My D15 Series 1 Build

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=127341

Printed Date: 19 Dec 2025 at 7:32am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: My D15 Series 1 Build

Posted By: bigredisb

Subject: My D15 Series 1 Build

Date Posted: 16 Aug 2016 at 4:09pm

|

Hello everyone. I have been lurking on your forum for quite some time as I prepared myself to start fixing up my very special to me Allis Chalmers D15 Series 1. It all started as a very young boy when my grandpa and I would plow snow and if I was lucky he would let me run his WD. His WD was the first of a lot of firsts for me. Thats me already running the loader controls. I couldn't wait for seat time on his WD.  When it all started:  After a few close calls with the narrow front loader tractor he was quite determined to find a wide front tractor that I could get into less trouble with. We headed to Ella Wisconsin where he purchased a D15 and had it completely gone through (we were the second owners) and painted and a loader installed. When we were at the dealer trading in our WD he got me a toy WD to remember it by.     As soon as he had the chance he let me drive her. I always remember that day. I was about 7 years old or so and in those days these tractors felt like monsters to me. http://s993.photobucket.com/user/bigredisb/media/IMG_3213_zpsyjsjp3hl.jpg.html" rel="nofollow -    Fast forward 30 years and we recently laid grandpa to rest. He went quick and we had some good times before we parted ways. At his ceremony only a handful of people saw me put my WD toy that he had got me the day we received our D15 into his coffin with him. He was a die hard Allis Chalmers fan to the end and he was even able to forgive me for going to work at Case IH. After he passed some time went by and I was really concerned over the D15 and where it would end up. About a year after he passed my grandma realized how much it meant to me and even though I live smack dab in the city she gave me the tractor.  I have had the tractor for about a year and other than changing all the fluids and adding the 3 point conversion I just recently got started on the true repairs and restoration. I am removing the Paulson loader as we got every cent of life out of it. The loader frame had cracks all over it and the loader frame mounts were also cracked all over. The pump was also shot. I am wanting to restore the tractor back to a condition quality that still allows me to put it to use. Grandpa wouldn't see the value in a trailer queen. I have put my 49 Super A on hold for now to get the Allis back in shape. Most of my projects are all mechanically in great shape as that is what I am used to doing. Its the body work and paint that I am a total rookie.  Bad part is that the D15 is a smoker. It runs great and under the rocker cover she is spotless but again we used the hell out of it for a long time. I ordered a in frame kit with pistons, liners, and gaskets. The bearings are still nice and tight on it as she does not rattle at all and holds incredible oil pressure.       I just finished up getting all the gauges working again. New tach, new traction booster, tach cable. The only sheet metal we were really missing was the right hand panel which I was just fitting up here:  The power shift wheel locks were fun to get broke loose but I got them and narrowed it up a bit. The tires were full of calcium chloride. When I say full I mean it. they would puke calcium even with the stem all the way up. I got most of it removed as I would rather run weights as needed.  New steering wheel installed loosely prior to getting her ready for paint and other work. I am planning to make a memorial that I can hang on the wall with his original wheel that had the creme well worn off it.  I also just converted it to 3 point so that I could use some other attachments easily. I didn't have the snap coupler hands but just ordered some so that it is somewhat complete. I would really like to put a 3-14 allis snap coupler plow on behind it. Ill be posting questions and new developments as I go. Just waiting on parts to show up and busy hunting for headlights and 26x11 wheels (they are rotten from the the fluid). ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Replies:

Posted By: bigredisb

Date Posted: 16 Aug 2016 at 4:15pm

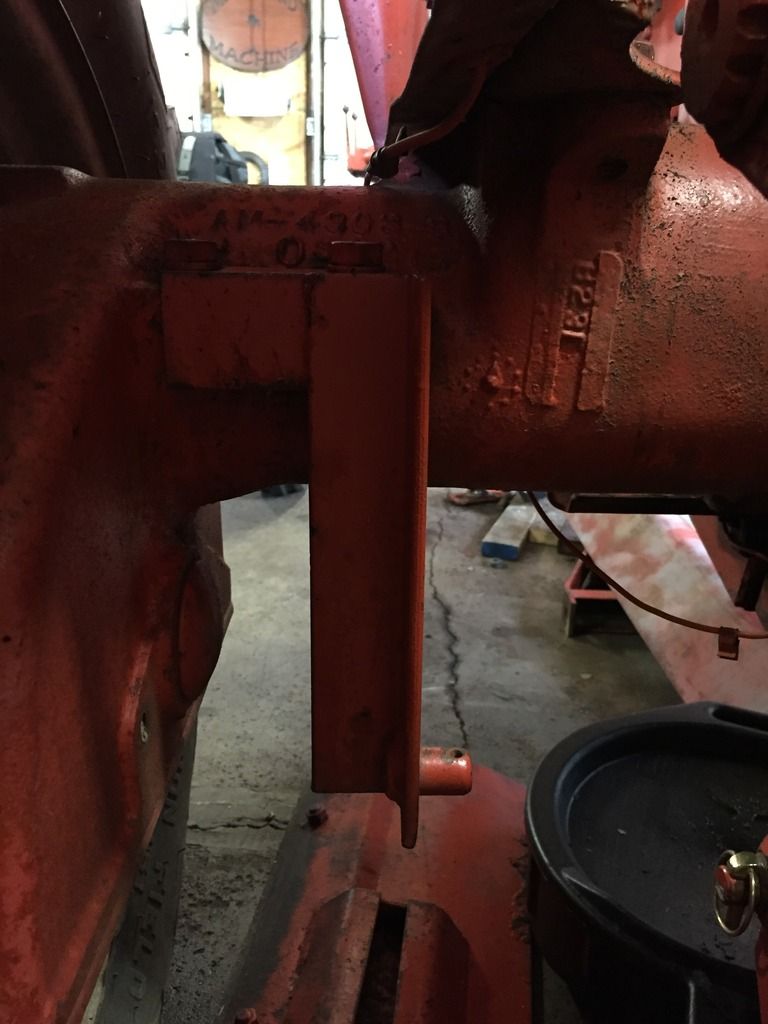

I found a couple of items on the tractor that were on it when we received it. Again we were second owners. On Facebook someone mentioned this was a for a toolbar depth control:  Also what appears to be some sort of homemade sway control for a 3 point possibly:  |

Posted By: hillmonkey

Date Posted: 16 Aug 2016 at 6:03pm

| Nice, great story and pics. keepem coming. |

Posted By: Sugarmaker

Date Posted: 16 Aug 2016 at 10:10pm

|

Welcome and just a awesome start! (I am a picture nut so really enjoyed the story and the pictures with it!) You were very lucky to be here to tell this after that WD roll over! Hope you have fun on the forum. Great tractor! Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: ACthunder

Date Posted: 16 Aug 2016 at 10:55pm

|

Could you post a pic of your 3 point conversion that allows for your drawbar to be hooked up as well? Thanks, |

Posted By: Allis dave

Date Posted: 17 Aug 2016 at 6:53am

| That's a great story, and the tractor looks to be in very good condition. It'll be a great tractor once you get the motor freshened up. |

Posted By: bigredisb

Date Posted: 17 Aug 2016 at 9:08am

|

Thanks for the comments folks. I will get some pictures of my three point as soon as my snap coupler ends come in so I can put the hitch back on it. |

Posted By: bigredisb

Date Posted: 17 Aug 2016 at 9:24am

|

Yeah we were really lucky using that WD Narrow with the loader. A lot of close calls. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: TimNearFortWorth

Date Posted: 17 Aug 2016 at 1:40pm

|

If doing an in-frame, do yourself a favor and roll the front away to check the everything for wear. Nothing like finding it later after all painted up and I'm bettin it has some wear from the loader size that was on it, especially since it did not have connector pieces run to the rear axle so the load was more distributed. May also want to check the front spindles internal bushings as they do get worn. Good looking unit, 1960/61 from the aluminum name plates and the 149 c.i. is a tad cheaper to re-do, vs. the 160 c.i. in the D15 Series II. |

Posted By: bigredisb

Date Posted: 17 Aug 2016 at 2:10pm

|

Great advice I appreciate it. I didn't fully remove the front end yet on it but I did take a look at the front axle pivot and checked the spindles for play. Surprising the spindles were very tight. I would say the front pivot had no more than a 1/8th of an inch of play. I took the loader off the front end and checked end play in the pivots with a pry bar. My wheel bearings up front are in need of adjustment for sure. Looking at doing the in frame I think I have to remove the front end to get at the back two pan bolts which are tucked up under the rear axle pivot assembly. Yeah that loader size and the way it was mounted really concerned me with all the leverage and forces being applied to the center of the chassis and bellhousing. I figured I would be better off ditching the loader to preserve the life of the tractor for generations to come. |

Posted By: Tracy Martin TN

Date Posted: 17 Aug 2016 at 2:33pm

|

If the loader was used much, you will need a new pivot shaft and support bushing. If support housing is not to bad,a quick bore job and custom bushing will work. The pivot pin ca be made about 1 inch longer also.You can check and see how much will work on your tractor. The factory deal doesn't have near the wear surface it could or should have. A grill guard would save your nice grill also. HTH Tracy ------------- No greater gift than healthy grandkids! |

Posted By: bigredisb

Date Posted: 17 Aug 2016 at 10:37pm

|

Not specific to a D15 but I just got a few changes to my harness completed for my AFS Pro 300 being used as a lightbar and mapping. http://s993.photobucket.com/user/bigredisb/media/C051FEE7-6903-47C0-BC01-B90F1DBA444C_zpsu8jvlvjr.jpg.html" rel="nofollow">

------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Allis dave

Date Posted: 18 Aug 2016 at 7:58am

|

pretty cool. You may have the first D15 with a light bar. We used to harass the John Deere dealership when they said they could add auto steer to any Deere tractor. Can we get Grandpa's old JD 70 updated? |

Posted By: bigredisb

Date Posted: 18 Aug 2016 at 6:38pm

|

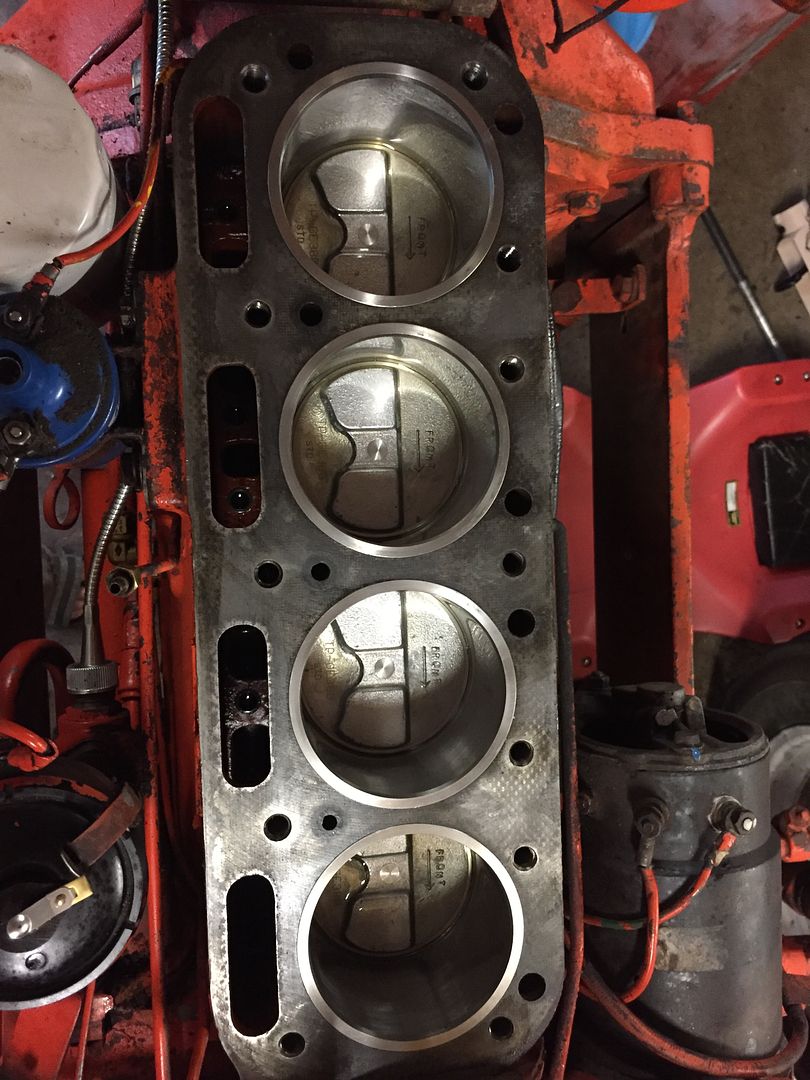

So I received my piston and liner kit today but they don't seem right. The Pistons look like these: http://s993.photobucket.com/user/bigredisb/media/38D57EBD-D329-472E-A97C-555A1CD4D143_zpstyzqkcft.png.html" rel="nofollow">  And the box says: beka1128-lcb (Diesel kit) and I ordered a Becka1127-lcb (Gas Kit) kit. These are from tisco and the gasket set appears to the same. Looking through the plug hole my Pistons look like dished or crater Pistons where the ones they sent are domed. Does the picture above look like gas Pistons? |

Posted By: bigredisb

Date Posted: 18 Aug 2016 at 6:41pm

|

Pictures of the hitch as requested: http://s993.photobucket.com/user/bigredisb/media/01C4962A-3E21-4267-AA53-2B3C773762B4_zps61daeu1l.jpg.html" rel="nofollow">  http://s993.photobucket.com/user/bigredisb/media/BC5A86E8-0928-4823-AEFB-DE6BCB8F8B3A_zpsoklekhoi.jpg.html" rel="nofollow">  http://s993.photobucket.com/user/bigredisb/media/D2C816C0-0D3B-4E14-94E7-39B6D02CB1BF_zpssuxtmhbu.jpg.html" rel="nofollow">  http://s993.photobucket.com/user/bigredisb/media/6634C3B3-A21F-4176-842C-27236CA94000_zpsi3luka0j.jpg.html" rel="nofollow">

|

Posted By: JeffMOnt

Date Posted: 19 Aug 2016 at 10:25am

|

the Beka1127-lcb is a gas kit. the Beka1128-lcb is a diesel kit. You will get domed pistons with the gas kit as well, I have the A&I kit which came with domed and works great. But you will need to contact the guys you got it from and have it swapped out for the right kit. |

Posted By: bigredisb

Date Posted: 19 Aug 2016 at 2:01pm

|

So here is what I figured out. I ordered the gas kit but got a diesel kit with gas gasket set and LP Pistons so I am told. They are sending me some dished pistons as well to decide which ones I want to try. http://s993.photobucket.com/user/bigredisb/media/98D2BB58-16A0-4024-8D10-785B90936315_zpsukamszxb.jpg.html" rel="nofollow">

|

Posted By: ACthunder

Date Posted: 19 Aug 2016 at 9:48pm

|

Thanks for the hitch pics.. that helps out a bunch. One last thing, what is the length of that crossbar angle iron. Thanks again. |

Posted By: bigredisb

Date Posted: 21 Aug 2016 at 9:16pm

|

Next time I am out in the shop I will grab the dimension for you. I have a graphics design guy creating this logo so that I can trace the image in Silhouette (my decal cutter) to recreate this image:  |

Posted By: bigredisb

Date Posted: 22 Aug 2016 at 9:55am

| Finally found my serial number under a couple of layers of paint. It wasn't stamped real deep. Its 3952. |

Posted By: bigredisb

Date Posted: 22 Aug 2016 at 8:16pm

Not too shabby: |

Posted By: bigredisb

Date Posted: 23 Aug 2016 at 4:20pm

Well the other pistons and kit showed up but they are obviously diesel pistons by mistake. I talked to a senior guy at TISCO and we went through all the parts and casting numbers and verified that I have what I need to get moving. The Diesel kit that arrived today was so badly damaged by UPS that one of the liners was bent at the bottom basically pinching the piston in the sleeve. |

Posted By: bigredisb

Date Posted: 23 Aug 2016 at 6:09pm

16.5 inches wide |

Posted By: bigredisb

Date Posted: 23 Aug 2016 at 8:51pm

|

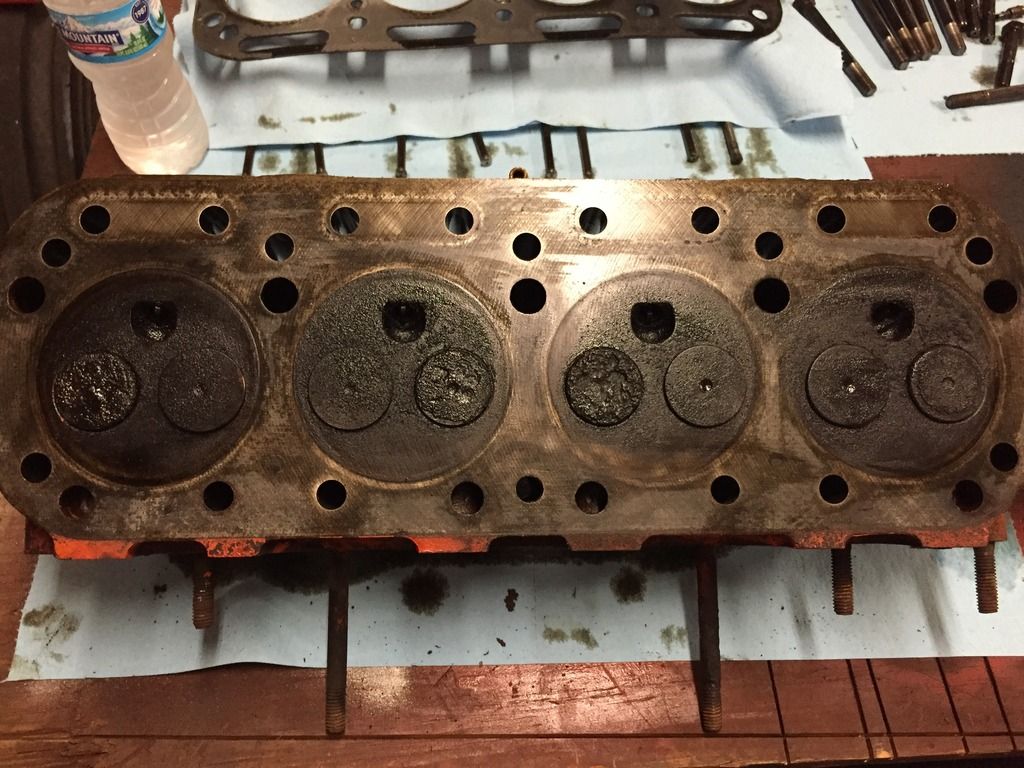

Well I got some work done on her. Tells me a bit of the story of her life prior to us. Cylinder #1 looked to have dropped a valve at one time. Witness marks in the piston but no marks on the valve and a aftermarket push rod on that cylinder: http://s993.photobucket.com/user/bigredisb/media/3B70FA76-9D53-4065-A602-4021B474BB7C_zpsx8pqxeqm.jpg.html" rel="nofollow">  Cylinder #2 had a bad score in it that will rip a finger nail right off. Hard to believe it was contributing much at all and explains part of the blow by I had: http://s993.photobucket.com/user/bigredisb/media/39B105E2-E126-4587-AADF-AB0287BC04D6_zpsm2g1sanb.jpg.html" rel="nofollow">  Cylinder #4 had the most oil sitting in the crater of the piston: http://s993.photobucket.com/user/bigredisb/media/97A23FE6-9C91-4278-9567-DA5E4E428844_zpse0rgix0d.jpg.html" rel="nofollow">  lots of crap burned to the valves: http://s993.photobucket.com/user/bigredisb/media/FCA28E73-D54D-4C10-90E8-032C5042ED91_zpsjraogdwa.jpg.html" rel="nofollow">  Where I left it at tonight: http://s993.photobucket.com/user/bigredisb/media/17676FAC-6CE8-4F81-9070-5063D9B6326F_zpskosfrsax.jpg.html" rel="nofollow">  |

Posted By: ACthunder

Date Posted: 23 Aug 2016 at 10:45pm

| Thank you for the measurement. |

Posted By: Allis dave

Date Posted: 24 Aug 2016 at 6:55am

| And the rebuild had begun! Are you saying they sent you the wrong pistons a 2nd time also?? if so wow. Good to see your progress. It will be an exciting one to complete. Unfortunately I don't know much about D15's so I'm not much real help. |

Posted By: bigredisb

Date Posted: 24 Aug 2016 at 7:53am

| Yes they sent me the wrong pistons again but I discovered that TISCO does not produce a powercrater piston anymore. It has been replaced with the LP piston I have in the picture above. It's a direct replacement and bumps compression up. The first kit components they sent were right but mislabeled the box as a diesel kit. The second kit I got was labeled diesel and had diesel parts in it. I gave up dealing with yesterday's tractors and called TISCO directly to get the right info this time. |

Posted By: Alberta Phil

Date Posted: 24 Aug 2016 at 9:47am

| Might be better off dealing with some of the suppliers on this site. I've had excellent service from any I've dealt with over the years. Also, they know Allis! |

Posted By: ac45dave

Date Posted: 24 Aug 2016 at 9:57am

------------- 54 wd-45gas ; 56 wd-45d N/F w/fact p/s ; 63 d-17 sIII N/F gas ; 60 D14 N/F ; 67 d-17 sIV N/F gas ; 63D15 sII W/F; 39rc#667 ; 2021 massey 4710 fwa ; gravely 2 wheel tractors |

Posted By: peterh

Date Posted: 24 Aug 2016 at 10:23am

|

awesome story, great tractor- love the advice on this site, but love stories like this even more ------------- 1947 C, 1949 B, 195? CA 60 series cultivator fertilizer side dresser 2 bottom snap coupler plow 1 bottom plow, Cole planter |

Posted By: bigredisb

Date Posted: 24 Aug 2016 at 11:18am

Yeah, I learned a lesson. Of course when I really laid in to Yesterdays Tractors and asked for support I got no return calls or email responses. They are off my list of preferred vendors. |

Posted By: bigredisb

Date Posted: 24 Aug 2016 at 11:25am

Thank you for your comments. the tractor means a lot to me. A lot of learning occurred on that seat and lots of good times with my grandpa and that tractor. I think these forums are helpful for the advice as well but as you mention I enjoy the stories too. When I was looking for photos and details I was having a hard time finding a ton of D15 info so I figured I would take lots of pics and document everything I could so that others had a resource if they were new to these tractors as far as going through certain areas of them. |

Posted By: bigredisb

Date Posted: 24 Aug 2016 at 2:21pm

|

Well this isn't tractor related but I wanted to post it anyway. This was my grandpas ship that he took to Japan. He was posted in Japan after the close of WWII and then on to Korea after that.  |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 7:30am

|

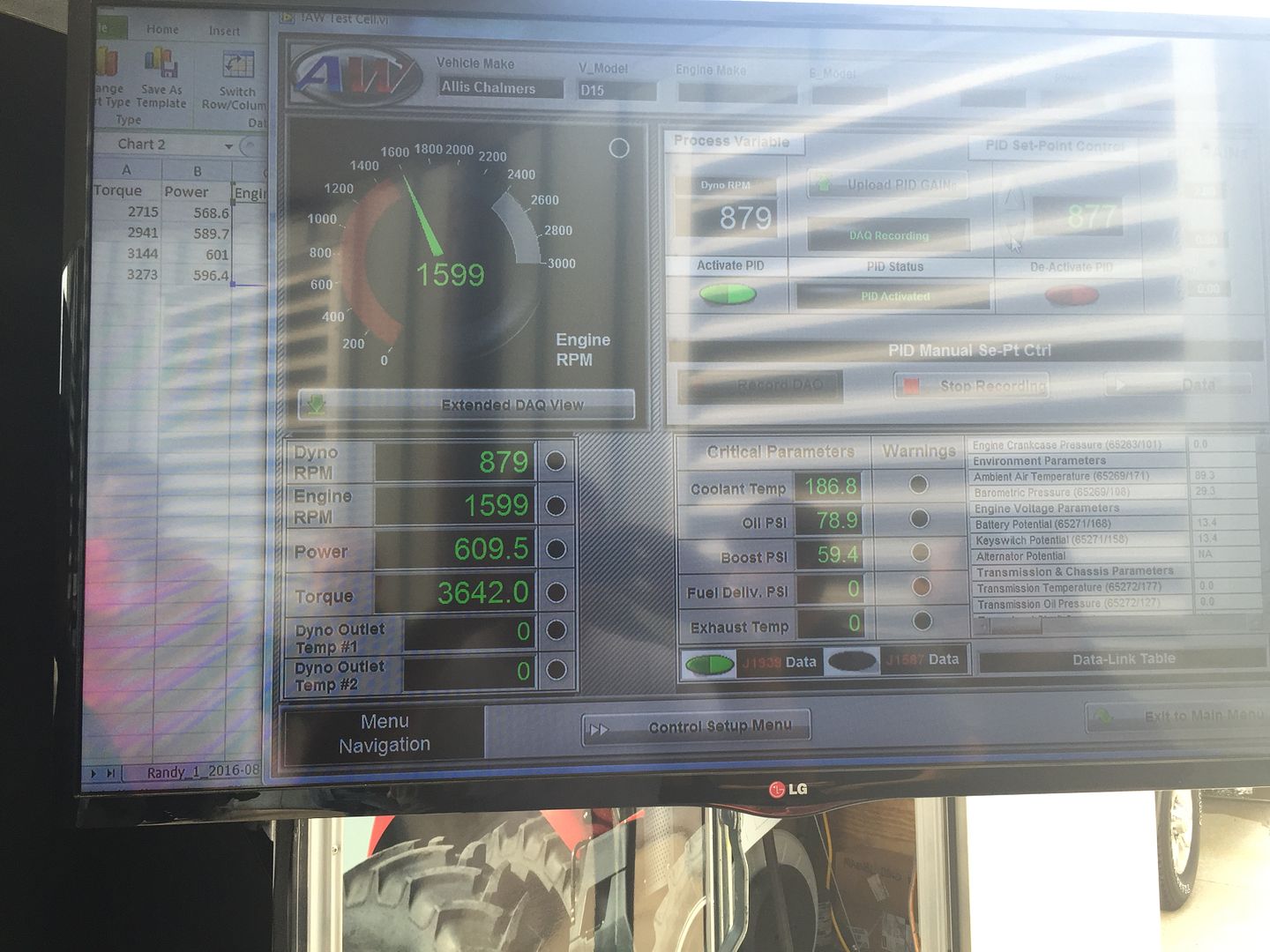

Well a little more progress. I got all my Pistons out and rods swapped over to the new Pistons. Incredibly the engine is very clean and show little to no wear on any of the bearings. http://s993.photobucket.com/user/bigredisb/media/6A107410-34FF-4C5A-ABF0-58C9229CAFBF_zpsh7x3g4ez.jpg.html" rel="nofollow">  So far I only have 2 of the liners out and they are a bastard to get out. I made my own pulled but without a Torrington bearings the all thread binds up and I am using a steel rod from the underside to strike my puller base under the liner to get them to pop free. http://s993.photobucket.com/user/bigredisb/media/141CA262-69CE-4FDF-86D3-36D4621BB5EC_zpsvwhhju7m.jpg.html" rel="nofollow">  And I have been working on the dyno that I have accessible to me to get it setup for a run in of the new motor. It's a bit big at 800 horse so it should hold whatever I throw at it with the D15! http://s993.photobucket.com/user/bigredisb/media/9AC5A6A8-50E8-448F-AD5A-B2828A8DD68F_zpsiaedkicx.jpg.html" rel="nofollow">  http://i993.photobucket.com/albums/af59/bigredisb/E0AC8A9E-2229-4224-A6FE-E2A6117F530D_zpsugcumvbn.mp4" rel="nofollow">  |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 7:46am

| Any suggestions on a break in process using the dyno? Basically I can set it to auto and take the tractor to full throttle and it will hold the PTO rpm I set it at by using load. |

Posted By: DrAllis

Date Posted: 26 Aug 2016 at 8:22am

| Make sure you set the ignition timing with a timing light and at full throttle to the FIRE mark or F or F-25 whatever the flywheel is marked at. I always use lighter oil for break-in, like a 5W-20 or 5W-30. |

Posted By: desertjoe

Date Posted: 26 Aug 2016 at 8:22am

|

Hey BigRed,,,that is a great project you got goin there. Keep the pics coming,,,!! The new pistons you got, look to be the same design that were in the 149 I installed in my D14 Industrial Backhoe/loader. Did the vendor tell you what the compression bumped up to with the pop-up design?? I noticed in your pics, the driveshaft for the front mounted hydraulic pump is going to need some repairs, mine was bout that bad, and if you plan to re-install the pump,,PM me and I will give you a money savin alternative. Keep the pics comin,,,,  |

Posted By: Sugarmaker

Date Posted: 26 Aug 2016 at 8:23am

|

I know nothing about dyno's, but that is a cool looking unit!! Great documentation! Like the picture of the ship in its work clothes too! I agree that the status and progression pictures may just help another AC guy with a D15 project. Lots of good resources on here too! Don (MO) should be in your cell phone!:) Regards, Chris ------------- D17 1958 (NFE), WD45 1954 (NFE), WD 1952 (NFE), WD 1950 (WFE), Allis F-40 forklift, Allis CA, Allis D14, Ford Jubilee, Many IH Cub Cadets, 32 Ford Dump, 65 Comet. |

Posted By: CAL(KS)

Date Posted: 26 Aug 2016 at 8:38am

|

if this was my tractor i would vary the RPM and LOAD as opposed to just setting it to pto speed and running it for awhile, but there are varying opinions on this. ------------- Me -C,U,UC,WC,WD45,190XT,TL-12,145T,HD6G,HD16,HD20 Dad- WD, D17D, D19D, RT100A, 7020, 7080,7580, 2-8550's, 2-S77, HD15 |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 8:39am

| Good info thanks! Ill do some reports on what she does when I get her together, tuned a bit and hooked up to the "Judge" as we call our dyno. |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 8:43am

Joe, I wont be putting the pump back on the front. I am keeping the loader off of it. Yes the guy at Tisco that I talked to sad that the old crater pistons have not been offered for the last 11 years and everything has gone to the pop up style. As a FYI I was told that the compression with the new pistons is 8.75:1 vs the crater pistons 7.5:1. Plus these new pistons are 3.56 bore which I believe puts the G149 to 156 cubes as well. |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 8:47am

|

Joe, Did you notice anything different in cranking speeds or load on the starter after you installed these pistons in your D14? |

Posted By: Dan73

Date Posted: 26 Aug 2016 at 1:54pm

| Guess I am late to the post here. Powermax makes the power crater pistons still. I am ordering a set for my d17 as soon as I get the crank issues sorted out. Jensales carries powermax and I think there is a vendor in here as well I just don't remember who. I know with the 226 motor you need to be careful alot of the aftermarket kits actually lower your compression. |

Posted By: desertjoe

Date Posted: 26 Aug 2016 at 3:53pm

|

Hey BigRed,,,NAW,,,the original 149 engine was tore down when I bought the tractor,,so I have no clue bout the difference if any. I bought an engine from Iowa and it is the one that has the pop-up pistons, and is in the tractor as we speak,,,,I would of thought with that much difference in squish area would of bounced the compression up more than just one point,,but I didn't run the numbers before I lashed it up after the overhaul. Fact is,,,you've got me to thinkin,,and I may run a compression test on it just for funs,,,,   |

Posted By: Dan73

Date Posted: 26 Aug 2016 at 3:56pm

| Joe most of the aftermarket pistons don't travel as high to leave valve clearance so the allis power crater design can give you higher compression or that is how I understand it. |

Posted By: desertjoe

Date Posted: 26 Aug 2016 at 5:36pm

|

Hey Dan,,I hear what you're sayin,,,but don't make sense to fashion a piston with the pop-ups, obviously to bump the compression ratio but then again with the flat head the 149's use, you would have to be very meticulous in verifying the piston/valve clearance,,which I did on mine,,,but can't remember what the clearance was but seems like it was way more than I would have wanted if I had bought those pistons with the idea of lookin for more horse power,,,,  I also intended to CC the total area of the combustion chamber for my curiousity,,and forgot that little tidbit,,,,, I also intended to CC the total area of the combustion chamber for my curiousity,,and forgot that little tidbit,,,,,  Maybe ole BigRed will do all these checks to clear up some questions for us,,,hint,,,hint,,,,   |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 5:37pm

|

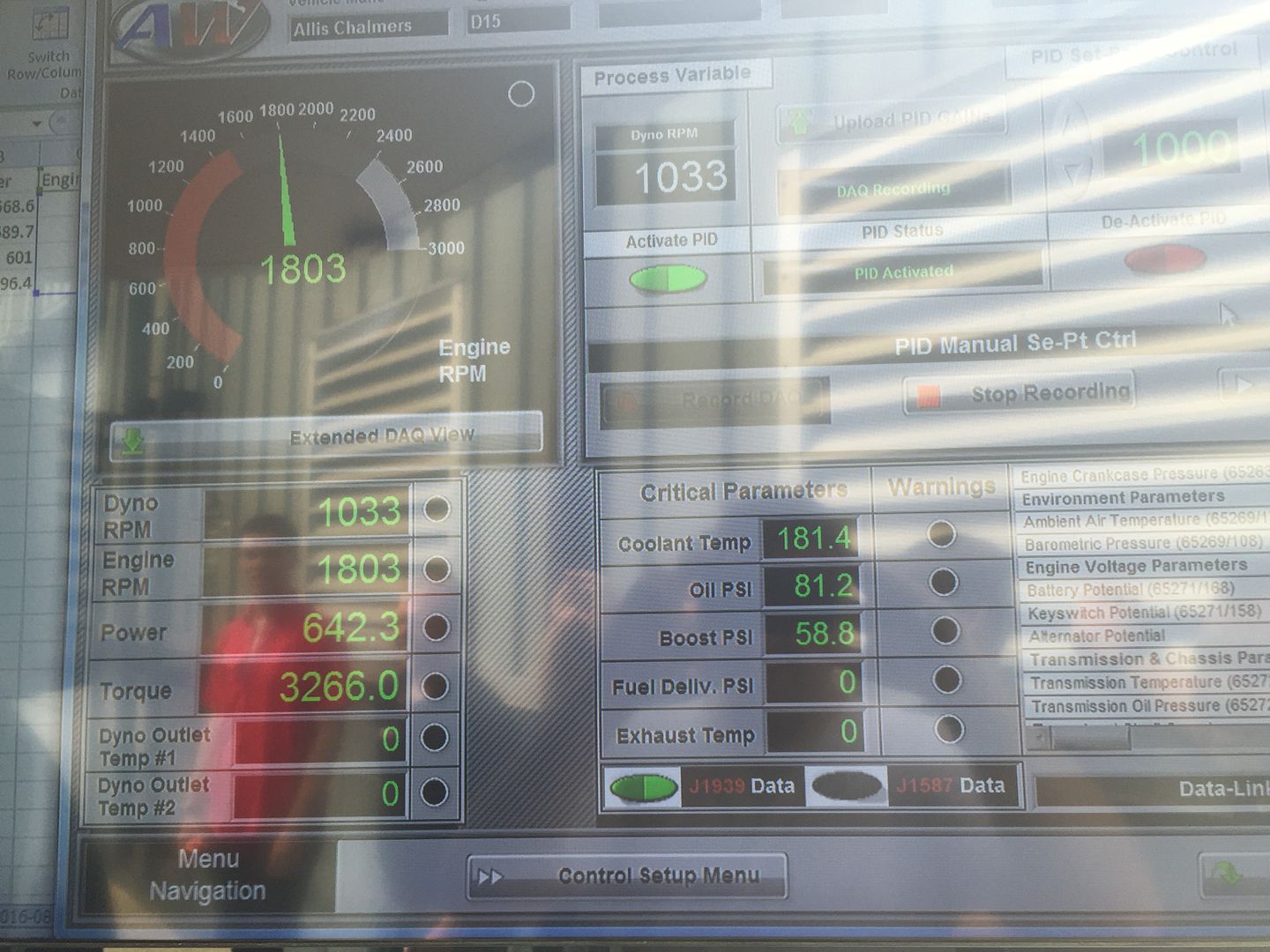

Got her on the dyno today! http://s993.photobucket.com/user/bigredisb/media/4B096C1F-26D1-4957-A6DA-6C0445DC2CFD_zpsyi35u4ft.jpg.html" rel="nofollow">  Look at the top of the pic. Decided to have a little fun with a 620 Stieger Quad Trac today. http://i993.photobucket.com/albums/af59/bigredisb/60C69EED-3F0F-4D4D-96A6-252DC518A54A_zpsvqpsl90u.mp4" rel="nofollow">  Peak torque: http://s993.photobucket.com/user/bigredisb/media/C67613B3-F683-43D9-81CA-19D73C6E73AD_zps0d6gouol.jpg.html" rel="nofollow">

|

Posted By: desertjoe

Date Posted: 26 Aug 2016 at 5:39pm

|

DANG,,,Big Red,,,,how many turbos did you strap on thet engine,,,,?????  |

Posted By: bigredisb

Date Posted: 26 Aug 2016 at 6:22pm

| It's a bone stock 620 with compound turbos. An absolute beast. Heated up 500 gallons of cold water on the dyno in the blink of an eye. |

Posted By: patrickmull

Date Posted: 27 Aug 2016 at 7:04am

| looking good |

Posted By: bigredisb

Date Posted: 27 Aug 2016 at 3:39pm

|

Well she's back together and runs like a charm. My friend cut the valves, seats, and ported the heads last night and I got her all together today and tried her. Popped right off. http://s993.photobucket.com/user/bigredisb/media/AF22F955-92F4-4D5F-ABBB-C7F64C728EC7_zpse9d2xroc.jpg.html" rel="nofollow">  http://s993.photobucket.com/user/bigredisb/media/7868943E-AA0F-4568-8EF7-D4031D8CCA33_zpsu4hozhvz.jpg.html" rel="nofollow">  I'll have a video of it running in a little bit. |

Posted By: bigredisb

Date Posted: 27 Aug 2016 at 10:02pm

|

Video of the second start after I adjusted valve lash. I am bumping the engine rpm up and down checking for hesitations. Prior to the build the throttle response was nowhere near this snappy. https://youtu.be/uaKb7YodlL8" rel="nofollow - https://youtu.be/uaKb7YodlL8 Hoping to be able to dial in the timing, and mixture adjustments tomorrow as well as swap from 295 Autolites to 303's. If I am correct I believe the 303's are colder than the 295's. It's kind of weird to hit the key and not have a ton of smoke pour out if it.

|

Posted By: Don(MO)

Date Posted: 28 Aug 2016 at 2:35pm

|

You have a nice piece of family history and looks like you are going to keep it in the family so my hat is off to you. Just a word to the wise, Tisco pitons are known for burning tops of the pistons if you put to much timing into them. If you power tune for top horse power please don't go over 25* total timing in her.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: bigredisb

Date Posted: 28 Aug 2016 at 4:52pm

| That's good info for sure. I am not going for all out power. Just dependable and clean running tune. I will admit today was timing day and I was a bit bewildered for a little bit as I couldn't find any f marks on the front pulley! I did find it in the bell housing hole so life is good. It was set about 6 or 7 degrees retarded. I turned the dizzy until "F25" at wot was clearly visible in the window. The engines tone is much deeper at this setting especially at idle and the exhaust flow seems much higher as the rain cap used to bang and clang up and down with the timing retarded. I ended up giving a little more fuel on the idle and fast speed mixture screws as well to smooth her out a bit. I put points in it a year ago but I am not certain I had it at tdc and rocking the dizzy to verify they were just opening so I may need to redo that. It starts great with no kicking and runs smooth all the way through the rpm range. |

Posted By: Dan73

Date Posted: 28 Aug 2016 at 5:42pm

| You should check the timming again at full throttle. I know on the 160 gas motor it is critical that you time it at full throttle not idle. |

Posted By: bigredisb

Date Posted: 28 Aug 2016 at 8:09pm

|

Yes I checked it at full throttle. That's what I meant with my acronym of "wot" or wide open throttle. I also took the dizzy apart and cleaned and lubed the advance mechanism as well. Just got done servicing the wheel bearings as well. They looked good but one was way out of adjustment (loose). I also just ordered some decent copper plug wires from a guy that posts on here (bb electric or something like that). Also got my bottomless toolbox off. All of the carriage bolts that pass through the tool box were spinning so I welded nuts to the heads to get them out as well as welded up some random holes in the sheet metal up front from what appears to have been wire routing for random lights. |

Posted By: bigredisb

Date Posted: 28 Aug 2016 at 10:07pm

| Any of you guys have a D15 hydraulic pump you are willing to separate from? The lift has always been really "ratchety" if that makes any sense. Feels like of the 4 Pistons isn't moving oil but it still has plenty of lift power and kicks off from pressure at the top of the lift stroke easily. Just seems way to jerky in its lift but maybe it's normal?? This tractor has been that way from the day we got it so I just figured it was normal. |

Posted By: Dan73

Date Posted: 28 Aug 2016 at 10:12pm

| Are you getting water in the oil? Almost sounds to me like a pump fighting water issues. |

Posted By: bigredisb

Date Posted: 28 Aug 2016 at 10:28pm

| No signs of water in the oil. I changed it a year ago and didn't find any obvious signs of metal in it either. After it has ran a while the oil is still a nice Amber color not milky at all. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 10:15am

|

Also looking for some advice on what paint I need to be using. Persian Orange 1 or 2 for a 61? Found this great post but not sure what colors I should be using other than Crème: http://www.allischalmers.com/forum/forum_posts.asp?TID=119834&title=paint-codes" rel="nofollow - Paint codes |

Posted By: Dan73

Date Posted: 29 Aug 2016 at 10:21am

| PO2 it started in 60. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 10:35am

Thanks Dan! |

Posted By: DrAllis

Date Posted: 29 Aug 2016 at 11:41am

| Every D-15 was always Persion #2 with cream grille and wheels. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 12:50pm

|

Thanks for the info. I am still brushing up on my Allis history a bit. Where were you finding the info on what years and paint or is it just tribal knowledge? |

Posted By: Allis dave

Date Posted: 29 Aug 2016 at 1:11pm

|

A lot of that info is in Norm Swinford's book "Allis Chalmers Farm Equipment 1914-1985" I think a lot of guys here have that sitting next to their Bible. |

Posted By: Dan73

Date Posted: 29 Aug 2016 at 2:57pm

| Yup that is a great book but it is hard to find now. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 7:10pm

|

Break in is done! I started out with it set at f25 for timing but it wouldn't hardly pull any load and was only making 21hp. I set it back to the advanced mark where I had originally ran it for years it made 39 hp and 289 ft lb's of torque. I advanced it past my original mark and it brought power up a hair but I also heard a little detonation so I took her well back off of that. Not sure why it runs so crappy at F25. http://s993.photobucket.com/user/bigredisb/media/B5045EB5-2265-4A5A-BFF8-29F814A3AD44_zpsooevva0y.jpg.html" rel="nofollow">  http://s993.photobucket.com/user/bigredisb/media/7DEE88E0-01CB-425C-860A-BC205A338159_zps7ywnq0ze.jpg.html" rel="nofollow">  |

Posted By: Don(MO)

Date Posted: 29 Aug 2016 at 9:25pm

|

Sounds like you might have mixed-up the F-25 mark and the Center (or TDC) mark. At 26*(or more) before TDC it will burn pistons. That's one big a$$ Dyno! Looks like one of them buggy's they used to drive around on the moon back in the 70's.lol ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 10:28pm

| Yeah I thought I must have missed something as well but verified it again. Runs like total garbage at "F25". It's very clear in the belhousing hole as the flywheel was polished up nice from a mouse nest in it. Not sure why it would be doing this. I went a degree or two less than the original setting that we had it at for years with no burned piston issues on them. Could something with funky points be throwing off my readings? When I had the engine at TDC on the front pointer (which could be my mistake) the points are well away from the lobe on the dizzy to get them to open. It runs great. Good throttle response and idles just great. |

Posted By: bigredisb

Date Posted: 29 Aug 2016 at 10:31pm

| Yeah I don't know how accurate an AW Nebraska 800 dyno is at 30ish horsepower. We had the base custom built and we have a 400 ish gallon water tank in the front of the trailer for additional water capacity so we can run it without external water sources. We have 2 water pumps that circulate the water through the dyno and on the return a radiator to try to take some heat out of her. |

Posted By: Allis dave

Date Posted: 30 Aug 2016 at 6:54am

| I bet it gets some looks from the neighbors when it's out there running! Don't worry about that though. Looks like you've got some support from about everywhere! |

Posted By: bigredisb

Date Posted: 30 Aug 2016 at 7:39am

|

Ha ha ha, yeah it drew a crowd of them behind me. They were a bit perplexed as to what I was doing. One neighbor put it best saying "You know some neighbors just mow the lawn or maybe even change their own oil on something but not this guy, he has to bring a mobile dyno center home". I am still just little frustrated with the whole timing challenge I have and what would be causing the tractor not to run right when its set tot the proper flywheel marks. Late last night verified my plug gaps were at .030 and my points were at .020. I set it again while the engine was toasty to "F25" and it wouldn't hardly idle and was laboring really bad. As far as how much over the f25 mark I measured how much I have to turn the distributer counterclockwise (advanced) to get it to run right and its only 1/8th of an inch at the base of my distributer different than may mark on put on the dizzy base at f25. |

Posted By: DrAllis

Date Posted: 30 Aug 2016 at 7:43am

| Are you sure your advance mechanism is working (not stuck)?? Should be F-25 at wide open throttle and near/close to TDC at a very slow idle. |

Posted By: Dan73

Date Posted: 30 Aug 2016 at 7:46am

| Good point doc. I thought my advance was ok testing my d15 by hand but it was a mess took it apart this spring had my mechanic rebuild the distributor and it made a world of difference. |

Posted By: bigredisb

Date Posted: 30 Aug 2016 at 8:44am

|

I don't recall seeing a TDC mark on the flywheel at idle. I found the F25 mark at wide open throttle only in the window. I took the plate below the points off and had lightly lubed it and cleaned the centrifugal advance system. Grabbing the rotor and turning it forward, the advance feels nice and smooth and using the timing light you can see the timing advancing and retarding based on engine speed. Something's really odd. With it set at the F25 (at wide open throttle) the engine almost stalls just lifting the lift arms. With the distributer turned 1/8th inch clockwise (advanced) the engine at idle does not even pull down the RPM when using the lift. This advanced timing setting is where the tractor had been set for the last 25+ years with no burned pistons so maybe its ok at that setting. when I was testing it at full rpm and full load I had to turn it another 1/8 inch advanced to start hearing a tiny bit of spark knock so I feel like I am a ways away from detonation issues. I do all kinds of diagnostics on automotive engines and rebuild them and tune them and diesel engines all the time so timing isn't totally foreign to me but I don't mess with points very often which I wonder if I am missing something related to them. I don't plan on converting this to electronic ignition as it runs so good with points and I have never had an issue with it starting even with a wore out engine in the past. |

Posted By: bigredisb

Date Posted: 30 Aug 2016 at 1:37pm

|

Just timed it again at lunch. If I set the high speed timing to F25 and bring her back down to idle the TDC mark is spot on. I guess I will leave it that way but man it runs awful. |

Posted By: Allis dave

Date Posted: 30 Aug 2016 at 2:34pm

| I would set it where it runs good with no detonation. Your dyno will tell you where your best timing and carb setting is. Like you said, "that's where it always was" |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 9:54am

|

Timing is set for now so on to the next challenge. I need to figure out if I really do have a hydraulic pump issue. I figure I will take a video and post it on here for some opinions. I posted a thread on the classifieds area and the one guy that came back saying they have several pumps needs a casting number. Is the casting near the hydraulic line from the casting on the bottom of the trans housing the pump? Its a stupid question I know but I have never had the pump out of one of these. Is the casting number next to the hydraulic line the number they are looking for or is that just a cover? Started on the electrical last night. While I was digging around laying on my back I discovered something jammed above the floorboard and behind the guard on the left hand side of the trans. As a kid I remember my grandpa letting me plow snow at his grocery store and I was so eager to run it that I dropped the key in the snow and we couldn't find it. My grandpa (a bit annoyed) ran back home to get another key for it. Well I found the key that I thought I lost! I have been also trying to get my tie rods freed up. I want to bring the front axle in one position and the axle slides easily but those tie rods are stubborn. I heated them up and have been dousing them with PB blaster so hopefully they finally budge soon. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Allis dave

Date Posted: 31 Aug 2016 at 1:46pm

| That's pretty funny about the key. The tie rods on my 45 were pretty froze. I spent a little effort in getting them apart, then just bought 2 new ones that were good and tight for about $60 each. No steering slop now. |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 1:51pm

|

Any suggestions on this plow? I really like the looks of the skeleton plows. What was the advantages of this plow and with our soil having some clay in it here would it even be worth messing around with? http://madison.craigslist.org/grd/5750539767.html" rel="nofollow - Plow ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: DrAllis

Date Posted: 31 Aug 2016 at 2:40pm

| When using the timing light, you are shining it thru the 1 inch hole in the right side of the bellhousing?? |

Posted By: Allis dave

Date Posted: 31 Aug 2016 at 2:57pm

|

Those are called slat plows. They work good is hard scouring sticky soils like muck or sticky clay. There is less molboard surface area so the dirt keeps flowing instead of balling up on the molboard. THe only problem with them is that there are no new slats being made. If you need a replacement you have to find a used one somewhere which can be tough. So if it's all complete and all the slats are there and good, it should be a good plow. If even one slat is missing or broke, I wouldn't buy it. $300 is an average price for a 3 bottom Allis plow. The shares for almost all Allis plows are getting hard to find. I think a couple years ago DaveThePlowMan on here started reproducing shares for some models. I redrilled my plow a few years ago to accept a still in production share. I kick myself bc I didn't bid $100 on a 4-14 slat bottom plow at an auction about 5 years ago, until the gavel had already fell. It was in good shape. I thought it was too big for my WD45 and was even younger than I am now with even less money. |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 3:11pm

Yes. Timing marks are cleaned up and clearly visible with the light while its running. At idle the TDC mark lines up in the window next to the little rough casted pointer and at full throttle (2100 ish rpm) the "f25" is clearly visible. When set to that it stumbles and carries on and the dyno proved it fell on its face. Would only make about 21 hp at that setting. I am maybe only a degree or two over the F25 mark and it runs clean and smooth and power was back up into the high 30's. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 3:14pm

Thanks Dave this is all good info. I would only be using the plow for maybe less than 10 acres a year for plowdays and stuff like that. I use my Super A for gardens and things. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 3:36pm

I also adjusted the carb settings to see if that could somehow be impacted by timing but it made little to no difference. Could the different pistons and compression be impacting the timing a couple of degrees? Its like F25 is just on the ragged edge ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Dan73

Date Posted: 31 Aug 2016 at 3:40pm

| I think Joe said he has the same poisons you have and he didn't have any trouble with timing. I have been thinking about this alot one stupid question but when you setup your timing light you use the spark plug closest to the front of the motor correct? Just want to make sure you are #1 not #4. |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 3:43pm

Ha ha ha, Yeah I have been using #1 all along BUT the other night I looked it up to make sure the front cylinder was indeed referenced as number 1. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: DrAllis

Date Posted: 31 Aug 2016 at 4:50pm

| Maybe we should run a quick compression test......wide open throttle.....all plugs removed.....battery charger on the battery......that engine should be like 170 to maybe 180 psi. Any more than that might solve your timing mystery ?? |

Posted By: bigredisb

Date Posted: 31 Aug 2016 at 8:44pm

|

Sure, when I get a chance I can check compression. Here is a video of the lift arms running. Seem very jumpy. The lift arms bouncing around make it look worse than it probably is: https://youtu.be/oMqsHFvpGRw" rel="nofollow - Hitch raise video ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Allis dave

Date Posted: 01 Sep 2016 at 7:32am

|

are they jumpy at both higher and lower rpms? I'm trying to remember, seems like my 45 is a little like that at lower rpm, but smooths out when running faster. I haven't ran that tractor for almost a years. sad... Can you put a pressure gauge on the remote to see what pressure you're making? I'm betting that you have access to one. |

Posted By: Dan73

Date Posted: 01 Sep 2016 at 7:35am

| I watched your hitch video. I don't think that would bother me. I am guessing the Draft control is probably not setup perfect but to know for sure you would have to add some weight on the hitch. Ti my eye the supports that hold the lift arms are bouncing probably have some serious play in them from age but the two upper arms doing the actual lift move smoothly. |

Posted By: bigredisb

Date Posted: 01 Sep 2016 at 7:45am

|

I did run a pressure gauge on it and the pressure is a little bouncy but with no load you aren't making much pressure at all as its just flow until you reach end of stroke. I appreciate the responses. I don't know anyone else with an Allis in the area to be able to hear and see another lift mechanism working and as you know with these cam driven piston pumps they are a bit noisy which I am just not used to working on modern machinery every day. I need to go through the adjustment procedures of setting the linkage and things like that for the traction booster. I am sure it hasn't been done in 30 years. The arms do smoothen out a bit at higher RPM. I was only running about 1100 RPM in the video. The 3 point conversion that I have on the tractor from OK tractor has a lot of play in the parts which I believe is intentional but it sort of amplifies the impression it leaves as you saw. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Dan73

Date Posted: 01 Sep 2016 at 7:49am

| I would say get about 300 pounds on it and see how it acts with that load. I bet it smooths out alot with a actual work load the gravity down systems I have seen don't really behave well without a load. |

Posted By: cottonpatch

Date Posted: 01 Sep 2016 at 9:03am

Agree with above. My series II 15 is bouncy without a load. Much smoother with a load. That hydraulic pump in those tractors is pretty crude compared to newer style pumps. ------------- '52 CA, '61 D10 II, ‘61 D15, '66 D15II, '63 D17D III, ‘69 170, '73 185 Crop Hustler, '79 185, '79 7000, '77 7040 |

Posted By: bigredisb

Date Posted: 01 Sep 2016 at 9:16am

|

Thanks guys. That really helps me a lot. Like I said it was that way when we got it years ago but I figured since I was tearing stuff apart now would be the time to repair it if needed. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: cottonpatch

Date Posted: 01 Sep 2016 at 9:34am

I can appreciate what you're doing. I have gone through my D15 front to rear and top to bottom. I am going to split it this fall for a leak at the PTO lever seal and rework the power director as these are the last two items to address. I don't even want to post how much money I have in it. ------------- '52 CA, '61 D10 II, ‘61 D15, '66 D15II, '63 D17D III, ‘69 170, '73 185 Crop Hustler, '79 185, '79 7000, '77 7040 |

Posted By: Dan73

Date Posted: 01 Sep 2016 at 2:34pm

I will just say yours might not be the most expensive one out there. Mine has had the shuttle clutch rebuilt the motor rebuilt the loader towers rebuild for a price that I could have bought an entire tractor. It has a 100 percent new custom hydraulic system and now I need to rebuilt the hydraulic cylinders because they leak by too much to use. I don't know what else I have done but these old tractors need alot of love if they are to run right again. |

Posted By: bigredisb

Date Posted: 01 Sep 2016 at 3:54pm

|

One thing that I think about a lot is if we will ever see today's tractors still running in 50 years. While we all have a passion for these tractors at least we know that they are solid foundations to put some work in to. Today's society is such a throw away one that to me none of this modern equipment is built to the level that these old tractors were. ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

Posted By: Dan73

Date Posted: 01 Sep 2016 at 5:06pm

|

Tractors from the 90s are hard to keep running newer then that are about hopeless. Once you get the electronic circuit boards in them they don't want you to fix them so the boards are expensive or just not out there. When I bought my ih 5240 someone told me I was lucky that was the last generation of case ih you could actually fix. He had one in the next generation beyond that and had to send it back because it was about 4 years old and was already have a very hard time keeping the circuit boards working. New ones are disposable. It pains me to say that because I worked as a controls engineer for years building electronics in industrial equipment but that stuff has a 20 year lifespan and the market is just based on the concept that in 10 years it is obsolete and no one would want to fix it anyway they will replace it. |

Posted By: bigredisb

Date Posted: 02 Sep 2016 at 11:01am

|

So I think I am going to get that slat plow. Says all the coulters are free and in good shape and all the slats are on the plow. Said he would take 250 which is a little high BUT I don't have to drive far at all to get it which is worth something to me. That being said how hard is it to find wheel weights for my 26 inch spinouts? I would love to find AC ones but are there any other brand weights that are interchangeable? ------------- 1961 Allis-Chalmers D15 1949 Farmall Super A |

bigredisb wrote:

bigredisb wrote: