT,7000,8010x2,7060,8070 |

Posted By: modirt

Date Posted: 24 Apr 2019 at 10:36am

|

For those wondering.......here is the final outcome of the hitch issue. It has been converted back to a Snap Coupler setup, using hitch parts from Cross Manufacturing, including a new drawbar.  This setup retains the use of drawbar or 3 point arms with no conversions needed, including the original lift arms (lugs). While a far cry from what ought to be or should have been, it is what it is. Note this setup also uses a rub bar bracket that eliminates the sway chains, which along with everything else on the factory 3 point, was IMHO, flimsy beyond belief. The 3 point lift arms being not much more robust than what might be found on some large garden tractors.....and about half as beefy as what are found on some modern era compact tractors....half the size and hp of this otherwise great little D15. But at any rate, this will enable the tractor to resume work....... |

Posted By: modirt

Date Posted: 24 Apr 2019 at 10:52am

|

Epilogue on the factory 3 point........ I posted a while back that the bracket had been dropped off with another welder to get a quote and thoughts. Next thing I knew, I got a call to tell me it was done.  Both legs had been brazed on. I quizzed the guy who did it and this is what I was told..... Not much, if any difference between brazing rod and nickle rod.....both being soft metals with some flex to them. I have concerns about the strength of the weld. A better way to do this might have been to place the entire casting in some type of forge to get both the legs and casting glowing red hot, then use an arc welder on the cracks to essentially melt and fuse the casting.....then while still hot....bury the whole thing in hot sand to slow down the rate of cooling. Once cooled, it would then have been critical to mill all four legs to return them to dead flat so when bolted back into place, all 4 would get the same load. Note this casting had been welded before. Likely as not, all 4 legs were NOT left flush, so when bolted up......two of the legs were put into a bind and subject to tension and easily snapped at the first little stress put on them. That then put a lot of stress on the two remaining bolts.......and amid all this, if any of the bolts had worked loose and were being "worked", that also means you are "working" the holes in the transmission casting......so nothing ever bolts up tight again. Related to this, is the fact that cast iron parts of this type have great strength in compression......but little if any if flexed. If at any time, one or more of the bolts holding them in place work loose, this allows flexing, so they snap. If you have one of these castings, and it remains intact, it would be critical to check these bolts on a frequent basis to make sure they are tight. So what became of the factory 3 point parts? I built a little wooden coffin and have them all boxed up and saved in case the next guy wants to convert it back.  |

Posted By: modirt

Date Posted: 24 Apr 2019 at 11:03am

|

Lastly, considering all the options I could find.......including the Cross conversions.......not of them look to hot to me. The Cross hitch is held together with bolts.......at least 5 or so beyond the studs or bolts used to hold the hitch brackets to the tractor frame. Too many moving parts for my taste. What is needed is some type of after market hitch that mimics what I see on a D17 series 4. Basically what is found on a host of similar sized and rated tractors. This is the drawbar support frame for my Ford 5610............in my mind, a far better drawbar support assembly than anything I found for the D15's........the Ginger Tractor being the best of the lot........  So in this setup, instead of the drawbar being held up by a U shaped strap over the drawbar.....held up by two bolts.......and kept from swinging by a strap over the strap.....and held in place by two bolts........drawbar is sandwiched between two have plates with just a pair of hitch pins to keep it from swinging. Something like this ought to have been welded in place for the drawbar hanger.....vs all those straps and bolts. So when you after market fabricators get going on this, please consider doing it this way! |

Posted By: modirt

Date Posted: 24 Apr 2019 at 11:05am

|

Ginger tractor hitch for review.......note.....among other things, it has vertical straps from the frame to support the vertical loads of a heavy drawbar to reduce the leverage on the four bolts holding the drawbar support brackets up. Some type of vertical straps of this type would seem to be essential to any long term fix of this hitch.  |

Posted By: modirt

Date Posted: 24 Apr 2019 at 11:13am

|

Lastly.....since I don't live THAT far away, to assure I was getting what I wanted, when hunting down the Cross parts, I decided to go to the source to make sure I got what I was looking for. This is what the source inventory looks like.......  And spin out rims on the other side of the room......  For reference, rims for the D15 cost $275 each........... |

Posted By: modirt

Date Posted: 24 Apr 2019 at 11:27am

|

One last thing....... When I was quizzing the welder about his repair job, I also asked if it would be possible to fabricate and weld a replacement bracket up from steel. Response was........yes, it would likely be possible......but would be expensive. The next person time a person responds to a request as to how much something might cost........with "would be expensive".......I may lose it. I have gotten that at least 3 or 4 times with this casting alone, and have yet to get a number from anyone. Expensive???? Is that $200 or $2,000????? I even got that from a salesman at a tire shop the other day. Pair of Firestone rear tractor tires.......30 inch tires. So I ask him.......those tractor tires........"about how much would those cost"????? Response was......."can't say for certain, but they would be expensive". WT@#$%^&***&^%%$%^^#!!!!!!!!!!

|

Posted By: chaskaduo

Date Posted: 24 Apr 2019 at 6:09pm

|

I hate that to. I tell them "well I can't do expensive, so I'll have to check for some one else." That usually brings em back to reality. Usually they are fishing to see how desperate a person is. If you show desperation the price starts in the clouds. Good to hear you got you Allis up to snuff and rearing to go.  Quando omni flunkus, moritati ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: modirt

Date Posted: 24 Apr 2019 at 8:30pm

|

I guess my issue is with vague, non descriptive responses. Expensive isn't a number.....its a relative concept. If I ask someone how far is it......"quite a ways" or "farther than you might think" are not answers. About 100 miles is an answer. Example.....I was told the spin out rims were "expensive". Come to find out they were $275 each. Compared to mucking around trying to patch weld rusted out rims, that didn't sound bad. That decision took all of 10 seconds for me. For someone else scrimping pennies who has a welder and knows how to use it, perhaps $275 is "expensive"? But at least is is a number to work with. All I need is the number. "Expensive" is not a number.  BTW, it took me 3 tries and 30 seconds of badgering, but I finally got the tire salesman to give me a number on the Firestones. Ballpark of $800 each. OK! So about $1600 to $1800 for a set? Yes. OK........that does sound "expensive"!

|

Posted By: Tracy Martin TN

Date Posted: 24 Apr 2019 at 9:46pm

|

Are the rails on the rims, welded like factory or welded inside of rim and edge of rails towards wheel center? Tracy ------------- No greater gift than healthy grandkids! |

Posted By: modirt

Date Posted: 25 Apr 2019 at 7:30am

Not sure I understand the question.......but here is an enlarged photo of a couple rims with rails......perhaps you can tell from this? These come with 4 rails.....one drilled at an angle for AC stops, the other drilled straight across for Massey stops.  BTW, I'd like to compare them to the original rims, but those are no longer around. I guess someone saw them as an opportunity to score a bargain and without my knowledge or consent, dropped by the shop......informed the guys they were there for the rims......paid $75 for the pair and left with them. I don't know if $75 for the pair was a fair price or not.....doesn't matter......point was they did it without my knowledge or consent. I don't mind guys being frugal and scrounging around for used stuff they can take and make work......admire the trait in fact, but only when done with with permission. Done the way it was left a bad taste in my mouth.

|

Posted By: BrianC

Date Posted: 25 Apr 2019 at 8:03am

|

Did you ever figure out how the rice drawbar mounted up? Converting back to snap coupler, did that involve a new hydraulic position valve? You have the Traction Booster feature working? |

Posted By: Sugarmaker

Date Posted: 25 Apr 2019 at 8:15am

|

The rim selection looks good. And $275 per rim is a good value. I have fixed most of mine and avoided some cost at the present time. But new rims should be good fo another 60 pears, Thats what about $10 per year!:) Tracy, Not sure of your question but I found two types of welds on these spin out rims. Some with a bead of weld next to the rails, and some which were resistance welded through the rim and melted into the rail. The latter is harder to repair if you have to remove some of the rim under the resistance welded rail. Welds on the first type can be cut and rewelded. In the above picture these look to have several long fillet weld beads next to the rails. Modirt the tires sound more than at my shop. I priced Firestones for the WD 13.9-28 and they were about $1000 for the pair with tubes. Maybe not same ones you spec ed? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: modirt

Date Posted: 25 Apr 2019 at 10:00am

Places that sell this Cross drawbar list it under a parts number as a replacement for the HD drawbar for both the D15 Rice hitch AND a HD hitch for the D17. That is the drawbar itself. Never have figured out where or what the vertical straps were to fasten to. On this D15, there isn't anything there. It may be possible there is something else shown on a different section of the parts book. Perhaps a mod or different option for the top link bracket? But as for snap coupler drawbars that will work with this Cross after market conversion, I think a lot of them would work. WD, probably WD45 and D17 drawbars should work. Folks that sell the drawbar I bought list it for a number of different tractors, including the D17 (early series), D14, D15, etc. We put all the SC stuff back on and hooked it to the traction boost and it seems to be working normally.....lift arms go up and down as they are supposed to. You have to have that linkage hooked up or the traction boost will send the hydraulic lift into panic mode to get the arms lifted.....and it will just sit there pounding away. This setup does allow continued use of the traction boost just as the factory 3 point does, except it does it through the SC linkage. Front pins for the 3 point arms mounted to this "cross" piece that is bolted to the drawbar in front of the drawbar hanger....  If you can find all the rest off a SC parts tractor, the "cross" on the left may be the only part you would have to buy to make this conversion.

|

Posted By: 615partsneeded

Date Posted: 17 Jun 2019 at 4:28am

| Hello Joe, I just purchased a 615 industrial, loader with backhoe, I'm interested in any parts you might have or possibly the complete machine, thanks |

Butch(OH) wrote:

Butch(OH) wrote: