Positive / Negative Ground

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=154486

Printed Date: 13 Sep 2025 at 11:04am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: Positive / Negative Ground

Posted By: Coke

Subject: Positive / Negative Ground

Date Posted: 02 Oct 2018 at 6:45pm

|

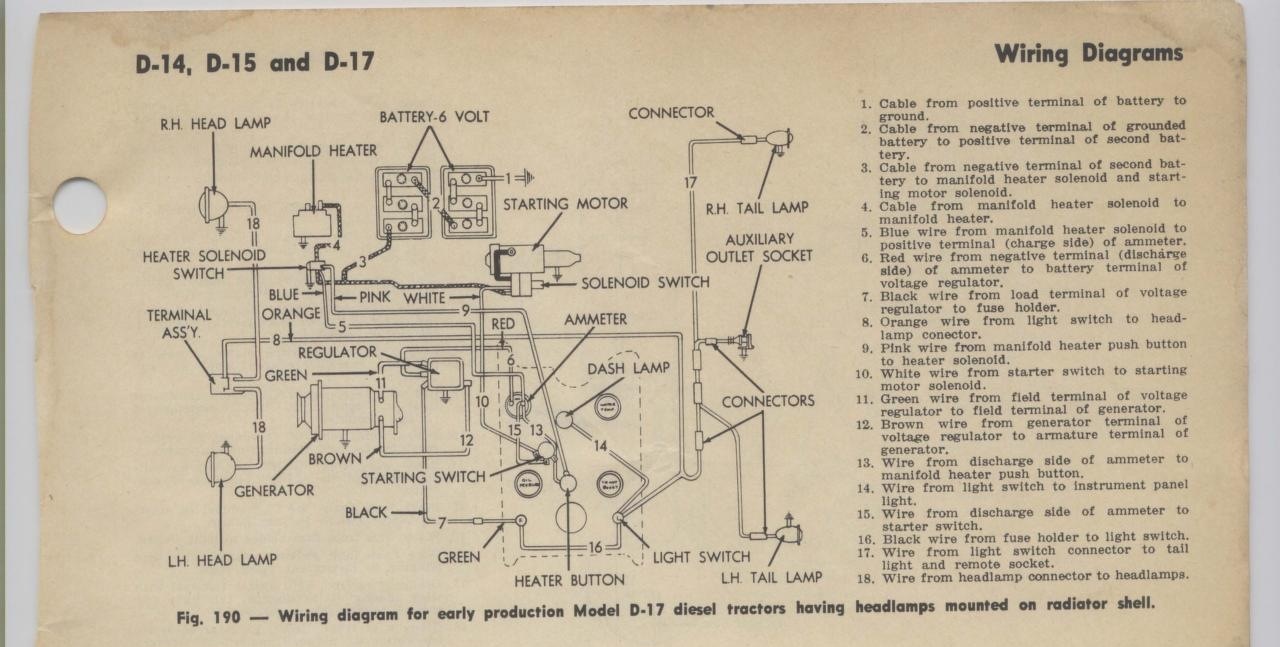

My D17 has starting / electrical issues. The tractor is wired negative ground, and, when it works, the tractor starts fine. To me this implies it must have been set to run negative ground, else the starter would spin the wrong way, yes? I'd like to fix the wiring, but I'm not sure how things should be wired if it's negative ground. I also see a manifold heater mentioned in the wiring diagram in the I&T. Is that on all diesels, or was it an option? Thanks in advance.  ------------- 1957 D17 Diesel w/ M&W Pistons |

Replies:

Posted By: DougS

Date Posted: 02 Oct 2018 at 7:15pm

| The starter doesn't care which polarity. Manifold heater is only available on the diesel. Generally speaking it doesn't matter which polarity your tractor is configured for, but negative ground has become the standard. It's hard to find a 12 volt add-on accessory that isn't negative ground. |

Posted By: Gerald J.

Date Posted: 02 Oct 2018 at 7:35pm

|

For the first several decades of electrical starters and electrical systems on tractors, trucks, and cars engineers and supervisors argued over polarity. Their experiences generally proved that either polarity worked so long as it was maintained, e.g. the battery connected properly and the generator flashed when the generator was replaced or was left setting a long time. Even when vacuum tube radios came along they were generally tolerant of either polarity if they used a vibrator and a rectifier. If they used a multiple pole vibrator to create AC and to rectify it as some two way radios did they were polarity sensitive but weren't destroyed if the polarity was reversed, just didn't work. Many used a special vibrator that could be rotated in its socket to change the polarity to solve that problem. As transistor radios came along in the early 60s they were absolutely intolerant of reversed polarity because reversed polarity destroyed all the transistors in the radio. As a result, the SAE standard for vehicular electrical systems about 1963 specified that only negative ground was allowed. Deere ignored that for a few years but by about 1975 followed it. Long about that time the SAE standard also removed 6 volt systems and limited 24 volt systems. The normal starter uses a single power connection and a series field so that reversing the power polarity doesn't change the rotation direction. Incandescent lamps are not polarity sensitive either. Fuel gauges can be power polarity sensitive, and ignition coils are polarity sensitive for sure as are battery monitoring ammeters. But for those reversed polarity isn't destructive, just the ammeter reads wrong and the reversed polarity ignition coil doesn't produce as great a spark. Having equipment with mixed battery polarities was always confusing to users without some electrical training and jumping with the wrong polarity could destroy both machines because it essentially hooks both batteries in series and then shorts them. Negative polarity as the universal standard since the 1960s removes that chance of confusion and is good for safety and there never was any evidence that otherwise the polarity of the electrical system affected its performance or longevity. And with today's LED lights they are polarity sensitive like radios. Gerald J. |

Posted By: Coke

Date Posted: 02 Oct 2018 at 8:07pm

|

And the bendix on the starter? Also not polarity sensitive? ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: DougS

Date Posted: 02 Oct 2018 at 9:10pm

|

Nope. It's either inertially or magnetically driven. All you have to switch to positive ground on that diagram is reverse the battery leads, swap the ammeter connections and repolarize the generator. Actually you don't have to reverse the ammeter, but you'd have to know that - means + and + means -. |

Posted By: Coke

Date Posted: 02 Oct 2018 at 9:22pm

|

And the regulator is OK? I should say that the wiring is a bit of a dogs dinner, so I want to go thru it all with my meter, I just wasn't sure how things like the starter, regulator, and so on work with reversed polarity, I knew the lights would be fine, what about the temp gauge? Being diesel, with no solenoid fuel shutoff, once it's running, it doesn't need electrical power, which is good as it doesn't generate any just now  ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: steve(ill)

Date Posted: 02 Oct 2018 at 9:28pm

|

you should have a 12 volt regulator.. some were OK for pos or neg ground... it might be printed inside the cover... You need to "polarize" the charging system once to tell the system how you have it connected... Normally taking a jumper wire and flashing the B and G terminals for 1 second will do that. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 02 Oct 2018 at 9:30pm

|

Yea, don't worry about the charging system.. Get it running good, and charge the battery once a week as needed --- overnight when not in use. ------------- Like them all, but love the "B"s. |

Posted By: Jim.ME

Date Posted: 02 Oct 2018 at 9:48pm

| Unless someone has changed it to electric, it has a mechanical temperature gauge as indicated on the wiring diagram you posted. The ammeter should be the only electrical gauge on the tractor. |

Posted By: WF owner

Date Posted: 03 Oct 2018 at 4:06am

| All D-17's came with a distributer, so you do need charge in a battery for them to run. Early tractors, that had a magneto, only needed the battery for starting or lights, but a distributor/coil won't generate a spark without an electrical input. |

Posted By: DougS

Date Posted: 03 Oct 2018 at 4:29am

This being the advantage of negative ground. If you ever need to replace a gauge, electric gauges are more readily available. Most are negative ground. |

Posted By: AaronSEIA

Date Posted: 03 Oct 2018 at 5:50am

|

My D17 doesn't charge. I use it 2-3 times a week and charge it maybe every 3 months with a trickle charger. Same with my boys C. I think I charge it maybe twice a year. AaronSEIA

|

Posted By: DougS

Date Posted: 03 Oct 2018 at 7:30am

|

That's okay if you check the specific gravity going into the winter. Let it go too low while there's a nasty arctic front passing through and you might end up with a frozen battery. |

Posted By: Brian Jasper co. Ia

Date Posted: 03 Oct 2018 at 8:09am

|

Generator regulators usually have a marking on them as to being positive or negative ground. Generally they all will work either way, but a regulator engineered for positive ground typically doesn't last as long run negative ground. The cheap ones from the land of almost right are even shorter lived on reverse polarity.

------------- "Any man who thinks he can be happy and prosperous by letting the government take care of him better take a closer look at the American Indian." Henry Ford |

Posted By: Dennis J OPKs

Date Posted: 03 Oct 2018 at 1:45pm

| I'm glad to know that I'm not the only operating without an functioning charging system. Almost rebuilt it this spring but the tractor only operates 6 or 8 hrs a week during the mowing season. A battery tender to the rescue. Works fine and the battery is removed and stored during winter. It's made it 10 years that way. |

Posted By: Coke

Date Posted: 03 Oct 2018 at 2:35pm

|

I'd like to get mine working, mainly because I don't have power in my storage shed. To that end I tried polarizing the generator today, 12V to the A terminal, still don't get any voltage on the A or B terminals wrt ground. I didn't try unhooking the connections as I recall maybe generators shouldn't be run unloaded? My starting issue however isn't electrical, it's electromechanical, the solenoid on the starter always engages, but doesn't always connect the battery to the motor. Tried cleaning the exterior part with brake cleaner and WD-40, but it looks like I may need to pull the starter to get to it. BTW is the little external mechanical doohickey on the solenoid loose in the slot for everyone, or should I tighten that sucker down? ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: DougS

Date Posted: 03 Oct 2018 at 7:35pm

|

Did you get a spark when you polarized? |

Posted By: steve(ill)

Date Posted: 03 Oct 2018 at 7:52pm

|

you can bypass the regulator for a quick test......... if you have a volt meter, check voltage between the A and F terminals when the tractor is running... You should have some generator output... If it is NOT getting to the battery, then the regulator don't work ( assuming you have voltage at "A") .... You can also try grounding the "F" terminal to the frame temporarily to see if the grounding side of the regulator is not working... Ground "F" and see if the dash amp meter responds. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Oct 2018 at 7:57pm

|

I don't know what is "loose" on your starter solenoid... There should be a small and large wire on the back that are TIGHT on the terminals, and a strap that connects the solenoid to the starter... all studs should be TIGHT.... if there is a cover on the other end that is loose, that may or may not be a problem. ------------- Like them all, but love the "B"s. |

Posted By: steve(ill)

Date Posted: 03 Oct 2018 at 8:01pm

|

the heater and generator should have nothing to do with starting... the battery cable goes straight to the starter motors solenoid.. The little wire comes from the switch.. Energize the small wire and pulls in the solenoid contacts and the big battery wire spins the motor.. If the battery is charged and cables are good, and it don't spin, then the solenoid is not engaging or the starter motor is bad. ------------- Like them all, but love the "B"s. |

Posted By: Coke

Date Posted: 03 Oct 2018 at 8:31pm

|

Where is the regulator located? The jiggly doo-dad is from the solenoid on the starter to like a cam switch of some kind, which has a slot in it and the end of the solenoid but is loose in the cam slot, it's the opposite end from the terminals. I'd expect it to engage the gear for the starter, and that always clicks, but sometimes it doesn't connect 12V across the solenoid, so the motor don't spin. This is the diesel D17, a 1957 if it helps. I can snap a pic of it tomorrow, no light in the shed. How do those starters come out? 1,2,3 or 4 bolts? Sorry, I'm faultfinding both the charging and starting at the same time, hence the unrelated questions. ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: DougS

Date Posted: 03 Oct 2018 at 9:10pm

| Don’t overlook a failty ammeter. All the charging current flows through it. |

Posted By: Jim.ME

Date Posted: 03 Oct 2018 at 9:29pm

|

You description sounds like the lever that moves the starter drive to engage the ring gear is exposed on that starter. If that is the case that lever will have some play. When you turn the key to start the solenoid should receive power to turn it into a magnet. It should pull the plunger inside it forward, causing a plate inside the solenoid to make contact between the large solenoid terminals, supplying power to turn the starter motor. At the same time the solenoid should pull the lever with it moving the starter drive into mesh with the ring gear. If all the connections are good, you are sure it is not loosing voltage or ground when you engage it, and the solenoid is clicking; you may need to pull the starter with the solenoid on it and have them gone through or replace them. Find your starter at the AGCO parts books on line and it will help you identify the "jiggly doo-dad", for others. I don't know about a D17 but on a D14 the voltage regulator is behind the panel on the left side of the tractor, under the fuel tank. |

Posted By: Coke

Date Posted: 04 Oct 2018 at 12:42am

|

Thanks Jim, I figured it (doo-dad) was meant to be exposed, as it was painted orange. Yes, best I can tell I always get the click of the gear engaging, but my 12V rarely appears on the other large terminal, it's solid on the lower one, but the upper one only sometimes happens. ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: Coke

Date Posted: 04 Oct 2018 at 1:29am

------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: Jim.ME

Date Posted: 04 Oct 2018 at 6:20am

| The lower terminal I have to assume is the one on the solenoid with the positive battery cable hooked to it, as you say 12 volts is solid there. Check all the battery cables and connections again. A bad ground may loose connection when power is applied to the starter. Check the terminals and lug fittings on the cables closely. If it is not already, connect the ground cable to one of the starter mounting bolts or other bolt on the engine block. If the solenoid has two small wires as well as the two large ones, one should be a ground. Make sure the wire is good and well grounded. Make sure the tractor is in neutral and try using a jumper wire to energize the solenoid (jump between the large battery positive cable on the solenoid and the terminal that has the small wire from the switch connected to it) to bypass the start switch/button. If that makes it works you likely have bad start contacts in your switch or starter button. Once you are sure the cables and connections are good and you have tried bypassing the start switch and the solenoid still only clicked, it indicates at least the solenoid is bad. At that point you should consider removing it and taking the starter, with solenoid on it, to a good electrical shop to be checked out and repaired or getting a replacement unit. |

Posted By: Coke

Date Posted: 07 Oct 2018 at 10:23am

|

uploads/19005/photo18.JPG" rel="nofollow - I'm gonna go out on a limb here, and say I found the problem. That center washer is the contact point (I reckon), when the solenoid energizes, it gets pushed agains the contact points of the two bolts. Given that it, and the bolt bottoms are black with crud, I'm going to say that's where I've been losing the connection, the two shiny points must be my intermittent. A few minutes with a dremel, and everything is nice and shiny again, and a bit of epoxy seals the crack in the case for now. We'll see if it works, and if it lasts. It's too wet right now to go out and fit it all back in the tractor. Worst case scenario, a new one is $20 on eBay. uploads/19005/photo18.JPG" rel="nofollow - ------------- 1957 D17 Diesel w/ M&W Pistons |

Posted By: DougS

Date Posted: 07 Oct 2018 at 10:41am

|

Lots of wear on the bolt you are holding. Turn it 180 when you re-install it. Yup, that could do it. If it does it again just give it a toss. That one looks like it's gone beyond its design life. Copper oxidizes. A silver plated one wouldn't. At least silver oxidation still conducts. |

Posted By: Coke

Date Posted: 07 Oct 2018 at 6:30pm

|

Yeah, I'd have been more tempted to take it apart if it didn't have a weird 5-pointed screw holding it together. I just cleaned it and the bolts up with a dremel, sealed the crack in the plastic cap, and put it all back together. So far, it's started everytime. ------------- 1957 D17 Diesel w/ M&W Pistons |

Jim.ME wrote:

Jim.ME wrote: