WD45 Oil Pump

Printed From: Unofficial Allis

Category: Allis Chalmers

Forum Name: Farm Equipment

Forum Description: everything about Allis-Chalmers farm equipment

URL: https://www.allischalmers.com/forum/forum_posts.asp?TID=127210

Printed Date: 24 Aug 2025 at 9:07am

Software Version: Web Wiz Forums 11.10 - http://www.webwizforums.com

Topic: WD45 Oil Pump

Posted By: 79fordblake

Subject: WD45 Oil Pump

Date Posted: 13 Aug 2016 at 10:01pm

|

Got around to cleaning the oil pump for the WD45 engine build but noticed something. This pump has a internal relief valve. Is this from a D17? Little back story. I bought a complete WD45 engine from my cousin supposedly ran fine 10yrs ago to rebuild. Tore it down and block was cracked. I got another block now. I just went and looked at the first block and it didn't have any modifications. There was a nut behind the relief valve in side of engine like they tried to make it stay closed or something. So I guess I need to find a WD45 oil pump to make this right.

|

Replies:

Posted By: Allis dave

Date Posted: 13 Aug 2016 at 10:09pm

|

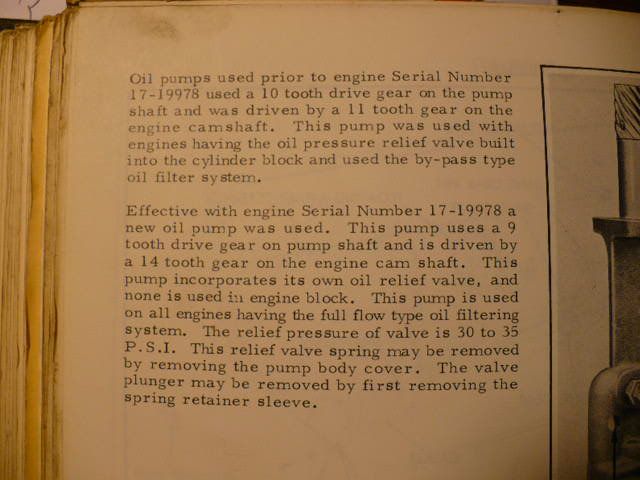

This was discussed a few months ago. It will hurt nothing to use that pump in your tractor as long as long as it's a 10 tooth to match the wd45 cam. It must be because it was already in there. They stopped making the 45 pump so that is a replacement pump. It must've had a bad pump sometime and received an allis replacement. You don't need to modify the block relief cable either. Wen it hits a certain psi, either he block or pump relief valve will open. It doesn't matter which. Internally, the pumps flow the same amount of oil. |

Posted By: DanD

Date Posted: 13 Aug 2016 at 10:13pm

| No need to find a different oil pump. When they switched over to the full flow pump, Allis basically discontinued servicing or providing the old style pump in the parts department and said to use the newer pump with the built in relief valve in the older engines. Just need to change over the pump drive gear to match the camshaft. Id you look at AGCO parts book, you will see that the part number for a complete pump is the same from a WC through a 175...but you have to order the gear separately. |

Posted By: 79fordblake

Date Posted: 13 Aug 2016 at 10:14pm

| Oh ok that makes me feel better. Is that spring supposed to be riding on the end plate? That doesn't seem right. I didn't see anything fly out when I took cover off. I looked in my D17 book and it shows a plunger I suppose you would call it on both sides of spring. Clearance between gears is .011 I forgot to check pump body to gear. |

Posted By: Don(MO)

Date Posted: 13 Aug 2016 at 11:08pm

|

The guys are spot on, you have the up-dated pump. the spring rides on the end plate with the plunger below the spring in the pump housing, lots of WC/WD/WD45 engines had and some still do have a nut or washers behind the plug holding the spring in. I plane the end cap back flat and note the gasket go's around the spring so the oil can come out with out blowing the gasket out. if you look at you pic on the side of the pump housing below the spring you can see the relief valve drain hole. the plunger is just below that hole. If you make the cover gasket use the same thickens gasket as the old one. I true the cover before installing it. bend one of the four tabs on the intake sump and slide it sideways off the intake then clean the screen on both sides of it.

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 14 Aug 2016 at 9:10am

Oh ok so spring sets just like in this pic. I have .011 between the gears and .006 between gear and body. I can also move shaft back and forth ever so slightly. With all the money I have in this engine build this little bit of wear is bothering me alot. What do y'all think?

|

Posted By: CTuckerNWIL

Date Posted: 14 Aug 2016 at 10:07am

|

I don't know what the tolerances were for an Allis oil pump, but .006 seems like a lot to me. I also don't know where you get .011 "between gears". Are you talking backlash? Have a look at this video if you want to tighten up your oil pump. [TUBE]dCQp1_cVStY[/TUBE] ------------- http://www.ae-ta.com" rel="nofollow - http://www.ae-ta.com Lena 1935 WC12xxx, Willie 1951 CA6xx Dad bought new, 1954WD45 PS, 1960 D17 NF |

Posted By: Don(MO)

Date Posted: 14 Aug 2016 at 10:19am

|

I think you are still OK with the pump housing and gear wear, yes they have some but if you can even find a replacement pump or even the gears they are going to be very high priced. I'd plane the cover back flat and go down it-tell the gear markings are gone. Post a shot of the oil pump driven gear and one of the camshaft oil pump drive gear, Have you pulled the relief valves out of the pump and block and looked at them? ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 14 Aug 2016 at 10:37am

|

Gear on cam and pump look good. The relief valve is out of block. One in pump is currently stuck. I'll get a pic of it a little later today. Book says .008 max between body and gears. I have .006 It says .015 max backlash I have .011 |

Posted By: Don(MO)

Date Posted: 14 Aug 2016 at 10:48am

|

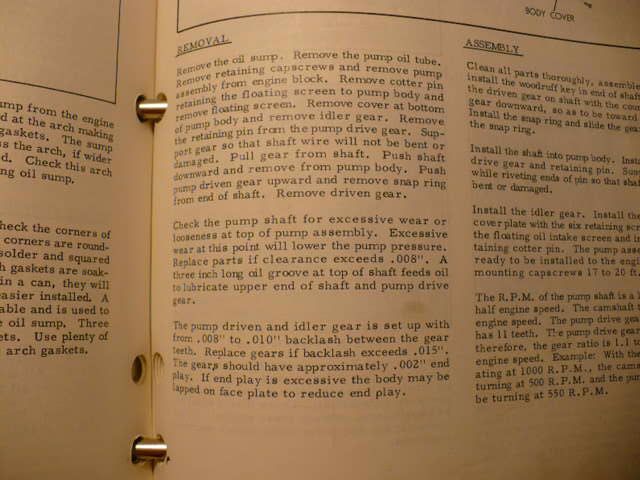

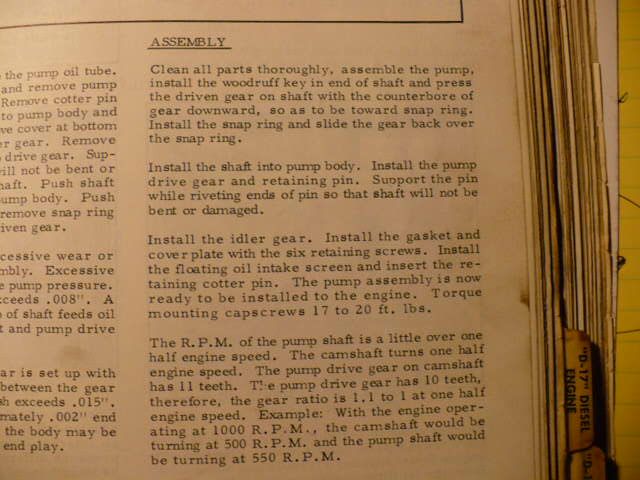

This might help you out. If you get an AC shop manual all this INFO is in it and the IT books are sometimes a little short INFO.    ------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 14 Aug 2016 at 12:33pm

I have the Agco book and IT book. On the body to gear spec it's close to the max which worrys me on about a $4500 engine. Here is pics of the gears. It's kind of a toss up for me. Anything close to out of spec I have been throwing it away or fixing it. I still have to get a better crank as well. The one I have is .020 on mains and .010 on rods already. It would work but with the theme I've been going with its not good enough...lol.

|

Posted By: Don(MO)

Date Posted: 14 Aug 2016 at 3:50pm

|

You are thinking the best for the WD45 and that's good, I don't think you will find an after market pump new or used one, so you might call your AGCO dealer and see if they still show the pump is for sale and price it. What are you thinking on doing with the crankshaft ? to me a .020" main shaft is OK to reuse, I'd have it checked for size before hunting for a better one, but that's just me. lol

------------- 3 WD45's with power steering,G,D15 fork lift,D19, W-Speed Patrol, "A" Gleaner with a 330 corn head,"66" combine,roto-baler, and lots of Snap Coupler implements to make them work for their keep. |

Posted By: 79fordblake

Date Posted: 14 Aug 2016 at 4:19pm

|

Yeah I was wondering if any new parts for the pump are available. I think I have also decided to make it full flow oiling......it just keeps snowballing LOL! The crank looks pretty good but does have some scratches...probably would need to be turned again. Would like to find one that is standard with minor flaws that would clean up at .010 Tractor disease is a horrible condition....everybody at work thinks I'm crazy....lol. :) |

Posted By: Allis dave

Date Posted: 15 Aug 2016 at 7:29am

| You are crazy, but we are too, so it's ok. |