Looking for a stud......

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=154648

Printed Date: 23 Sep 2025 at 3:13am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Looking for a stud......

Posted By: modirt

Subject: Looking for a stud......

Date Posted: 08 Oct 2018 at 10:17am

|

First, I should probably preface this by acknowledging that while the term "stud" applies to many of you on the forum, YOU are not what I"m looking for. The stud I'm looking for is of the parts kind. On the D15, the hitch assembly for the drawbar and factory 3 point hitch is held up by 3 cap screws (3/4" x 3") and one stud. Of the four holes used to hold the hitch assembly on, the stud hole is the front right, and the stud hole opens into the transmission case. Take out the stud and all the transmission oil dumps out on the ground. We are on the hunt for just such a stud. The AGCO parts books shows it to be part number 70228028, and the same stud is found on the D14, D15 and D17 (both snap coupler and 3 point tractors). It is 3/4" diameter by an unknown length. Parts book only describes it as a stud, with no dimensions given. * So looking for somebody who has one. If nothing else, it would be helpful if you could pull it from a parts tractor to measure it to tell us what length it is. It is probably 3 1/2" all the way up to 5". We don't know. I checked with Cook's in Clinton, and despite this exact part being used on a lot of tractors, they don't have one in inventory. None of the parts tractors we have found has one either. * One of my pet peeves is when looking for specifics, you get vague generalities instead. Like "just use a piece of string". Piece of string? Is it 12" or 36"? And what diameter and made of what? If you are supposed to use a 48" length of 1/4" braided poly rope, say so......don't tell me "piece of string". Or how far is it? Pretty far. Well how long will it take me to get there? Quite a while? How many miles, exactly? More than you might think. Of if you are trying to duplicate a recipe, you get exact measurements for everything except some key ingredient......like sugar. For that, its "add sugar to taste". Does that mean 1/4 cup, more or less, or 2 cups, more or less, or how &*$*$^$*#$(* much!!!!!   Stud?

|

Replies:

Posted By: chaskaduo

Date Posted: 08 Oct 2018 at 10:26am

You had me worried.  ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: ocharry

Date Posted: 08 Oct 2018 at 11:07am

|

so Mo,,,,i dont want to be or seem like a smart donkey here,,,,but,,,,couldnt you use a piece of hard or tempered ALL THREAD,,,they make it in a soft or mild steel version and i think a grade 8 tempered version,,,in coarse and fine thread or you could use a grade 8 bolt and cut the head off and cut it to the length you need and then thread the other end for the nut i would,, since you have already pulled the bolt and the tranny is empty use a piece of wire with a bend on the end(slide it into the bolt hole turn it to hook it on the inside of the casting and then mark it pull iti out and measure) to see how thick the casting is,,,i wouldnt think you would want the stud sticking into the gear box any deeper than needed,,,mark it,,,the wire,,,and then add what you think you want for length for the nut and lock washer(part sticking out past the nut isnt to important) then cut to what ever length you need i would be careful when you tighten it up,, unless there is a shoulder???( does the original style have a shoulder or a space between the threaded ends?? do you have at least a picture or diagram of the said stud??),,if you make one that would be easy to do so the part going into the tranny only goes in so far,,,when you tighten the nut it could run that stud into the tranny deeper,,if it doesnt have a shoulder,,,make sure you glue the threads up good with thread sealer or loc-tite,,,,i would think loc-tite would be best but i aint doin it,,,,clean the threads in the tranny casting really well with acetone or some other cleaner good,,,let it dry and put lots of sealer on both,,,the internal and external threads and screw then together and let it set,,,,get away from it for at least 24 hrs if i can help ,,,,make a stud for you let me know,,,,i will need some dimensions,,,length,,diameter and threads per inch just some thoughts and my .02 ocharry

|

Posted By: Tracy Martin TN

Date Posted: 08 Oct 2018 at 11:19am

|

I have made them before. Bought a grade eight bolt, cut the head off and threaded the end for tractor. Single point chased it on a lathe. Made it a few thousands larger than normal to fit the threads in housing tighter. Used a non hardening sealer on it. You need enough threads to go into housing correctly, a non threaded portion ,only slightly less than thickness of mounted bracket, so it tightens up properly, and enough threads for nut and lock washer. HTH Tracy ------------- No greater gift than healthy grandkids! |

Posted By: modirt

Date Posted: 08 Oct 2018 at 12:44pm

|

ocharry: Good suggestions and questions. As for sketches and all else, we don't know. Parts books are void of any detail and nobody seems to have ever laid in eye on one. Studs yes, exact dimensions of this stud so it can be duplicated, no. Frustrating. Also, lacking this level of mechanical knowledge, I'm struggling to understand the difference in function between a cap screw (bolt) and stud. Why one vs. the other? We took a cap screw that matches the other three out of the hole. It had worked loose, so was leaking oil and would not remain tight. So how would a cap screw differ from a stud, provided you cleaned up the casting hole and used the same locking sealant on both? Or in other words, why did the engineer who designed the thing use a stud vs. the same cap screw he used in the other 3 holes? So when you are trying to decide on what to do..... 1. Find a stud no matter what? (and BTW, what grade is this stud?) 2. Best alternative is grade 8 threaded rod....meaning no shoulder? 3. Last alternative......grade 8 cap screw? |

Posted By: modirt

Date Posted: 08 Oct 2018 at 12:48pm

|

BTW, there are 8 similar studs holding the wheel castings on to the transmission case. 4 on each side. We have 8 of those on a parts tractor....but those studs are a different part number. So no idea if they are the same, as we don't know what the dimensions of the hitch assembly stud is. Which is why I'm trying hard to find the original correct one to measure. If they were the same, we have a pant load of those.

|

Posted By: NomoreJohnDeere

Date Posted: 08 Oct 2018 at 12:55pm

|

you say you have a pant load of studs? ------------- HD3 |

Posted By: john(MI)

Date Posted: 08 Oct 2018 at 1:37pm

|

I just replaced the four on my D14 with thread rod cut to 4 1/2". Clean out the holes with a tap and some brake cleaner and put some locktite on the stud. I used a double nut to tighten them. I recently took the 3 point adapter off and after a couple years, none had come loose. I got my thread rod at Midstate Nut and Bolt. It has a strange, to me, rating but it is hardened. Just provide the size and tell them #8 and they'll know. https://www.midstatesbolt.com/" rel="nofollow - https://www.midstatesbolt.com/

------------- D14, D17, 5020, 612H, CASE 446 |

Posted By: bradley6874

Date Posted: 08 Oct 2018 at 1:48pm

|

The bolt works loose because when you draw it tight you putt the thread to one side of the whole this allows a small amount of oil to seep down the other side of the thread to the head with a constant oil supply it doesn't take long to loosen up got a 17 rear laying buy the shop will check it tonight ------------- You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul |

Posted By: modirt

Date Posted: 08 Oct 2018 at 1:59pm

Yes I do! (on the housing) Any other reference to pant load and studs should be in the singular form of stud (as in only one).....both for the hitch and actual pants.  (except I don't have one for the hitch) (except I don't have one for the hitch) |

Posted By: ocharry

Date Posted: 08 Oct 2018 at 2:19pm

|

just guessing but the stud could be there for a reference to put the hitch back on,,instead of trying to find a hole you find a stud and put a nut on,,,usually studs are a little stronger or it could be they didnt want a bolt falling out while the tractor is working letting all the fluid out with out the operator knowing it,,,would or could be real ugly,,,,this is just a guess,,,,sometimes it is hard for me to understand some of the big brain thinking grade 8 for sure,,,it is the hitch,,draw bar you could use threaded rod,,,but i would want some kind of stop on it so it only goes in so far,,,,mess up the threads,,,,put a spot of weld on it and grind it back smooth,,,, something to stop it from going farther in you need to measure the casting thickness so you know how much thread you need so it doesnt go into the tranny to far if you have studs from a parts tractor that are the right length on both ends,, even though they are different part no. they are more than likely the same grade and will work fine,,,i wouldnt be afraid to use them here or cut a grade 8 bolt head off,,,thread the end going into the casting to the proper length and have a shoulder to stop it from going into the casting to far first you need to know how long the casting side of the stud needs to be,,,,and then i would be looking at those studs from the donor tractor,,,,if they are the right size that what i would use,,, stud would be my first pick my .02 ocharry

|

Posted By: Sugarmaker

Date Posted: 08 Oct 2018 at 3:02pm

|

Napa might have a assortment of studs, Also might try Sandy Lake Implement with the part number they might have one. Trying to be helpful, here I called Brenda at Sandy Lake, gave here the part number and in about 15 seconds she said she can get one out of Tennessee for 3 bucks and freight. Could be a solution to your stud issue?? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: DiyDave

Date Posted: 08 Oct 2018 at 5:54pm

If Brenda can't find it, no one can!

|

Posted By: modirt

Date Posted: 08 Oct 2018 at 6:58pm

That may be the solution I'm looking for. I"m not familiar with Brenda or Sandy Lake. Do you have a phone number? Edited......of course you have a phone number. Correct question was if you could share the phone number? |

Posted By: Wayne180d

Date Posted: 08 Oct 2018 at 7:07pm

| I will second that for Brenda. When I still had my Model T Gleaner she found me everything that I needed for it. Superb lady |

Posted By: AC720Man

Date Posted: 08 Oct 2018 at 7:59pm

|

888-252-0656 ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: AC720Man

Date Posted: 08 Oct 2018 at 8:00pm

|

Keep that number, she is the AC whisperer. She has magical AC powers to find parts. ------------- 1968 B-208, 1976 720 (2 of them)Danco brush hog, single bottom plow,52" snow thrower, belly mower,rear tine tiller, rear blade, front blade, 57"sickle bar,1983 917 hydro, 1968 7hp sno-bee, 1968 190XTD |

Posted By: Sugarmaker

Date Posted: 08 Oct 2018 at 8:00pm

|

Thanks! Yep they are a very good resource for the Allis tractors. I believe she may have worked on them some too? Regards, Chris

------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: Dusty MI

Date Posted: 09 Oct 2018 at 12:30pm

|

Some studs have different threads on opposite ends, NF on one end NC on the other, or wood screw on one end. Maybe in case of the tractors it was easier in assembly at the factory to have a stud to slide the part on then put nut on then install the cap screws. Dusty ------------- 917 H, '48 G, '65 D-10 series III "Allis Express" |

Posted By: modirt

Date Posted: 09 Oct 2018 at 12:51pm

|

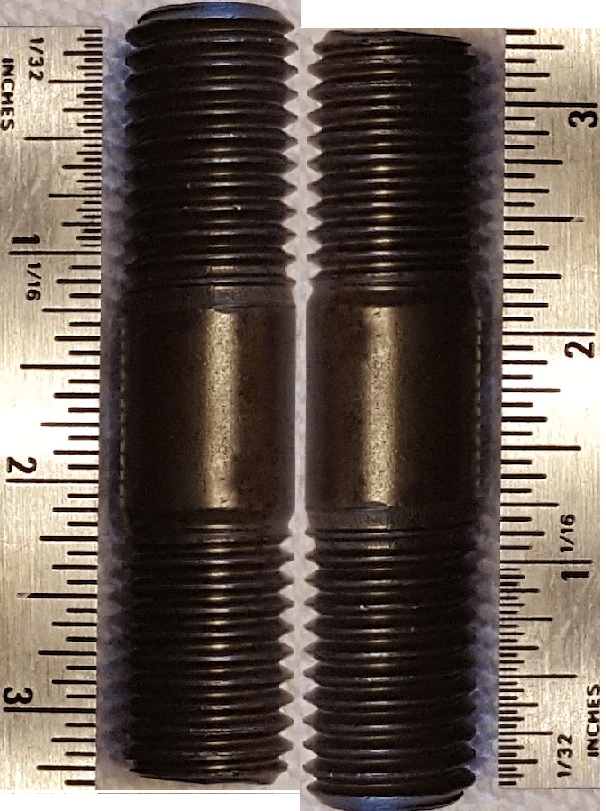

An update.......shop where work is being done just happens to have

a stripped down transmission casting off a D14, which we think is the

same as for the D15. Part number of the stud is the same, at any rate. So

we pulled one of the the 8 studs holding the axle assembly on to test

it in the stud hole for the draw bar / 3 point hitch assembly. This is what the axle stud looks like and how it mounts in the casting:   So basic plan is to coat it with a sealant, then screw it into the casting hole until the threads on the stud run out, where it jams against casting. Flat spot with no threads bears the load placed on it by the assembly part being held up, then the 2nd threaded part that stands proud outside the assembly is fitted with nut and washer to pull part tight to the casting. Stud coated with sealant or locktite was not under any load when it went in, and jammed up like it is cannot turn like all thread would. And it really only needs to hold in place against the force of the nut turning against it. This is the view from inside the casting......  Red circle shows where stud from draw hitch enters case. Stud coming in from axle is above it. They all stand a bit proud inside the casting so as to use all of the casting threads. To be continued..........

|

Posted By: modirt

Date Posted: 09 Oct 2018 at 12:56pm

|

Our guess was this stud needs to have about 1 1/2" of thread, a 1" flat spot in the middle, and an additional 1 1/2" threaded piece.....or 4" total. The one in the photo is only 3 inches coast to coast. Owing to the recommendation of "stud" Chris on the forum, I did call Brenda and she has an OEM stud on the way. So it looks like we will finally get our hands on the real deal stud to find out. Stay tuned!

|

Posted By: modirt

Date Posted: 09 Oct 2018 at 1:03pm

|

BTW, still wondering why the guy who designed the thing would use 3 cap screws that bottom out inside the casting (do not touch oil) and one stud that opens up into the casting into the transmission case where it can leak oil. Why not make all 4 of them the same? And on the D17, at least early series, all four of the rear fasteners holding the hitch assembly up are studs. No cap screws on those. At least that is how the parts book shows it.

|

Posted By: Sugarmaker

Date Posted: 09 Oct 2018 at 1:26pm

|

Mo, Good you have a stud on the way. My guess is same as someone else mentioned. When installing the hitch this stud is used as a alignment feature and also when the hitch is up in place only a nut/washer combo is required to hold it while you go find the other bolts that you lost when you took it apart. Other than that no good reason that I see. Why it goes through into the case? Not sure? maybe that area of the casting is different?? Tapping engagement for a stud may have had to be deeper than a cap screw. Its not supposed to be the drain. Need to talk to the old Allis design department!  Ok went back and looked at the red circle picture. The casting has a depression in that area compared to the bump across from it, which is probably the threaded hole for a cap screw. If that's the case then the stud was never supposed to come out during removal of the hitch. It was to stay in place and act as a plug for the oil, but also have the function of a fastener. Time and much hard work changes everything! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: modirt

Date Posted: 09 Oct 2018 at 1:39pm

|

BTW, I was curious how Brenda was able to find this OEM part since AGCO lists them as NA. She explained she works with one or more companies that go around and purchase all remaining parts inventory of implement dealers that close down. They then place them in their inventory. So a bit like Cooks in Clinton, MO, except many if not most of these remain OEM new parts, not used. And for better or for worse, they do not up-charge them based on scarcity. One left in inventory or 100.....all the same price. Amazing.

|

Posted By: modirt

Date Posted: 09 Oct 2018 at 1:42pm

|

Yes, that is the threaded hole for the cap screw. In the photo, it had the 3" stud screwed into it, but since it only has 1" of threads, it stopped short of standing proud from the hole as the one above it does. So you can't see it. That helped my decide how long the threads need to be, and for now, I"m guessing 1 1/2". |

Posted By: Bill_MN

Date Posted: 09 Oct 2018 at 2:05pm

|

Is there a low spot in the casting there where oil might not be able to drain? Thinking since the stud hole goes all the way through and not the other bolt holes, it serves as a drain plug. They use a stud so you can get the hitch off without letting all the oil out. Other theory I think someone mentioned above that the stud is a reference point for putting the hitch back on to help you line it up with the holes instead of fumbling with a bolt. ------------- 1951 WD #78283, 1918 Case 28x50 Thresher #76738, Case Centennial B 2x16 Plow |

Posted By: modirt

Date Posted: 09 Oct 2018 at 2:18pm

|

Drain plug is in the lowest spot. The stud hole in the casting is about 2" above it. Transmission holds nearly 15 quarts and all but 1 or 2 of those dumped from the stud hole. The rest came out the drain plug. BTW, in addition to the draw bar/hitch assembly stud, all 8 of the studs for the rear axles open into the transmission case and all are wet. Except they screw in from the side instead of from the bottom. Still, might pay to keep an eye out for leaks on those too.

|

Posted By: DaveKamp

Date Posted: 09 Oct 2018 at 2:44pm

|

Enstilled upon me by a 'real' engineering professor was a rule of engineering design I have never violated: "Never expound effort to resolve a problem, when you could expound the same effort, or even slightly more, to solve at least three or more problems in one operation." Studs provide several advantages over bolts- ease of alignment when in off-angle positions is one of those advantages... slip a component over the stud, start a nut, and it holds itself in place. Extra hand. Another, is shear strength. In many applications, the load on a joint puts shearing force (like scissors) on a fastener. Shouldered studs (rather than just allthread) have an uninterrupted surface, and tighter fit on the mating holes, thus, the mating faces cannot move enough to shear. Tension: when you tighten a nut, it pulls on the stud, which is already fully threaded into the other side component. If you thread in a bolt, and the bolt only reaches in a few threads, your fitting strength is limited to the yield strength of the other side's metal quality and a few turns of thread. In a stud, you have the entire threaded depth (typically 1.5x the diameter of the stud), and a fully engaged nut on the other. Bolts are not as efficient in getting proper fastening tension. When you tighten a bolt, the head is dragging against washers, which are against the face below... same as a stud... however, on a bolt, you're trying to twist a bolt which is dragging on the two segments, and in case of the threaded side, it's surface areas are dragging on the far side casting (which may be fouled with dirt, debris, and corrosion). Finally... wear and tear- if you take a bolt in and out of a casting a dozen times, each time, the threads will be worn deeper, eventually, the casting will not 'hold' the bolt tight. use a stud from the git-go, and the casting will hold tight, and when the nut and stud are worn at the other end, just replace the stud. As for the depression, nothing comes to mind, BUT... I'm certain there's a reason. ------------- Ten Amendments, Ten Commandments, and one Golden Rule solve most every problem. Citrus hand-cleaner with Pumice does the rest. |

Posted By: BrianC

Date Posted: 09 Oct 2018 at 5:14pm

|

When you get the official part, I hope you post a picture and dimensions. I would also like to know if the casting threads are a little "tighter" than the nut end. Test with a nut, or in the casting. There are double ended studs, and also "tap end" studs. Usually the tap end stud's thread is shorter thread length and of a tighter thread class. I wonder, if AGCO did have this stud, how many they would sell per year. I bet not many, and if so, can we blame them for not stocking it. Wouldn't it be great it the online parts books mentioned or linked you to industry sources for parts AGCO doesn't carry. Like in this case "McMaster xyz or Fastenal #123. Legal or liability problems? |

Posted By: ocharry

Date Posted: 09 Oct 2018 at 9:48pm

|

Glad you found the right stud Mo. But I had the lathe warmed up...lol...just in case When you get that ol gal finished up and working for you I'm sure all this will be worth it....you gona love her Ocharry |

Posted By: ACinSC

Date Posted: 11 Oct 2018 at 11:04am

| Modirt , can you please post the axle stud part number . My D 15 has 7 studs and 1 bolt . Of course the bolt's leaking . Thanks |

Posted By: wfmurray

Date Posted: 11 Oct 2018 at 11:56am

| Reading about stud.Have a well worn 1940 machinest handbook. It has some details on studs.Helped dad put a pto on a wc when about 10 years old and it came with studs.Install stud by double nuts and run stud in all the way so it tightens on inperfect thread.This keeps it from leaking and keep it intack when removing nuts. Glad you found some studs.WAy to go BRENDA! |

Posted By: modirt

Date Posted: 11 Oct 2018 at 1:33pm

Part number for the axle studs should be 70227525. That stud is about 3" in length. Part number for hitch assembly, the one I've been looking for, is 70228028. Hasn't arrived yet, so we don't know what size it is. BTW, before finding out I could get the OEM stud, I took a guess and ordered one from McMaster Carr. They called it a "setup stud". That one isn't going to work. Instead of a solid/smooth section in the middle, it has flat spots on it so you can turn it with a box end wrench. So no load bearing surface in the middle. In that, no better than all thread, even though it is a stud.

|

Posted By: modirt

Date Posted: 11 Oct 2018 at 1:41pm

We didn't have the manual, but after some deep thinking and discussion, came to the same conclusion on how to install it. Brilliant minds think alike?  Plus a sealant of some kind or locktite to "lock it" in place (tightening against the smooth, threadless part in the middle may also lock it in place), but it needs some kind of sealant to keep the oil from seeping out through the threads, plus if the threads are wet with oil, they will work loose easier. Plus a sealant of some kind or locktite to "lock it" in place (tightening against the smooth, threadless part in the middle may also lock it in place), but it needs some kind of sealant to keep the oil from seeping out through the threads, plus if the threads are wet with oil, they will work loose easier. Working loose and falling out must be an issue as none of the tractors we have to look at have the stud. It's been missing in action everywhere we look.

|

Posted By: bradley6874

Date Posted: 11 Oct 2018 at 2:42pm

|

Just curious did any brackets bolt to that stud say for a mid mount mower or mounted picker ? maybe !! never seen one on so just guessing ------------- You can wash the dirt off the body but you can’t wash the farmer out of the heart and soul |

Posted By: ACinSC

Date Posted: 11 Oct 2018 at 2:56pm

| Thanks modirt . Have my bolt out . Gonna take it to tractor supply and see what they have . |

Posted By: modirt

Date Posted: 12 Oct 2018 at 2:32pm

|

Well crap...... OEM stud arrived today and if this is right, I've got it all wrong.  From top to bottom..... Cap screw....a 3/4" x 3" bolt. This is the one that came out of the hole. Look close at 4 bottom threads and you will see those have been flattened out. Next down (#2) is the stud from the axle. When I screwed this stud up into the hole on the empty D14 casting we have to play with, it ran out of stud thread before it ran out of casting thread, so was going to need to be at least 1 1/4" of thread, plus the nearly 1" of flat spot for the hitch assembly to ride on, plus enough remaining thread for lock washer and nut. I figured it would need to be at least 3 1/2" long, and maybe 4". The all thread we have in it to plug the hole temp is 4". #2 stud is 3" long. So #3 down from the top (red box) is what I was sent as the OEM part#70228028. Either I have it all wrong or this is NOT that part. This thing does not have enough thread to cover all the casting threads, and no flat spot for the hitch assembly to ride on like the #2 axle. In short, I have serious doubts this is the right part. #4 down from the top is the stud I ordered from McMaster Carr. It seems to me to be closer to being right than any of the others, but again, has the flat spots on the middle part that will bear no weight. So back to the drawing board. If anyone has a D14, D15 or D17 parts tractor with one of these studs still in it, I would dearly love to have you pull it out to see what it is really supposed to be.

|

Posted By: DiyDave

Date Posted: 12 Oct 2018 at 5:32pm

| The mcmaster carr one looks like the threads were rolled on, steada being cut with a die... |

Posted By: Sugarmaker

Date Posted: 12 Oct 2018 at 6:22pm

|

Mo, part#70228028 Looks like a stud. Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: modirt

Date Posted: 12 Oct 2018 at 7:02pm

|

Yes it is a stud.....question is if the stud they sent me an honest to goodness 70228028.....or is it something else. The stud itself has no markings on it. None of them do. Worse, there is no place we can find with any sort of description in the way of dimensions. It is only described as a "stud". BTW, Brenda found two locations who had these in stock. One in TN, another in WI. Mine came from TN. I called her back and she is going to check with WI to have them measure the OEM studs they claim to have and see if it is identical to this one. If it is, we have some head scratching to do. In every way I look at it, it seems wrong to me. It is too short and has no load bearing flat spot in the middle. Basically no different than a piece of all thread that is too short to work.  And of course this all happens on a Friday, so good luck getting any kind of answer until next week. |

Posted By: BrianC

Date Posted: 12 Oct 2018 at 8:23pm

|

D14/D15 had industrial versions I60, I600, 615. Fiat bought the industrial part of Allis. Minn-Parr has Fiat-Allis parts. They have the manuals for the above (AGCO does not) available for download. There is a draw bar bracket, held on with 3 bolts and one stud (3/4NC). Look around pdf page 186-194. Fiat-Allis p/n for that stud is 0236541-9 (615 tractor) or 236541 (for I600). It might be the same as the ag tractors, in stock, who knows. FYI, the 3/4 bolts are listed as 2.5" long. So maybe Brenda's official stud is the real deal. |

Posted By: Sugarmaker

Date Posted: 13 Oct 2018 at 12:21am

|

Mo, How thick is the plate and washer and nut stack up, that gets bolted on? That 7022... should bottom out ok when double nutted and locktite/sealant applied. Not sure which end goes in case? By design you only need 1.5 times thread sized for max engagement/ strength. Also not sure about the grade of all these, the AGco one might be the toughest???? Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: ACinSC

Date Posted: 13 Oct 2018 at 8:24am

| Maybe I missed it but are the 8 axle studs 3/4 10 NC ?? Thanks !! |

Posted By: modirt

Date Posted: 13 Oct 2018 at 10:42am

|

7022 Axle stud is 3/4 10. OK, Brenda (gods gift to AC) called back this morning with two bits of news. WI checked their entire inventory and all are exactly the same. Plus, she had someone go out and check a parts tractor that is thought to have a factory installed stud and it is the same. So as near as we can tell, that 2 1/2" stud is the honest to goodness OEM stud.....which makes no sense whatsoever. There is roughly 1 1/4" to 1 1/2" of thread in the transmission casting. So if you want to fill the entire hole with threads, you need that much. Or 1.5 x .75" = 1 1/8", but that wouldn't fill the threads. But even with that, the drawbar/hitch assembly still has about 3/4" to 1" of flat smooth surface that rides on the edge of the stud, and would still need enough thread left to mount a nut and washer protruding out beyond. If you were to use the 2 1/2" OEM stud, it would offer little if any structural support to the hitch assembly acting as nothing more than a drain plug to fill the hole. Considering that all drawbar and 3 point loads are taken up in sheer and tension by just these 4 fasteners, giving up one of them to act as a cosmetic drain plug makes no sense. If this is right, it is no better than a simple piece of all thread, which offers minimal support to the drawbar assembly. The tips of the threads would quickly be rounded over and start doing nothing. That had already taken place on the existing cap screw. Of all the options I have now, the 3" stud put in backwards to put the longest thread section in the casting to cover as many threads as possible, then let the hitch assembly ride on the smooth middle section, and hope you have enough threads left to attach a nut...is the best option. Next best would be a cap screw like all the others, but it may take a shorter one with only a small area of smooth shoulder for the assembly to ride on. One with 1 1/2" of thread and about 1" smooth section below the head. 2 1/2" may be about right. That may not fill all the casting threads, but will get most of it. Will plug the hole and offer load bearing surface to boot. Now that I think about it, the existing 3" cap screw may have stopped going in when the smooth section of bolt hit the casting threads. Tightening up on that vs. the lock washer and bolt head drawing down tight. Maybe that is why it kept backing out? Considering all of the tractors we have found that have no studs in them, it seems they were all replaced for some reason. Either they fell out, or were the wrong part for the job.

|

Posted By: wfmurray

Date Posted: 13 Oct 2018 at 12:01pm

| Think i would take some good measuements and have some made.Stud needs to bottom out on imperfect thread and have three threads below nut.I have made things out of a meterial called rye cut ,it is strong and tough. |

Posted By: modirt

Date Posted: 13 Oct 2018 at 1:03pm

|

Machining up something from scratch is certainly an option, but considering the large number of tractors there are......all with the same issue, finding an off the shelf solution would seem to be the best alternative. If an actual stud is to be used (vs putting another cap screw back in), the 3" stud from the axle housing looks like the best option so far. And again, the parts unit we have has 8 of them just sitting around doing nothing.

|

Posted By: DiyDave

Date Posted: 13 Oct 2018 at 6:51pm

I'd just go with the axle stud. They are free, more or less, for you to use...

|

Posted By: ACinSC

Date Posted: 14 Oct 2018 at 7:51am

| Thanks modirt , I bought a grade 8 bolt at TSC . Couldn't find a stud . Cost $1.02 . Leak seems better . Good luck with your D 15 |

Posted By: wbecker

Date Posted: 14 Oct 2018 at 9:14am

|

I think you may have ordered the wrong type of stud from McMaster. The one I think you need is what they call a "self locking stud". It has longer threads on one end, and the threads that go into the casting are slightly larger diameter so they fit the casting tight. I'm thinking you may have ordered a "spacing stud" ?? ------------- Allis B, IB, Low B, G, D10, JD M, 8KCAB, C152 |

Posted By: chaskaduo

Date Posted: 14 Oct 2018 at 9:35am

|

I wonder if the ladies have this much trouble finding a stud that fits? ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: modirt

Date Posted: 14 Oct 2018 at 11:15am

|

Below from McMaster Carr......I think this is the type you were thinking of. Problem being selection is limited, and none of the right size. Best option still seems to be the Axle stud we already have. Still hard to believe that with so many of these tractors out there, this issue has not popped up before with a known solution already devised. Steel Vibration-Resistant Threaded Rods Also known as tap-end studs, these rods have friction-fit threads on one end to resist loosening. Screw the friction-fit threaded end into a tapped hole with a standard thread fit to keep the rod securely in place as you fasten objects to it. The friction-fit end has a Class 5 thread fit and the machine-threaded end has a Class 2A thread fit. Rods can be removed and reused.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Posted By: DrAllis

Date Posted: 14 Oct 2018 at 12:01pm

| Well, with a 60,000 lb tensile strength, you better get more than one. That equates to a Gr #2 bolt. You'd think you were building a rocket ship to go to Mars. Use one of those good axle studs ( I know they are good quality) and add enough HARD washers if they are too long and use tons of Loctite after cleaning out the hole with tons of brake kleen and air dry. Or, simply get a Gr #8 bolt of proper length, using HARD flat washer/washers and a Gr #8 nut and torque to Gr #8 specs and get on with it !!! If you use a cheap soft flat washer anywhere on this repair, you are setting yourself up for failure down the road. |

Posted By: TramwayGuy

Date Posted: 14 Oct 2018 at 4:42pm

| If this uses a split-type lockwasher, I wouldn’t think you would benefit with more than grade 2. Certainly not grade 8. |

Posted By: DiyDave

Date Posted: 14 Oct 2018 at 6:06pm

If the axle stud gives you the room, use a lock nut, on the remaining threads. I've had good service, out of the nylon insert grade 8 locknuts...

|

Posted By: Mikez

Date Posted: 14 Oct 2018 at 9:47pm

| Sorry if you already got them, didn't read all posts but have nos studs your looking for |

Posted By: modirt

Date Posted: 15 Oct 2018 at 2:22am

|

If you have NOS, can you measure one and give the dimensions and possibly post a photo of it? Curious if it is the same or different than the NOS stud we found before. Unless it is different, we will be using the axle stud.

|

Posted By: modirt

Date Posted: 15 Oct 2018 at 11:41am

OK, now that I have had a chance to test the OEM stud on the parts casting, Brian's theory proved out. The two threads do not match. One is a tight fit, the other a loose fit. The same is also true of the axle stud. However, as the axle stud came from the casting, the loose fit end was in the casting, yet it was not loose. I didn't take it out, but the guy who did had to use a pipe wrench on it and said it was moving the entire casting around to get it to free up. A 3/4" nut spins on easy on one end, and is very tight on the other. So decision time. Tight or loose fit end into the casting? BTW, on the OEM stud, threads are 1 1/4" (that will cover all casting threads), or 1 1/8", with half of a thread in the casting left exposed. Balance of the 2 1/2" stud being the 1/8" transition in the middle. And still think the better option remains to use the axle stud with load bearing flat spot on it to take the load of the drawbar/hitch assembly vs. letting any load ride on the tips of the threads. Photos below......casting was laid on it's side to test fit things. Top stud is one of the axle studs, lower one is an axle stud in the hole.....loose fit in. 2nd photo shows the OEM stud in the hole. There would probably be enough exposed thread to start a nut, but again, hitch assembly load would be riding on the tips of the threads.   |

Posted By: Jim.ME

Date Posted: 15 Oct 2018 at 1:13pm

|

I would put the tight fit end in the casting, with sealant. My understanding is the interference fit on the threads is to help prevent them from working in the casting. If you put the loose end in you might as well use a bolt, as the thread fit will be like the bolt and the nut may lock up on the interference threads, and act like a bolt head. If the interference fit is enough with the nut, the stud will turn in the housing, like the bolt. I have dealt with this type interference fit stud threads on some Allis Chalmers hydro turbines and other industrial equipment. The interference fit end was always in a casting and the nuts were on the running fit end. Those are my thoughts for what they are worth. |

Posted By: modirt

Date Posted: 15 Oct 2018 at 1:18pm

|

That is how we see it too, and for those exact reasons, but wanted to run it by folks here first to confirm. |

Posted By: modirt

Date Posted: 22 Oct 2018 at 8:40am

|

The mystery of the OEM stud is starting to clear up. Turns out I screwed up. When searching for the part number, the stud I found was for the snap coupler assembly. It was the same for several models. While searching for parts for the factory 3 point, I again noticed the mounting stud, looked, and lo and behold different part number. The correct part number for the factory 3 point is 70236541. Called Brenda and she found one of these too. And here is what the correct OEM looks like:  This one is about 3/8" longer than the axle stud, and the main difference is the width of the flat spot in the middle, which corresponds to the depth of the casting that mounts to it, plus threads on both ends are a bit longer. I have not checked to see if the threads differ, but suspect they do. Both the axle stud and this stud have an R etched on one end. My guess is that is the end that gets inserted. Don't know what R means, perhaps someone else does? The other end is smooth.

|

Posted By: chaskaduo

Date Posted: 22 Oct 2018 at 10:35am

|

Clip Paste Flip, just another way to look at it.  ------------- 1938 B, 79 Dynamark 11/36 6spd, 95 Weed-Eater 16hp, 2010 Bolens 14hp |

Posted By: DiyDave

Date Posted: 22 Oct 2018 at 7:25pm

When used as wheel studs, R stands for right hand thread.

|

Posted By: Mikez

Date Posted: 22 Oct 2018 at 8:43pm

| Have card on that number to |

Posted By: Sugarmaker

Date Posted: 22 Oct 2018 at 9:28pm

|

mo, Looks like the correct replacement item was found. Good job! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

NomoreJohnDeere wrote:

NomoreJohnDeere wrote: